Professional Documents

Culture Documents

Material Type: Austenitic Steels (TP304, 310, 316, 321, 347)

Uploaded by

MamacintOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Type: Austenitic Steels (TP304, 310, 316, 321, 347)

Uploaded by

MamacintCopyright:

Available Formats

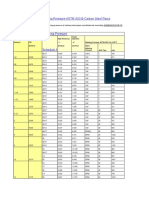

1 Only RED font cells are meant for Input.

BB

2 PMS Line Class ID = 9R0JL Select / Input Special Requirements, if any = Low Temperature Process

3 ASME Flange Rating = 900#RF Optional Comments: Non-Lethal Low Temperature Process Hydrcarbons

4 Fluid / Service = Non-Lethal Low Temperature Process Hydrcarbons

5 Material Specification = A312 Gr TP304 Material Type: Austenitic steels (TP304, 310, 316, 321, 347)

6 Quality Factor, E = 1.00 Pipe Manufacturing Type = Seamless Pipe or Tube

7 Design Pressure = 148.93 barg = 2160.05 psig Please input pressure value in barg.

8 Design Temperature = 38.0C = 100.4F Please input temperature value in C.

9 Allow. Stress @ 38C = 20.000 ksi = 137.90 MPa Please check from Table A-1 of ASME B31.3 Latest Edition.

10 Corrosion Allowance = 0.00 mm = 0.00 inch Mill Tolerance = 12.5% Please input

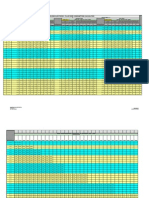

11 Y Coefficient @ 38C = 0.4 Valid for t<D/6 Please check from ASME B31.3 Table 304.1.1.

12 Ratio of (P/SE) = 0.108 Check Passed.

13 tpressure = (P x D) / [2 x {(S.E) + (P.Y)}] = (2,160.0 x D) / [2 x {(20,000.0 x 1.00) + (2,160.0 x 0.4)}]

14 (Valid for t<D/6) = 0.0517648840 x D inch

15 Where, (As per para. 304.1.2 of of ASME B31.3 2002 Edition)

16 D = Outside diameter of pipe in inch and also derived in mm; Refer ASME B36.10M-1996.

17 P = Internal design gage pressure in psi and also derived in bar;

18 tmin = Minimum required thickness, including mechanical, corrosion and erosion allowances;

19 tpressure = Pressure design thickness, as calculated in accordance with para. 304.1.2, for internal pressure;

20 S = Allowable stress value from Table A-1 of ASME B31.3;

21 E = Quality factor from Table A-1A or A-1B of ASME B31.3;

22 Y = Coefficient from Table 304.1.1 of ASME B31.3, valid for t<D/6;

23 T = The minimum wall thickness for the pipe selected or purchased, considering manufacturer's minus

24 tolerance shall be NOT less than t min. For t min, refer Column "A" and for T, refer Column "B".

25 (All nomenclatures, definitions and parameters are generally in accordance with ASME B31.3 2002 Edition.)

26 Selected

27 Pipe NPS Pipe OD tpressure tmin Sch / Nominal Min. Thk. Max.Allow. Ratio Check

28 inch (mm) D (mm) (mm) (mm) Thk. (inch) Thk. (mm) T (mm) P (barg) (D/t) (T>tmin)

29 Column "A" Tnom Column "B" Check (>6)

30 " (15) 21.34 1.10 1.10 Sch.40S 2.77 2.42 344.4 8.8 Passed.

31 " (20) 26.67 1.38 1.38 Sch.40S 2.87 2.51 280.9 10.6 Passed.

32 1" (25) 33.40 1.73 1.73 Sch.40S 3.38 2.96 262.7 11.3 Passed.

33 1" (32) 42.16 2.18 2.18 Sch.40S 3.56 3.11 216.3 13.6 Passed.

34 1" (40) 48.26 2.50 2.50 Sch.40S 3.68 3.22 194.6 15.0 Passed.

35 2" (50) 60.33 3.12 3.12 Sch.40S 3.91 3.42 163.9 17.6 Passed.

36 2" (65) 73.03 3.78 3.78 Sch.40S 5.16 4.51 179.3 16.2 Passed.

37 3" (80) 88.90 4.60 4.60 Sch.40S 5.49 4.80 155.7 18.5 Passed.

38 3" (90) 101.60 5.26 5.26 Sch.80S 8.08 7.07 203.2 14.4 Passed.

39 4" (100) 114.30 5.92 5.92 Sch.80S 8.56 7.49 190.7 15.3 Passed.

40 5" (125) 141.30 7.31 7.31 Sch.80S 9.53 8.33 170.7 17.0 Passed.

41 6" (150) 168.28 8.71 8.71 Sch.80S 10.97 9.60 164.9 17.5 Passed.

42 8" (200) 219.08 11.34 11.34 Sch.100 15.09 13.20 174.6 16.6 Passed.

43 10" (250) 273.05 14.13 14.13 Sch.100 18.26 15.98 169.3 17.1 Passed.

44 12" (300) 323.85 16.76 16.76 Sch.100 21.44 18.76 167.5 17.3 Passed.

45 14" (350) 355.60 18.41 18.41 Sch.100 23.83 20.85 169.6 17.1 Passed.

46 16" (400) 406.40 21.04 21.04 Sch.100 26.19 22.91 162.8 17.7 Passed.

47 18" (450) 457.20 23.67 23.67 Sch.100 29.36 25.69 162.3 17.8 Passed.

48 20" (500) 508.00 26.30 26.30 Sch.100 32.54 28.47 161.8 17.8 Passed.

49 22" (550) 558.80 28.93 28.93 Sch.100 34.93 30.56 157.7 18.3 Passed.

50 24" (600) 609.60 31.56 31.56 Sch.100 38.89 34.03 161.1 17.9 Passed.

51 Notes: 1. The user shall arrive at the worst case P-T condition, based on maximum (P/SE) ratio.

52 2. The user shall be responsible to check the allowable stress value for the material & temp.

53 3. The user shall be responsible to check the applicable Y Coefficient value for the material & temp.

PTC & Branch Calc_ASME B31.3_Upto NPS 24 JOB NUMBER CALCULATION NUMBER PIPE

Version: 1.11 XXXX XXXX - 9R0JL - PTC - 001 CLASS

XXXX REV. CALC. BY DATE CHKD. BY DATE

CLIENT: XXXX 3

9R0JL

PROJECT: XXXX 2

LOCATION: XXXX 1

SUBJECT: Internal Pressure Thk. Calc. Sheet 0 Name 07-May-03 Name 07-May-03 SH 1 OF 1

You might also like

- Pipe Wall Thickness Calculation SheetDocument88 pagesPipe Wall Thickness Calculation SheetSunday Paul100% (2)

- PTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washingDocument4 pagesPTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washingalvinchuan100% (1)

- PTC Cacls Asme b31.3Document1 pagePTC Cacls Asme b31.3MamacintNo ratings yet

- Piping Material Tracking (12-April-15)Document22 pagesPiping Material Tracking (12-April-15)vishal bailurNo ratings yet

- ASME/ASTM standards overview for mechanical engineersDocument3 pagesASME/ASTM standards overview for mechanical engineersrajesh100% (2)

- BG 10053-P-ET-001-Piping ClassDocument87 pagesBG 10053-P-ET-001-Piping ClassKathia Espinoza RojasNo ratings yet

- Pt. Bahana Karya Mandiri: Data SheetDocument8 pagesPt. Bahana Karya Mandiri: Data SheetBowo Edhi WibowoNo ratings yet

- Sale of Petroleum Products Company LimitedDocument1 pageSale of Petroleum Products Company Limitedayuda_dNo ratings yet

- Comparison Table For Tubes, Line Pipes and FittingDocument2 pagesComparison Table For Tubes, Line Pipes and FittingNamye Yelus100% (1)

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDocument3 pagesDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanNo ratings yet

- Hydrostatic Test Pressure Formula GuideDocument26 pagesHydrostatic Test Pressure Formula Guiderudrakr0% (1)

- Artilce - Potential Detrimental Consequences of Excessive PWHT On Steel PropertiesDocument8 pagesArtilce - Potential Detrimental Consequences of Excessive PWHT On Steel PropertieswholenumberNo ratings yet

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDocument1 pagePY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540No ratings yet

- Hot Tap Daily Welding Report 1Document1 pageHot Tap Daily Welding Report 1Jamal BakhtNo ratings yet

- PIPING MATERIALS COMPARISON TABLEDocument12 pagesPIPING MATERIALS COMPARISON TABLEJay Vinoth100% (2)

- Hot TapDocument4 pagesHot TapmiteshNo ratings yet

- Piping Material Specification Line Class: Doc No.: MBD-SPM-001Document4 pagesPiping Material Specification Line Class: Doc No.: MBD-SPM-001wenny_tpdNo ratings yet

- Igat6 D PL Me SPC 0007 01 Spec For Barred TeeDocument9 pagesIgat6 D PL Me SPC 0007 01 Spec For Barred Teeamini_mohi100% (1)

- PN01SA0B03Document5 pagesPN01SA0B03Julian GaleanoNo ratings yet

- API 5l Practice Questions Doc r2Document4 pagesAPI 5l Practice Questions Doc r2Anonymous SLI4aGNo ratings yet

- TABLA ASME - B31.3 - Ed.2018 (001-269) (114-117)Document4 pagesTABLA ASME - B31.3 - Ed.2018 (001-269) (114-117)ANDRES LOPEZNo ratings yet

- Saipem Wps ListDocument2 pagesSaipem Wps ListookaNo ratings yet

- Blind Flange Thickness CalculationDocument1 pageBlind Flange Thickness Calculationmamughal123No ratings yet

- ASME CALculationDocument6 pagesASME CALculationMakrame BattazNo ratings yet

- Piping Class Summary - CM2Document1 pagePiping Class Summary - CM2narutothunderjet216100% (1)

- Electrode CalculationDocument2 pagesElectrode Calculationtejasp8388100% (1)

- Bolting Gasket SizingDocument1 pageBolting Gasket SizingKamlesh DalavadiNo ratings yet

- Asme - B31.4 InterpretacionesDocument9 pagesAsme - B31.4 InterpretacionesJusebar ArisNo ratings yet

- Hydrotest Calculation FormulaDocument1 pageHydrotest Calculation FormulaSandipPatelNo ratings yet

- Steel PropertiesDocument22 pagesSteel PropertiesMOHD SALMANNo ratings yet

- Appendix 1Document22 pagesAppendix 1HudaFiHayyat0% (1)

- Weld DefectDocument3 pagesWeld DefectumeshNo ratings yet

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDocument2 pagesMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamNo ratings yet

- JFE SteelDocument62 pagesJFE Steelxmas12345No ratings yet

- PipeDocument44 pagesPipesudokuNo ratings yet

- Pressure Test Plan FormDocument3 pagesPressure Test Plan FormSurajNo ratings yet

- WM PWHTDocument18 pagesWM PWHTFaiz IshakNo ratings yet

- Yanbu Export Refinery Piping Materials ChartDocument7 pagesYanbu Export Refinery Piping Materials ChartJanakiraman MalligaNo ratings yet

- ASME SecVIII Div-2 Hydro TestDocument2 pagesASME SecVIII Div-2 Hydro Testsouren1975No ratings yet

- Piping Class San 3120 P Et 003Document42 pagesPiping Class San 3120 P Et 003cecilNo ratings yet

- Simple beam spreadsheetDocument65 pagesSimple beam spreadsheetKrishn DevNo ratings yet

- Connectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsDocument2 pagesConnectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsTTNo ratings yet

- Comparison TableDocument6 pagesComparison TablePand AemonaEonNo ratings yet

- Pipes General - Materials Equivalent Used ASTM Grades Bolts NutsDocument4 pagesPipes General - Materials Equivalent Used ASTM Grades Bolts Nutsskilach100% (1)

- Easyflex Flexible Hose DatasheetDocument2 pagesEasyflex Flexible Hose DatasheetzassssNo ratings yet

- Wall ThicknessDocument6 pagesWall ThicknessKrishant Krishant KrishantNo ratings yet

- Data Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueDocument2 pagesData Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueYusri Fakhrizal100% (1)

- RTJ Flange Dimensions - Class 150 To Class 2500 PDFDocument13 pagesRTJ Flange Dimensions - Class 150 To Class 2500 PDFRommy RomanzaNo ratings yet

- Pipes. Wall Thickness Calculation According ASME B31.3Document125 pagesPipes. Wall Thickness Calculation According ASME B31.3musaveerNo ratings yet

- Itp For All MaterialsDocument59 pagesItp For All MaterialsTauqueerAhmad100% (1)

- Monolithic Insulating JointsDocument5 pagesMonolithic Insulating JointsTran Thanh TungNo ratings yet

- Common Alloys SpecificationsDocument1 pageCommon Alloys SpecificationsSARATH KRISHNAKUMARNo ratings yet

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialsChee WeiNo ratings yet

- B31.3 - Reinf Pad CalculationDocument2 pagesB31.3 - Reinf Pad CalculationasafhoxlNo ratings yet

- TN10 Critical Line List SampleDocument2 pagesTN10 Critical Line List Sampleyulianus_srNo ratings yet

- API Valve Trim ChartDocument2 pagesAPI Valve Trim ChartkhaireddinNo ratings yet

- All Materials DocumentsDocument1 pageAll Materials DocumentsRonit PatelNo ratings yet

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- p3 Paint SelectionDocument3 pagesp3 Paint SelectionMamacintNo ratings yet

- p3 Paint SelectionDocument3 pagesp3 Paint SelectionMamacintNo ratings yet

- Pictorial List of Space Marine Chapters M-Z - Warhammer 40kDocument32 pagesPictorial List of Space Marine Chapters M-Z - Warhammer 40kMamacint100% (3)

- Img 20180811 201727Document1 pageImg 20180811 201727MamacintNo ratings yet

- Simulation - Instability Diagnosis PDFDocument7 pagesSimulation - Instability Diagnosis PDFMamacintNo ratings yet

- Simulation - Instability DiagnosisDocument72 pagesSimulation - Instability DiagnosisMamacintNo ratings yet

- Manulife CoverMe FollowMe Health Comp Chart Jan 2018 ENGLISHDocument2 pagesManulife CoverMe FollowMe Health Comp Chart Jan 2018 ENGLISHMamacintNo ratings yet

- ASME Pressure Vessel Design-BDocument120 pagesASME Pressure Vessel Design-BSidra KhanNo ratings yet

- Colour Card 100 PDFDocument2 pagesColour Card 100 PDFMamacintNo ratings yet

- A2K5D8 - CNRL Pipeline Specifications 2009Document241 pagesA2K5D8 - CNRL Pipeline Specifications 2009MamacintNo ratings yet

- Fracture Mechanics Using Solidworks Cosmosworks2Document10 pagesFracture Mechanics Using Solidworks Cosmosworks2Maeschi CatalinNo ratings yet

- 100-955 Bearings in Centrifugal Pumps - TCM - 12-154513Document38 pages100-955 Bearings in Centrifugal Pumps - TCM - 12-154513최승원No ratings yet

- PV Newsletter - February 2013 PDFDocument12 pagesPV Newsletter - February 2013 PDFMamacintNo ratings yet

- ASME Pressure Vessel Design-BDocument120 pagesASME Pressure Vessel Design-BSidra KhanNo ratings yet

- Support Catalogue+ ++metric+2011+ (111011)Document292 pagesSupport Catalogue+ ++metric+2011+ (111011)Mvss PrakashNo ratings yet

- (Process Industry Practices) Piping Flexibility OrgDocument9 pages(Process Industry Practices) Piping Flexibility OrgMursid Lafaliana Nuari100% (3)

- Eng201 BookDocument180 pagesEng201 BookMamacintNo ratings yet

- Caracteristicas Normas ASME B31Document3 pagesCaracteristicas Normas ASME B31darthneoNo ratings yet

- Bcsa Circular For Pressure Piping Registration - Revised July 02-2015Document3 pagesBcsa Circular For Pressure Piping Registration - Revised July 02-2015MamacintNo ratings yet

- Garlock Sample Torque CalculationDocument1 pageGarlock Sample Torque CalculationMamacintNo ratings yet

- Permit Seminar2013Document46 pagesPermit Seminar2013MamacintNo ratings yet

- Hy Span 3500 BrochureDocument16 pagesHy Span 3500 BrochureMamacintNo ratings yet

- Weights of Piping MaterialsDocument26 pagesWeights of Piping MaterialsGicuNo ratings yet

- Bcsa Circular For Pressure Piping Registration - Revised July 02-2015Document3 pagesBcsa Circular For Pressure Piping Registration - Revised July 02-2015MamacintNo ratings yet

- Memletics Effective Speed Reading Course PDFDocument110 pagesMemletics Effective Speed Reading Course PDFChris GonzalesNo ratings yet

- Canada: Du Canada of Canada Government GouvernementDocument1 pageCanada: Du Canada of Canada Government GouvernementMamacintNo ratings yet

- Posture PowerDocument37 pagesPosture PowerPachacuti0100% (3)

- Chapter 1 - Equations of Statics & Free Body Diagrams: 1.1 Basic DefinitionsDocument4 pagesChapter 1 - Equations of Statics & Free Body Diagrams: 1.1 Basic DefinitionsRavi KhandelwalNo ratings yet

- Compressible Flow Presentation Compressible - Flow - Presentation - Chapter7Jane - Chapter7JaneDocument11 pagesCompressible Flow Presentation Compressible - Flow - Presentation - Chapter7Jane - Chapter7JaneAbbas MohajerNo ratings yet

- Kansai Group Corporation Invoice for Vehicle Export to MaldivesDocument1 pageKansai Group Corporation Invoice for Vehicle Export to MaldivesIbrahim JaleelNo ratings yet

- EPCM TheMisunderstoodContractDocument6 pagesEPCM TheMisunderstoodContractmonikatickoo4412100% (2)

- 1 Maritime TransportDocument413 pages1 Maritime TransportWondwosen Tiruneh100% (1)

- Wheels of Thunder October 2012Document84 pagesWheels of Thunder October 2012Scott RobinsonNo ratings yet

- Aisi S220-11 PDFDocument0 pagesAisi S220-11 PDFLutfi VerdyNo ratings yet

- HiTEC-5724 PDS PDFDocument2 pagesHiTEC-5724 PDS PDFahmetNo ratings yet

- Packer Shoes Casing Manual Section 7Document22 pagesPacker Shoes Casing Manual Section 7Tong Chaipanyakul100% (1)

- Book To PrintDocument291 pagesBook To PrintIan Untalan67% (6)

- Slaa 116Document21 pagesSlaa 116misaelrodrigoNo ratings yet

- Titan Support SystemDocument12 pagesTitan Support SystemKovacs Zsolt-IstvanNo ratings yet

- Chapter 6 Layout Planning Model and Design Final FinalDocument28 pagesChapter 6 Layout Planning Model and Design Final Finaluser 123No ratings yet

- Beam Analysis BS5950Document229 pagesBeam Analysis BS5950cataiceNo ratings yet

- As NZS 1865 1997 Aluminium and Aluminium Alloys Drawn Wire Rod Bar and StripDocument7 pagesAs NZS 1865 1997 Aluminium and Aluminium Alloys Drawn Wire Rod Bar and StripYasser Hammad MohamedNo ratings yet

- Baron 55Document1,113 pagesBaron 55Dú VieiraNo ratings yet

- Baddi University Syll of MEDocument102 pagesBaddi University Syll of MEKunal KumbhaNo ratings yet

- Case 5 - DatavisionDocument5 pagesCase 5 - DatavisionSri Nandhni100% (1)

- Ball Bearings 1Document17 pagesBall Bearings 1ManicharanNo ratings yet

- SamsungDocument80 pagesSamsungRicha Khetan50% (4)

- Sathya Seelan resume for electrical engineerDocument4 pagesSathya Seelan resume for electrical engineerSathyaSeelan Veerasamy KumaresanNo ratings yet

- Sage015061 PDFDocument13 pagesSage015061 PDFaliNo ratings yet

- Chapter 1Document31 pagesChapter 1Mohit PariharNo ratings yet

- Z Drive TechnologyDocument16 pagesZ Drive Technologyebey_endun100% (1)

- Recommender System Based On Customer Behaviour For Retail StoresDocument12 pagesRecommender System Based On Customer Behaviour For Retail StoresPriscila GuayasamínNo ratings yet

- ORings-NOK S SS SeriesDocument2 pagesORings-NOK S SS SeriesKudanthai SenthilkumarNo ratings yet

- Identity Theft Prevention: Protect Yourself and OthersDocument4 pagesIdentity Theft Prevention: Protect Yourself and OtherscherryfooNo ratings yet

- Wilderness 1500 X Study Plans Complete A 4Document29 pagesWilderness 1500 X Study Plans Complete A 4Anonymous eiCiKcVkNo ratings yet

- Cement Grinding OptimizationDocument9 pagesCement Grinding OptimizationFran JimenezNo ratings yet

- Improving BOLDFlash's Internal ProcessesDocument10 pagesImproving BOLDFlash's Internal Processessivaabhilash100% (1)

- SDLC (Software Development Life Cycle) : by SapnaDocument20 pagesSDLC (Software Development Life Cycle) : by SapnaZerihun Alemayehu100% (1)