Professional Documents

Culture Documents

Rubber Closures For Containers PDF

Uploaded by

Karla RodríguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rubber Closures For Containers PDF

Uploaded by

Karla RodríguezCopyright:

Available Formats

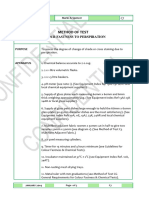

3.2.9. Rubber closures for containers EUROPEAN PHARMACOPOEIA 5.

01/2005:30209 of detecting differences in a batch compared to the closures

used for compatibility testing. One or more of the following

analytical methods may be applied for this purpose :

3.2.9. RUBBER CLOSURES FOR determination of relative density, determination of

CONTAINERS FOR AQUEOUS sulphated ash, determination of sulphur content, thin-layer

PARENTERAL PREPARATIONS, FOR chromatography carried out on an extract, ultraviolet

POWDERS AND FOR FREEZE-DRIED absorption spectrophotometry of an extract, infrared

absorption spectrophotometry of a pyrolysate.

POWDERS

IDENTIFICATION

Rubber closures for containers for aqueous parenteral A. The elasticity is such that a strip of material with a

preparations for powders and for freeze-dried powders are cross-section of 1 mm2 to 5 mm2 can be stretched by hand

made of materials obtained by vulcanisation (cross-linking) to at least twice its original length. Having been stretched

of macromolecular organic substances (elastomers), with to twice its length for l min, it contracts to less than

appropriate additives. The specification also applies to 1.2 times its original length within 30 s.

closures for containers for powders and freeze-dried B. Heat 1 g to 2 g in a heat-resistant test-tube over an open

products to be dissolved in water immediately before use. flame to dry the sample and continue heating until

The specification does not apply to closures made from pyrolysate vapours are condensed near the top edge

silicone elastomer (which are dealt with in 3.1.9. Silicone of the test-tube. Deposit a few drops of the pyrolysate

elastomer for closures and tubing), to laminated closures on a potassium bromide disc and examine by infrared

or to lacquered closures. The elastomers are produced absorption spectrophotometry (2.2.24), comparing with

from natural or synthetic substances by polymerisation, the spectrum obtained with the type sample.

polyaddition or polycondensation. The nature of the C. The total ash (2.4.16) is within 10 per cent of the result

principal components and of the various additives (for obtained with the type sample.

example vulcanisers, accelerators, stabilisers, pigments)

depends on the properties required for the finished article. TESTS

Rubber closures may be classified in 2 types : type I closures The samples to be analysed may be washed and sterilised

are those which meet the strictest requirements and which before use.

are to be preferred ; type II closures are those which, having Solution S. Introduce a number of uncut closures

mechanical properties suitable for special uses (for example, corresponding to a surface area of about 100 cm2 in a

multiple piercing), cannot meet requirements as severe suitable glass container, cover with water for injections R,

as those for the first category because of their chemical boil for 5 min and rinse 5 times with cold water for

composition. injections R. Place the washed closures in a wide-necked

The closures chosen for use with a particular preparation flask (glass type I, 3.2.1), add 200 ml of water for

are such that : injections R and weigh. Cover the mouth of the flask with

the components of the preparation in contact with the a borosilicate-glass beaker. Heat in an autoclave so that a

closure are not adsorbed onto the surface of the closure temperature of 121 2 C is reached within 20 min to 30 min

and do not migrate into or through the closure to an and maintain at this temperature for 30 min. Cool to room

extent sufficient to affect the preparation adversely, temperature over about 30 min. Make up to the original

mass with water for injections R. Shake and immediately

the closure does not yield to the preparation substances separate the solution from the rubber by decantation. Shake

in quantities sufficient to affect its stability or to present a solution S before each test

risk of toxicity.

Blank. Prepare a blank in the same manner using 200 ml of

The closures are compatible with the preparation for which water for injections R.

they are used throughout its period of validity.

Appearance of solution. Solution S is not more opalescent

The manufacturer of the preparation must obtain from the than reference suspension II for type I closures and is not

supplier an assurance that the composition of the closure more opalescent than reference suspension III for type II

does not vary and that it is identical to that of the closure closures (2.2.1). Solution S is not more intensely coloured

used during compatibility testing. When the supplier informs than reference solution GY5 (2.2.2, Method II).

the manufacturer of the preparation of changes in the Acidity or alkalinity. To 20 ml of solution S add 0.1 ml of

composition, compatibility testing must be repeated, totally bromothymol blue solution R1. Not more than 0.3 ml of

or partly, depending on the nature of the changes. 0.01 M sodium hydroxide or 0.8 ml of 0.01 M hydrochloric

The closures are washed and may be sterilised before use. acid is required to obtain either a blue or a yellow colour,

respectively.

CHARACTERS Absorbance. Carry out the test within 5 h of preparation

Rubber closures are elastic ; they are translucent or opaque of solution S. Filter solution S on a membrane filter having

and have no characteristic colour, the latter depending approximately 0.45 m pores rejecting the first few millilitres

on the additives used. They are practically insoluble in of filtrate. Measure the absorbance (2.2.25) of the filtrate at

tetrahydrofuran, in which, however, a considerable reversible wavelengths from 220 nm to 360 nm using the blank (see

swelling may occur. They are homogeneous and practically solution S) as compensation liquid. At these wavelengths,

free from flash and adventitious materials (for example the absorbance does not exceed 0.2 for type I closures or 4.0

fibres, foreign particles, waste rubber). for type II closures. If necessary, dilute the filtrate before

Identification of the type of rubber used for the closures is measurement of the absorbance and correct the result for

not within the scope of this specification. The identification the dilution.

test given below distinguishes elastomer and non-elastomer Reducing substances. Carry out the test within 4 h of

closures but does not differentiate the various types of preparation of solution S. To 20.0 ml of solution S add

rubber. Other identity tests may be carried out with the aim 1 ml of dilute sulphuric acid R and 20.0 ml of 0.002 M

316 See the information section on general monographs (cover pages)

EUROPEAN PHARMACOPOEIA 5.0 3.2.9. Rubber closures for containers

potassium permanganate. Boil for 3 min. Cool. Add 1 g Penetrability. For closures intended to be pierced by a

of potassium iodide R and titrate immediately with 0.01 M hypodermic needle, carry out the following test. Fill 10

sodium thiosulphate, using 0.25 ml of starch solution R as suitable vials to the nominal volume with water R, fit the

indicator. Carry out a titration using 20.0 ml of the blank. closures to be examined and secure with a cap. Using for

The difference between the titration volumes is not greater each closure a new, lubricated long-bevel(1) (bevel angle

than 3.0 ml for type I closures and 7.0 ml for type II closures. 12 2) hypodermic needle with an external diameter of

Ammonium (2.4.1) : maximum 2 ppm. 0.8 mm, pierce the closures with the needle perpendicular

to the surface. The force required for piercing, determined

Dilute 5 ml of solution S to 14 ml with water R. The solution with an accuracy of 0.25 N (25 gf), is not greater than 10 N

complies with limit test A. (1 kgf) for each closure.

Extractable zinc : maximum of 5 g of extractable Zn per Fragmentation. For closures intended to be pierced by

millilitre of solution S. a hypodermic needle, carry out the following test. If the

Atomic absorption spectrophotometry (2.2.23, Method I). closures are to be used for aqueous preparations, place in

Test solution. Dilute 10.0 ml of solution S to 100 ml with 12 clean vials a volume of water R corresponding to the

0.1 M hydrochloric acid. nominal volume minus 4 ml, close the vials with the closures

to be examined, secure with a cap and allow to stand for

Reference solutions. Prepare the reference solutions using 16 h. If the closures are to be used with dry preparations,

zinc standard solution (10 ppm Zn) R diluted with 0.1 M close 12 clean vials with the closures to be examined. Using

hydrochloric acid. a lubricated long-bevel(1) (bevel angle 12 2) hypodermic

Source : zinc hollow-cathode lamp. needle with an external diameter of 0.8 mm fitted to a clean

Wavelength : 213.9 nm. syringe, inject into the vial 1 ml of water R and remove 1 ml

of air ; carry out this operation 4 times for each closure,

Flame : air-acetylene. piercing each time at a different site. Use a new needle for

Extractable heavy metals (2.4.8) : maximum 2 ppm. each closure and check that the needle is not blunted during

Solution S complies with limit test A. Prepare the standard the test. Pass the liquid in the vials through a filter having

using lead standard solution (2 ppm Pb) R. approximately 0.5 m pores. Count the fragments of rubber

visible to the naked eye. The total number of fragments does

Residue on evaporation. Evaporate 50.0 ml of solution S to not exceed 5. This limit is based on the assumption that

dryness on a water-bath and dry at 100 C to 105 C. The fragments with a diameter equal to or greater than 50 m

residue weighs not more than 2.0 mg for type I rubber and are visible to the naked eye ; in cases of doubt or dispute, the

not more than 4.0 mg for type II rubber. fragments are examined with a microscope to verify their

Volatile sulphides. Place closures, cut if necessary, with a nature and size.

total surface area of 20 2 cm2 in a 100 ml conical flask Self-sealing test. For closures intended to be used with

and add 50 ml of a 20 g/l solution of citric acid R. Place a multidose containers, carry out the following test. Fill 10

piece of lead acetate paper R over the mouth of the flask suitable vials to the nominal volume with water R, fit the

and maintain the paper in position by placing over it an closures to be examined and secure with a cap. Using for

inverted weighing bottle. Heat in an autoclave at 121 2 C each closure a new hypodermic needle with an external

for 30 min. Any black stain on the paper is not more intense diameter of 0.8 mm, pierce each closure 10 times, piercing

than that of a standard prepared at the same time in the each time at a different site. Immerse the vials upright in a

same manner using 0.154 mg of sodium sulphide R and 1 g/l solution of methylene blue R and reduce the external

50 ml of a 20 g/l solution of citric acid R. pressure by 27 kPa for 10 min. Restore atmospheric pressure

For the tests for penetrability, fragmentation and and leave the vials immersed for 30 min. Rinse the outside

self-sealing, use the closures treated as described for the of the vials. None of the vials contains any trace of coloured

preparation of solution S and allowed to dry. solution.

(1) See ISO 7864 "Sterile hypodermic needles for single use".

General Notices (1) apply to all monographs and other texts 317

You might also like

- 3.2.9. Rubber Closures For Containers For Aqueous Parenteral Preparations, For Powders and For Freeze-Dried PowdersDocument2 pages3.2.9. Rubber Closures For Containers For Aqueous Parenteral Preparations, For Powders and For Freeze-Dried PowdersG_RanjithNo ratings yet

- 3.2. 3. Sterile Plastic Containers For Human Blood and Blood Components 30203eDocument3 pages3.2. 3. Sterile Plastic Containers For Human Blood and Blood Components 30203esajittNo ratings yet

- Ep9.0 01 293Document2 pagesEp9.0 01 293AlexandraNo ratings yet

- 3.2.2. 1. Plastic Containers For Aqueous Solutions For Infusion 90003eDocument1 page3.2.2. 1. Plastic Containers For Aqueous Solutions For Infusion 90003eAshvini PrakashNo ratings yet

- C 282 - 99 - Qzi4mgDocument3 pagesC 282 - 99 - Qzi4mgEmre DalgicNo ratings yet

- C07 - Colour Fastness To PerspirationDocument5 pagesC07 - Colour Fastness To PerspirationChandru TGNo ratings yet

- USP 660 - Containers - GlassDocument4 pagesUSP 660 - Containers - Glasskunalkp88100% (1)

- 3.2.8. Sterile Single-Use Plastic Syringes-2Document2 pages3.2.8. Sterile Single-Use Plastic Syringes-2Avinash Kumar33% (3)

- EUROPEAN PHARMACOPOEIA 5.0: Cotton, absorbentDocument2 pagesEUROPEAN PHARMACOPOEIA 5.0: Cotton, absorbentluca_sergiuNo ratings yet

- Bresle Test Kit PDFDocument4 pagesBresle Test Kit PDFmuthukumarNo ratings yet

- Corrosion removal and protection of magnesium alloysDocument300 pagesCorrosion removal and protection of magnesium alloyshector eduardo moya benavidesNo ratings yet

- PackagingDocument18 pagesPackagingAli HNo ratings yet

- Tests For GlassDocument4 pagesTests For GlassFera PermatasariNo ratings yet

- ASTM D 1417 - 97 Rubber Latices-SyntheticDocument11 pagesASTM D 1417 - 97 Rubber Latices-Syntheticalin2005No ratings yet

- PH Euro 3.2.2 Plastic Containers and ClosuresDocument3 pagesPH Euro 3.2.2 Plastic Containers and Closuresryad bmza100% (1)

- Recipe Cards UpdateDocument12 pagesRecipe Cards UpdateAnonymous JWUsx1No ratings yet

- Corona Remedies Pvt. LTDDocument9 pagesCorona Remedies Pvt. LTDAnkur PatelNo ratings yet

- Kelompok 3 - PSPA 40Document15 pagesKelompok 3 - PSPA 40rahmaNo ratings yet

- Method of Test For High Float Emulsified AsphaltsDocument11 pagesMethod of Test For High Float Emulsified Asphaltsming_zhu10No ratings yet

- Jotun Resist 5WFDocument4 pagesJotun Resist 5WFSergio SmithNo ratings yet

- EUROPHARM CROSPOVIDONEDocument2 pagesEUROPHARM CROSPOVIDONExuan y phanNo ratings yet

- Scope: CautionDocument7 pagesScope: CautionJavier Oswaldo Gonzalez AceroNo ratings yet

- Preparation of Perlite-Based Magnesium Perchlorate Desiccant With Colour IndicatorDocument5 pagesPreparation of Perlite-Based Magnesium Perchlorate Desiccant With Colour IndicatorMuhammad HairuddinNo ratings yet

- USP EP - 2.4.13 - Sulfates, 2.4.16 - Total AshDocument1 pageUSP EP - 2.4.13 - Sulfates, 2.4.16 - Total AshVinz Phillip LeonardoNo ratings yet

- NIOZ 1 Corrosion Resistant Zinc-Rich PrimerDocument3 pagesNIOZ 1 Corrosion Resistant Zinc-Rich PrimerabdulhadiNo ratings yet

- Ceramic Coating Product Data SheetDocument3 pagesCeramic Coating Product Data SheetANIBALLOPEZVEGANo ratings yet

- 3.2.2. Plastic Containers and Closures For Pharmaceutical UseDocument2 pages3.2.2. Plastic Containers and Closures For Pharmaceutical UseDeepak Kabbur80% (5)

- Method of AnalysisDocument37 pagesMethod of Analysisisaiah mathengeNo ratings yet

- Pharmaceutical Packaging Processes and Impact on Drug StabilityDocument69 pagesPharmaceutical Packaging Processes and Impact on Drug StabilitysumanchyNo ratings yet

- D1725Document3 pagesD1725Ненад КнежевићNo ratings yet

- Determination of Stripping ValueDocument4 pagesDetermination of Stripping ValueHemanth RaoNo ratings yet

- Alodine T-5900 TdsDocument5 pagesAlodine T-5900 TdsImeblaNo ratings yet

- Bresle PatchesDocument1 pageBresle PatchesPedro Juan Dàvila ZùñigaNo ratings yet

- TDS-JOTACOTE 5-EnglishDocument4 pagesTDS-JOTACOTE 5-EnglishthirdNo ratings yet

- Astm D-1712 Color Fading TestDocument2 pagesAstm D-1712 Color Fading TestMurugan PalanisamyNo ratings yet

- EUROPEAN PHARMACOPOEIA TEST FOR STERILE PLASTIC SYRINGESDocument3 pagesEUROPEAN PHARMACOPOEIA TEST FOR STERILE PLASTIC SYRINGESAvinash KumarNo ratings yet

- D 1579 - 97 Rde1nzktotcDocument2 pagesD 1579 - 97 Rde1nzktotcMarceloNo ratings yet

- Appendix XIX G. Sterile Single-Use Plastic SyringesDocument9 pagesAppendix XIX G. Sterile Single-Use Plastic Syringessyed zafar ullah shahNo ratings yet

- Cotton, Absorbent: Lanugo Gossypii AbsorbensDocument2 pagesCotton, Absorbent: Lanugo Gossypii AbsorbensHamed GholamiNo ratings yet

- Acid and Mortar Resistance of Factory-Applied Clear Coatings On Extruded Aluminum ProductsDocument2 pagesAcid and Mortar Resistance of Factory-Applied Clear Coatings On Extruded Aluminum ProductsAnonymous mBP0NlH0DTNo ratings yet

- Basf Masterprotect 1818 TdsDocument2 pagesBasf Masterprotect 1818 TdsHarz IndNo ratings yet

- USP 660 - 43 - Glass Grain TestDocument2 pagesUSP 660 - 43 - Glass Grain Testamitdi001_667397546No ratings yet

- Total Immersion Corrosion Test For Soak Tank Metal CleanersDocument4 pagesTotal Immersion Corrosion Test For Soak Tank Metal CleanersJail MartinezNo ratings yet

- Weg Fenoxi HTDocument4 pagesWeg Fenoxi HTCARLOSNo ratings yet

- Permastic Vinyl Acrylic EmulsionDocument1 pagePermastic Vinyl Acrylic EmulsionCynthia MillerNo ratings yet

- G4258 Silver - Pds-EnDocument3 pagesG4258 Silver - Pds-EnuraliNo ratings yet

- MSC Circulars.670Document23 pagesMSC Circulars.670Wonchul ParkNo ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- Clau Astm PDFDocument3 pagesClau Astm PDFLezlie Berenice Serrano GalindoNo ratings yet

- Corrocoat Graphite SDocument3 pagesCorrocoat Graphite SstelioskoNo ratings yet

- D 3272 - 76 (2003) PDFDocument2 pagesD 3272 - 76 (2003) PDFAl7amdlellahNo ratings yet

- Measuring and Interpreting SDI TestsDocument4 pagesMeasuring and Interpreting SDI TestsDo Hong NhungNo ratings yet

- MT 158 Determination of Mercury On Treated Seeds: Miscellaneous Techniques and ImpuritiesDocument18 pagesMT 158 Determination of Mercury On Treated Seeds: Miscellaneous Techniques and ImpuritiesFelipe Navarrete100% (1)

- Usp NF 660Document7 pagesUsp NF 660AkashNo ratings yet

- Fisa Tehnica - Absorbanti Pentru Substante Chimice - enDocument2 pagesFisa Tehnica - Absorbanti Pentru Substante Chimice - engeorge_rusuNo ratings yet

- Protective Concrete Coating GuideDocument3 pagesProtective Concrete Coating GuideTori SmallNo ratings yet

- D 1579 - 01 Rde1nzk - PDFDocument2 pagesD 1579 - 01 Rde1nzk - PDFMarceloNo ratings yet

- Epoxy Red Oxide PrimerDocument2 pagesEpoxy Red Oxide PrimerBalakrishna ChowdaryNo ratings yet

- Characteristics: Uses ApplicationDocument2 pagesCharacteristics: Uses Applicationazam RazzaqNo ratings yet

- 20b. Global S CycleDocument15 pages20b. Global S CyclerossydaNo ratings yet

- Astm 1351 1 REPLICADocument6 pagesAstm 1351 1 REPLICAmaheshNo ratings yet

- High Performance Butterfly Valve HP 111Document4 pagesHigh Performance Butterfly Valve HP 111JOHNNo ratings yet

- Ti OSO4Document4 pagesTi OSO4Liz AfanadorNo ratings yet

- Nucleic Acids BrochureDocument2 pagesNucleic Acids BrochureCring-cring NavarroNo ratings yet

- Astm D1785-15Document11 pagesAstm D1785-15david franco0% (1)

- Sspc-Ab 1Document5 pagesSspc-Ab 1Anton Thomas Punzalan100% (3)

- Chloroplast, PPTDocument21 pagesChloroplast, PPTSuchitra Sk88% (8)

- Report GCWDocument34 pagesReport GCWArchit HaldiaNo ratings yet

- ESSO Shaft Sealing Systems SpecificationDocument13 pagesESSO Shaft Sealing Systems SpecificationFlorin Daniel AnghelNo ratings yet

- DESN 10041 - Exam-2020-MainDocument4 pagesDESN 10041 - Exam-2020-MainZikani NyirendaNo ratings yet

- Pogil - Periodic Trends RHSDDocument7 pagesPogil - Periodic Trends RHSDErin DodsonNo ratings yet

- Chinese GMP 2010Document115 pagesChinese GMP 2010Atul SharmaNo ratings yet

- Process Integration Using Pinch Analysis: A Cement Industry Case StudyDocument4 pagesProcess Integration Using Pinch Analysis: A Cement Industry Case StudyReggie DueñasNo ratings yet

- Photos of Defects Found in RadiographyDocument14 pagesPhotos of Defects Found in RadiographyKavipriyan KaviNo ratings yet

- MN 206 Market Survey CopperDocument210 pagesMN 206 Market Survey CopperArjun MishraNo ratings yet

- Cracking of Inconel 800H - SMRDocument8 pagesCracking of Inconel 800H - SMRkoyasrujanaNo ratings yet

- SIP MeenakshDocument17 pagesSIP MeenakshRati GuptaNo ratings yet

- S1XBIG58 M500 4 Tech InfoDocument15 pagesS1XBIG58 M500 4 Tech InfoFredy DanielNo ratings yet

- Low Temp Refrigeration Oil DataDocument1 pageLow Temp Refrigeration Oil DataGeorgiana DumitruNo ratings yet

- Thermoplastics and Thermosetting PlasticDocument24 pagesThermoplastics and Thermosetting PlasticKAPIL SINGHNo ratings yet

- II - ITP - Defect Work FabricationDocument5 pagesII - ITP - Defect Work Fabricationmohd as shahiddin jafriNo ratings yet

- Exporters: Index by CountryDocument113 pagesExporters: Index by CountrySyam WadiNo ratings yet

- Expwb3ans eDocument67 pagesExpwb3ans eOlivia LinNo ratings yet

- Sublimation InstructionsDocument4 pagesSublimation InstructionsNanette A. Marañon-SansanoNo ratings yet

- ConChem q1 m1Document28 pagesConChem q1 m1Leonora Alejo100% (1)

- Sansico Top Access Floor Trap - S3Document20 pagesSansico Top Access Floor Trap - S3Biggie ColdAngelNo ratings yet

- How buffers maintain pH levelsDocument4 pagesHow buffers maintain pH levelsManP13No ratings yet

- BenchTop Orbital Shakers GuideDocument8 pagesBenchTop Orbital Shakers Guidedéborah_rosales100% (1)