Professional Documents

Culture Documents

Manual Valves

Uploaded by

mahdi gazeriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Valves

Uploaded by

mahdi gazeriCopyright:

Available Formats

Catalog HY15-3502/US

Contents Manual Valves

CV

SERIES CAVITY DESCRIPTION FLOW PRESSURE PAGE NO.

LPM/GPM BAR/PSI

Valves

Check

DL081 ............... C08-2 .......... 2 Position, 2 Way, N.C. Poppet,

.............................................. Pull to Open ....................................................... 30/8 ...... 210/3000 ..................... MV1

SH

DL101 ............... C10-2 .......... 2 Position, 2 Way, N.C. Poppet,

.............................................. Pull to Open ..................................................... 49/13 ...... 210/3000 ..................... MV2

Shuttle

Valves

LM

Load/Motor

GM0212 ........... C08-2 .......... 2 Position, 2 Way, N.O. Poppet,

Controls

.............................................. Push to Close .................................................. 45/12 ...... 350/5000 ..................... MV3

FC

GM0233 ........... C08-3 .......... 2 Position, 3 Way, Spool Type,

Controls

.............................................. Pull to Shift ........................................................ 19/5 ...... 350/5000 ..................... MV4

Flow

PC

Pressure

Controls

DM103 ............. C10-3 .......... 3 Way, Rotary Spool .......................................... 22/6 ...... 240/3500 ............ MV5-MV6

90 DM104 ............. C10-4 .......... 4 Way, Rotary Spool ............................................ 7/2 ...... 240/3500 ............ MV7-MV8

LE

Elements

90

Logic

GM0240XS ....... C08-4 .......... 2 Position, 4 Way, Push to Shift ........................ 15/4 ...... 350/5000 ..................... MV9 DC

Directional

GM0240CS ....... C08-4 .......... 2 Position, 4 Way, Push to Shift ........................ 15/4 ...... 350/5000 ................... MV10

Controls

MV

Manual

Valves

DMH085C1 ....... C08-4 .......... 3 Position, 4 Way, Closed Center,

.............................................. Pull to Shift and Push to Shift ........................... 17/5 ...... 350/5000 ........ MV11-MV12

DMH085C4 ....... C08-4 .......... 3 Position, 4 Way, Float Center, SV

.............................................. Pull to Shift and Push to Shift ........................... 17/5 ...... 350/5000 ........ MV11-MV12

Solenoid

DMH085C9 ....... C08-4 .......... 3 Position, 4 Way, Tandem Center,

Valves

.............................................. Pull to Shift and Push to Shift ........................... 15/4 ...... 350/5000 ........ MV11-MV12

DMH085C2 ....... C08-4 .......... 3 Position, 4 Way, Open Center,

.............................................. Pull to Shift and Push to Shift ........................... 15/4 ...... 350/5000 ........ MV11-MV12 PV

Proportional

DMH085** Series will be available January 1, 2011.

Valves

CE

Electronics

Coils &

BC

Bodies &

Cavities

TD

Technical

Data

Parker Hannifin Corporation

Hydraulic Cartridge Systems

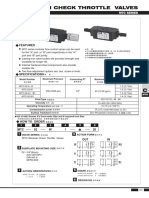

Catalog HY15-3502/US 2-Way Manual Poppet Valve

Technical Information Series DL081

CV

General Description

2-Way Manual Poppet Valve. The DL081 Series Valves

Valves

Check

are suited for emergency lowering applications and on-

off flow applications.

SH

Operation

Shuttle

Valves

The DL081 Series Valves are mechanically operated

check valves. Hydraulic force on the poppet is bal-

LM anced by having equal area between the poppet seat

Load/Motor

and the valve stem, allowing the poppet to be manually

Controls

pulled off the seat. When released, the bias spring will

return the valve poppet to its closed position. Back

pressure of more than 5.5 Bar (80 PSI) will prevent the Out (1)

FC (2)

bias spring from closing the poppet and must be In

avoided.

Controls

Flow

In (2)

Features (1)

PC Low leakage design Out

Flip lever, pull handle, or detented pin design

Pressure

Controls

All external parts zinc plated

Dimensions Millimeters (Inches)

LE

Performance Curve 27.8 39.3

Flow vs. Pressure Drop (Through cartridge only) DL081K (1.09) (1.55)

Elements

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt) (2)

Logic

100 6.9

12.6 (1) 25.4

(.48) (1.0)

Pressure Drop ( P)

DC 75 5.1

Directional

3/4-16 UNF-2A 7/8" Hex.

Controls

Thread 20 Nm (15 lb. ft.)

50 3.5 Torque

2.4 (.09) Thru For

Roll Pin Attachment Detent Position 25.4

MV 25 1.7 1/4-20 UNC-2A 31.8 (1.0)

Thread 54.6 (1.25)

(2.15)

Slot @ 39.3

Manual

0

Valves

Lock (1.55)

LPM 7.6 15.1 22.7 30.3 32.2 28.2 90 To Pin

0 (1.27) (1.11) Lock Pin

GPM 2 4 6 8

Flow (Q)

SV DL081T DL081L DL081P

Specifications

Solenoid

Valves

Nominal Flow 30 LPM (8 GPM) Ordering Information

Max. Inlet Pressure 210 Bar (3000 PSI)

PV

Leakage at 5 drops/min. (.33 cc/min.) DL081

Proportional

150 SSU (32 cSt) at 210 Bar (3000 PSI)

Valves

08 Size Actuator Seals Body Port

Max. Allowable 5.5 Bar (80 PSI) Manual Poppet Type Material Size

Tankline Pressure Valve

CE Operating Temp. -40C to +93.3C (Nitrile) Code Actuator Type Code Body Material

Electronics

Range (Ambient) (-40F to +200F) K Knob (852525) Omit Steel

Coils &

-31.7C to +121.1C (Fluorocarbon)

T Stem A Aluminum

(-25F to +250F)

L Lever

Cartridge Material Stem, stainless steel. Code Port Size Body Part No.

BC All other parts hardened steel. P Lock Pin

Omit Cartridge Only

Bodies &

Fliltration ISO code 16/13,

Cavities

Code Seals / Kit No. 4P 1/4 NPTF (B08-2-*4P)

SAE Class 4 or better 6P 3/8 NPTF (B08-2-*6P)

Omit Nitrile / (SK08-2N)

Approx. Weight 0.08 kg (0.17 lbs.) 4T SAE-4 (B08-2-*4T)

V Fluorocarbon / 6T SAE-6 (B08-2-*6T)

TD Cavity C08-2 (SK08-2V)

6B 3/8 BSPG (B08-2-*6B)

Technical

Form Tool Rougher None * Add A for aluminum,omit for steel.

Finisher NFT08-2F

Data

MV1 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 2-Way Manual Poppet Valve

Technical Information Series DL101

CV

General Description

2-Way Manual Poppet Valve. The DL101 Series Valves

Valves

Check

are suited for emergency lowering applications and on-

off flow applications.

SH

Operation

Shuttle

Valves

The DL101 Series Valves are mechanically operated

check valves. Hydraulic force on the poppet is bal-

anced by having equal area between the poppet seat LM

Load/Motor

and the valve stem, allowing the poppet to be manually

Controls

pulled off the seat. When released, the bias spring will

return the valve poppet to its closed position. Back

pressure of more than 17.3 Bar (250 PSI) will prevent In (2)

(2) FC

the bias spring from closing the poppet and must be In

avoided.

Controls

Flow

Out (1) (1)

Features Out

Low shut-off leakage PC

Cartridge design

Pressure

Controls

Pull-to-Open design

All external parts zinc plated Dimensions Millimeters (Inches)

Performance Curve LE

Pressure Drop vs. Flow (Through cartridge only)

Elements

1/4 - 20UNC-2A Thread

Logic

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt) .2489/.2408 Major Dia.

100 6.9 31.8 .2164/.2127 Pitch Dia.

(1.35)

DC

Pressure Drop ( P)

7.9

Directional

75 5.2 (.31)

Controls

1" Hex.

22 Nm 35.1

50 3.5 (16 lb. ft.)

Torque

(1.38)

7/8-14 UNC-2A

MV

31.8

25 1.7

(1.25) Thread

(2)

Manual

Valves

0

LPM 7.6 15 23 30 38 45 53 60

0 (1) 2.33 (.622)

GPM 2 4 6 8 10 12 14 16 2.32 (.620) SV

Flow (Q)

Specifications

Solenoid

Valves

Nominal Flow 48.8 LPM (13 GPM) Ordering Information

Max. Inlet Pressure 240 Bar (3500 PSI)

PV

Leakage at 5 drops/min. (.33 cc/min.) DL101

Proportional

150 SSU (32 cSt) at 240 Bar (3500 PSI)

Valves

10 Size Actuator Seals Body Port

Max. Allowable 17.3 Bar (250 PSI) Manual Poppet Type Material Size

Tankline Pressure Valve

Operating Temp. -40C to +93.3C (Nitrile) CE

Code Actuator Type Code Body Material

Electronics

Range (Ambient) (-40F to +200F) K Knob (850020K) Omit Steel

Coils &

-31.7C to +121.1C (Fluorocarbon)

T Stem A Aluminum

(-25F to +250F)

Cartridge Material Stem, stainless steel. Code Seals / Kit No. Code Port Size Body Part No.

All other parts hardened steel. BC

Omit Nitrlie / (SK10-2N) Omit Cartridge Only

Bodies &

Fliltration ISO code 16/13,

Cavities

V Fluorocarbon / 4P 1/4 NPTF (B10-2-*4P)

SAE Class 4 or better (SK10-2V) 6P 3/8 NPTF (B10-2-*6P)

Approx. Weight 0.09 kg (0.21 lbs.) 8P 1/2 NPTF (B10-2-*8P)

6T SAE-6 (B10-2-*6T) TD

Cavity C10-2 * Add A for aluminum,

8T SAE-8 (B10-2-*8T)

omit for steel.

Technical

Form Tool Rougher None Steel body only. T8T SAE-8 (B10-2-T8T)

Finisher NFT10-2F

Data

MV2 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 2-Way Manual Poppet Valve

Technical Information Series GM02 12

CV

General Description

2-Way, 2 Position, Normally Open Manual Poppet

Valves

Check

Valve.

SH Features

Hardened poppet for minimal wear and greater durability

Shuttle

Valves

Poppet type construction for minimal internal leakage

Internal pilot operation provides power leverage

LM Cavity common with solenoid operated valves

Load/Motor

Screw-on detent is optional

Controls

All external parts zinc plated (2)

In

Operation Out (1)

FC

In neutral position, pressure applied to port 2 creates (1)

pilot flow across the pilot seat causing poppet to lift. Out

Controls

Flow passes from port 2 to port 1 until manual opera-

Flow

In (2)

tor is pushed forcing pilot into its seat preventing pilot

PC flow to firmly close the poppet. In neutral position, flow

is restricted from port 1 to port 2.

Pressure

Dimensions

Controls

Millimeters (Inches)

Performance Curve

2.7 - (0.11) Stroke

Pressure Drop vs. Flow (Through cartridge only) (push to operate)

LE

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

Detented Manual

Elements

120 8.3

Override Option

Pressure Drop ( P)

Logic

(screw to operate)

80 5.5 54.7 7/8 Hex. 53.4

DC (2.15) 27 Nm (2.10)

(20 lb. ft.)

Directional

Torque

Controls

40 2.8

28.0 3/4-16 UNF

(1.10) (2) Thread

0

MV LPM 7.6 15.2 22.7 30.2 38.0 45.4

0

GPM 2 4 6 8 10 12 (1)

Flow (Q)

Manual

12.7 Part Number

Valves

(0.50) 900690

Specifications

SV Rated Flow 45 LPM (12 GPM)

Maximum Input 350 Bar (5000 PSI) Ordering Information

Solenoid

Valves

Pressure @ Port 2

Leakage at 0.33 ml/min. (5 drops/min.) GM02 12

PV 150 SSU (32 cSt) @ 210 Bar (3000 PSI)

08 Size Manual Valve Manual Filter Seals Body Port

Proportional

Cartridge Material All parts steel. All operating parts Poppet Type Button Screen Material Size

hardened steel. Normally Open

Valves

Operating Temp. -40C to +93.3C (Nitrile, Buna-N) Code Manual Button Code Body Material

Range/Seals (-40F to +200F)

CE 0 Non-Detented (Std.) Omit Steel

-31.7C to +121.1C (Fluorocarbon)

Electronics

(-25F to +250F) 1 Detented (With use A Aluminum

of part #900690

Coils &

Fluid Mineral-based or synthetic with

Compatibility/ lubricating properties at viscosities Code Port Size Body Part No.

Viscosity of 45 to 2000 SSU (6 to 420 cSt) Code Filter Screen Omit Cartridge Only

BC 0 Not required

Filtration ISO code 16/13, 4P 1/4 NPTF (B08-2-*4P)

1 60 mesh screen 6P 3/8 NPTF (B08-2-*6P)

Bodies &

SAE Class 4 or better

Cavities

4T SAE-4 (B08-2-*4T)

Approx. Weight .13 kg (.31 lbs.) 6T SAE-6 (B08-2-*6T)

Code Seals / Kit No.

Cavity C08-2 6B 3/8 BSPG (B08-2-*6B)

TD N Nitrile, Buna-N /

(See BC Section for more details) (SK30065N-1) * Add A for aluminum, omit for steel.

Technical

V Fluorocarbon /

(SK30065V-1)

Data

MV3 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 3-Way Manual Spool Valve

Technical Information Series GM02 33

CV

General Description

3-Way, 2 Position Manual Spool Valve. Designed to

Valves

Check

operate single acting cylinders, pilot circuits and uni-

directional motors.

SH

Features

Shuttle

Valves

High flow capacity with reduced space requirements

One piece cartridge housing ensures internal

concentricity LM

Load/Motor

Low mechanical operating force required

Controls

Detented option available

All external parts zinc plated

(2)

(3)

Operation FC

Neutral flow is 2 to 1. Pull to shift for flow from 3 to 2. (2)

Controls

Flow

(1) (3)

Performance Curve

Pressure Drop vs. Flow (Through cartridge only) (1) PC

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

Pressure

Controls

200 14.0

Dimensions

Pressure Drop ( P)

150 10.5

Millimeters (Inches)

3 to 2

LE

40.0 31.0

Elements

Travel

100 7.0 (1.56) (1.22) 2.03

Logic

2 to 1 (0.08)

50 3.5 (2) (3)

DC

Directional

Controls

0

(1) 25.0

LPM 3.8 7.6 11.4 15.2 19 (1.00)

0

GPM 1 2 3 4 5

Flow (Q)

MV

3/4-16UNF Detent pin

Specifications Thread

7/8 Hex.

optional

Manual

Valves

30 Nm (22 lb. ft.)

Rated Flow 19 LPM (5 GPM) Torque

Operating Side Ports - 350 Bar (5000 PSI) SV

Pressure Bottom Port - 35 Bar (500 PSI)

Ordering Information

Solenoid

Max. Operating 5 kg (11 lbs.)

Valves

Pushing or Pulling

Force Required GM02 33

Cartridge Material All parts steel. All operating parts 08 Size Manual Valve Detent Seals

PV

Body Port

Proportional

hardened steel. Spool Type Option Material Size

Valves

Operating Temp. -40C to +93.3C (Nitrile, Buna-N)

Range/Seals (-40F to +200F) Code Detent Option Code Body Material

-31.7C to +121.1C (Fluorocarbon)

Omit Non-Detented (Std.) Omit Steel CE

(-25F to +250F)

Electronics

1 Detented A Aluminum

Fluid Mineral-based or synthetic with

Coils &

Compatibility/ lubricating properties at viscosities

Viscosity of 45 to 2000 SSU (6 to 420 cSt) Code Seals / Kit No. Code Port Size Body Part No.

N Nitrile, Buna-N / Omit Cartridge Only

Filtration ISO code 16/13, BC

(SK30077N-1) 4P 1/4 NPTF (B08-3-*4P)

SAE Class 4 or better

V Fluorocarbon /

Bodies &

4T SAE-4 (B08-3-*4T)

Cavities

Approx. Weight .10 kg (.20 lbs.) (SK30077V-1) 6T SAE-6 (B08-3-*6T)

Cavity C08-3 6B 3/8 BSPG (B08-3-*6B)

(See BC Section for more details) * Add A for aluminum, omit for steel. TD

Technical

Data

MV4 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 3-Way Rotary Spool Valve

Technical Information Series DM103

CV

General Description

Knob

Valves

3-Way Rotary Spool Valve. The DM103 Series Valves

Check

are suited for any 3-way application (such as a selec-

SH tor function) where manual operation is desired.

For additional information see Technical Tips

pages MV1-MV2.

Shuttle

Valves

Features

LM

Several lever and knob options available

Load/Motor

Detented versions available

Controls

(3)

Serviceable cartridge design

FC All external parts zinc plated DM103LD

(2)

(1)

Operation

Controls

90

Flow

The K, LD, and FKD options require a full 90 rotation (1)

to shift the spool from one offset position to the other. (3) (2)

PC The LN and FKN options require a full 45 rotation

from center to either offset position. The knob (or lever)

Pressure

Controls

position indicator can be positioned anywhere within

the 360 circle.

LE Performance Curve

Specifications Flow vs. Pressure Drop

Elements

(Through cartridge only)

Logic

Nominal Flow 22.5 LPM (6 GPM)

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

DC 100 6.9

Maximum Inlet 240 Bar (3500 PSI)

Directional

Pressure

Controls

75 5.2

Pressure Drop ( P)

Degrees of K, LD, and FKD Styles: 90 from

Rotation Offset to Offset (2 positions)

MV LN, FKN Style: 45 from center to

either Offset (3 positions) 50 3.5

Manual

Valves

Leakage at 164 cc/min.

150 SSU (32 cSt) at 240 Bar (3500 PSI) 25 1.7

SV

Cartridge Material Stem, stainless steel.

Solenoid

All other parts hardened steel.

Valves

0

LPM 7.6 15 23 30

0

Operating Temp. -40C to +93.3C (Nitrile) GPM 2 4 6 8

PV Range/Seals (-40F to +200F) Flow (Q)

Proportional

-31.7C to +121.1C (Fluorocarbon)

(-25F to +250F)

Valves

Fluid Mineral-based or synthetic with

CE Compatibility/ lubricating properties at viscosities

Viscosity of 45 to 2000 SSU (6 to 420 cSt)

Electronics

Coils &

Fliltration ISO code 16/13,

SAE Class 4 or better

BC

Approx. Weight 0.11 kg (.30 lbs.)

Bodies &

Cavities

Cavity C10-3

(See BC Section for more details)

TD

Form Tool Rougher NFT10-3R

Technical

Finisher NFT10-3F

Data

MV5 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 3-Way Rotary Spool Valve

Technical Information Series DM103

CV

Dimensions Millimeters (Inches)

Valves

Check

Operation (1) Lever 80.5

DM103L* (3.17)

(3) (2)

SH

Shuttle

(1) (1)

Valves

36.4

57.2

(3) (2) (3) (2) (1.43)

(2.25) LM

Load/Motor

34.9

Controls

(1.38)

40.1

Knob (1.58)

DM103K

FC

37.9

Controls

(1.49) 1-1/4" Hex.

Flow

17.5 22 Nm

(0.69) (16 lb. ft.) Finger Knob

Torque DM103FK*

PC

35.5

7/8-14 UNF-2A (1.40)

Pressure

Controls

46.2 (3) Thread

(1.82)

(2)

LE

(1)

Elements

15.8 (0.62) THIRD-ANGLE

Logic

PROJECTION

17.4 (0.68)

DC

Directional

Controls

Ordering Information

DM103 MV

10 Size Acuator Seals Body Port

Manual

Valves

Rotary Spool Type Material Size

Valve

Code / Actuator Type Code Seals / Kit. No. Code Body Material SV

K (1) Omit Nitrlie / (SK10-3N) Omit Steel

Solenoid

Knob

Valves

90 V Fluorocarbon / A Aluminum

(SK10-3V)

(3) (2)

Code Port Size Body Part No.

LD (1) PV

Omit Cartridge Only

Proportional

Lever with 90

2 position 4P 1/4 NPTF (B10-3-*4P)

Valves

detent (3) (2) 6P 3/8 NPTF (B10-3-*6P)

8P 1/2 NPTF (B10-3-*8P)

LN (1) 4T SAE - 4 (B10-3-*4T) CE

Lever with 45 6T SAE - 6 (B10-3-*6T)

Electronics

3 position 45

6B 3/8 BSPG (B10-3-6B)

Coils &

detent (3) (2)

8B 1/2 BSPG (B10-3-*8B)

* Add A for aluminum, omit for steel.

FKD (1)

Steel body only.

Finger Knob 90 BC

with 2 position

detent (3) (2)

Bodies &

Cavities

FKN (1)

Finger Knob 45

with 3 position 45 TD

detent (3) (2)

Technical

Data

MV6 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 4-Way Rotary Spool Valve

Technical Information Series DM104

CV

Knob

General Description

Valves

4-Way Rotary Spool Valve. The DM104 Series Valves

Check

are suited for all 4-way directional control applications

SH where manual operation is desired.

Features

Shuttle

Valves

Several lever and knob options available

LM Detented versions available

Serviceable cartridge design

Load/Motor

(4)

Controls

All external parts zinc plated

Operation DM104LD (3)

FC

The K, LD, and FKD options require a full 90 rotation (4) (2)

to shift the spool from one offset position to the other. (2)

Controls

90

Flow

The LN and FKN options require a full 45 rotation

from center to either offset position. The knob (or lever) (3) (1)

(1)

PC position indicator can be positioned anywhere within

the 360 circle.

Pressure

Controls

LE Specifications Performance Curve

Flow vs. Pressure Drop

Elements

Nominal Flow 7.5 LPM (2 GPM) (Through cartridge only)

Logic

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

Maximum Inlet 240 Bar (3500 PSI) 100 6.9

DC

Pressure

Directional

Controls

Degrees of K, LD, and FKD Styles: 90 from 75 5.2

Pressure Drop ( P)

Rotation Offset to Offset (2 positions)

LN and FKN Styles: 45 from center

MV to either Offset (3 positions)

o2

3t

50 3.5

1

Manual

to

Valves

Leakage at 164 cc/min. 3

150 SSU (32 cSt) at 240 Bar (3500 PSI)

4

to

25 1.7

3

SV

Cartridge Material All parts steel. All operating

parts hardened steel.

Solenoid

Valves

0

LPM 3.8 7.6 12 15

Operating Temp. -40C to +93.3C (Nitrile) 0

Range/Seals (-40F to +200F) GPM 1 2 3 4

PV Flow (Q)

-31.7C to +121.1C (Fluorocarbon)

Proportional

(-25F to +250F)

Valves

Fluid Mineral-based or synthetic with

Compatibility/ lubricating properties at viscosities

CE Viscosity of 45 to 2000 SSU (6 to 420 cSt)

Electronics

Coils &

Fliltration ISO code 16/13,

SAE Class 4 or better

BC Approx. Weight 0.11 kg (.30 lbs.)

Bodies &

Cavities

Cavity C10-4

(See BC Section for more details)

TD

Form Tool Rougher NFT10-4R

Technical

Finisher NFT10-4F

Data

MV7 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 4-Way Rotary Spool Valve

Technical Information Series DM104

CV

Dimensions Millimeters (Inches)

Valves

Check

Operation (4) (2) Lever 80.5

DM104L* (3.17)

SH

(3) (1)

(4) (2) (4) (2)

Shuttle

Valves

36.4

57.2

(3) (1) (3) (1) (1.43)

(2.25)

LM

Load/Motor

34.9

(1.38)

Controls

40.1

(1.58)

Knob

DM104K FC

37.9

1-1/4" Hex. 17.5 (1.49)

Controls

22 Nm (0.69)

Flow

(16 lb. ft.) Finger Knob

Torque DM104FK*

35.5

7/8-14 UNF-2A (1.40) PC

(4)

Thread

62.1

Pressure

Controls

(3) (2.44)

(2)

LE

(1)

Elements

15.8 (0.62)

Logic

17.4 (0.68)

THIRD-ANGLE

PROJECTION

18.9 (0.75)

DC

Directional

Controls

Ordering Information

MV

DM104

Manual

Valves

10 Size Acuator Spool Seals Body Port

Rotary Spool Type Option Material Size

Valve

SV

Code / Actuator Type Code / Spool Option Code Body Material

Solenoid

K (4) (2) 1 (4) (2) Omit Steel

Valves

Knob 90

Closed Center A Aluminum

(3) (1) (3) (1)

Code Port Size Body Part No. PV

Proportional

LD (4) (2) 8 (4) (2)

Omit Cartridge Only

Lever with Tandem Center

Valves

90 6P 3/8 NPTF (B10-4-*6P)

2 position

detent (3) (1) (3) (1) 6T SAE - 6 (B10-4-*6T)

8T SAE - 8 (B10-4-*8T)

LN (4)(2) CE

6B 3/8 BSPG (B10-4-6B)

Electronics

Lever with 45

Code Seals / Kit. No. * Add A for aluminum, omit for steel.

3 position 45

Coils &

Omit Nitrile / (SK10-4N) Steel body only.

detent (3)(1)

V Fluorocarbon /

FKD (4) (2) (SK10-4V)

Finger Knob BC

90

with 2 position

Bodies &

Cavities

detent (3) (1)

FKN (4)(2)

Finger Knob 45

with 3 position 45

TD

detent (3)(1)

Technical

Data

MV8 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 4-Way Manual Spool Valve

Technical Information Series GM02 40XS

CV

General Description

4-Way, 2 Position, Reversing Manual Spool Valve.

Valves

Check

Designed to operate double acting cylinders, pilot

circuits and bi-directional motors.

SH

Features

Shuttle

Valves

High flow capacity with reduced space requirements

One piece cartridge housing ensures internal

concentricity

LM

Load/Motor

Low mechanical operating force required

Controls

Detented option available B(4)

All external parts zinc plated

A(2) (4)B P(3)

FC Operation

Neutral, flow is 3 to 4 and 2 to 1. Push to shift for flow

Controls

3 to 2 and 4 to 1

Flow

P(3) (1)T A(2)

PC

Performance Curve

T(1)

Pressure

Pressure Drop vs. Flow (Through cartridge only)

Controls

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

200 14.0 Dimensions Millimeters (Inches)

LE

Pressure Drop ( P)

150 10.5 53.0 31.0

Elements

(2.10) (1.22)

Logic

100 7.0

(2) (3) (4)

DC

50 3.5

Directional

(1) 25.0

Controls

(1.00)

0

LPM 3.8 7.6 11.4 15.2 19

0

GPM 1 2 3 4 5

MV Flow (Q) 3/4-16UNF Detent pin

Thread 7/8 Hex. optional

30 Nm (22 lb. ft.)

Manual

Valves

Specifications Torque

Rated Flow 15 LPM (4 GPM)

SV

Operating Side Ports - 350 Bar (5000 PSI)

Ordering Information

Solenoid

Pressure Bottom Port - 35 Bar (500 PSI)

Valves

Max. Operating 5 kg (11 lbs.)

Pushing or Pulling GM02 40XS

PV Force Required 08 Size Manual Valve Detent Seals Body Port

Proportional

Cartridge Material All parts steel. All operating parts Spool Type Option Material Size

Reversing

Valves

hardened steel.

Operating Temp. -40C to +93.3C (Nitrile, Buna-N) Code Detent Option Code Body Material

Range/Seals (-40F to +200F) Omit Non-Detented (Std.) Omit Steel

CE

-31.7C to +121.1C (Fluorocarbon)

Electronics

1 Detented A Aluminum

(-25F to +250F)

Coils &

Fluid Mineral-based or synthetic with

Code Seals / Kit No. Code Port Size Body Part No.

Compatibility/ lubricating properties at viscosities

Viscosity of 45 to 2000 SSU (6 to 420 cSt) N Nitrile, Buna-N / Omit Cartridge Only

BC (SK30078N-1) 4T SAE-4 (B08-4-*4T)

Filtration ISO code 16/13,

V Fluorocarbon / 6T SAE-6 (B08-4-*6T)

Bodies &

SAE Class 4 or better

Cavities

(SK30078V-1) 6B 3/8 BSPG (B08-4-*6B)

Approx. Weight .10 kg (.20 lbs.) * Add A for aluminum, omit for steel.

Cavity C08-4

TD

(See BC Section for more details)

Technical

Data

MV9 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 4-Way Manual Spool Valve

Technical Information Series GM02 40CS

CV

General Description

4-Way, 2 Position, Normally Closed Manual Spool

Valves

Check

Valve. Designed to operate double acting cylinders,

pilot circuits and bi-directional motors.

SH

Features

Shuttle

Valves

High flow capacity with reduced space requirements

One piece cartridge housing ensures internal

concentricity LM

Load/Motor

Low mechanical operating force required

Controls

Detented option available B(4)

All external parts zinc plated

A(2) (4)B P(3)

Operation FC

Neutral, all ports blocked. Push to shift for flow 3 to 2

Controls

and 4 to 1.

Flow

P(3) (1)T A(2)

Performance Curve PC

T(1)

Pressure

Pressure Drop vs. Flow (Through cartridge only)

Controls

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

200 14.0 Dimensions Millimeters (Inches)

LE

Pressure Drop ( P)

150 10.5 53.0 31.0

Elements

(2.10) (1.22)

Logic

100 7.0

(2) (3) (4)

DC

50 3.5

Directional

(1) 25.0

Controls

(1.00)

0

LPM 3.8 7.6 11.4 15.2 19

0

GPM 1 2 3 4 5

Flow (Q) 3/4-16UNF Detent pin MV

Thread optional

7/8 Hex.

30 Nm (22 lb. ft.)

Manual

Valves

Specifications Torque

Rated Flow 15 LPM (4 GPM)

SV

Operating Side Ports - 350 Bar (5000 PSI)

Ordering Information

Solenoid

Pressure Bottom Port - 35 Bar (500 PSI)

Valves

Max. Operating 5 kg (11 lbs.)

Pushing or Pulling GM02 40CS

Force Required 08 Size Manual Valve Detent Seals

PV

Body Port

Proportional

Cartridge Material All parts steel. All operating parts Spool Type Option Material Size

Normally Closed

Valves

hardened steel.

Operating Temp. -40C to +93.3C (Nitrile, Buna-N) Code Detent Option Code Body Material

Range/Seals (-40F to +200F) Omit Non-Detented (Std.) Omit Steel CE

-31.7C to +121.1C (Fluorocarbon)

Electronics

1 Detented A Aluminum

(-25F to +250F)

Coils &

Fluid Mineral-based or synthetic with

Code Seals / Kit No. Code Port Size Body Part No.

Compatibility/ lubricating properties at viscosities

Viscosity of 45 to 2000 SSU (6 to 420 cSt) N Nitrile, Buna-N / Omit Cartridge Only

(SK30078N-1) BC

4T SAE-4 (B08-4-*4T)

Filtration ISO code 16/13,

V Fluorocarbon / 6T SAE-6 (B08-4-*6T)

Bodies &

SAE Class 4 or better

Cavities

(SK30078V-1) 6B 3/8 BSPG (B08-4-*6B)

Approx. Weight .12 kg (.25 lbs.) * Add A for aluminum, omit for steel.

Cavity C08-4

TD

(See BC Section for more details)

Technical

Data

MV10 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 4-Way Manual Spool Valve

Technical Information Series DMH085

CV

General Description

4-Way, 3 Position, Closed Center Manual Spool Valve.

Valves

Check

Designed to operate double acting cylinders, pilot

circuits and bi-directional motors.

SH

Shuttle

Valves

Features

High flow capacity with reduced space requirements

LM One piece cartridge housing ensures internal

Load/Motor

concentricity

Controls

Low mechanical operating force required

Detented option available

FC All external parts zinc plated A(2) (4)B

Controls

Operation

Flow

P(3) (1)T

Push to shift for flow 3 to 2 and 4 to 1. Pull to shift for DMH085C1

PC flow 3 to 4 and 2 to 1.

DMH085C2/C9

Pressure

Controls

NOTE: DMH085C1/C4

This series will be available January 1, 2011.

LE

Specifications Dimensions

Elements

Millimeters (Inches)

Logic

Rated Flow C1 17 LPM (4.5 GPM) 34.9 34.9

C2 15 LPM (4.0 GPM) (1.38) (1.38)

DC

C4 19 LPM (5.0 GPM)

Directional

C9 15 LPM (4.0 GPM)

Controls

Operating Side Ports - 350 Bar (5000 PSI)

Pressure Bottom Port - 35 Bar (500 PSI)

MV

Max. Operating 5 kg (11 lbs.)

Manual

Valves

Pushing or Pulling

Force Required

SV

Cartridge Material All parts steel. All operating parts

hardened steel. 117.9

Solenoid

(4.65)

Valves

Operating Temp. -45C to +93.3C (D-Ring)

Range/Seals (-50F to +200F)

PV -31.7C to +121.1C (Fluorocarbon)

Proportional

(-25F to +250F)

Valves

53.3 53.3

Fluid Mineral-based or synthetic with (2.10) (2.10)

Compatibility/ lubricating properties at viscosities

CE Viscosity of 45 to 2000 SSU (6 to 420 cSt)

Electronics

Coils &

Filtration ISO code 16/13,

SAE Class 4 or better

DMH085C1/C4 DMH085C2/C9

BC Approx. Weight .12 kg (.25 lbs.)

Note: D-Rings are standard on all spool configurations, but optional

Bodies &

Cavities

Buna/Fluorocarbon configurations as shown on the C2/C9 drawing

Cavity C08-4 are also available.

(See BC Section for more details)

TD

Technical

Data

MV11 Parker Hannifin Corporation

Hydraulic Cartridge Systems

Catalog HY15-3502/US 4-Way Manual Spool Valve

Technical Information Series DMH085

CV

Performance Curves

Pressure Drop vs. Flow (Through cartridge only)

Valves

Check

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt) PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

200 14.0 200 14.0 SH

B to T

DMH085C1 DMH085C2

Shuttle

Valves

Pressure Drop ( P)

Pressure Drop ( P)

150 10.5 150 10.5

A to T

LM

100 7.0 100 7.0

Load/Motor

P to B

Controls

P to A

50 3.5 50 3.5

FC

0 0

LPM 3.8 7.6 11.4 15.2 19 LPM 3.8 7.6 11.4 15.2 19

Controls

0 0

Flow

GPM 1 2 3 4 5 GPM 1 2 3 4 5

Flow (Q) Flow (Q)

PC

PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt) PSI Bar Hydraulic Oil 150 SSU @ 100F (32 cSt)

Pressure

Controls

200 14.0 200 14.0

DMH085C4 DMH085C9

Pressure Drop ( P)

150 10.5

Pressure Drop ( P) 150 10.5

LE

P to B P to A, P to B,

Elements

A to T, B to T

P to A

100 7.0 100 7.0

Logic

50 3.5 50 3.5 DC

Directional

A to T P to T

Controls

B to T

0 0

LPM 3.8 7.6 11.4 15.2 19 LPM 3.8 7.6 11.4 15.2 19

0 0

GPM 1 2 3 4 5 GPM 1 2 3 4 5

Flow (Q) Flow (Q) MV

Manual

Valves

Ordering Information

NOTE:

DMH085 This series will be available SV

January 1, 2011.

Solenoid

08 Size, 4-Way Style Detent Seals Body Port

Valves

Spool Type Option Material Size

Manual Valve

Code Style Code Detent Option Code Body Material PV

Proportional

A(2) (4)B Omit Non-Detented (Std.) Omit Steel

Valves

C1 D Detented A Aluminum

P(3) (1)T

Code Seals / Kit No. Code Port Size Body Part No. CE

A(2) (4)B Omit D-Ring / (SK08-2) Omit Cartridge Only

Electronics

C2 N Nitrile / (SK08-2N) 4T SAE-4 (B08-4-*4T)

Coils &

V Fluorocarbon / 6T SAE-6 (B08-4-*6T)

P(3) (1)T

(SK08-2V) 6B 3/8 BSPG (B08-4-*6B)

A(2) (4)B * Add A for aluminum, omit for steel. BC

C4

Bodies &

Cavities

P(3) (1)T

A(2) (4)B

TD

C9

Technical

P(3) (1)T

Data

MV12 Parker Hannifin Corporation

Hydraulic Cartridge Systems

You might also like

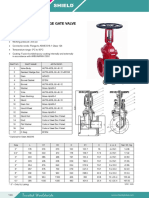

- Sans 1586-2021Document18 pagesSans 1586-2021mahdi gazeriNo ratings yet

- c124 127 MTC 02w (Throttle&Check Valve)Document4 pagesc124 127 MTC 02w (Throttle&Check Valve)mahdi gazeriNo ratings yet

- CircuitsDocument136 pagesCircuitsmariomatoNo ratings yet

- Gear PumpsDocument6 pagesGear Pumpsmahdi gazeriNo ratings yet

- DC SectionDocument21 pagesDC Sectionmahdi gazeriNo ratings yet

- Inlet and Outlet On Same Side Up To 100 L/min, Up To 280 BarDocument2 pagesInlet and Outlet On Same Side Up To 100 L/min, Up To 280 Barmahdi gazeriNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- QAPDocument31 pagesQAPlohitha100% (1)

- Hamid Sobirin: Hydrostatic Test, Etc., RFQ, Data Sheet of Piping, Standards and Codes I.E. ASTM, ANSI/ASMEDocument9 pagesHamid Sobirin: Hydrostatic Test, Etc., RFQ, Data Sheet of Piping, Standards and Codes I.E. ASTM, ANSI/ASMEm khaeronNo ratings yet

- Instruction Manual Fisher Vee Ball v150 v200 v300 Rotary Control Valves Nps 1 Through 12 en 135080Document56 pagesInstruction Manual Fisher Vee Ball v150 v200 v300 Rotary Control Valves Nps 1 Through 12 en 135080SebastianNo ratings yet

- Danfoss - Full Bore Ball ValvesDocument12 pagesDanfoss - Full Bore Ball ValvesmatjidiNo ratings yet

- Effect of Inlet Distortions, Co-Swirl and Counter-Swirl On Single Axial Fan and Contra-Rotating Axial FansDocument9 pagesEffect of Inlet Distortions, Co-Swirl and Counter-Swirl On Single Axial Fan and Contra-Rotating Axial Fansapi-3784429100% (1)

- NEW PRICELIST 2022-BI Fittings New PricelistDocument8 pagesNEW PRICELIST 2022-BI Fittings New PricelistJV BalisiNo ratings yet

- Reduce Exhaust Spread with Fuel Nozzle ServicesDocument5 pagesReduce Exhaust Spread with Fuel Nozzle Serviceschdeepak96100% (6)

- Practical-5 (System Design - Dryers)Document9 pagesPractical-5 (System Design - Dryers)Hassan Iftekhar AhmedNo ratings yet

- RVN Pump Performance CurvesDocument8 pagesRVN Pump Performance Curvesnefrain muchoNo ratings yet

- Catálogo M-DA InglêsDocument20 pagesCatálogo M-DA Inglêsjf2003No ratings yet

- Power Piping: ASME Code For Pressure Piping, 831Document6 pagesPower Piping: ASME Code For Pressure Piping, 831ammarashraf91No ratings yet

- Steam Network - Spirax Sarco - Submittal PDFDocument388 pagesSteam Network - Spirax Sarco - Submittal PDFRamy MahmoudNo ratings yet

- RR-02-PT-100-IN-DT-0063 Data Sheet For Orifice Plate Restriction OrificeDocument16 pagesRR-02-PT-100-IN-DT-0063 Data Sheet For Orifice Plate Restriction Orificemohsen ranjbar100% (1)

- HYDRAULIC PIPING ANGLE CYLINDE - pdf3Document1 pageHYDRAULIC PIPING ANGLE CYLINDE - pdf3eshopmanual limaNo ratings yet

- Morgan Stanley OilDocument19 pagesMorgan Stanley Oilephraim_tammyNo ratings yet

- OS & Y Gate Valve-OSY200FF-D PDFDocument1 pageOS & Y Gate Valve-OSY200FF-D PDFShoaib AhmedNo ratings yet

- PEP Session On Steam TurbinesDocument35 pagesPEP Session On Steam Turbinesdanish moinNo ratings yet

- Comparison of Qblade and CFD Results For Small-Scaled Horizontal Axis Wind Turbine AnalysisDocument6 pagesComparison of Qblade and CFD Results For Small-Scaled Horizontal Axis Wind Turbine AnalysisLuis SilvaNo ratings yet

- Fire Drencher System - Base-Engineer PDFDocument2 pagesFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- 88K Condensate Storage Tank 146.75 OD X 100ftDocument11,238 pages88K Condensate Storage Tank 146.75 OD X 100ftMichael HaiseNo ratings yet

- Structure and FunctionDocument88 pagesStructure and FunctionEko Sunaryo100% (2)

- Control Manifold (Brake, Hydraulic Fan 966Document15 pagesControl Manifold (Brake, Hydraulic Fan 966Ahmed RezkNo ratings yet

- Sky / Startup Vents: Modulating Control ValvesDocument8 pagesSky / Startup Vents: Modulating Control ValvesGaneshNo ratings yet

- Type NVN: Ball Valve With FEP/PFA LiningDocument2 pagesType NVN: Ball Valve With FEP/PFA LiningandrebitaNo ratings yet

- Pricelist Pats PompaDocument1 pagePricelist Pats PompaNugrohoAriePutrantoNo ratings yet

- Hydreco V3A4013 Brochure 2014Document8 pagesHydreco V3A4013 Brochure 2014Montes JorgeNo ratings yet

- Fuel Oil SystemDocument26 pagesFuel Oil SystemMuhammad luqmanNo ratings yet

- SA 831 - Separation System - Parts - 2006Document39 pagesSA 831 - Separation System - Parts - 2006Centrifugal SeparatorNo ratings yet

- Shutdown ValvesDocument2 pagesShutdown Valvesnazury2kNo ratings yet

- HKL Ope Manual EngDocument25 pagesHKL Ope Manual Engmjl47No ratings yet