Professional Documents

Culture Documents

Injectoare GPL

Uploaded by

Visan DragosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injectoare GPL

Uploaded by

Visan DragosCopyright:

Available Formats

INJECTOARE GPL

General description

Injectors are electrically operated valves which accurately control the quantity of fuel

delivered. By adding the fuel to the air sucked in by the engine, a mixture is created

with the required fuel/air ratio.

Injectoarele sunt supape actionate electric cu o precizie foarte mare ce

controleaza cantitatea de combistibil injectate. Prin adaugarea de combustibil in

aerul ce urmeaza sa intre in cilindru se creeaza amestecul de aer/combustibil.

Liquefied Petroleum Gas (LPG) and CNG (compressed natural gas) have become

one of the most important alternative fuels in the automotive world sector, and it is

also becoming one of the most important in the conversions of internal fuel engines.

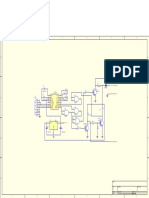

Principle of operation of the LPG/CNG system and injectors

Fig. Injector de GPL

Injectors have two ends, both connected to the engine controller. Output signal is a

series of pulses with a specific shape. There are two types of LPG/CNG injectors:

Injectoarele sunt conectate la calculatorul de injectie al carui semnal de iesire

este o pulsatie de o anumita amplitudine si forma.Exista doua tipuri de

injectoare pentru GPL:

De impedanta joasa ce au rezistenta cuprinsa intre 1-3 ohm;

De impedenta ridicata ce au rezistenta cuprinsa intre 11-15 ohm;

low impedance type with resistance between 1 and 3 ohms;

high impedance type with resistance between 11 and 15 ohms.

Each fuel injector has a supply passage and a return passage. The fuel injector rails

have the same concentric design as the fuel lines. The passage in the injector from

the supply section to the return section is restricted by a cooling bushing.

Fiecare injector are conducte de tur si de retur.Exista doua tipuri de injectoare

din punct de vedere al principiului de functionare:

There are two types of LPG injection: vapor and liquid.

Vapor injection operation principle:

As liquid propane passes through the cooling bushing, a pressure reduction takes

place, which causes the propane to vaporize and effectively cools the area around

the supply section. This is called a refrigeration cycle and aids in maintaining the fuel

in a liquid state for all driving conditions, regardless of the outside temperature. The

injector delivers propane in a liquid state into the intake port. It vaporizes

immediately upon exiting the injector. This rapidly expanding liquid cools the

incoming air to the engine often resulting in a little more horsepower than the

gasoline system could achieve, not to mention the inherently improved exhaust

emissions that propane is known for.

Principiul funcionrii injeciei de vapori:

Cand propanul lichid trece prin buca de rcire, are loc o reducere a presiunii,

ceea ce determin vaporizarea propanului i rcirea eficient a zonei din jurul

seciunii de alimentare. Aceasta se numete ciclu de rcire i ajut la

meninerea combustibilului n stare lichid in toate situatiile, indiferent de

temperatura exterioar. Injectorul livreaz propanul ntr-o stare lichid n

orificiul de admisie, iar acesta vaporizeaz imediat la ieirea din injector.

Acest lichid care se extinde rapid rcete aerul care intr n motor, rezultnd

adesea o putere mai mic dect puterea sistemului de benzin.

Liquid injection operation principle and advantages:

The LPG-Liquid-Inject System shows an increase, typically 10%, over that

obtainable from the same engine using petrol as a fuel. The balance in favor of LPG

can be increased by increasing the compression ratio or adding boost pressure to

optimize the higher octane rating of LPG. Vaporizer systems are normally 15% down

on power versus petrol. Liquid Injection is far superior to vaporizer or gas injection

systems - 5% to 20% better. Great advantage of the liquid injection is that the

embarrassing backfires as on gaseous systems are eliminated. Multi-point, liquid

LPG injection sharply reduces accelerator lag. Spark timing can be adjusted to give

optimum performance with Liquid Injection. Liquid Injection does not need to start or

stop on petrol, or need petrol to offset higher combustion temperatures. The LPG is

kept in the liquid state and injected in the multi-point petrol fashion, hence engine

starting at low temperatures is assisted (to around minus 40 degrees Celsius). There

is no vaporizer to freeze the moisture present and hence the system.

Principiul funcionrii injeciei cu lichid i avantaje:

Sistemul de injecie cu lichid (GPL) indic o cretere, de obicei de 10%, fa de

cea obinut de la acelai motor care utilizeaz benzin ca i combustibil.

Avantajul n favoarea GPL-ului poate fi mrit prin creterea raportului de

compresie sau prin marirea presiunii pentru a optimiza cifra octanica a GPL-

ului. Sistemele pe baza de vaporizare sunt, n mod normal, cu 15% mai putin

eficiente n comparaie cu benzina. Injecia lichid este cu mult superioar

sistemelor de vaporizator sau de injecie cu gaz - cu 5% pn la 20% mai bune..

Injecia lichida de GPL, reduce intarzierea care apare in timpul accelerari.

Timpul de aprindere poate fi reglat pentru a obine o performan optim. Atunci

cand se foloseste acest tip de injectie pornirea si oprirea motorului nu este

obligatoriu facuta folosind benzina. GPL-ul este meninut n stare lichid i este

injectat n sistemul de injectie multipunct,astfel motorul pornind la temperaturi

sczute (pn la minus 40 de grade Celsius). La acest tip de injectie nu exist

vaporizator.

Posibile defectari ale sistemului:

-un scurtcircut la sistemul electric

-conexiuni defectuoase

-defectiuni mecanice ale componentelor

-cablul de masa este interrupt

Possible damage to the LPG/CNG injectors:

Open circuit or short to positive or to ground in wire(s);

No or poor plug connection conduction;

Ground connection is loose or corroded;

Mechanical fault in component.

You might also like

- ENG - Use & Maintenance Manual For Sequential (August 03)Document19 pagesENG - Use & Maintenance Manual For Sequential (August 03)George DimitroulisNo ratings yet

- Reglaj Injectoare AVF TDIDocument6 pagesReglaj Injectoare AVF TDIalexNo ratings yet

- Hks Navigator ManualDocument28 pagesHks Navigator ManualBarm BarmByNo ratings yet

- FIS Module ProgrammerDocument6 pagesFIS Module ProgrammerFer Nando100% (1)

- OmvlDocument32 pagesOmvlAbalaru Ionut Daniel100% (1)

- Valve Lash Adjustment 8L 22L4 PDFDocument12 pagesValve Lash Adjustment 8L 22L4 PDFMindo.silitongaNo ratings yet

- Win 10activated - BatDocument1 pageWin 10activated - BatMySofARNo ratings yet

- Renault TwizyDocument16 pagesRenault TwizyUZNAPMNo ratings yet

- Motocultor Agria Piese de SchimbDocument14 pagesMotocultor Agria Piese de SchimbCristi HanNo ratings yet

- AUTOSAR 3.2 Based Protocol Data Unit Router ModuleDocument6 pagesAUTOSAR 3.2 Based Protocol Data Unit Router ModuleEditor IJRITCCNo ratings yet

- Skil 1614 Chainsaw ManualDocument19 pagesSkil 1614 Chainsaw Manualjohnnytugs1No ratings yet

- Vehicle BLDC MotorDocument11 pagesVehicle BLDC MotorDiego Martin SalaNo ratings yet

- DDT InterfaceDocument1 pageDDT Interfaceopa952ya.ru100% (1)

- Model S Owners Manual (v7.0)Document185 pagesModel S Owners Manual (v7.0)David BaranyaiNo ratings yet

- Vag Com WenasDocument4 pagesVag Com Wenasundok1No ratings yet

- Manual Winpic800Document1 pageManual Winpic800Igor Babiy100% (2)

- 2016 Technical Reference Guide Final InteractiveDocument150 pages2016 Technical Reference Guide Final InteractiveDean JohnsonNo ratings yet

- O2 Signal ModifierDocument3 pagesO2 Signal ModifierclistingacctNo ratings yet

- ATMEGA64M1 - CanBoard V1Document1 pageATMEGA64M1 - CanBoard V1Fabian Alfonso100% (1)

- Adaptare Cheie Contact VAGDocument2 pagesAdaptare Cheie Contact VAGCristi HanNo ratings yet

- Brusless Motor ControllerDocument12 pagesBrusless Motor ControllerDedi SupardiNo ratings yet

- ML 1660 Parts CatalogDocument22 pagesML 1660 Parts Catalogegel2458100% (1)

- PW-02 PHP FundamentalsDocument37 pagesPW-02 PHP FundamentalsAndika NugrahaNo ratings yet

- An-InD-1-004 Diagnostics Via Gateway in CANoeDocument15 pagesAn-InD-1-004 Diagnostics Via Gateway in CANoeWolfgang StarkmannNo ratings yet

- AMSS 8amsp Installation ManualDocument16 pagesAMSS 8amsp Installation ManualbardeepNo ratings yet

- Avr Isp All in OneDocument1 pageAvr Isp All in Onespy004100% (1)

- KATS Universal ProgrammerDocument6 pagesKATS Universal ProgrammerdorudNo ratings yet

- Prusa I3 Achatz Edition Frame Kit ManualDocument34 pagesPrusa I3 Achatz Edition Frame Kit ManualLászló BogárdiNo ratings yet

- Reverse Engineering Methods Huy Brecht S 2018Document11 pagesReverse Engineering Methods Huy Brecht S 2018Louis V. TelémarkNo ratings yet

- Build Your Own CMS With ZF2Document6 pagesBuild Your Own CMS With ZF2Marco GualacataNo ratings yet

- 2006 Ford Focus - SLDocument4 pages2006 Ford Focus - SLv_randall_mNo ratings yet

- PLC-Driver (V5) Bosch CL - Programming Interface (BUEP19E)Document8 pagesPLC-Driver (V5) Bosch CL - Programming Interface (BUEP19E)AdelmoKarig100% (2)

- GRANDE PUNTO ACTUAL EngDocument243 pagesGRANDE PUNTO ACTUAL Engmladja12No ratings yet

- Design of High Efficiency Electrical Motors For A Hybrid Electric VehicleDocument14 pagesDesign of High Efficiency Electrical Motors For A Hybrid Electric Vehicleapi-3709675100% (1)

- Fiat Punto Owner Handbook PDFDocument298 pagesFiat Punto Owner Handbook PDFNiponNo ratings yet

- 2011 03 B8 HVAC Drain PDFDocument12 pages2011 03 B8 HVAC Drain PDFJosipBrozTito100% (1)

- Manual Tastatura Rosslare PDFDocument65 pagesManual Tastatura Rosslare PDFKokoshmare100% (1)

- INSTALLATION 7.6 Audi A4 B6 B7Document3 pagesINSTALLATION 7.6 Audi A4 B6 B7Robert ChrisNo ratings yet

- Theory: CAN-Bus: 1 General InformationDocument7 pagesTheory: CAN-Bus: 1 General InformationDileep Kumar100% (1)

- W Waveform Injector 1.6L Mfi Vin 1Document2 pagesW Waveform Injector 1.6L Mfi Vin 1Jeferson SilvaNo ratings yet

- Prusa I3 Frame Kit Build Manual PDFDocument26 pagesPrusa I3 Frame Kit Build Manual PDFEuclides RezendeNo ratings yet

- Fuel InjectionDocument18 pagesFuel InjectionshihabNo ratings yet

- Development of Solar PV Charge Controller System For Rural ApplicationDocument5 pagesDevelopment of Solar PV Charge Controller System For Rural ApplicationPunit RatnaniNo ratings yet

- OMVL Tuning Instructions 081210Document2 pagesOMVL Tuning Instructions 081210leeroy381100% (2)

- Motoplat Information and TestingDocument3 pagesMotoplat Information and TestingMizioNo ratings yet

- Li-Ion Battery Charger PDFDocument1 pageLi-Ion Battery Charger PDFfarizatulakmam bujangNo ratings yet

- VW/Audi 1.8T Transverse (FWD) Ignition Wiring Replacement Kit Installation Guide Skill Level 2 - ModerateDocument21 pagesVW/Audi 1.8T Transverse (FWD) Ignition Wiring Replacement Kit Installation Guide Skill Level 2 - ModerateKushal ExpertNo ratings yet

- Defecte Presiune PneuriDocument37 pagesDefecte Presiune PneuriGoranka Bulatovic IlicNo ratings yet

- Gasoline Engine 160F-190F G120F-G420F - ManualDocument40 pagesGasoline Engine 160F-190F G120F-G420F - ManualConstantinNo ratings yet

- Pierburg PG - Si - 0096 - 30304465Document1 pagePierburg PG - Si - 0096 - 30304465marcglebNo ratings yet

- Indesit Dea 601 Dea 602 Dea 603 Dea 700 Eos Alarm Table Error CodesDocument4 pagesIndesit Dea 601 Dea 602 Dea 603 Dea 700 Eos Alarm Table Error CodesЕвгений СафоновNo ratings yet

- Jetta A5 January 2010Document10 pagesJetta A5 January 2010billydump100% (1)

- PLM Heat Exchanger Install Instructions - Audi B8 B8.5 A4 S4Document32 pagesPLM Heat Exchanger Install Instructions - Audi B8 B8.5 A4 S4fwu7258100% (1)

- Termostat k59Document4 pagesTermostat k59mungos967No ratings yet

- Jjmie: Comparative Performance and Emission Properties of Spark-Ignition Outboard Engine Powered by Gasoline and LPGDocument6 pagesJjmie: Comparative Performance and Emission Properties of Spark-Ignition Outboard Engine Powered by Gasoline and LPGShaun MendozaNo ratings yet

- Detroit Diesel DD Three Filter SystemDocument170 pagesDetroit Diesel DD Three Filter Systemcristian picadoNo ratings yet

- Common Rail Fuel Injection SystemDocument56 pagesCommon Rail Fuel Injection SystemMarcos Maciel100% (1)

- Returnless: Diagnosing Returnless Fuel SystemsDocument6 pagesReturnless: Diagnosing Returnless Fuel SystemsReynaldo FloresNo ratings yet

- Direct Petrol Injection: at A Glance..Document7 pagesDirect Petrol Injection: at A Glance..bhanuka2009No ratings yet

- Implementation of A Automatic Dual Fuel Injection System in A CI EngineDocument5 pagesImplementation of A Automatic Dual Fuel Injection System in A CI EngineGusma Hamdana PutraNo ratings yet

- International Relations MCQs - Weapons of Mass Destruction MCQsDocument5 pagesInternational Relations MCQs - Weapons of Mass Destruction MCQsSadia manzoorNo ratings yet

- Final Project PDFDocument2 pagesFinal Project PDFWillian MitziNo ratings yet

- SE Question-Paper Natural-Sciences 4-6 English 2022 BE ETDocument21 pagesSE Question-Paper Natural-Sciences 4-6 English 2022 BE ETGoce KuzeskiNo ratings yet

- Write Up For Voc TRGDocument12 pagesWrite Up For Voc TRGPritish MohanNo ratings yet

- June 2011 (v2) QP - Paper 1 CIE Chemistry IGCSEDocument16 pagesJune 2011 (v2) QP - Paper 1 CIE Chemistry IGCSEMedo O. EzzatNo ratings yet

- Datasheet LM384Document8 pagesDatasheet LM384Aldo Sorgentini SorNo ratings yet

- 12 Standards - Technical Seminar For Cathodic Protection To GOGC DesignDocument13 pages12 Standards - Technical Seminar For Cathodic Protection To GOGC DesignkbenjikaNo ratings yet

- Kirloskar Corrocoat GFC CaseStudyDocument35 pagesKirloskar Corrocoat GFC CaseStudyAbhishek SharmaNo ratings yet

- UN3480 - PI965 UN 3481 - PI966 UN3481 - PI967 Section PI965-Section IB PI966 - Section II PI967 - Section IIDocument1 pageUN3480 - PI965 UN 3481 - PI966 UN3481 - PI967 Section PI965-Section IB PI966 - Section II PI967 - Section IIzubeen RIZVINo ratings yet

- Lewis StructureDocument7 pagesLewis StructureKed LukkedNo ratings yet

- 1611 Saipem 12000Document2 pages1611 Saipem 12000xyxyro2794No ratings yet

- A Few Words About Safety: How To Use This ManualDocument120 pagesA Few Words About Safety: How To Use This ManualEdar Jhon Montenegro RimarachinNo ratings yet

- Katpp Project Report 17 AugustDocument41 pagesKatpp Project Report 17 AugustRamniwas DhakarNo ratings yet

- CII Bench Marking & MetricsDocument53 pagesCII Bench Marking & MetricsjorgearangogNo ratings yet

- Hertz HSK 165 6Document7 pagesHertz HSK 165 6syamkimi75No ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- 6d447606 E574 4313 A9b8 0f291183e8e2 Remove Install Camshaft AdjustersDocument2 pages6d447606 E574 4313 A9b8 0f291183e8e2 Remove Install Camshaft AdjustersDoğan TekinNo ratings yet

- Pre Commissioning Checklist For Screw ChillersDocument2 pagesPre Commissioning Checklist For Screw Chillersnihar039255No ratings yet

- Basic NDT - Et QB 1Document18 pagesBasic NDT - Et QB 1prabhakaran.S100% (1)

- Differential Expansion of Steam Turbine GeneratorsDocument4 pagesDifferential Expansion of Steam Turbine GeneratorsJurun_Bidanshi100% (1)

- U1 Actividad Integradora 305524Document2 pagesU1 Actividad Integradora 305524CESAR AUGUSTO MOLINA TREVIñONo ratings yet

- Protection of Power Systems: 8. Impedance (Distance) RelaysDocument41 pagesProtection of Power Systems: 8. Impedance (Distance) RelaysMonika LeonitaNo ratings yet

- DCI NEW Product GuideDocument24 pagesDCI NEW Product GuidePaul LairdNo ratings yet

- C13 110-100 Electricity Meter PDFDocument2 pagesC13 110-100 Electricity Meter PDFIfeanyi E-AgwuegboNo ratings yet

- Specimen (IAL) QP - Unit 4 Edexcel Chemistry A-LevelDocument24 pagesSpecimen (IAL) QP - Unit 4 Edexcel Chemistry A-LevelTanishka VermaNo ratings yet

- 320 ElectrDocument32 pages320 ElectrfalahNo ratings yet

- Production of Biodiesel by Enzymatic TransesterifiDocument18 pagesProduction of Biodiesel by Enzymatic TransesterifiLetso JamesNo ratings yet

- HAAS-Lubricant, Grease, and Sealant Tables For Haas Machine Components - Customer Resource CenterDocument16 pagesHAAS-Lubricant, Grease, and Sealant Tables For Haas Machine Components - Customer Resource CenterMichael Naím Dévora Quintanar100% (1)

- Phy 01Document212 pagesPhy 01Varsha Dange100% (1)

- Production Drawing & Pracctice Lab ManualDocument23 pagesProduction Drawing & Pracctice Lab ManualVenkateswar Reddy Mallepally88% (8)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceFrom EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNo ratings yet

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningFrom EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningRating: 5 out of 5 stars5/5 (4)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsFrom EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsRating: 4.5 out of 5 stars4.5/5 (17)

- Jamaica Driver's Education Handbook: A Comprehensive Driver Training GuideFrom EverandJamaica Driver's Education Handbook: A Comprehensive Driver Training GuideNo ratings yet

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingFrom EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNo ratings yet

- CDL Study Guide: Complete manual from A to Z on everything you need to know to pass the commercial driver's license examFrom EverandCDL Study Guide: Complete manual from A to Z on everything you need to know to pass the commercial driver's license examNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- How to Drive: Real World Instruction and Advice from Hollywood's Top DriverFrom EverandHow to Drive: Real World Instruction and Advice from Hollywood's Top DriverRating: 4 out of 5 stars4/5 (17)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)