Professional Documents

Culture Documents

An Assessment of The Double-Notch Shear Test For

Uploaded by

Jingbo SongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Assessment of The Double-Notch Shear Test For

Uploaded by

Jingbo SongCopyright:

Available Formats

Applied Composite Materials 5: 289–304, 1998.

289

© 1998 Kluwer Academic Publishers. Printed in the Netherlands.

Erratum

An Assessment of the Double-Notch Shear Test for

Interlaminar Shear Characterization of a

Unidirectional Graphite/Epoxy under Static and

Fatigue Loading ‡

MAHMOOD M. SHOKRIEH? and LARRY B. LESSARD??

Department of Mechanical Engineering, McGill University, Montréal, Québec, Canada

(Received 5 August 1996; accepted 21 May 1997)

Abstract. This research explores a modified testing technique for measuring interlaminar shear

properties of orthotropic composite materials. An existing test method (double-notched test method)

is examined here to characterize the interlaminar shear properties (strength and fatigue life) of a

unidirectional ply under both static and fatigue loading conditions. No complicated fixture is required

for the testing method which is beneficial for fatigue testing of the materials. The testing method

is verified by a finite element technique where an optimized geometry for the specimen is found.

AS4/3501-6 graphite/epoxy material is used in this study. The experimental results show that final

failure occurs in the gage area for both static and fatigue loading conditions. Moreover, a reasonable

amount of scatter for both the static strength and fatigue life is achieved.

Key words: composites, interlaminar shear test method, static, fatigue, characterization, double-

notched test.

1. Introduction

Interlaminar shear strength is defined as the shear strength at rupture in which

the plane of fracture is located between the layers of reinforcement of a plastic

reinforced structure [1]. To measure the interlaminar shear strength of a material,

a reliable and simple method must be found. The method must also be able to

determine fatigue properties of the material (such as fatigue life). In this research,

a test method is devised to measure interlaminar shear strength (Syz ) and fatigue

life of a unidirectional ply under interlaminar shear stress as a necessary contribu-

tion to a complete set of three-dimensional material properties. Figure 1 depicts a

‡ Previously published in Applied Composite Materials 5(1), 1998, 49–64. However, much to our

regret, due to a technical problem the last page of the article was omitted.

? PhD Student

?? Assistant Professor

VTEX(P) PIPS No.: 186535 (acmakap:mathfam) v.1.15

ACMAER1.tex; 27/08/1998; 15:12; p.1

290 MAHMOOD M. SHOKRIEH AND LARRY B. LESSARD

Figure 1. Three-dimensional geometry of a layer of composite material.

specially orthotropic material showing that there are essentially two planes which

have similar material appearance (x-y and x-z), thus shear strength Sxy and Sxz are

similar. The shear strength Syz is different and tends to be weaker than the other

two shear strengths. Accordingly, the test methods suitable for measuring Sxy and

Sxz are not applicable to Syz , thus another test method must be utilized.

The four main methods for determining the interlaminar shear strength of a

material are the short beam shear test [2–6], the four-point shear test [6, 7], the

Iosipescu test [6, 8–11] and the notched coupon [1, 6, 12–15]. Different authors

have shown that the short beam shear test [2–6], and four point shear test [6, 7]

are not reliable test methods. Moreover, a pure interlaminar shear stress can not be

induced which results in a complex fracture [8]. Also to measure the interlaminar

shear strength (Syz ), by utilizing these methods, a 90◦ unidirectional ply must be

used. It is clear that a 90◦ unidirectional ply can fail in matrix failure mode, caused

by σyy , before failure ever happens under interlaminar shear stress σyz . Therefore

it is very difficult to use these methods to measure the interlaminar shear strength

(Syz ).

The Iosipescu testing method has been examined extensively [6, 8–11]. Many

investigators verified the Iosipescu testing method as a highly effective and reliable

method. However measuring the interlaminar shear strength (Syz ) of a unidirec-

tional ply by this method is difficult. Notably, the fixture can be damaged during

fatigue tests. Furthermore, the type of specimen needed is complicated, as seen by

tests performed by Gipple and Hoyns [16] for measuring the interlaminar shear

stiffness and strength of a unidirectional AS4/3501-6 material system.

Unlike the Iosipescu test, the double-notched test method requires no extensive

set-up or fixture and the specimen (Figure 2) is simple. These features make the

double-notched test method attractive for fatigue testing. Markham and Dawson

[12] performed a study of the notched coupon test and they concluded that the

specimen always fails in shear. They also reported consistent results with fracture

occurring in a single plane unlike the complex fracture occurring with the short

ACMAER1.tex; 27/08/1998; 15:12; p.2

UNIDIRECTIONAL GRAPHITE/EPOXY UNDER STATIC AND FATIGUE LOADING 291

Figure 2. Specimen dimensions (all configurations are possible by varying notch depth d,

notch width w, notch distance l and specimen thickness t, according to Table I).

beam shear test. These results and the simplicity of the testing method in static

and fatigue loading conditions led to the belief that this may be an appropriate

testing method. However, there are some disadvantages mentioned in the literature

about this testing method which are summarized in the following. Munjal [6] found

that it was difficult to control the notch depth in the notched coupon test and thus

had quite a scatter in the results. Chiao et al. [8] postulated that the shear strength

data obtained in by this testing method was lower than that by other methods.

Tarnopol’skii and Kincis [13] discussed the disadvantages of this test method by

testing samples with nonsymmetrically placed notches. Fixtures for prevention

of specimen bending were necessary and the results were highly sensitive to the

accuracy of cutting the notches.

This study examines all the disadvantages postulated by other authors, and

shows that all these difficulties can be eliminated by selecting a proper specimen

geometry found by finite element analysis.

2. Description of the Problem

The double-notched specimen test is selected as suggested in the ASTM Standard

D 3846-79 reapproved 1985 [14] for reinforced plastics and further investigated in

the ASTM Standard D 2733-70 [1] for reinforced plastics at elevated temperatures.

This standard suggests two methods for finding shear strengths. Method A, tested

in compression, requires that a clamp be placed at the midsection of the specimen

for a distance of 65 mm and tightened evenly so as not to damage the specimen.

This should result in an interlaminar shear-type failure. Method B does not require

a clamp and is tested in tension to failure. Method A will be referred to as clamped

and method B will be referred to as unclamped. It is desired to study the behaviour

of a double-notched sample under these two testing conditions. This is performed

by applying a finite element analysis and through an experimental program.

The behaviour of the double-lap shear specimen is similar to the notched coupon,

with interlaminar shear failure being introduced at the interface of two layers. Pre-

vious results [15] showed a non uniform stress region over the failed area but were

influenced by large and almost equal shear stress concentrations at each end of the

failure plane resulting in a variation in the shear strength. It is thus desired to see

ACMAER1.tex; 27/08/1998; 15:12; p.3

292 MAHMOOD M. SHOKRIEH AND LARRY B. LESSARD

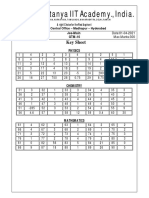

Table I. Different configurations for the double-notched specimen.

a (mm) W (mm) d (mm) l (mm) t (mm)

w1 , w2 , w3 66.67 1.13, 2.29, 4.57 1.59 6.35 3.17

d1 , d2 , d3 66.67 2.29 1.52, 1.59, 1.66 6.35 3.17

l1 63.50 2.29 1.59 12.70 3.17

l2 66.67 2.29 1.59 6.35 3.17

l3 68.26 2.29 1.59 3.175 3.17

t16 , t24 , t32 66.67 2.29 1.06, 1.59, 2.17 6.35 2.12, 3.18, 4.33

whether these results also occur in a notched specimen and what effect variations

of the notch size has on the results.

In order to induce pure interlaminar shear (σyz ) in the gage area of a double-

notched specimen, a 90-degree lay-up must be used. However, the material is

weaker in matrix tension than in interlaminar shear loading. Therefore, a ten-

sile load applied to a double-notch specimen with 90-degree lay-up results in a

tensile matrix failure prior to failure in interlaminar shear. There are two solu-

tions to this problem. The first solution is to use (0/90)s laminate instead of a

90-degree lay-up. However, experimental evidence show that failure for this con-

figuration occurs between the 0 and 90 degree layers. On the other hand, it is

known that the strength of the material in matrix compression loading is higher

than in matrix tension. Therefore, the second solution is to apply a compressive

load instead of a tensile load on a 90-degree lay-up. However, the disadvantage

of the second method is the possibility of out-of-plane deformation, which can be

avoided by using clamps. The clamp used in this study and clamp dimensions are

shown in Figure 3. Various testing programs are also analyzed, including using

a specimen of pure 90 degree layers or a hybrid of 90 degree layers being sup-

ported by 0 degree layers. Analysis is also performed of whether better results

are obtained from testing the sample in tension or compression, with or without

clamp.

The specimens of dimensions as given in Figure 2 and Table I were considered

for analysis. The coupon was a laminated composite plate consisting of 16, 24 or

32 layers. The composite plate configuration was (9016 ), (9024 ) or (9032 ) in the

analysis.

The effect of notch width was first examined by Tarnopol’skii et al. [13] who

stated that the double-notch shear test is very sensitive to the accuracy of cutting

the notches. To examine this difficulty, three different widths: w1 , w2 , and w3 are

analyzed in this study. Another disadvantage of the double-notched shear test given

by Munjal [6] and Chiao et al. [8], is said to be the difficulty in accurately cutting

ACMAER1.tex; 27/08/1998; 15:12; p.4

UNIDIRECTIONAL GRAPHITE/EPOXY UNDER STATIC AND FATIGUE LOADING 293

Figure 3. Clamp used to eliminate the out-of-place deformation (dimensions are in mm).

the notches to the prescribed depth (see Figure 2). Thus a study was undertaken to

analyze the depth effect by testing three different notch depths: d1 , d2 , and d3 . These

depths correspond to half of the thickness of the specimen, an overcut (too deep),

or an undercut (too shallow). The distance at which the notches are cut (see ‘l’ in

Figure 2) is also variable due to the difficulty in machining the specimen accurately.

Thus three distances between the notches were examined: l1 , l2 , and l3 . The final

analysis was to determine the effect of the specimen thickness. Three specimen

thicknesses were examined: t16 , t24 , and t32 , corresponding to either 16, 24, or 32

ACMAER1.tex; 27/08/1998; 15:12; p.5

294 MAHMOOD M. SHOKRIEH AND LARRY B. LESSARD

plies. Due to the difficulty in manufacturing thick specimens, more than 32 plies

would not be feasible. Less than 16 plies, was also undesirable due to sensitivity to

external effects, including out-of-plane deformation. Different configurations for

the notched specimen are summarized in Table I.

The material used in this study is AS4/3501-6 with the following material

properties: longitudinal modulus (Exx = 150 GPa), transverse or normal modulus

(Eyy = Ezz = 8 GPa), in-plane shear modulus (Exy = Ezx = 5 GPa), out-of-plane

shear modulus (Eyz = 3 GPa, calculated by transversely isotropic assumption),

Poisson’s ratios (νxy = 0.3, measured) and (νxz = νyz = 0.3, assumed), trans-

verse or normal tensile strength (Yt = Zt = 53.98 MPa), transverse or normal

compressive strength (Yc = Zc = 203.69 MPa) and the interlaminar shear strength

(Syz = 42 MPa, as measured in this study). The material properties were measured

in the Composite Materials Laboratory of McGill University.

3. Finite Element Analysis

To predict the behaviour of the notched coupon, a stress analysis is performed using

the SDRC I-DEAS finite element software [17]. The specimen was modeled using

eight-node quadrilateral isoparametric elements. Since the stresses between the two

notches are of main interest, elements were concentrated in this area. Even though

shear stresses are of great importance to the problem at hand, nonlinear material

properties were not considered in this work. The softening effect of nonlinear shear

stress/strain behaviour could have an impact on the final stress analysis.

3.1. BOUNDARY CONDITIONS

By considering plane stress conditions in y-z plane (Figure 2), a cross section of

the specimen can be modeled by two-dimensional finite elements. Since there is

no symmetry with respect to y-axis, the entire cross section of the specimen in

y-z plane is modeled. The boundary conditions for the unclamped case are shown

in Figure 4(a). One end of the specimen is fixed and an edge pressure is applied

to the thickness at the other end. Moreover, to simulate the gripped ends of the

testing machine, the displacement of the nodes in the gripped area were fixed in

z-direction (Figure 4(a)).

The displacement field of the nodes in the gauge area is examined for the

unclamped model (Figure 4(b)). The out-of-plane deformation, observed by fi-

nite element analysis and by experimental techniques, is due to the antisymmetric

geometry of the specimen. To eliminate this behaviour, a simple clamp (Figure 3) is

used. To simulate the clamped case in the finite element model, fixed displacement

boundary conditions in z-direction are applied on appropriate nodes in the clamped

region (Figure 4(c)). Note that not all nodes under the clamped area are fixed.

The induced bending due to loading means that only some parts of the clamp are

ACMAER1.tex; 27/08/1998; 15:12; p.6

UNIDIRECTIONAL GRAPHITE/EPOXY UNDER STATIC AND FATIGUE LOADING 295

Figure 4. Load and displacement boundary conditions.

applying pressure to the specimen to keep it from bending. The appropriate nodes

were found by an iterative process.

3.2. RESULTS OF FINITE ELEMENT ANALYSIS

The results of the finite element analysis are presented here for various notch

widths, depths, lengths and specimen thicknesses.

3.2.1. Loading Analysis

ASTM Standard D 2733-70 [1] suggests applying tensile loading on the notched

specimen with or without a clamp (method A and B). The specimen in tension

created positive σyy and σzz stresses whereas the specimen in compression created

negative σyy and σzz stresses. Since the material in the matrix direction is weaker

in tension than in compression, it is desired to keep the normal stresses negative so

that they do not cause failure. Thus the compression version of the test was chosen.

The results of the stress analysis of the specimen with or without a clamp under

compressive loading are shown in Figure 5. The stresses in the gage area, between

notches, from point A to B (Figure 2) are plotted (Figure 5). The results indicate

that the σyy and σzz stresses in the gage area were reduced by adding the clamp and

the stress concentrations at the notch tips were reduced. As shown in this figure,

the stresses are normalized with respect to their related strengths. To normalize

ACMAER1.tex; 27/08/1998; 15:12; p.7

296 MAHMOOD M. SHOKRIEH AND LARRY B. LESSARD

Figure 5. Stress analysis of clamped and unclamped specimen.

Figure 6. The results of stress analysis for different notch widths.

σyy and σzz stresses, they were divided by the strength in transverse direction (Y )

which is assumed to be equal to the strength in normal direction (Z). The tensile

stresses are normalized by tensile strength and compressive stresses are normalized

by compressive strength. The interlaminar shear stress (σyz ) is normalized by the

interlaminar shear strength. The σyz stress exhibited the same behaviour with lower

stress concentrations at the notches and adding the clamp increased the shear stress

in the gage area which is favored. With the clamp, interlaminar shear stress (σyz )

becomes the dominant stress, thus most likely to cause failure. The clamped speci-

men or method A tested in compression is thus the preferred case and is considered

from here on.

3.2.2. Effect of the Notch Width

The effect of the notch widths w1 , w2 and w3 was examined. Three different models

(w1 , w2 and w3 ) are considered with dimensions given in Figure 2 and Table I. The

results of stress analysis for the clamped conditions show that the variation of the

notch width does not alter the σyy , σzz and σyz stresses significantly. For example,

ACMAER1.tex; 27/08/1998; 15:12; p.8

UNIDIRECTIONAL GRAPHITE/EPOXY UNDER STATIC AND FATIGUE LOADING 297

Figure 7. The results of stress analysis for different notch depths (overcutting and exact give

nearly identical stress results).

the variation of σzz for the three models is shown in Figure 6. This indicates that

the notch width does not have an important influence on specimen strength.

3.2.3. Effect of the Notch Depth

The effect of the notch depths d1 , d2 and d3 was examined. Three different models

(d1 , d2 and d3 ) are considered with dimensions given in Figure 2 and Table I. It

would seem likely that if the depth of the notch is more than half the depth of

the specimen, or overcut, then bending stresses should occur in the gauge area.

Also, if the depth of the notch is less than half the depth of the specimen, or

undercut, then compressive stresses should occur in the gauge area. To examine the

effect of the notch depth, stress analyses for different notch depths are performed

and it was determined that the change of depth did not effect the stresses in the

gauge area, but alters the normal stress σzz near the notch locations (Figure 7).

Undercutting causes higher magnitudes of σzz normal stress at the notch location.

Also it causes higher positive σzz just inside the notch location which can lead to

premature failure. Therefore, it is concluded that undercutting should be avoided

during manufacturing. There is no significant change in the behaviour of transverse

stress (σyy ) and interlaminar shear stress (σyz ) with varying the notch depth.

3.2.4. Effect of the Length Between Notches

The effect of the length between notches was studied. Three different models (l1 , l2

and l3 ) are considered with dimensions given in Figure 2 and Table I. The results of

the stress analysis indicate that if the distance between the notches is too close then

high σyy and σzz stresses exist and the interlaminar shear stress, σyz , also increases.

Normal and shear stresses are lowered by increasing the notch length. The variation

of σzz for three cases is shown in Figure 8. Therefore, a proper notch length can be

selected by examining the transverse and normal stresses (σyy and σzz ) compared

to the strength of the material in these directions. Although doubling or halving

ACMAER1.tex; 27/08/1998; 15:12; p.9

298 MAHMOOD M. SHOKRIEH AND LARRY B. LESSARD

Figure 8. The results of stress analysis for different notch lengths.

Figure 9. The results of stress analysis for different specimen thickness.

the notch length changes the state of stress, however the state of stress is not very

sensitive to small variations of the notch length. Therefore the effect of a small

variation of the notch length about a nominal value is not critical.

3.2.5. Effect of the Specimen Thickness

The specimen thickness effect was then investigated. For this study, three thick-

nesses were examined which correspond to t16 , t24 , and t32 , or 16 plies, 24 plies

and 32 plies. The dimensions are given in Figure 2 and Table I. It was determined

that by increasing the amount of layers the transverse and normal stresses (σyy and

σzz ) remained the same. However the interlaminar shear stress (σyz ) increases with

increasing the number of plies (Figure 9). It is concluded that to perform a better

test, the number of plies should be as high as possible.

ACMAER1.tex; 27/08/1998; 15:12; p.10

UNIDIRECTIONAL GRAPHITE/EPOXY UNDER STATIC AND FATIGUE LOADING 299

3.2.6. Summary of Theoretical Findings

Based on the finite element analysis of different samples, the (9024 ) lay-up with

a notch width of w = 2.286 mm, notch depth of d = 1.5875 mm, notch distance

of l = 6.35 mm, and total length of L = 139.7 mm (Figure 2) was selected for

the experimental studies. It is also recommended that the notches be cut exactly

(neither undercut nor overcut).

4. Experimental Program

To examine the analytical study an experimental program is conducted. The de-

scription of the experimental setup and the results are explained in the following

sections.

4.1. MANUFACTURING OF SPECIMENS

The specimens used in this research were made of unidirectional AS4/3501-6. The

unidirectional prepreg sheets were aligned and processed in an autoclave. The

individual specimens were then cut from the sheets to the length and width as

described in Figure 2 using a diamond impregnated saw. A critical aspect of the

manufacturing was the cutting of the notches. Since some tolerance exists in the

thickness from the curing process, the average thickness of the gage area of each

specimen was found and divided in half. After clamping the specimen into a milling

machine the depth was then cut into the specimen at one end using a fast cutting

speed (1500 rpm) and small depth increments to reduce microcracking. The same

process was then used on the other side to a depth of the total thickness minus the

depth of the existing notch. This ensured no overcutting of the notches.

4.2. EXPERIMENTAL SETUP

Tests were performed using an MTS 810 testing system, equipped with hydraulic

grips and computerized for data acquisition. Displacement and load were moni-

tored for static experiments. In fatigue tests, maximum and minimum displace-

ment, load as well as number of cycles were monitored. Static tests were per-

formed under displacement control, while the fatigue tests were carried out under

load control conditions. To avoid temperature effects, which could degrade the

material properties, fatigue tests were performed at frequencies less than 10 Hz.

All tests were performed in ambient temperature. The simple clamp was used to

eliminate the out-of-plane deformation caused by the antisymmetric geometry of

the specimen as described in Section 3.1 (see Figure 3). The nuts of the clamp were

tightened by using a torque wrench to 0.113 + 0.000, −0.028 nm.

ACMAER1.tex; 27/08/1998; 15:12; p.11

300 MAHMOOD M. SHOKRIEH AND LARRY B. LESSARD

(a) thickness too small

(b) overcut notches

(c) undercut notches

Figure 10. Final static failure mode of double-notched specimen (overcut and undercut) with

(90)24 configuration.

ACMAER1.tex; 27/08/1998; 15:12; p.12

UNIDIRECTIONAL GRAPHITE/EPOXY UNDER STATIC AND FATIGUE LOADING 301

Figure 11. Final static failure mode of double-notched specimen (exact cut) with (90)24

configuration.

4.3. TEST RESULTS

In the following sections, the results of experiments to verify the results of the

finite element analysis are summarized. Moreover, the results of static and fa-

tigue characterization of AS4/3501-6 graphite/epoxy unidirectional material under

interlaminar shear stress are presented.

4.3.1. Verification of the Finite Element Results

To verify the results of the finite element study, an experimental program is con-

ducted. Several static tests on double-notched specimens yielded unsuccessful re-

sults, three of which are shown in Figure 10. Figure 10(a) shows the result of a

test where the thickness was too small, i.e., the (90)16 configuration. As shown, the

specimen failed at the notch location rather than on the line connecting the notches.

In Figures 10(b) and 10(c), thicker (90)24 samples are examined and overcutting

and undercutting are studied. As shown, failure occurs near the location of stress

concentrations and correct modes of failure in the gage area are not achieved for

these cases. Finally, samples with (90)24 configurations are manufactured by the

exact cut procedure explained in Section 4.1, and tested under static loading con-

ditions. The test result is shown in Figure 11. As shown, the specimen failed under

interlaminar shear stress, right in the gage area. The successful mode of failure

for this configuration verifies the results obtained by finite element analysis. By

achieving the successful mode of failure using the (90)24 ply specimens, samples

with (90)32 configurations need not be manufactured.

4.3.2. Characterization of AS4/3501-6 Graphite/Epoxy Unidirectional Material

The results of static experiments for measuring the interlaminar strength of the

material under out-of-plane shear loading using (9024 ) specimens are summarized.

The results are shown in Figure 12, compared with the results of Gipple and Hoyns

ACMAER1.tex; 27/08/1998; 15:12; p.13

302 MAHMOOD M. SHOKRIEH AND LARRY B. LESSARD

Figure 12. Static strength measurements for out-of-plane shear.

Figure 13. Final fatigue failure mode of double-notched specimen (exact cut) with (90)24

configuration.

[16] using the Iosipescu method. The average magnitude for the interlaminar shear

strength is about 42 MPa which is about 30% higher than that of measured by

Gipple and Hoyns [16]. By considering the reasonable standard deviation achieved,

it is concluded the experimental scatter is acceptable and test method is reliable for

measuring the interlaminar shear strength of the material.

Fatigue experiments were performed under load control conditions and the fa-

tigue load was applied in a sinusoidal form. The fatigue tests were loaded with

maximum stress equal to 80% of the maximum strength, stress ratio (κ = σmin /σmax )

equal to 0.1, and frequency between 1 to 10 Hz. An edge view picture of a speci-

men, failed under out-of-plane shear fatigue loading, is shown in Figure 13. Note

that this type of test also shows a correct mode of failure, along the shear plane

between the notches.

The fatigue life of the material was measured for different samples by applying

the maximum interlaminar shear stress (σyz ) equal to various percentages of the

ACMAER1.tex; 27/08/1998; 15:12; p.14

UNIDIRECTIONAL GRAPHITE/EPOXY UNDER STATIC AND FATIGUE LOADING 303

Figure 14. Results of fatigue life tests.

maximum interlaminar shear strength and stress ratio equal to 0.1. Tests were

continued until catastrophic failure was achieved. The results of fatigue life tests

are shown in Figure 14. It is clear that to fully characterize the interlaminar shear

fatigue properties of the material (e.g., fatigue life and residual strength) more tests

must be performed at different maximum stress and various stress ratios. Although

a limited number of fatigue tests are shown, a reasonable scatter was achieved

which shows the reliability of the test method.

5. Conclusions

The double-notched test method is verified as a simple and reliable test method

to measure the interlaminar shear properties of composite materials under static

and fatigue loading conditions. No complicated fixture is required for this method

which is greatly beneficial in fatigue testing of the materials. Out-of-plane defor-

mation, due to the antisymmetric geometry of the specimen, can be eliminated by

using a simple clamp. The results of a stress analysis, using a finite element tech-

nique, of the double-notched specimen show that by selecting the proper geometry,

a relatively uniform state of interlaminar shear stress (σyz ) can be achieved in the

gage area. Also, results show the magnitudes of the other stresses in the gage length

region (σyy and σzz ) are not as critical compared to interlaminar shear stress (σyz ).

Tested specimens confirm that a reliable geometry has been found for further test-

ing. The failed specimens under static and fatigue loading conditions show that the

correct final failure mode occurs in the gage area. The results of the experimental

studies for static and fatigue cases show reasonable scatter for the magnitude of

static strength and fatigue life of the material, which confirm the reliability of the

test method.

ACMAER1.tex; 27/08/1998; 15:12; p.15

304 MAHMOOD M. SHOKRIEH AND LARRY B. LESSARD

Acknowledgements

The authors would like to thank graduate students Ms. Olivia P. Eilers, and Mr.

Peter Kotsiopriftis for their help during the course of this study.

References

1. ASTM Designation D-2733-70, ‘Interlaminar shear strength of structural reinforced plastics at

elevated temperatures’, ASTM Designation, 1970, 773–776.

2. ASTM Designation D-2344-76, ‘Apparent horizontal shear strength of reinforced plastics by

short beam method’, ASTM Designation, 1976, 361–364.

3. ASTM Designation D-2344-84 (Reapproved 1989), ‘Standard test method for apparent inter-

laminar shear strength of parallel fiber composites by short-beam method’, ASTM Designation,

1989, 43–45.

4. Ewins, P. D., ‘Techniques for measuring the mechanical properties of composite materials’,

Composite-Standards Testing and Design, National Physical Laboratory, 1974, pp. 144–154.

5. Whitney, J. M. and Browning, C. E., ‘On short-beam shear tests for composite materials’,

Experimental Mechanics 25, 1985, 294–300.

6. Munjal, A. K., ‘Test methods for determining design allowables for fiber reinforced com-

posites’, in Test Methods for Design Allowables for Fiber Composites, ASTM STP 1003,

C. C. Chamis and K. L. Reifsnider (eds.), 1989, 93–110.

7. Sideridis, E., Ashton, J. N. and Kitching, R., ‘Measurement of the interlaminar shear strength

of glass-reinforced plastics of different construction using the off-axis four-point bending test’,

Composite Structures 18, 1991, 139–161.

8. Chiao, C. C., Moore, R. L. and Chiao, T. T., ‘Measurement of shear properties of fibre

composites, Part 1. Evaluation of test methods’, Composites, 1977, 161–169.

9. Adams D. F. and Walrath, D. E., ‘Current status of the Iosipescu shear test method’, J.

Composite Materials 21, 1987, 494–507.

10. Ho, H., Tsai, M. Y., Morton, J. and Farley, G. L., ‘Numerical analysis of the Iosipescu specimen

for composite materials’, Composites Science and Technology 46(2), 1993, 115–128.

11. Chang, F. K., Tang, J. M. and Peterson, D. G., ‘Effect of testing methods on the shear

strength distribution in laminated composites’, J. Reinforced Plastics and Composites 6(4),

1987, 304–318.

12. Markham M. F. and Dawson, D., ‘Interlaminar shear strength of fibre-reinforced composites’,

Composites, 1975, 173–176.

13. Tarnopol’skii, Y. M. and Kincis, T., ‘Method of static testing for composites’, in Handbook of

Composites, Vol. 3, Mechanics of Composite Materials, Chap. 5, G. P. Sendeckyj (ed.), 1985,

215–275.

14. ASTM Designation D-3846-79 (Reapproved 1985), ‘Standard test method for in-plane shear

strength of reinforced plastics’, ASTM Designation, 1985, 208–210.

15. Harding, J. and Li, Y. L., ‘Determination of interlaminar shear strength for glass/epoxy and

carbon/epoxy laminates at impact rates of strain’, Composites Science and Technology, 1992,

161–171.

16. Gipple, K. L. and Hoyns, D., Measurement of the out-of-plane shear response of thick section

composite materials using the V-notched beam specimen’, J. Composite Materials 28(6), 1994,

543–572.

17. SDRC I-DEAS, version VI, Integrated design engineering software, Structural Dynamic

Research Corporation, 1991.

ACMAER1.tex; 27/08/1998; 15:12; p.16

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Risk, Return, and The Capital Asset Pricing ModelDocument52 pagesRisk, Return, and The Capital Asset Pricing ModelFaryal ShahidNo ratings yet

- Principles of Robot Autonomy I: Robotic Sensors and Introduction To Computer VisionDocument38 pagesPrinciples of Robot Autonomy I: Robotic Sensors and Introduction To Computer VisionratjerryNo ratings yet

- RD Sharma Solutions (Ex - 1. 5, 1.6, 1.7 & 1.8) - Rational Numbers - RD Sharma SolDocument15 pagesRD Sharma Solutions (Ex - 1. 5, 1.6, 1.7 & 1.8) - Rational Numbers - RD Sharma SolSunil AnandNo ratings yet

- English Task For 11th GradeDocument8 pagesEnglish Task For 11th GradeDevi NurulhudaNo ratings yet

- 01-04-2021 SR - Super60 & All Jee-Main GTM-16 Key & Sol'sDocument12 pages01-04-2021 SR - Super60 & All Jee-Main GTM-16 Key & Sol'sGowri ShankarNo ratings yet

- Maths exam questions for class 2Document2 pagesMaths exam questions for class 2Mandeep ThakurNo ratings yet

- ΔΣ Modulator with Low power Using Charge- Pump Based Switched-Capacitor IntegratorDocument5 pagesΔΣ Modulator with Low power Using Charge- Pump Based Switched-Capacitor IntegratorIPASJNo ratings yet

- Material Models in PlaxisDocument136 pagesMaterial Models in PlaxismpvfolloscoNo ratings yet

- Assignment 1 - Simple Harmonic MotionDocument2 pagesAssignment 1 - Simple Harmonic MotionDr. Pradeep Kumar SharmaNo ratings yet

- Strength of Materials MarksDocument28 pagesStrength of Materials Markslogeshboy007No ratings yet

- IIR FILTER COEFFICIENTSDocument2 pagesIIR FILTER COEFFICIENTSharun or rashidNo ratings yet

- 23 Response OptimizationDocument30 pages23 Response OptimizationafonsopilarNo ratings yet

- Sachin S. Pawar: Career ObjectivesDocument3 pagesSachin S. Pawar: Career ObjectivesSachin PawarNo ratings yet

- ECON 233-Introduction To Game Theory - Husnain Fateh AhmadDocument7 pagesECON 233-Introduction To Game Theory - Husnain Fateh AhmadAdeel ShaikhNo ratings yet

- Assignment 2Document2 pagesAssignment 2yathasamboNo ratings yet

- E122Document5 pagesE122zudujawalo100% (1)

- A Theory of Dynamic Oligopoly II Price Competition Kinked Demand Curves and Edgeworth CyclesDocument29 pagesA Theory of Dynamic Oligopoly II Price Competition Kinked Demand Curves and Edgeworth CyclesGiovanna Larissa MendesNo ratings yet

- Application of Modified Euler's Method in Obtaining Numerical Solution of Swing EquationDocument7 pagesApplication of Modified Euler's Method in Obtaining Numerical Solution of Swing EquationijsretNo ratings yet

- Jyothi Swarup's SAS Programming ResumeDocument4 pagesJyothi Swarup's SAS Programming Resumethiru_lageshetti368No ratings yet

- Anees Abdul MFSslidesDocument46 pagesAnees Abdul MFSslidesjoseNo ratings yet

- Bs 8666 of 2005 Bas Shape CodesDocument5 pagesBs 8666 of 2005 Bas Shape CodesopulitheNo ratings yet

- ICCM2014Document28 pagesICCM2014chenlei07No ratings yet

- MCQDocument6 pagesMCQShamara RodrigoNo ratings yet

- Kakuro #1-4: 6X6 Kakuro Puzzles by Krazydad, Volume 1, Book 2Document3 pagesKakuro #1-4: 6X6 Kakuro Puzzles by Krazydad, Volume 1, Book 2Aashirtha SNo ratings yet

- Math 9Document8 pagesMath 9Erich GallardoNo ratings yet

- Calculating Surface Integrals and Parameterizing SurfacesDocument28 pagesCalculating Surface Integrals and Parameterizing SurfacesKenn SharpeyesNo ratings yet

- Trigonometric Functions and Equations (Unit - 1)Document76 pagesTrigonometric Functions and Equations (Unit - 1)Santosh YaramatiNo ratings yet

- Data Exploration in Python PDFDocument1 pageData Exploration in Python PDFTuncay SakaogluNo ratings yet

- Math6338 hw1Document5 pagesMath6338 hw1Ricardo E.No ratings yet