Professional Documents

Culture Documents

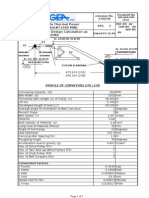

Travelling Tripper Calculation

Uploaded by

HarshGupta100%(1)100% found this document useful (1 vote)

1K views5 pagesTravelling Tripper Calculation

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTravelling Tripper Calculation

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views5 pagesTravelling Tripper Calculation

Uploaded by

HarshGuptaTravelling Tripper Calculation

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 5

Sl No DESCRIPTION SYMBOLVALUE UNIT REMARK

1 Belt width B 1600 mm

2 Tripper length L 18.7 m

3 Vertical lift of material on trip H 5m

4 Design capacity Cd 1680 tph

5 Belt speed Vb 2.8 m/s

6 Tripper speed V 9.42 m/min Minimum 10% of belt speed if not specified

7 Weight of material mg 166.67 kg/m

8 Weight of belt mb 24.35 kg/m

9 Belt tension at tripper Th1 3315 kg

10 Belt inclination at discharge pu1 14 degrees

11 Belt inclination at bend pulley 2 2.2 degrees

12 Bend pulley resistance Rb 882.9 N Consider a resistance of 200lbs.

13 Belt sealing roller resistance Rbs 441.45 N Rbs=Rb/2

14 Number of bend and dischargeNt 2

15 Number of belt sealing rollers Nbs 4

16 Wheel axle diameter at bearinDb 0.14 m

17 Estimated total weight of trippW 22000 kg

18 Wheel diameter Dw 0.3 m

19 Length of skirt board on the tr Lb 6m

20 Skirt board friction factor Cs 0.0754

21 Depth of material touching ski hs 6.3 inch Consider 10% of the belt width

22 Coeficient of friction for beari m 0.015

23 Coefficient of rolling friction k 0.0005

Factor for friction between rail and wheel

24 flange f 2.5

25 Coefficient of adhesion fa 0.15 NTPC stipulation

26 Acceleration value of tripper a 0.0314 m/s Considering an acceleration time of 5 secs

POWER CALCULATION

27 Tripper resistance Te1 568.33 kgf Te1= (f x W) x (2 x k + m x Db))/Dw

28 Resistance due to bend pulley Te2 180 kgf Te2= Rb x Nt/9.81

29 Resistance due to belt sealing Te3 180 kgf Te3=Nbs x Rbs/9.81

30 Approx pull due to CRD Te4 0 kgf Cable festoon envisaged

31 Force required to lift the materTe5 955.1 kgf Te5= (Wb+Wm) x H

32 Resistance due to belt tension Te6 96.03 kgf Te6=Th1 x (cos2- cos 1)

33 Resistance due to tripper accelTe7 70.42 kgf Te7= W x a/9.81

34 Skirt board resistance Te8 80.44 kgf Te8= Lb x ( Cs x hs + 6 )/2.2

35 Total tripper resistance F 2130.3 kgf F=Te1+Te2+Te3+Te4+Te5+Te6+Te7+Te8

36 Motor power required Pr 4.1013 kW Pr=F x V/60000/.8

37 Taking 20% margin, power req Pm 4.9216 kW

38 Motor Power selected P 2 x 3.7 kW Hence Ok

Sl No DESCRIPTION SYMBOLVALUE UNIT REMARK

1 Belt width B 1400 mm

2 Tripper length L 18.07 m

3 Vertical lift of material on trip H 5.308 m

4 Design capacity Cd 1500 tph

5 Belt speed Vb 2.65 m/s

6 Tripper speed V 15 m/min Minimum 10% of belt speed if not specified

7 Weight of material mg 157.23 kg/m

8 Weight of belt mb 24.35 kg/m

9 Belt tension at tripper Th1 6600 kg

10 Belt inclination at discharge pu1 9.626 degrees

11 Belt inclination at bend pulley 2 0 degrees

12 Bend pulley resistance Rb 882.9 N Consider a resistance of 200lbs.

13 Belt sealing roller resistance Rbs 441.45 N Rbs=Rb/2

14 Number of bend and dischargeNt 2

15 Number of belt sealing rollers Nbs 4

16 Wheel axle diameter at bearinDb 0.14 m

17 Estimated total weight of trippW 25000 kg

18 Wheel diameter Dw 0.75 m

19 Length of skirt board on the tr Lb 6m

20 Skirt board friction factor Cs 0.0754

21 Depth of material touching ski hs 5.51 inch Consider 10% of the belt width

22 Coeficient of friction for beari m 0.015

23 Coefficient of rolling friction k 0.0005 Referring to NITC publication

Factor for friction between rail and wheel

24 flange f 2.5

25 Coefficient of adhesion fa 0.15

26 Acceleration value of tripper a 0.05 m/s Considering an acceleration time of 5 secs

POWER CALCULATION

27 Tripper resistance Te1 258.33 kgf Te1= (f x W) x (2 x k + m x Db))/Dw

28 Resistance due to bend pulley Te2 180 kgf Te2= Rb x Nt/9.81

29 Resistance due to belt sealing Te3 180 kgf Te3=Nbs x Rbs/9.81

30 Approx pull due to CRD Te4 100 kgf Cable festoon envisaged

31 Force required to lift the materTe5 963.83 kgf Te5= (Wb+Wm) x H

32 Resistance due to belt tension Te6 92.93 kgf Te6=Th1 x (cos2- cos 1)

33 Resistance due to tripper accelTe7 127.42 kgf Te7= W x a/9.81

34 Skirt board resistance Te8 74.15 kgf Te8= Lb x ( Cs x hs + 6 )/2.2

35 Total tripper resistance F 1976.7 kgf F=Te1+Te2+Te3+Te4+Te5+Te6+Te7+Te8

36 Motor power required Pr 6.0597 kW Pr=F x V/60000/.8

37 Taking 20% margin, power req Pm 7.2716 kW

38 Motor Power selected P 2 X 5.5Kw OK

Sl No DESCRIPTION SYMBOLVALUE UNIT REMARK

1 Belt width B 1200 mm

2 Tripper length L 8m

3 Vertical lift of material on trip H 3.05 m

4 Design capacity Cd 960 tph

5 Belt speed Vb 2.5 m/s

6 Tripper speed V 15 m/min Minimum 10% of belt speed if not specified

7 Weight of material mg 106.67 kg/m

8 Weight of belt mb 24.35 kg/m

9 Belt tension at tripper Th1 6600 kg

10 Belt inclination at discharge pu1 12 degrees

11 Belt inclination at bend pulley 2 2.2 degrees

12 Bend pulley resistance Rb 882.9 N Consider a resistance of 200lbs.

13 Belt sealing roller resistance Rbs 441.45 N Rbs=Rb/2

14 Number of bend and dischargeNt 2

15 Number of belt sealing rollers Nbs 4

16 Wheel axle diameter at bearinDb 0.1 m

17 Estimated total weight of trippW 25000 kg

18 Wheel diameter Dw 0.5 m

19 Length of skirt board on the tr Lb 6m

20 Skirt board friction factor Cs 0.0754

21 Depth of material touching ski hs 4.72 inch Consider 10% of the belt width

22 Coeficient of friction for beari m 0.015 NTPC stipulation

23 Coefficient of rolling friction k 0.0005 Referring to NITC publication

Factor for friction between rail and wheel

24 flange f 2.5

25 Coefficient of adhesion fa 0.15

26 Acceleration value of tripper a 0.05 m/s Considering an acceleration time of 5 secs

POWER CALCULATION

27 Tripper resistance Te1 312.5 kgf Te1= (f x W) x (2 x k + m x Db))/Dw

28 Resistance due to bend pulley Te2 180 kgf Te2= Rb x Nt/9.81

29 Resistance due to belt sealing Te3 180 kgf Te3=Nbs x Rbs/9.81

30 Approx pull due to CRD Te4 100 kgf Cable festoon envisaged

31 Force required to lift the materTe5 399.61 kgf Te5= (Wb+Wm) x H

32 Resistance due to belt tension Te6 139.36 kgf Te6=Th1 x (cos2- cos 1)

33 Resistance due to tripper accelTe7 127.42 kgf Te7= W x a/9.81

34 Skirt board resistance Te8 68.7 kgf Te8= Lb x ( Cs x hs + 6 )/2.2

35 Total tripper resistance F 1507.6 kgf F=Te1+Te2+Te3+Te4+Te5+Te6+Te7+Te8

36 Motor power required Pr 4.6217 kW Pr=F x V/60000/.8

37 Taking 20% margin, power req Pm 5.5461 kW

38 Motor Power selected P 2 X 3.7 Kw OK

Sl No DESCRIPTION SYMBOLVALUE UNIT REMARK

1 Belt width B 1400 mm

2 Tripper length L 11.4 m

3 Vertical lift of material on trip H 4.55 m

4 Design capacity Cd 1000 tph

5 Belt speed Vb 2.2 m/s

6 Tripper speed V 12.5 m/min Minimum 10% of belt speed if not specified

7 Weight of material mg 126.26 kg/m

8 Weight of belt mb 24.35 kg/m

9 Belt tension at tripper Th1 5854 kg

10 Belt inclination at discharge pu1 15 degrees

11 Belt inclination at bend pulley 2 2.2 degrees

12 Bend pulley resistance Rb 882.9 N Consider a resistance of 200lbs.

13 Belt sealing roller resistance Rbs 441.45 N Rbs=Rb/2

14 Number of bend and dischargeNt 2

15 Number of belt sealing rollers Nbs 4

16 Wheel axle diameter at bearinDb 0.14 m

17 Estimated total weight of trippW 21200 kg

18 Wheel diameter Dw 0.3 m

19 Length of skirt board on the tr Lb 6m

20 Skirt board friction factor Cs 0.0754

21 Depth of material touching ski hs 5.51 inch Consider 10% of the belt width

22 Coeficient of friction for beari m 0.015 NTPC stipulation

23 Coefficient of rolling friction k 0.0005 Referring to NITC publication

Factor for friction between rail and wheel

24 flange f 2.5

25 Coefficient of adhesion fa 0.15

26 Acceleration value of tripper a 0.0417 m/s Considering an acceleration time of 5 secs

POWER CALCULATION

27 Tripper resistance Te1 547.67 kgf Te1= (f x W) x (2 x k + m x Db))/Dw

28 Resistance due to bend pulley Te2 180 kgf Te2= Rb x Nt/9.81

29 Resistance due to belt sealing Te3 180 kgf Te3=Nbs x Rbs/9.81

30 Approx pull due to CRD Te4 0 kgf Cable festoon envisaged

31 Force required to lift the materTe5 685.28 kgf Te5= (Wb+Wm) x H

32 Resistance due to belt tension Te6 195.16 kgf Te6=Th1 x (cos2- cos 1)

33 Resistance due to tripper accelTe7 90.04 kgf Te7= W x a/9.81

34 Skirt board resistance Te8 74.15 kgf Te8= Lb x ( Cs x hs + 6 )/2.2

35 Total tripper resistance F 1952.3 kgf F=Te1+Te2+Te3+Te4+Te5+Te6+Te7+Te8

36 Motor power required Pr 4.9875 kW Pr=F x V/60000/.8

37 Taking 20% margin, power req Pm 5.985 kW

38 Motor Power selected P 2 x 5.5 kW Hence Ok

Sl No DESCRIPTION SYMBOLVALUE UNIT REMARK

1 Belt width B 1000 mm

2 Tripper length L 12.9 m

3 Vertical lift of material on trip H 5.375 m

4 Design capacity Cd 500 tph

5 Belt speed Vb 2 m/s

6 Tripper speed V 10 m/min Minimum 10% of belt speed if not specified

7 Weight of material mg 69.44 kg/m

8 Weight of belt mb 24.35 kg/m

9 Belt tension at tripper Th1 3000 kg

10 Belt inclination at discharge pu1 15 degrees

11 Belt inclination at bend pulley 2 2.2 degrees

12 Bend pulley resistance Rb 882.9 N Consider a resistance of 200lbs.

13 Belt sealing roller resistance Rbs 441.45 N Rbs=Rb/2

14 Number of bend and dischargeNt 2

15 Number of belt sealing rollers Nbs 4

16 Wheel axle diameter at bearinDb 0.115 m

17 Estimated total weight of trippW 16000 kg

18 Wheel diameter Dw 0.3 m

19 Length of skirt board on the tr Lb 6m

20 Skirt board friction factor Cs 0.0754

21 Depth of material touching ski hs 3.94 inch Consider 10% of the belt width

22 Coeficient of friction for beari m 0.015 NTPC stipulation

23 Coefficient of rolling friction k 0.0005 Referring to NITC publication

Factor for friction between rail and wheel

24 flange f 2.5

25 Coefficient of adhesion fa 0.15

26 Acceleration value of tripper a 0.0333 m/s Considering an acceleration time of 5 secs

POWER CALCULATION

27 Tripper resistance Te1 363.33 kgf Te1= (f x W) x (2 x k + m x Db))/Dw

28 Resistance due to bend pulley Te2 180 kgf Te2= Rb x Nt/9.81

29 Resistance due to belt sealing Te3 180 kgf Te3=Nbs x Rbs/9.81

30 Approx pull due to CRD Te4 100 kgf Cable festoon envisaged

31 Force required to lift the materTe5 504.12 kgf Te5= (Wb+Wm) x H

32 Resistance due to belt tension Te6 100.01 kgf Te6=Th1 x (cos2- cos 1)

33 Resistance due to tripper accelTe7 54.37 kgf Te7= W x a/9.81

34 Skirt board resistance Te8 64.14 kgf Te8= Lb x ( Cs x hs + 6 )/2.2

35 Total tripper resistance F 1546 kgf F=Te1+Te2+Te3+Te4+Te5+Te6+Te7+Te8

36 Motor power required Pr 3.1596 kW Pr=F x V/60000/.8

37 Taking 20% margin, power req Pm 3.7915 kW

38 Motor Power selected P 1.5 + .75 kW Not OK

You might also like

- CONVEYOR CALCULATION SHEET DraftDocument37 pagesCONVEYOR CALCULATION SHEET Drafttvpham12350% (6)

- Conveyor Structure DesignDocument44 pagesConveyor Structure DesignAizaz Shaikh83% (6)

- Conveyor Belt Gallery PDFDocument44 pagesConveyor Belt Gallery PDFAngelin sheeba50% (2)

- Apron Feeder Power Calculations PDFDocument4 pagesApron Feeder Power Calculations PDFtuba25% (4)

- Conveyor Pulley DesignDocument2 pagesConveyor Pulley DesignZoebair100% (1)

- Wagon Tippler DesignDocument34 pagesWagon Tippler DesignAnku Pandey71% (7)

- Wagon TipplerDocument429 pagesWagon Tipplerparuchurivenkat52720% (1)

- BELT CONVEYOR - Discharge TrajectoryDocument3 pagesBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteNo ratings yet

- Design Storage Bins Bunkers SilosDocument15 pagesDesign Storage Bins Bunkers Siloskrishna kumar70% (10)

- Travelling Tripper CalculationDocument5 pagesTravelling Tripper CalculationHarshGuptaNo ratings yet

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADocument7 pagesProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMASara Lopez100% (8)

- Belt Feeder Calculation CEMADocument7 pagesBelt Feeder Calculation CEMANAITIK100% (4)

- Belt Feeder Calc. Pns Line 1Document4 pagesBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- Design of Silos 2010Document21 pagesDesign of Silos 2010Topaca Paec100% (3)

- Conveyor Belt Loading AnalysisDocument4 pagesConveyor Belt Loading Analysisfcbeltrano3699No ratings yet

- CHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORDocument2 pagesCHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORdeddy ariyanto100% (1)

- TYPICAL MANUAL CALCULATIONDocument32 pagesTYPICAL MANUAL CALCULATIONSergio Diaz100% (1)

- Chute Calculation ExampleDocument1 pageChute Calculation ExampleRené Mella CidNo ratings yet

- Sidewinder ManualDocument245 pagesSidewinder ManualkukstrongNo ratings yet

- Chapter 13 D1 CEMA Bucket Elevator HP and CalculationsDocument4 pagesChapter 13 D1 CEMA Bucket Elevator HP and Calculationshafidh naufaldiNo ratings yet

- Chute Calculation ExampleDocument1 pageChute Calculation ExampleBimal DeyNo ratings yet

- Design, Fabrication and Testing of A Low Headroom Conveyor Transfer ChuteDocument132 pagesDesign, Fabrication and Testing of A Low Headroom Conveyor Transfer ChuteJakesNo ratings yet

- Conveyor design parameters for slag ash materialDocument33 pagesConveyor design parameters for slag ash materialMustafa AkbarNo ratings yet

- Conveyor Design DraftDocument25 pagesConveyor Design DraftDxFxNo ratings yet

- Design Aspects of A Motorised Travelling TripperDocument5 pagesDesign Aspects of A Motorised Travelling Trippercar5lyle100% (1)

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdeNo ratings yet

- JSW Toranagallu 24m Gallery DesignDocument5 pagesJSW Toranagallu 24m Gallery DesignvivekNo ratings yet

- Bulk Material Handling Belt-Conveyor-CatalogDocument21 pagesBulk Material Handling Belt-Conveyor-CatalogjayNo ratings yet

- Design Calculation For Fly Ash Storage Silo Stage-II - Rev.2 - Z1660 TalcherDocument135 pagesDesign Calculation For Fly Ash Storage Silo Stage-II - Rev.2 - Z1660 TalcherSwapan Kumar BoseNo ratings yet

- Travelling Trippers PDFDocument4 pagesTravelling Trippers PDFkalai0% (1)

- Belt Conveyor Take Up DesignDocument4 pagesBelt Conveyor Take Up DesignKroya HunNo ratings yet

- Conveyor Belt Scale Data SheetDocument2 pagesConveyor Belt Scale Data SheetEDUARDONo ratings yet

- Manual Helix Delta t6Document309 pagesManual Helix Delta t6Ricardo Garay Reinoso100% (2)

- Silo Capacity CalculationDocument1 pageSilo Capacity Calculationlbc123No ratings yet

- DOWNHILL BELT CONVEYOR SPEED CONTROLDocument9 pagesDOWNHILL BELT CONVEYOR SPEED CONTROLShipra ShaliniNo ratings yet

- BELT FEEDER Preliminary Dimension IngDocument29 pagesBELT FEEDER Preliminary Dimension Ingshani5573100% (1)

- Silo BucklingDocument14 pagesSilo BucklingrahilmlNo ratings yet

- Apron FeederDocument2 pagesApron FeederRaji Suri100% (1)

- IS Code For StackerDocument20 pagesIS Code For StackerManish VermaNo ratings yet

- BELT CONVEYOR - Discharge TrajectoryDocument1 pageBELT CONVEYOR - Discharge TrajectoryEslam FaroukNo ratings yet

- Chute Design Considerations For Feeding and TransferDocument22 pagesChute Design Considerations For Feeding and TransferIsaac Kendall100% (2)

- ChuteDesignFormulas Paper43Document11 pagesChuteDesignFormulas Paper43Martin LarochelleNo ratings yet

- Analisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIDocument10 pagesAnalisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIWaris La Joi WakatobiNo ratings yet

- CEMA8 5pgDocument5 pagesCEMA8 5pgkmats100% (2)

- Pipe ConveyorDocument4 pagesPipe ConveyorDIBYENDU MONDALNo ratings yet

- Hoist DesignDocument16 pagesHoist DesignluisparedesNo ratings yet

- Belt Catalog #2 Bridge StoneDocument55 pagesBelt Catalog #2 Bridge Stonetinyfalse100% (3)

- Conveyor CalculationDocument46 pagesConveyor CalculationBuditama Chandranegara100% (1)

- Conveyor Design CalcDocument6 pagesConveyor Design CalcGregory Nick Toledo VelizNo ratings yet

- Technical Specification - Conveyor SystemDocument38 pagesTechnical Specification - Conveyor SystemTeguh Yuliardi Putra100% (1)

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcspandu_chemengNo ratings yet

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiNo ratings yet

- Bin and Hopper Design GuideDocument73 pagesBin and Hopper Design GuideGanesh Aditya100% (4)

- Calculation p1 07-09-19 1Document208 pagesCalculation p1 07-09-19 1Partha GangopadhyayNo ratings yet

- Carrier Calculation For ReferenceDocument1 pageCarrier Calculation For ReferencedgmNo ratings yet

- Desain Pelat Deck (Sap 2000) : 1. Data - Data PerencanaanDocument4 pagesDesain Pelat Deck (Sap 2000) : 1. Data - Data PerencanaanMuhammad Rizki AnwarNo ratings yet

- DDocument2 pagesDharshNo ratings yet

- Tecnical Calculation Belt ConveyorDocument2 pagesTecnical Calculation Belt ConveyorWacoman RazanNo ratings yet

- Calculation Leading To Equipment Selection and SpecificationDocument12 pagesCalculation Leading To Equipment Selection and SpecificationJohn Louie PimentelNo ratings yet

- This Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodDocument9 pagesThis Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodsopnanairNo ratings yet

- PTD Project Objective & ScopeDocument4 pagesPTD Project Objective & ScopeHarshGuptaNo ratings yet

- BSDK WilpDocument5 pagesBSDK WilpHarshGuptaNo ratings yet

- Is 808-1989 Steel TableDocument24 pagesIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- Master Conveyor Deliverable ListDocument10 pagesMaster Conveyor Deliverable ListHarshGuptaNo ratings yet

- WheelsDocument4 pagesWheelsHarshGuptaNo ratings yet

- Conveyors - 1 Harsh GuptaDocument12 pagesConveyors - 1 Harsh GuptaHarshGuptaNo ratings yet

- House Chakk deDocument4 pagesHouse Chakk deHarshGuptaNo ratings yet

- PTD Project ReferencesDocument21 pagesPTD Project ReferencesHarshGuptaNo ratings yet

- HT Motors Frame SelectionDocument1 pageHT Motors Frame SelectionHarshGuptaNo ratings yet

- Motor Starter Types - Technology of Motor Starter and ApplicationsDocument8 pagesMotor Starter Types - Technology of Motor Starter and ApplicationsHarshGuptaNo ratings yet

- 4 1aDocument226 pages4 1ahydroturbinesNo ratings yet

- CRD - PracticeDocument10 pagesCRD - PracticeHarshGuptaNo ratings yet

- Internal Scraper ComparisonDocument11 pagesInternal Scraper ComparisonHarshGuptaNo ratings yet

- Belt Tension Theory - FactorsDocument5 pagesBelt Tension Theory - FactorsHarshGuptaNo ratings yet

- Counting of VibrofeedersDocument1 pageCounting of VibrofeedersHarshGuptaNo ratings yet

- Bulk Materials Handling - Harsh - GuptaDocument4 pagesBulk Materials Handling - Harsh - GuptaHarshGuptaNo ratings yet

- Conveyor Drives and ControlDocument1 pageConveyor Drives and ControlHarshGuptaNo ratings yet

- Data Sheet For Metal DetectorDocument1 pageData Sheet For Metal DetectorHarshGuptaNo ratings yet

- Conveyor Frame WorkDocument1 pageConveyor Frame WorkHarshGuptaNo ratings yet

- MOTOR SELECTION GUIDE FOR STUDENTSDocument56 pagesMOTOR SELECTION GUIDE FOR STUDENTSAshokNo ratings yet

- Screening TheoryDocument6 pagesScreening TheoryHarshGuptaNo ratings yet

- MRP 103 Curve PDFDocument1 pageMRP 103 Curve PDFHarshGuptaNo ratings yet

- MNDocument4 pagesMNDarmawan PutrantoNo ratings yet

- FanDocument23 pagesFanlp mishraNo ratings yet

- Weekly Report by HARSH - Week - 31Document1 pageWeekly Report by HARSH - Week - 31HarshGuptaNo ratings yet

- Comments - MSEL 25072017 Rod Mill RequirementDocument14 pagesComments - MSEL 25072017 Rod Mill RequirementHarshGuptaNo ratings yet

- Advantages of Metal CastingDocument6 pagesAdvantages of Metal CastingHarshGuptaNo ratings yet

- Epil TSDocument11 pagesEpil TSHarshGuptaNo ratings yet

- Catalogue: Product Offering 51Document56 pagesCatalogue: Product Offering 51Bruno MartinsNo ratings yet

- Plenaristas León 2022xDocument6 pagesPlenaristas León 2022xGloria MontielNo ratings yet

- Understanding Logistics and Supply Chain Management ConceptsDocument12 pagesUnderstanding Logistics and Supply Chain Management Conceptsarfat kabraNo ratings yet

- DrdoDocument2 pagesDrdoAvneet SinghNo ratings yet

- Non-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesDocument2 pagesNon-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesveeramalaiNo ratings yet

- Language II Module 2 Adjectives and AdverbsDocument25 pagesLanguage II Module 2 Adjectives and AdverbsCarla Arredondo MagnereNo ratings yet

- 2VAA001695 en S Control NTCS04 Controller Station Termination UnitDocument43 pages2VAA001695 en S Control NTCS04 Controller Station Termination UnitanbarasanNo ratings yet

- TCBE - Conversation Skills TemplateDocument10 pagesTCBE - Conversation Skills TemplateAryoma GoswamiNo ratings yet

- Guimaras State CollegeDocument5 pagesGuimaras State CollegeBabarianCocBermejoNo ratings yet

- ADL MATRIX STRATEGY FOR BPCL'S GROWTHDocument17 pagesADL MATRIX STRATEGY FOR BPCL'S GROWTHSachin Nagar100% (1)

- 5 Grade - Lesson 1.3 Dissolving and Back Again: ObjectiveDocument4 pages5 Grade - Lesson 1.3 Dissolving and Back Again: ObjectiveManushka ThomasNo ratings yet

- 31 Legacy of Ancient Greece (Contributions)Document10 pages31 Legacy of Ancient Greece (Contributions)LyreNo ratings yet

- READING 4.1 - Language and The Perception of Space, Motion, and TimeDocument10 pagesREADING 4.1 - Language and The Perception of Space, Motion, and TimeBan MaiNo ratings yet

- Kuliah 1 - Konservasi GeologiDocument5 pagesKuliah 1 - Konservasi GeologiFerdianNo ratings yet

- Naaqs 2009Document2 pagesNaaqs 2009sreenNo ratings yet

- Destination Phrasal Verbs @destination - b1 - b2 - c1Document25 pagesDestination Phrasal Verbs @destination - b1 - b2 - c1Samira GulomovaNo ratings yet

- Xiaomi Mi Drone 4K User Manual GuideDocument47 pagesXiaomi Mi Drone 4K User Manual GuideΜιχάλης ΛαχανάςNo ratings yet

- The Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12Document313 pagesThe Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12justice hayfordNo ratings yet

- UN Habitat UPCL Myanmar TranslationDocument254 pagesUN Habitat UPCL Myanmar TranslationzayyarNo ratings yet

- GCSE H3 02g4 02 3D TrigonometryDocument2 pagesGCSE H3 02g4 02 3D TrigonometryAndrei StanescuNo ratings yet

- Feasibility of Traditional Milk DeliveryDocument21 pagesFeasibility of Traditional Milk DeliverySumit TomarNo ratings yet

- Manufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaDocument28 pagesManufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- Okto Engineering Experience ShareDocument66 pagesOkto Engineering Experience Sharecengiz kutukcuNo ratings yet

- Detect Plant Diseases Using Image ProcessingDocument11 pagesDetect Plant Diseases Using Image Processingvinayak100% (1)

- Smell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaDocument35 pagesSmell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaUniversity of Washington PressNo ratings yet

- Sulzer MC EquipmentDocument12 pagesSulzer MC EquipmentsnthmlgtNo ratings yet

- Silicon ManufacturingDocument132 pagesSilicon ManufacturingAndrea SottocornolaNo ratings yet

- Designers' Guide To Eurocode 7 Geothechnical DesignDocument213 pagesDesigners' Guide To Eurocode 7 Geothechnical DesignJoão Gamboias100% (9)

- Senior Design Projects 201-2020 - For Website - MEDocument5 pagesSenior Design Projects 201-2020 - For Website - MEYujbvhujgNo ratings yet

- India An Archaeological History Palaeolithic Beginnings To Early Historic Foundations (Dilip K. Chakrabarti) (Z-Library)Document437 pagesIndia An Archaeological History Palaeolithic Beginnings To Early Historic Foundations (Dilip K. Chakrabarti) (Z-Library)soumadri.2023.1301No ratings yet