Professional Documents

Culture Documents

P876 Piezo Energy Harvester Transducer

Uploaded by

ivfeenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P876 Piezo Energy Harvester Transducer

Uploaded by

ivfeenCopyright:

Available Formats

Piezo Nano Positioning

P-876 DuraAct

Piezoelectric Patch Transducers

feature a rugged design with

Ordering Information

the mechanical stability of a

structural material. P-876.A11

DuraAct Patch Transducer,

61 x 35 x 0,4 mm

Energy Harvesting: Self-

P-876.A12

Sustaining Systems in a DuraAct Patch Transducer,

Small Package 61 x 35 x 0,5 mm

Another operation mode of P-876.A15

DuraAct patch transducers DuraAct Patch Transducer,

is the application as energy 61 x 35 x 0,8 mm

harvester. The transformation P-876.SP1

The small-sized P-876.SP1 DuraAct transducers (left)

of mechanical vibrations up to DuraAct Patch Transducer,

some kilohertz may yield elec- 16 x 13 x 0.5 mm

are designed for applications where space is at a premium.

On the right, the P-876.A12 series transducer trical power in the milliwatt Ask about custom designs!

(golf ball for size comparison)

range. This power supplies

miniature electronic devices

Flexible choice of thickness

like LEDs, sensors or even

and bending properties

Actuator, Sensor or Energy Source transmitters for remote data

Highly Formable Ceramics control. Flexible choice of piezo-

Can be Applied to Curved Surfaces ceramic materials and

Notes operating temperature

Customized Solutions on Request

Cost-Effective DuraAct Transducers can be Various electrical connection

offered in highly customized designs

Physik Instrumente (PI) GmbH & Co. KG 2008. Subject to change without notice. All data are superseded by any new release.

versions:

P-876 DuraAct patch trans- Integration into Adaptive Combining sensor and actuator

Flexible choice of functions (multiple ceramic

ducers combine the functional- Systems

dimensions layers)

ity of piezoceramic materials as With their compact design,

sensors and actuators as well DuraAct transducers can be

as for electrical charge genera- applied to structure areas where

tion and storage. Used as a deformations are to be generat-

bender actuator, they allow ed or detected. For this purpose

high deflection with high force the transducers can be affixed

and precision. Other possible to the surface of structures or

operation modes of DuraAct

The newest release for data sheets is available for download at www.pi.ws. R2 10/03/25.0

they can be integrated as struc-

transducers are as high- tural elements. Whole areas

dynamics sensor (e. g. for are monitored effectively by

structural health monitoring) or applying an array of several

for energy harvesting. DuraAct on a surface.

DuraActpatch transducers

are ideally suited for active and

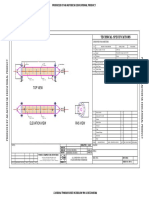

P-876.Axx series, dimensions in mm

adaptive systems. Embedded

in a servo-control loop, vibra-

Application Examples tions can be reduced and struc-

tures can be controlled in the

High-dynamics actuators nanometer range.

Adaptive systems

Robust and Cost-Effective

Vibration and noise Design for Industrial

cancellation Applications

Deformation control and The laminated design consist-

stabilization ing of a piezoceramic plate and

polymers provides a mechani-

Damage monitoring cally preloaded and electrically

insulated device for easy han- Lateral contraction of a DuraAct patch transducer

Energy harvesting when voltage is applied

dling. P-876 patch transducers

Piezo Nano Positioning

Linear Actuators & Motors

PiezoWalk Motors / Actuators

PILine Ultrasonic Motors

DC-Servo & Stepper Actuators

Piezo Actuators & Components

Guided / Preloaded Actuators

Unpackaged stack Actuators

Patches /Benders/Tubes /Shear..

Nanopositioning / Piezoelectrics

Deflection of a bending transducer as a function of the substrate thickness for different

materials. A bending transducer consists of a substrate with a P-876 actuator

Nanometrology

(here: P-876.A15) glued to one side. A contraction of the actuator effects a deflection W

Micropositioning

Index

Design principle of the transducer P-876.SP1, dimensions in mm

Technical Data

Model P-876.A11 P-876.A12 P-876.A15 P-876.SP1 Tolerances

Operating voltage -50 to +200 V -100 to +400 V -250 to +1000 V -100 to +400 V

Motion and positioning

Lateral contraction, open-loop 400 m/m 650 m/m 800 m/m 650 m/m min. (+20 %/-0)

1.6 m/m/V 1.3 m/m/V 0.64 m/m/V 1.3 m/m/V min. (+20 %/-0)

Mechanical properties

Blocking force 90 N 265 N 775 N 280 N

Length 61 mm 61 mm 61 mm 16 mm 0.5 mm

Width 35 mm 35 mm 35 mm 13 mm 0.5 mm

Thickness 0.4 mm 0.5 mm 0.8 mm 0.5 mm 0.5 mm

Bending radius 12 mm 20 mm 70 mm max.

Drive properties

Ceramic type PIC 252 PIC 255 PIC 255 PIC 255

Layer thickness: 100 m Layer thickness: 200 m Layer thickness: 500 m Layer thickness: 200 m

Electrical Capacitance 150 nF 90 nF 45 nF 8 nF 20 %

Miscellaneous

Operating temperature range* -20 to +150 C -20 to +150 C -20 to +150 C -20 to +150 C

Mass 2.1 g 3.5 g 7.2 g 0.3 g 10 %

Voltage connection Soldering pads Soldering pads Soldering pads Soldering pads

Recommended controller / amplifier E-413.D2 (s. p. 2-120) E-413.D2 (s. p. 2-120) E-508 (s. p. 2-150) E-413.D2 (s. p. 2-120)

(actuator mode) E-835 (s. p. 2-166) E-835 (s. p. 2-166) E-835 (s. p. 2-166) E-835 (s. p. 2-166)

* Short-term operation up to 180 C

You might also like

- Duraact Patch Transducer: Bendable and RobustDocument5 pagesDuraact Patch Transducer: Bendable and RobustYan Naung AyeNo ratings yet

- 04 PDFDocument1 page04 PDFsesostrisserbiusNo ratings yet

- ISD715 Transport Magnetic Antenna (Active) : Installation GuideDocument2 pagesISD715 Transport Magnetic Antenna (Active) : Installation GuideravikkotaNo ratings yet

- Product 150 OMDocument2 pagesProduct 150 OMAhmad MehribanliNo ratings yet

- k3fAD2A SheetDocument2 pagesk3fAD2A SheetLili SugengNo ratings yet

- Spec Summitx163Document1 pageSpec Summitx163Dominique L'HeureuxNo ratings yet

- Manual Nivel Laser Ryobi PDFDocument2 pagesManual Nivel Laser Ryobi PDFGSOTOHNo ratings yet

- RT Manual RT-128 112114Document24 pagesRT Manual RT-128 112114LoserNo ratings yet

- Cutmaster 42 Cutmaster True Series: Light Duty Plasma Cutting SystemsDocument1 pageCutmaster 42 Cutmaster True Series: Light Duty Plasma Cutting SystemsLeonardo Martínez LópezNo ratings yet

- 906 & 908 Electrical System Compact Wheel Loader: Electrical Schematic Symbols and DefinitionsDocument2 pages906 & 908 Electrical System Compact Wheel Loader: Electrical Schematic Symbols and Definitionsait mimouneNo ratings yet

- Cat-00043 Chapter 5Document108 pagesCat-00043 Chapter 5aguilavmNo ratings yet

- 64 Kbit (8 K X 8) Autostore Nvsram: Features Functional DescriptionDocument23 pages64 Kbit (8 K X 8) Autostore Nvsram: Features Functional DescriptionAmine EmineNo ratings yet

- Shell & Tube Type Heat Exchanger Model.Document1 pageShell & Tube Type Heat Exchanger Model.Anurag SharmaNo ratings yet

- Aerodrome Chart - Icao: East Apron West ApronDocument1 pageAerodrome Chart - Icao: East Apron West ApronVicko SabriNo ratings yet

- SCP Series: Prizmacap™Document8 pagesSCP Series: Prizmacap™zamphirjoNo ratings yet

- Irobot Catalogue Glance PDFDocument2 pagesIrobot Catalogue Glance PDFsekarNo ratings yet

- 1100.004.01 B31.3 STOPPLE FitDocument6 pages1100.004.01 B31.3 STOPPLE FitRaymundo Maldonado AlvarezNo ratings yet

- Zund PN Series PrecisionCuttingDocument6 pagesZund PN Series PrecisionCuttingjajjjNo ratings yet

- k3p 07AS SheetDocument2 pagesk3p 07AS SheetsoniNo ratings yet

- Fill Product InformationDocument1 pageFill Product InformationJuanes CantanteNo ratings yet

- 5.desion TreeDocument18 pages5.desion Treepatil_555No ratings yet

- Allen Telecom AntennaDocument32 pagesAllen Telecom AntennaRoy AdhiwibowoNo ratings yet

- Tele-Relee de Timp PDFDocument52 pagesTele-Relee de Timp PDFChioibasNicolaeNo ratings yet

- Comibi - Surface - Thickness Planner PDFDocument5 pagesComibi - Surface - Thickness Planner PDFGyan ChandNo ratings yet

- Three Axis CNC Machine (Julius de Waal)Document6 pagesThree Axis CNC Machine (Julius de Waal)atef.selmi01No ratings yet

- Abck ErasDocument2 pagesAbck ErasSreenivasulu GNo ratings yet

- Technical Specifications: All PowerfulDocument4 pagesTechnical Specifications: All PowerfulDtodglxhlcNo ratings yet

- Luminaria CleanlineDocument2 pagesLuminaria CleanlineMilenaNo ratings yet

- As - Built: D-1408 DHT Stripper Reflux Drum EA-1402 DHT Stripper Condenser E-1406 DHT Stripper Trim Condenser NotesDocument1 pageAs - Built: D-1408 DHT Stripper Reflux Drum EA-1402 DHT Stripper Condenser E-1406 DHT Stripper Trim Condenser NotesAhmed MahdiNo ratings yet

- Vintage LEDDocument1 pageVintage LEDMuhammad Shahzad JavedNo ratings yet

- IDEALARC DC-1000 - PARTS LISTING INDEX (P146a)Document24 pagesIDEALARC DC-1000 - PARTS LISTING INDEX (P146a)Julio BacilioNo ratings yet

- HPH LevelDocument2 pagesHPH Levelom prakash pathakNo ratings yet

- 9869 0135 01b - Robbins - 73-Series - Technical - Specification - EnglishDocument5 pages9869 0135 01b - Robbins - 73-Series - Technical - Specification - EnglishBhargav PagadalaNo ratings yet

- Q.Peak Duo Xl-G11.3: Enduring High PerformanceDocument2 pagesQ.Peak Duo Xl-G11.3: Enduring High PerformanceSánchez Condado JesúsNo ratings yet

- MCCB - DRX 125 - Thermal Magnetic - Icu 36 Ka - 415 V - 2P - 50 ADocument1 pageMCCB - DRX 125 - Thermal Magnetic - Icu 36 Ka - 415 V - 2P - 50 AJosé Luis Julca GarcíaNo ratings yet

- NOTE: LSD DP Blinks During Programming.: Operating ModesDocument2 pagesNOTE: LSD DP Blinks During Programming.: Operating Modeselectrifier_suren0% (1)

- Sl-Vtad1 eDocument1 pageSl-Vtad1 eAjay MayalNo ratings yet

- Hira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraDocument4 pagesHira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraZuberYousufNo ratings yet

- Single-Phase Motors - Technical Catalogue 10-141/16Document15 pagesSingle-Phase Motors - Technical Catalogue 10-141/16Jonny MossNo ratings yet

- 02-2006 enDocument2 pages02-2006 enRalf MaurerNo ratings yet

- Q CELLS Data SheetDocument2 pagesQ CELLS Data SheetJorgeMauricioCastilloOssesNo ratings yet

- 42/47RE Transmissions: Won't Shift Without The AlternatorDocument7 pages42/47RE Transmissions: Won't Shift Without The AlternatorRicardo Rangel PosadasNo ratings yet

- CX-N999 SX N999 Tniit: Compact Disc Stereo SystemDocument80 pagesCX-N999 SX N999 Tniit: Compact Disc Stereo SystemHermo MedranoNo ratings yet

- Guide BarsDocument4 pagesGuide BarsDAYONo ratings yet

- Acbmitsu 131031031457 Phpapp01Document64 pagesAcbmitsu 131031031457 Phpapp01Quang TiênNo ratings yet

- Komet Dihart Reamax TS: Modular Reaming SystemDocument8 pagesKomet Dihart Reamax TS: Modular Reaming SystemLuis LopezNo ratings yet

- Powered by ExperienceDocument8 pagesPowered by ExperienceFigo ChengNo ratings yet

- BW Atmn 2049 BSS PCS ZSS 04Document11 pagesBW Atmn 2049 BSS PCS ZSS 04Ganesh KumarNo ratings yet

- Asus FX516PR Ux482Document76 pagesAsus FX516PR Ux482Jonard DuranNo ratings yet

- SW4S enDocument4 pagesSW4S engolden-eagleNo ratings yet

- Thread o Ring FittingsDocument4 pagesThread o Ring FittingsLê Đức ThiệnNo ratings yet

- CleanlineDocument2 pagesCleanlineravNo ratings yet

- Ratchet Wheel Drawing Sheet (Autodesk Inventor 2012)Document1 pageRatchet Wheel Drawing Sheet (Autodesk Inventor 2012)ionut8312No ratings yet

- Technical Data: Electrical Data, Dimensions and Weights of Earthing SwitchesDocument1 pageTechnical Data: Electrical Data, Dimensions and Weights of Earthing SwitchesttyNo ratings yet

- Sample One-Line DiagramDocument1 pageSample One-Line DiagramCHAMARA DEVAPPRIYANo ratings yet

- Lutron Adaptive Power ModuleDocument9 pagesLutron Adaptive Power ModuleDinanath SharmaNo ratings yet

- DWB - UL489 ListedDocument15 pagesDWB - UL489 ListedHélio SousaNo ratings yet

- Window StickerDocument1 pageWindow StickerKevinNo ratings yet

- Thread-O-Ring Fittings: For Sizes: 2-And 3-InchDocument3 pagesThread-O-Ring Fittings: For Sizes: 2-And 3-InchrodrigoperezsimoneNo ratings yet

- Magnum X5, X7, ProX7 & ProX9 Airless Paint Sprayer Instruction ManualDocument34 pagesMagnum X5, X7, ProX7 & ProX9 Airless Paint Sprayer Instruction Manualwhitewolf777100% (1)

- Tpi 28 - Pkir - Pkis - en - 201411Document24 pagesTpi 28 - Pkir - Pkis - en - 201411KundzoNo ratings yet

- Formujet Photo InksDocument2 pagesFormujet Photo InksAmey MandhareNo ratings yet

- Chapter 11 - Industry and ManufacturingDocument36 pagesChapter 11 - Industry and ManufacturingNolan NelsonNo ratings yet

- Exibitor List - As of 28nov08Document6 pagesExibitor List - As of 28nov08Soldier MayNo ratings yet

- Reported by ACI/TMS Committee 216Document26 pagesReported by ACI/TMS Committee 216DIDIER ANGEL LOPEZ RINCONNo ratings yet

- Research ReviewDocument8 pagesResearch ReviewJOSEPH OLUWABUKOLANo ratings yet

- Jaw Crusher: Group A3Document20 pagesJaw Crusher: Group A3fyza8790No ratings yet

- Synthesis and Analysis of A Coordination CompoundDocument3 pagesSynthesis and Analysis of A Coordination CompoundDozdi67% (6)

- Steel - WikipediaDocument15 pagesSteel - WikipediaARIF AHAMEDNo ratings yet

- FilmTec ManualDocument205 pagesFilmTec ManualSarmad HameedNo ratings yet

- M606 CAD Module 3Document6 pagesM606 CAD Module 3jobingpNo ratings yet

- Pipe WeldingDocument13 pagesPipe WeldingFord Katim100% (4)

- Pipe Valves and Fittings - 15000Document11 pagesPipe Valves and Fittings - 15000willianNo ratings yet

- Engineering Standard Specification For Steam TracingDocument53 pagesEngineering Standard Specification For Steam Tracingkaruna346100% (1)

- Using Waste Plastic Bottles As AdditiveDocument6 pagesUsing Waste Plastic Bottles As AdditiveGyanna LlenaresasNo ratings yet

- Bo Ride Nozzle CatalogDocument46 pagesBo Ride Nozzle CatalogsossieNo ratings yet

- ΝΟ-Inspection and Maintenance of Wooden Poles StructuresDocument5 pagesΝΟ-Inspection and Maintenance of Wooden Poles Structureshalel111No ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- Successful PlasteringDocument13 pagesSuccessful PlasteringCoulis UtaumireNo ratings yet

- Product Industry Consumer Analysis - Steel: Suman Sourabh, Sudipto Sen Gupta, Goutham KrishnamurthyDocument28 pagesProduct Industry Consumer Analysis - Steel: Suman Sourabh, Sudipto Sen Gupta, Goutham KrishnamurthyGouthamKrishnamurthy100% (1)

- Comitrol Processor Model 1700: Controlled Particle Size ReductionDocument2 pagesComitrol Processor Model 1700: Controlled Particle Size ReductionNguyễn Lê Anh KhoaNo ratings yet

- DSFDocument3 pagesDSFJose Maria SantosNo ratings yet

- Fragmentation and Its Impact On Downstream ProcessingDocument4 pagesFragmentation and Its Impact On Downstream Processingalvaroaac4No ratings yet

- Oil Well CementingDocument20 pagesOil Well CementingDozie Kesieme100% (7)

- Dream Residences - Water Supply & Fire Protection BOMDocument1 pageDream Residences - Water Supply & Fire Protection BOMPatrick LlenaresNo ratings yet

- GOST R 52029-2003 Water. Unit of HardnessDocument4 pagesGOST R 52029-2003 Water. Unit of HardnessOMER EKERNo ratings yet

- Candy CB 82 TDocument33 pagesCandy CB 82 TIsabel Belmonte CiborroNo ratings yet

- Impact of Plastic Formwork Over Conventional FormworkDocument6 pagesImpact of Plastic Formwork Over Conventional FormworkAchmad Zaki Zulkarnain100% (1)