Professional Documents

Culture Documents

FM451

Uploaded by

javier perezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FM451

Uploaded by

javier perezCopyright:

Available Formats

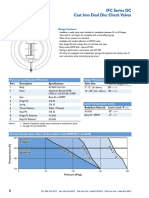

FM451 Applications - wafer check valves with spring loaded flap provide

instantaneous response to changes in velocity pressure for all fluid media

PN16 compatible with the materials of construction. They are suitable for all piping

systems within the P/T limits shown and may be installed in vertical or horizontal

Resilient seated pipelines. When installed in vertical pipelines the flow must be in an upward

direction. Low weight and short face-to-face dimensions mean easy installation

DN50 to DN300 without the need for expensive support.

Specification - one piece flangeless cast iron body suitable for use between

flanges drilled in accordance with BS 4504 PN10 and PN16, ANSI Class 125

and 150, BS10 Tables D and E.

Installation - wafer check valves must be correctly aligned to achieve

efficient valve operation with minimum headloss and to prevent the valve disk

fouling downstream piping. With some flange/valve combinations the pipe

flange bolting fits closely around the valve body, automatically centralising

the valve in the pipeline. However, in a number of cases there is too much

clearance between the flange bolting and the valve body to obtain correct

alignment without careful manual positioning. To overcome this problem Crane

has developed a unique system of colour coded centralising sleeves. A set of

centralising sleeves is supplied with every valve together with easy to follow

instructions. The sleeves have varying outside diameters/bore to suit the different

flange/valve combinations. When fitting to horizontal pipelines the sleeves are

placed over bolts in the lower half of the flanges to cradle the valve during

installation and prior to bolt tightening. In vertical pipelines the sleeves are

fitted to bolts evenly spaced around the valve body to ensure the valve is

positioned centrally in the pipeline.

FM451

P/T ratings

Swing pattern Temperature

Celsius

-10 to

+100 120

Spring loaded Pressure

bar 16 16

Materials

Part Material Part Material

Body Cast iron Hinge pin Stainless steel

Body seat facing EPDM rubber Spacer PTFE (Glass filled)

Disk DN50-DN80 Bronze Spring Stainless steel

DN100-DN300 Ductile (SG) iron Plug Bronze

Disk facing Hinge nut Stainless steel

DN50-DN80 Integral Eye bolt

DN100-DN300 Bronze DN100-DN300 Steel

Hinge Stainless steel

Testing - each valve is hydrostatically tested for seat and stem tightness.

Dimensions mm / Weights / Flow coefficients

DN in A B C C1 kg Kv

50 2 99 43 57 - 1.3 48

65 2 / 111 46 67 - 1.8 79

80 3 130 49 73 - 2.6 115

100 4 162 56 88 - 4.7 184

125 5 194 64 102 - 7.0 311

150 6 216 70 - 168 9.8 388

200 8 273 71 - 194 15.0 723

250 10 330 76 - 227 20.0 1192

300 12 380 83 - 255 30.0 1682

Options - bronze trim; all iron.

64

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Tozen Valve CatalogueDocument45 pagesTozen Valve CatalogueMyo Kyaw Kyaw100% (1)

- Dm941 Da941 Fodrv Balancingvalves Cranefs Ds 160418Document1 pageDm941 Da941 Fodrv Balancingvalves Cranefs Ds 160418mikebhassigNo ratings yet

- Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageWafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- Specification: Flanged BSEN 1092-2 PN16 (Formerly BS4504) For Two Unit SystemDocument1 pageSpecification: Flanged BSEN 1092-2 PN16 (Formerly BS4504) For Two Unit Systemjustice judgeNo ratings yet

- PF-SUB-832 Fitting ClassDocument3 pagesPF-SUB-832 Fitting ClassHassan KhattabNo ratings yet

- Dm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Document1 pageDm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Hasan V SNo ratings yet

- Series dc125Document2 pagesSeries dc125Daniel FigueroaNo ratings yet

- V-Cone Ficha TécnicaDocument2 pagesV-Cone Ficha TécnicaIrving Uc Fernandez100% (1)

- HEROSEDocument9 pagesHEROSEpt tabNo ratings yet

- 300-Wafer Type Butterfly ValveDocument2 pages300-Wafer Type Butterfly ValveNguyễn Chu ThànhNo ratings yet

- Dembla Globe Control Valve BrochureDocument19 pagesDembla Globe Control Valve BrochureArman MominNo ratings yet

- Bronze Relief Valve DN10 DN15 DN20Document2 pagesBronze Relief Valve DN10 DN15 DN20billNo ratings yet

- Wafer Type Butterfly Valve Gear OperatedDocument1 pageWafer Type Butterfly Valve Gear OperatedTiến Nguyễn SongNo ratings yet

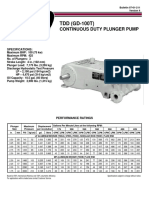

- Data Sheet TDD-GD100T PDFDocument2 pagesData Sheet TDD-GD100T PDFjhon peñaNo ratings yet

- Typo 1321 NDocument1 pageTypo 1321 NVikas PatelNo ratings yet

- Asco Flow Control Valves CatalogDocument4 pagesAsco Flow Control Valves CatalogCristian GutiérrezNo ratings yet

- Fig 520 High Lift Safety Valve: Features & BenefitsDocument3 pagesFig 520 High Lift Safety Valve: Features & Benefitst_rajith1179No ratings yet

- Balancing Valve - HONEY WELLDocument9 pagesBalancing Valve - HONEY WELLdesignNo ratings yet

- 1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmDocument1 page1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmNon Etabas GadnatamNo ratings yet

- Nibco 609Document1 pageNibco 609juanbcarrizales08No ratings yet

- CombineDocument3 pagesCombineJf OngNo ratings yet

- KW900WFPDocument1 pageKW900WFPAlfredo BravoNo ratings yet

- Type 01321 - Globe ValveDocument1 pageType 01321 - Globe ValveJoan ReigNo ratings yet

- Typ 01343 3 enDocument1 pageTyp 01343 3 enEntropay UserNo ratings yet

- Type 01262 - Bellow Sealed Globe Valve: Fire Safe ValvesDocument1 pageType 01262 - Bellow Sealed Globe Valve: Fire Safe ValvesArun BabuNo ratings yet

- 45-51 AVK Gate Valve Non Rising Stem UL-FMDocument2 pages45-51 AVK Gate Valve Non Rising Stem UL-FMImtiyaz KhanNo ratings yet

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

- Grooved OS&Y Gate Valve: Main Parts and MaterialDocument1 pageGrooved OS&Y Gate Valve: Main Parts and Materialmourad laatatNo ratings yet

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- 3521 Gala Gate Valve CatalogDocument1 page3521 Gala Gate Valve CatalogChhomNo ratings yet

- T376APBI-Nibco Angular Bronze ValveDocument1 pageT376APBI-Nibco Angular Bronze Valvemax_powerNo ratings yet

- Wafer Type Butterfly Valve Lever Operated-2Document1 pageWafer Type Butterfly Valve Lever Operated-2Tiến Nguyễn SongNo ratings yet

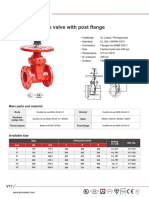

- Flanged NRS Gate Valve With Post Flange: Main Parts and MaterialDocument1 pageFlanged NRS Gate Valve With Post Flange: Main Parts and Materialmourad laatatNo ratings yet

- Avk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument3 pagesAvk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocument2 pages2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNo ratings yet

- Electric Actuator Butterfly Valve ZIPDocument5 pagesElectric Actuator Butterfly Valve ZIPwoodali9115991100% (1)

- Lugged Type Butterfly Valve Gear OperatedDocument1 pageLugged Type Butterfly Valve Gear OperatedTiến Nguyễn SongNo ratings yet

- F615 F625 F629 ButterflyValves DS CraneFSDocument1 pageF615 F625 F629 ButterflyValves DS CraneFSmohamed ghareebNo ratings yet

- NR-040 FS: Removable Cover Check Valves For Reclaimed Water, Wastewater and SludgeDocument4 pagesNR-040 FS: Removable Cover Check Valves For Reclaimed Water, Wastewater and SludgeOleg ShkolnikNo ratings yet

- Ball Segment Valve Si-111 EN Type KVTF and KVXF PN 50Document4 pagesBall Segment Valve Si-111 EN Type KVTF and KVXF PN 50Nicole Andre Tapia SegoviaNo ratings yet

- Crane Bronze StrainerDocument1 pageCrane Bronze StrainerstephenlongislandNo ratings yet

- 2211 Ca P0Document1 page2211 Ca P0Oleg ShkolnikNo ratings yet

- Norm Ex ValvesDocument6 pagesNorm Ex Valvesapi-3712612No ratings yet

- Avk Ball Float ValveDocument2 pagesAvk Ball Float ValveDota NgNo ratings yet

- Features: Water WaterDocument1 pageFeatures: Water WaterajsdlkasjdklNo ratings yet

- UL FM NRS Gate Valve, AWWA C515 - ANSI 250-300 Flanged Ends - Water Works - Fire Protection - Model 2510Document1 pageUL FM NRS Gate Valve, AWWA C515 - ANSI 250-300 Flanged Ends - Water Works - Fire Protection - Model 2510alanNo ratings yet

- Asco Valve 8262h 8263h GP Spec r3Document4 pagesAsco Valve 8262h 8263h GP Spec r3Anonymous 6VCG1YRdNo ratings yet

- T-413-B, Class 125 Bronze Check ValvesDocument1 pageT-413-B, Class 125 Bronze Check ValvesBalderas Rosas WilibaldoNo ratings yet

- Wo Euro Marine Valves DinDocument236 pagesWo Euro Marine Valves DinGilbert MejulioNo ratings yet

- Kitazawa 3Document1 pageKitazawa 3Nam Nguyễn ĐứcNo ratings yet

- Removable Cover Check Valves For Potable Water Pump StationsDocument4 pagesRemovable Cover Check Valves For Potable Water Pump StationsOleg ShkolnikNo ratings yet

- Technical Data: Globe Valve - AngleDocument1 pageTechnical Data: Globe Valve - Angledona gangulyNo ratings yet

- Spring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)Document4 pagesSpring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)cmpuckNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- Flanged + Grooved NRS Gate Valve: Main Parts and MaterialDocument1 pageFlanged + Grooved NRS Gate Valve: Main Parts and Materialmourad laatatNo ratings yet

- T 1-2 - 1 - en - 2 Disc Valves LvsDocument6 pagesT 1-2 - 1 - en - 2 Disc Valves LvsIvanNo ratings yet

- Victaulic AGS Grooved End Fittings: 1.0 Product DescriptionDocument17 pagesVictaulic AGS Grooved End Fittings: 1.0 Product DescriptionDiego Francisco Ancajima CuevaNo ratings yet

- Ab-Ss: Keeping The World FlowingDocument4 pagesAb-Ss: Keeping The World FlowingGourav SharmaNo ratings yet

- Lithonia Twr2250mtbscwalpi SpecsDocument1 pageLithonia Twr2250mtbscwalpi Specsjavier perezNo ratings yet

- The Mathematics of Pumping Water PDFDocument9 pagesThe Mathematics of Pumping Water PDFOualid LamraouiNo ratings yet

- CobertechoDocument1 pageCobertechojavier perezNo ratings yet

- Shaft Alignment ReportDocument1 pageShaft Alignment ReportLazzarus Az GunawanNo ratings yet

- Ficha Tecnica Lithonia Twr2 M S 250w Metal HalideDocument3 pagesFicha Tecnica Lithonia Twr2 M S 250w Metal Halidejavier perezNo ratings yet

- Bomba SumergibleDocument2 pagesBomba Sumergiblejavier perezNo ratings yet

- Euroflex Mooring Tail (R-5) PDFDocument1 pageEuroflex Mooring Tail (R-5) PDFjavier perezNo ratings yet

- Hydraulic HandbookDocument251 pagesHydraulic Handbookdwdobbs92% (25)

- Lithonia Twr2250mtbscwalpi WarrantyDocument2 pagesLithonia Twr2250mtbscwalpi Warrantyjavier perezNo ratings yet

- Reducing Bushing 6-4 RB-SS Parker FittingDocument3 pagesReducing Bushing 6-4 RB-SS Parker Fittingjavier perezNo ratings yet

- LGMT2 Datasheet eDocument1 pageLGMT2 Datasheet ejavier perezNo ratings yet

- D704-99 (2012) Standard Specification For Melamine-Formaldehyde Molding CompoundsDocument3 pagesD704-99 (2012) Standard Specification For Melamine-Formaldehyde Molding Compoundsjavier perezNo ratings yet

- Features & Specifications: Intended Use ConstructionDocument2 pagesFeatures & Specifications: Intended Use Constructionjavier perezNo ratings yet

- Lockout Tag Out SpanishDocument1 pageLockout Tag Out Spanishjavier perezNo ratings yet

- E439-10 Standard Test Methods For Chemical Analysis of BerylliumDocument8 pagesE439-10 Standard Test Methods For Chemical Analysis of Berylliumjavier perezNo ratings yet

- Bomba de Vácuo Sotorbilt 4mrDocument12 pagesBomba de Vácuo Sotorbilt 4mrWormInchNo ratings yet

- LGMT2 Datasheet eDocument1 pageLGMT2 Datasheet ejavier perezNo ratings yet

- Cable Plano - Polipasto - 19016Document4 pagesCable Plano - Polipasto - 19016javier perezNo ratings yet

- Bushing DimensionDocument1 pageBushing Dimensionjavier perezNo ratings yet

- Check Swig Cast Steel Williams E DimensionsDocument2 pagesCheck Swig Cast Steel Williams E Dimensionsjavier perezNo ratings yet

- D2412-11 Standard Test Method For Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate LoadingDocument7 pagesD2412-11 Standard Test Method For Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loadingjavier perezNo ratings yet

- D4759-11 Standard Practice For Determining The Specification Conformance of GeosyntheticsDocument5 pagesD4759-11 Standard Practice For Determining The Specification Conformance of Geosyntheticsjavier perezNo ratings yet

- Mouse ElectricDocument1 pageMouse Electricjavier perezNo ratings yet

- Slurry TransportDocument15 pagesSlurry Transportjavier perezNo ratings yet

- E1714-07 (2013) Standard Guide For Properties of A Universal Healthcare Identifier (UHID)Document6 pagesE1714-07 (2013) Standard Guide For Properties of A Universal Healthcare Identifier (UHID)javier perezNo ratings yet

- D2444-99 (2010) Standard Test Method For DeterminatDocument9 pagesD2444-99 (2010) Standard Test Method For Determinatjavier perezNo ratings yet

- D2122-15 Standard Test Method For Determining Dimensions of Thermoplastic Pipe and FittingsDocument5 pagesD2122-15 Standard Test Method For Determining Dimensions of Thermoplastic Pipe and Fittingsjavier perezNo ratings yet

- D3275-08 (2013) Standard Classification System For E-CTFE-Fluoroplastic Molding, Extrusion, and Coating MaterialsDocument4 pagesD3275-08 (2013) Standard Classification System For E-CTFE-Fluoroplastic Molding, Extrusion, and Coating Materialsjavier perezNo ratings yet

- D2122-15 Standard Test Method For Determining Dimensions of Thermoplastic Pipe and FittingsDocument5 pagesD2122-15 Standard Test Method For Determining Dimensions of Thermoplastic Pipe and Fittingsjavier perezNo ratings yet

- Dunham Bush Midwall Split R410a InverterDocument2 pagesDunham Bush Midwall Split R410a InverterAgnaldo Caetano100% (1)

- Unit List MUZAFFARPUR - Feb 18 PDFDocument28 pagesUnit List MUZAFFARPUR - Feb 18 PDFPawan Kumar100% (1)

- Frito Lay AssignmentDocument14 pagesFrito Lay AssignmentSamarth Anand100% (1)

- Annotated Portfolio - Wired EyeDocument26 pagesAnnotated Portfolio - Wired Eyeanu1905No ratings yet

- To Syed Ubed - For UpdationDocument1 pageTo Syed Ubed - For Updationshrikanth5singhNo ratings yet

- Strategic Management ModelsDocument4 pagesStrategic Management ModelsBarno NicholusNo ratings yet

- Chapter03 - How To Retrieve Data From A Single TableDocument35 pagesChapter03 - How To Retrieve Data From A Single TableGML KillNo ratings yet

- CNS Manual Vol III Version 2.0Document54 pagesCNS Manual Vol III Version 2.0rono9796No ratings yet

- Reading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1Document27 pagesReading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1shehla khanNo ratings yet

- Prepositions Below by in On To of Above at Between From/toDocument2 pagesPrepositions Below by in On To of Above at Between From/toVille VianNo ratings yet

- Spine Beam - SCHEME 4Document28 pagesSpine Beam - SCHEME 4Edi ObrayanNo ratings yet

- VoIP Testing With TEMS InvestigationDocument20 pagesVoIP Testing With TEMS Investigationquantum3510No ratings yet

- Pet Care in VietnamFull Market ReportDocument51 pagesPet Care in VietnamFull Market ReportTrâm Bảo100% (1)

- 14 CE Chapter 14 - Developing Pricing StrategiesDocument34 pages14 CE Chapter 14 - Developing Pricing StrategiesAsha JaylalNo ratings yet

- Failure of A Gasket During A Hydrostatic TestDocument7 pagesFailure of A Gasket During A Hydrostatic TesthazopmanNo ratings yet

- I5386-Bulk SigmaDocument1 pageI5386-Bulk SigmaCleaver BrightNo ratings yet

- Medical Devices RegulationsDocument59 pagesMedical Devices RegulationsPablo CzNo ratings yet

- The Fundamentals of Investing PPT 2.4.4.G1Document36 pagesThe Fundamentals of Investing PPT 2.4.4.G1Lùh HùñçhòNo ratings yet

- 01 RFI Technical Form BiodataDocument8 pages01 RFI Technical Form BiodataRafiq RizkiNo ratings yet

- ODF-2 - Learning MaterialDocument24 pagesODF-2 - Learning MateriallevychafsNo ratings yet

- Typical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpDocument2 pagesTypical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpSabrinadeFeraNo ratings yet

- Seminar Report of Automatic Street Light: Presented byDocument14 pagesSeminar Report of Automatic Street Light: Presented byTeri Maa Ki100% (2)

- X HM11 S Manual AUpdfDocument228 pagesX HM11 S Manual AUpdfAntonio José Domínguez CornejoNo ratings yet

- ProAim InstructionsDocument1 pageProAim Instructionsfeli24arias06No ratings yet

- Invoice Acs # 18 TDH Dan Rof - Maret - 2021Document101 pagesInvoice Acs # 18 TDH Dan Rof - Maret - 2021Rafi RaziqNo ratings yet

- TRX Documentation20130403 PDFDocument49 pagesTRX Documentation20130403 PDFakasameNo ratings yet

- Drug Study TemplateDocument2 pagesDrug Study TemplateKistlerzane CABALLERONo ratings yet

- ASM INTERNATIONAL Carburizing Microstructures and Properties by Geoffrey ParrishDocument222 pagesASM INTERNATIONAL Carburizing Microstructures and Properties by Geoffrey ParrishAdheith South NgalamNo ratings yet

- VB 850Document333 pagesVB 850Laura ValentinaNo ratings yet

- Computer System Sevicing NC Ii: SectorDocument44 pagesComputer System Sevicing NC Ii: SectorJess QuizzaganNo ratings yet