Professional Documents

Culture Documents

FRAMECAD Comparison Chart - 0815 PDF

Uploaded by

amazonfed2433Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FRAMECAD Comparison Chart - 0815 PDF

Uploaded by

amazonfed2433Copyright:

Available Formats

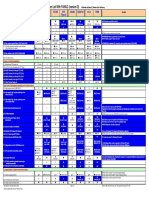

Model FRAMECAD F325iT FRAMECAD F450iT FRAMECAD TF550H

Description FRAMECAD Frame &Truss Plant FRAMECAD Frame & Truss Plant FRAMECAD Truss & Frame Plant

Design Software Options FRAMECAD Detailer and Detailer Plus

FRAMECAD Detailer and Detailer Plus

FRAMECAD Detailer and Detailer Plus

FRAMECAD Prodesign FRAMECAD Prodesign FRAMECAD Prodesign

Factory Software FRAMECAD Factory2 FRAMECAD Detailer and Detailer Plus FRAMECAD Factory2

Number and images of

Profiles

1xC 1xU 1xC 1xU 1xC 1xU

Assembly Method C in C C in C C in C

Profile Size Range 63 - 150mm (2.5 - 6) Dedicated, 75mm- 150mm (Standard: 89mm (3.5)) 75 - 150mm (3 - 6) Dedicated,

(Standard: 89mm (3.5)) (Standard: 89/150mm (3.5/6))

Material Thickness (BMT) 0.55- 1.15mm (24 - 18ga) 0.75- 1.55mm (22 - 16ga) 1.15 - 1.95mm (18 - 14ga)

Straightener - - 5 rolls: 2 over 3, chain coupled

Roll Forming Stations 10, Autogauging 11 Autogauging 14

Tooling Punches 11 (Service Hole, Web Notch, Lip Cut, 11 (Service Hole, Web Notch, Lip Cut, 11+1 (Service Hole, Web Notch, Lip Cut,

Flange Holes, Chamfer Cut, Swage, Flange Holes, Chamfer Cut, Swage, Chamfer Cut, Swage, Shear, Dimple,

Shear, Web Hole (Options), Flange cut Shear, Web Hole (Options), Flange cut Web Hole (Options), Flange cut left

left and right (Optional)) left and right (Optional)) + optional and right, Truss Hole, Spare)

custom extra 1(on request at time of

purchase of manufacturing system)

Typical Production Output 300m/hr - 750m/hr (985 ft/hr - 2,460ft/ 300 - 700m/hr TF550H: 300m/hr - 600m/hr

*1(actual dependent on hr) (985ft/hr - 1,970ft/hr)

framing design)

Max Line Speed Up to 1,750m/hr (5,740ft/hr) Up to 1,750m/hr (5,740ft/hr) TF550H: Up to 1,350m/hr (4,430ft/hr)

Main Drive Power (max) 7.5kW (10HP) 7.5KW (10HP) 11 kW (14.75HP)

Hydraulic Power 5.5kW (7.4HP) 5.5KW (7.4HP) TF550H: 7.5kW (10HP)

Hydraulic Reservoir*2 80L (21 gal) 80L (21 gal) 120L (32gal)

Ambient Temperature 0 - 40C 0 - 40C 0 - 40C

Range*3

Power Requirements*4 3 Phase, 400VAC, 25A, 50-60 Hz 3 phase, 400VAC, 25A, 50-60Hz TF550H:3 Phase, 400VAC, 40A,

50-60 Hz

Approximate Weight 1,700kg (3,748 lb) 1,820kg (4012 lbs) TF550H: 4,300kg (9,480lb)

Machine Dimension Length: 3.7m (12) Length: 4.5m (14 8) Length: 5.8m (19)

Width: 0.8m (27) Width: 0.8m (2 7) Width: 1.1m (32)

Height: 1.2m (4) to top of covers Height: 1.2m (4) Height: 1.4m (42) to top of covers

Recommended Floor Space 20m x 4m for decoiler, machine, run 20m x 4m (66 x 13) for decoiler, 23m x 4m for decoiler, machine, run

Needed out table machine and run out table. 20m x 12m out table

20m x 12m for rapid assembly kit, but (66 x 40) for rapid assembly kit but no 23m x 12m for rapid assembly kit, but

no storage storage no storage

Recommended Decoiler 3.5 - 4.5m behind the machine 3.5- 4.5 behind the machine 3.5 - 4.5m behind the machine

Position

Decoiler Capacity (Powered)*5 3,000kg (6,600lb) 3,000kg (6,600lb) Coil Outside Diameter 3,000kg (6,600lb)

Coil Outside Diameter 1,200mm (48) 1,200mm (48) Coil Outside Diameter 1,200mm (48)

Printer Yes Optional Yes

User Interface 21.5 Touch Screen 21.5 Touch Screen 21.5 Touch Screen

www.framecad.com/contact-us

*1 Estimated output depends on model, design complexity, component sizes and punching function. *2 Hydraulic Oil grade is dependent on ambient operating conditions *3 Based on Climate Class

EN60721-3-3, class3K3. *4 Please, contact FRAMECAD for additional precautions when using a standalone power supply. *5 Decoilers using 1,500mm coils can restrict maximum production rates. Due to

ongoing development specifications are subject to reconfirmation at time of ordering.

This document has been published for the purpose of providing information of a general nature only. Further, no guarantee, warranty, or any other form of assurance is given as to the accuracy, currency

or completeness of the information provided. Accordingly, any reliance on, or use, by you of any information contained within this document for any purpose whatsoever shall be entirely at your own risk,

and any liability to you is expressly disclaimed to the maximum extent permitted by law. FRAMECAD and the FRAMECAD logo are trademarks of FRAMECAD Ltd. Copyright 2015 FRAMECAD Ltd.

Reproduction of any part of this document is prohibited, except with the prior written consent of FRAMECAD Ltd.

FRAMECAD COMPARISON CHART 2015

Copyright 2015 FRAMECAD Ltd. All rights reserved 1

Model FRAMECAD FB150i FRAMECAD TM300iT FRAMECAD FL650

Description FRAMECAD Roof & Ceiling Batten Plant FRAMECAD Truss Plant FRAMECAD Flooring Plant

Design Software Options FRAMECAD Detailer and Detailer Plus

FRAMECAD Detailer and Detailer Plus

FRAMECAD Detailer and Detailer Plus

FRAMECAD ProDesign FRAMECAD Prodesign FRAMECAD ProDesign

Factory Software Cut to length controller FRAMECAD Factory2 FRAMECAD Factory2

Number and images of

Profiles

2x batten profiles - Ceiling and Roof 1xC 1xC 1xU

Assembly Method - Back to back C in U

Profile Size Range Roof batten: 40 x 87.5mm (1.57 x 75mm (3) Optimized 254 - 300mm (10-12) Dedicated,

3.45) (Standard: 300mm (12))

Ceiling batten: 22 x 61mm (.87 x 2.4)

Material Thickness (BMT) 0.40 - 0.75mm (26 - 22ga) 0.55 - 1.15mm (24 - 18ga) 1.15 - 2.25mm (18 - 12ga)

Straightener - - 6 rolls, 3 over 3, electric driven (Slave to

master drive)

Roll Forming Stations Roof Batten 9, Ceiling Batten 7 10, Autogauging 16

Tooling Punches - 4 (Flange cut - left and right; web triple 8 (Large service hole, Small service hole,

screw holes, Shear) Web tab cut, Web bolt hole, Flange bolt

hole, Flange screw hole, Flange lip cut,

Shear)

Typical Production Output 800m/hr (2,600ft/hr) 700m/hr (2,300ft/hr) 250m/hr - 600m/hr

*1(actual dependent on (825ft/hr - 1,970ft/hr)

framing design)

Max Line Speed Up to 1,200m/hr (4,000ft/hr) Up to 1,750m/hr (5,740ft/hr) Up to 1,350m/hr (4,430ft/hr)

Main Drive Power (max) 7.5kW (10HP) 7.5kW (10HP) 12kW (16HP)

Hydraulic Power 2.2kW (3.0HP) 5.5kW (7.4HP) 15kW (20HP)

Hydraulic Reservoir*2 40L (11 gal) 80L (21 gal) 200L (53gal)

Ambient Temperature 0 - 40C 0 - 40C 0 - 40C

Range*3

Power Requirements*4 3 Phase, 400VAC, 25A, 50-60 Hz 3 Phase, 400VAC, 25A, 50-60 Hz 3 Phase, 400VAC, 65A, 50-60 Hz

Approximate Weight 2,800 kg (4,400 lb) 1,820kg (4,012 lb) 13,000kg (28665lb)

Machine Dimension Length: 4.5m (149) Length: 3.7m (12) Length: 8.9m (29)

Width: 1.875m (62) Width: 0.8m (27) Width: 1.25m (41)

Height: 1.6m (53) Height: 1.2m (4) to top of covers Height: 1.4m (47) to top of covers

Recommended Floor Space 7m x 19m with fork hoist access from 20m x 4m for decoiler, machine, run out 24m x 4m for decoiler, machine and run

Needed one side of run out table table. 20m x 12m for rapid assembly kit, out for double joists, no storage

but no storage

Recommended Decoiler 3.5 - 4.5m behind the machine 3.5 - 4.5m behind the machine 3.5 - 4.5m behind the machine

Position

Decoiler Capacity (Powered)*5 2,000kg (4,400lb 3,000kg (6,600lb) 5,000kg (11,000lb)

Coil Outside Diameter 1,200mm (48) Coil Outside Diameter 1,200mm (48) Coil Outside Diameter 1,200mm (48)

Printer - Yes Yes

User Interface Separate controller with 200x150 (6x4) 21.5 Touch Screen 21.5 Touch Screen

Beck Cobalt Display

www.framecad.com/contact-us

*1 Estimated output depends on model, design complexity, component sizes and punching function. *2 Hydraulic Oil grade is dependent on ambient operating conditions *3 Based on Climate Class

EN60721-3-3, class3K3. *4 Please, contact FRAMECAD for additional precautions when using a standalone power supply. *5 Decoilers using 1,500mm coils can restrict maximum production rates. Due to

ongoing development specifications are subject to reconfirmation at time of ordering.

This document has been published for the purpose of providing information of a general nature only. Further, no guarantee, warranty, or any other form of assurance is given as to the accuracy, currency

or completeness of the information provided. Accordingly, any reliance on, or use, by you of any information contained within this document for any purpose whatsoever shall be entirely at your own risk,

and any liability to you is expressly disclaimed to the maximum extent permitted by law. FRAMECAD and the FRAMECAD logo are trademarks of FRAMECAD Ltd. Copyright 2015 FRAMECAD Ltd.

Reproduction of any part of this document is prohibited, except with the prior written consent of FRAMECAD Ltd.

FRAMECAD COMPARISON CHART 2015

Copyright 2015 FRAMECAD Ltd. All rights reserved 2

Model FRAMECAD ST800iT FRAMECAD ST1000-1200 FRAMECAD ST900iT

Description FRAMECAD Multi Profile Machine FRAMECAD Multi-profile framing, flooring FRAMECAD Multi Profile Heavy

and roofing system Flooring Machine

Design Software Options FRAMECAD Detailer and Detailer FRAMECAD Detailer and Detailer Plus FRAMECAD Detailer and Detailer Plus

PlusFRAMECAD ProDesign FRAMECAD ProDesign FRAMECAD ProDesign

Factory Software FRAMECAD Factory 2 FRAMECAD Factory2 FRAMECAD Factory 2

Number and images of Profiles

Multiple profiles (framing, flooring) Multiple profiles (framing, flooring) Multiple profiles (framing, flooring)

Assembly Method Stud and track C in U

Profile Size Range Widths: 4 Available 89-203mm (3.5-8) ST1000: 50-250mm (2-10) Multi-profile Widths: 4 Available 92-305mm (3 5/8

Flange Heights: 3 Available 41-63mm ST1200: 50-250mm (2-10) Multi-profile -12). Flange Heights: 3 Available 41-

(1.63-2.5) ST1200H: 89-300mm (3-12) Multi-profile 63mm (1.63-2.5)

Material Thickness (BMT) 0.75-1.55mm (22 - 16 gauge) ST1000: 0.55-1.55mm (24-16ga) 0.90 - 1.95mm (20 - 14 gauge)

ST1200: 0.75-1.95mm (22-14ga)

ST1200H: 0.75-1.95.0mm (22-14ga)

Straightener - 6 rolls, 3 over 3, electric driven (slave to -

master drive)

Roll Forming Stations 11 17 11

Tooling Punches 5 ST1000: 6 (including 1 multi process 6. Web holes, web notch, dimple screw

station) hole, flange screw holes, service hole

ST1200/ST1200H: 7 (including 1 multi and shear

process station)

Typical Production Output*1 300 - 1,200m/hr* (16.4 - 65.6 feet per 275m/hr - 640m/hr (900ft/hr - 2,100 ft/hr) 500 - 800m/hr* (16.4 - 65.6 feet per

(actual dependent on framing minute) minute)

design)

Max Line Speed 1,680m/hr (90 Feet per Minute) 1,600m/hr (5,250ft/hr) 1,680m/hr (90 Feet per Minute)

Main Drive Power 7.5KW (10HP) 6 AC Electro motors 19kW (25.5 HP) 7.5KW (10HP)

capacity with closed loop positioning (+/-

0.1mm)

Hydraulic Power 7.5KW (10HP) 11kW (14.75HP)+ accumulator 7.5KW (10HP)

Hydraulic Reservoir*2 80L (17 imp gal) 250L (66 gal) 80L (17 imp gal)

Ambient Temperature Range*3 0-40C 0 - 40C 0-40C

Power Requirements*4 3 phase, 380V(min) - 480V(max), 32A, 3 Phase, 400VAC, 65A, 50-60 Hz 3 phase, 380V(min) - 480V(max), 32A,

50-60Hz 50-60Hz

Approximate Weight 1,900kg - (4,190lbs) 14,000kg (30,864 lb) 2,100kg - (4,600lbs)

Machine Dimension Length: 4.25m (13.94) Length: 11m (36) Length: 4.88m - (16.01)

Width: 0.85m (2.79) Width: 2.7m (810) Width: 1.07m - (3.50)

Height: 1.30m (4.27) Height: 2.1m (611) +Hyd. Power pack Height: 1.60m - (5.25)

and MCC to one side

Recommended Floor Space 20m x 4m (66 x 13) for decoiler, 5.5m x 22m (decoiler, loop control, 20m x 4m (66 x 13) for decoiler,

Needed machine and run out table or 20m x machine, runout table, hydraulic power machine and run out table or 20m x

12m (66 x 40) for rapid assembly kit pack & cooler, MCC) 12m (66 x 40) for rapid assembly kit

but no storage but no storage

Recommended Decoiler 3.5 - 4.5m behind the machine 3 - 5 meters with loop control from the

Position in-feed guide

Decoiler Capacity (Powered)*5 3,000kg (6,600lb). Coil Outside 4,000kg (8800lb) (Single or dual head) 3,000kg (6,600lb). Coil Outside

Diameter 1,200mm (48) Coil Outside Diameter 1,550mm (61) Diameter 1,200mm (48)

maximum

Printer x 2 Ink Cartridge Yes x2 Ink Cartridge

User Interface 221.5 Touch Screen Networkable 21.5 Touch Screen FRAMECAD Factory 2

Linux 21.5 Touch Screen

Networkable Linux

www.framecad.com/contact-us

*1 Estimated output depends on model, design complexity, component sizes and punching function. *2 Hydraulic Oil grade is dependent on ambient operating conditions *3 Based on Climate Class

EN60721-3-3, class3K3. *4 Please, contact FRAMECAD for additional precautions when using a standalone power supply. *5 Decoilers using 1,500mm coils can restrict maximum production rates. Due to

ongoing development specifications are subject to reconfirmation at time of ordering.

This document has been published for the purpose of providing information of a general nature only. Further, no guarantee, warranty, or any other form of assurance is given as to the accuracy, currency

or completeness of the information provided. Accordingly, any reliance on, or use, by you of any information contained within this document for any purpose whatsoever shall be entirely at your own risk,

and any liability to you is expressly disclaimed to the maximum extent permitted by law. FRAMECAD and the FRAMECAD logo are trademarks of FRAMECAD Ltd. Copyright 2015 FRAMECAD Ltd.

Reproduction of any part of this document is prohibited, except with the prior written consent of FRAMECAD Ltd.

FRAMECAD COMPARISON CHART 2015

Copyright 2015 FRAMECAD Ltd. All rights reserved 3

You might also like

- FRAMECAD Comparison Chart 0815Document3 pagesFRAMECAD Comparison Chart 0815Gurjit SidhuNo ratings yet

- RACORDocument25 pagesRACORDaniel LaymeNo ratings yet

- Radial Drilling Machine: FRD-750S / FRD-900S FRD-1100SDocument4 pagesRadial Drilling Machine: FRD-750S / FRD-900S FRD-1100SMichell HernandezNo ratings yet

- Piccola Data SheetDocument2 pagesPiccola Data SheetDaniel ZabalaNo ratings yet

- FCR Prima t2 BrochureDocument2 pagesFCR Prima t2 BrochureBagoes PrasetyoNo ratings yet

- COP 1640+ / COP 1640EX: ServiceDocument2 pagesCOP 1640+ / COP 1640EX: ServiceESRA0% (1)

- Technical Specifications - ProcessorDocument12 pagesTechnical Specifications - ProcessorMilos GacparNo ratings yet

- DownloadDocument2 pagesDownloadAHMED KAMESHNo ratings yet

- Mirage Drilling Machine HT50Document3 pagesMirage Drilling Machine HT50Maria Dennis100% (1)

- SD-175 Vibratory Soil Compactor PRO-PAC™Document2 pagesSD-175 Vibratory Soil Compactor PRO-PAC™Mandiri Jaya BersamaNo ratings yet

- APS-TDS-SureDrill-Drilling-Dynamics-Monitor Real TimeDocument2 pagesAPS-TDS-SureDrill-Drilling-Dynamics-Monitor Real TimeGharib HashemNo ratings yet

- English - 325it 2014Document1 pageEnglish - 325it 2014Denis AkingbasoNo ratings yet

- 2171-4001 20 Rsx-CatDocument18 pages2171-4001 20 Rsx-CatCarlos Bruno MatosNo ratings yet

- Smart Mag™ Non Rotating String Magnet BlackDocument4 pagesSmart Mag™ Non Rotating String Magnet BlackAjith MohandasNo ratings yet

- SD-180 Vibratory Soil Compactor PRO-PAC™Document2 pagesSD-180 Vibratory Soil Compactor PRO-PAC™KasidinNo ratings yet

- SD-70 PRO-PAC™ Vibratory Soil Compactor: Standard FeaturesDocument2 pagesSD-70 PRO-PAC™ Vibratory Soil Compactor: Standard Featuresfernando medinaNo ratings yet

- Fujifilm FCR Prima T2 Brochure With Logo Ver. Dec. 2017Document2 pagesFujifilm FCR Prima T2 Brochure With Logo Ver. Dec. 2017luilorna27No ratings yet

- Imes-Icore Coritec Product Catalogue 2021 - Eng - Web 2Document24 pagesImes-Icore Coritec Product Catalogue 2021 - Eng - Web 2Hanganu AndreiNo ratings yet

- Thunder CGN Physical Appliance: Spec SheetDocument7 pagesThunder CGN Physical Appliance: Spec SheetPyae Sone TunNo ratings yet

- Technical Specifications ROMI C SeriesDocument28 pagesTechnical Specifications ROMI C Seriesmetall 4uNo ratings yet

- Includes Applications: Truck Mounted X-CELERATORDocument2 pagesIncludes Applications: Truck Mounted X-CELERATORinvidiuo0% (1)

- SD-100 PRO-PAC™ Vibratory Soil CompactorDocument2 pagesSD-100 PRO-PAC™ Vibratory Soil Compactorbayu enasoraNo ratings yet

- Man TGM & Man TGL - Specifications: ChassisDocument3 pagesMan TGM & Man TGL - Specifications: ChassisPhu DNNo ratings yet

- MM TL HT Drills Us 070 0119Document3 pagesMM TL HT Drills Us 070 0119pashaNo ratings yet

- Kalmar ECH Technical ChartDocument1 pageKalmar ECH Technical ChartAbdelhadi HoussinNo ratings yet

- Machine Doctor Technical Specsv 3Document2 pagesMachine Doctor Technical Specsv 3Karn DeeyingNo ratings yet

- Brochure dd70 dd70hf t2 en 21 20000257 CDocument4 pagesBrochure dd70 dd70hf t2 en 21 20000257 CJoshwa SimamoraNo ratings yet

- M70-700 (M) Functions Compare With Fanuc-Ver.D (ENG)Document2 pagesM70-700 (M) Functions Compare With Fanuc-Ver.D (ENG)Syahrul AbidinNo ratings yet

- Dyadic Mechatronics Cylinder CatalogDocument16 pagesDyadic Mechatronics Cylinder CatalogJuan Francisco Sanchez MassadiNo ratings yet

- Cisco Network Convergence System 540 Small Density RoutersDocument15 pagesCisco Network Convergence System 540 Small Density RoutersMohsen GoodarziNo ratings yet

- Smart Mag™ Non Rotating String Magnet WhiteDocument4 pagesSmart Mag™ Non Rotating String Magnet WhiteAjith MohandasNo ratings yet

- Key Advantages: Amazing Versatility. Unmatched DependabilityDocument3 pagesKey Advantages: Amazing Versatility. Unmatched DependabilitysubhankarNo ratings yet

- Volvo Double Drum CompactorsDocument4 pagesVolvo Double Drum CompactorsAhmadNo ratings yet

- Drake External Brochure EnglishDocument3 pagesDrake External Brochure EnglishSuresh GujjarNo ratings yet

- Ingersoll Rand Compactor Rollers Spec c97d04Document2 pagesIngersoll Rand Compactor Rollers Spec c97d04Tamquadistu Alex100% (1)

- JWX-10 Product Guide: Roland DG CorporationDocument21 pagesJWX-10 Product Guide: Roland DG CorporationSupport BiomedNo ratings yet

- 160 Series: HYUNDAI WIA Efficient Type CNC Turning CenterDocument20 pages160 Series: HYUNDAI WIA Efficient Type CNC Turning CenterAleksei MakarevichNo ratings yet

- 101475Document12 pages101475KantishNo ratings yet

- Programmable Focusing Optic: Scanner Optics For Welding and Vapor Pressure CuttingDocument2 pagesProgrammable Focusing Optic: Scanner Optics For Welding and Vapor Pressure CuttingRafael SchroerNo ratings yet

- 01 Manual de Mantenimiento Del RobotDocument10 pages01 Manual de Mantenimiento Del RobotCarlos Eduardo Segura VillarrealNo ratings yet

- Nutanix Spec SheetDocument1 pageNutanix Spec SheetShukur SharifNo ratings yet

- The Snack Food Bagmaker: Ishida Co.,LtdDocument4 pagesThe Snack Food Bagmaker: Ishida Co.,Ltdmanoel batista de c. filho100% (1)

- Productbrochure Pf4410 Volvo Tracked PaverDocument4 pagesProductbrochure Pf4410 Volvo Tracked PaverPaul GuillaumeNo ratings yet

- Kenwood NXDN-MotoTRBO-ICOM iDAS Digital Repeater Spec Comparison ChartDocument1 pageKenwood NXDN-MotoTRBO-ICOM iDAS Digital Repeater Spec Comparison ChartSparky01100% (2)

- Ils User GuideDocument126 pagesIls User GuideTom WasilewskiNo ratings yet

- Fanatics: CaraudioDocument16 pagesFanatics: CaraudioddautosoundNo ratings yet

- Dyadic Systems CatalogDocument14 pagesDyadic Systems CatalogJuan Francisco Sanchez MassadiNo ratings yet

- Mini Excavators - 8040, 8045 Zts and 8050 RTS/ZTS: Static DimensionsDocument6 pagesMini Excavators - 8040, 8045 Zts and 8050 RTS/ZTS: Static DimensionsMagyar Plazma és Lézervágó CNC MűvekNo ratings yet

- Plotter PDFDocument13 pagesPlotter PDFClifford RyanNo ratings yet

- Brochure-Filter Press.-TORODocument12 pagesBrochure-Filter Press.-TOROSebastian Gomez BetancourtNo ratings yet

- Bobcat Compact Track Loaders Loader T250 T300 T320 T140Document2 pagesBobcat Compact Track Loaders Loader T250 T300 T320 T140LTATECNICONo ratings yet

- 19 TWA TN Koma-Tsudakoma-23.0-finalDocument2 pages19 TWA TN Koma-Tsudakoma-23.0-finalDong BuiNo ratings yet

- Tork Drive WFT081738Document10 pagesTork Drive WFT081738CARLOS SANCHEZNo ratings yet

- C H, C H: Pneumatic Tired CompactorDocument2 pagesC H, C H: Pneumatic Tired CompactorVlad SuteuNo ratings yet

- Tire Building 1Document12 pagesTire Building 1Silvia CastilloNo ratings yet

- Climax Od Mount Flange Facers: Versatility. Durability. SafetyDocument12 pagesClimax Od Mount Flange Facers: Versatility. Durability. SafetyGerlianeNo ratings yet

- Volant Specs CRTi4-7.01 PDFDocument5 pagesVolant Specs CRTi4-7.01 PDFRaymond ChuNo ratings yet

- BMW 3 Series Sedan-G20-BroDocument23 pagesBMW 3 Series Sedan-G20-Broamazonfed2433No ratings yet

- Valaisinluettelo - 2016-2017 - en - 180dpi KJHHDocument192 pagesValaisinluettelo - 2016-2017 - en - 180dpi KJHHamazonfed2433No ratings yet

- 19-41-Industry-Brochure-Gb-Int JinDocument70 pages19-41-Industry-Brochure-Gb-Int Jinamazonfed2433No ratings yet

- 20 - 26-GB-int - E-Line - Next - LED KJLHDocument98 pages20 - 26-GB-int - E-Line - Next - LED KJLHamazonfed2433No ratings yet

- WelcomeDocument5 pagesWelcomeCatNo ratings yet

- Welcome To PDF ExpertDocument9 pagesWelcome To PDF ExpertSholihin NafarNo ratings yet

- Beginners - Guide - To - Selling - On - Amazon HHKJDocument9 pagesBeginners - Guide - To - Selling - On - Amazon HHKJamazonfed2433No ratings yet

- WelcomeDocument5 pagesWelcomeCatNo ratings yet

- Rothoblaas en Membranes and Tapes 01 17Document220 pagesRothoblaas en Membranes and Tapes 01 17amazonfed2433No ratings yet

- The Endless Possibilities of Cold Formed Steel Applications - Ebook (UK)Document28 pagesThe Endless Possibilities of Cold Formed Steel Applications - Ebook (UK)amazonfed2433No ratings yet

- ETA 07 0260 HIT-RE 500-SD Injection Mortar For Anchoring Application ETAG 001-05 Option 1 Approval Document ASSET DOC APPROVAL 0152Document52 pagesETA 07 0260 HIT-RE 500-SD Injection Mortar For Anchoring Application ETAG 001-05 Option 1 Approval Document ASSET DOC APPROVAL 0152Marcelo San MartinNo ratings yet

- 12', 18', 24' and 30' GSI Commercial Tower Dryer: Construction Manual PNEG-707Document446 pages12', 18', 24' and 30' GSI Commercial Tower Dryer: Construction Manual PNEG-707Rotiseria La FlammeNo ratings yet

- Accessories and Equipment Body-Interior & Exterior - Ram PickupDocument614 pagesAccessories and Equipment Body-Interior & Exterior - Ram PickupcharlesNo ratings yet

- Bucket Elevator Catalog Engg ManualDocument43 pagesBucket Elevator Catalog Engg ManualRodel RentaNo ratings yet

- WOOD Magazine - July 2013Document80 pagesWOOD Magazine - July 2013Filip Dan100% (7)

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument97 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedRAFEEQ PASHANo ratings yet

- Section 6. Shell Plating PDFDocument28 pagesSection 6. Shell Plating PDFMuhammadIlhamNugrohoNo ratings yet

- Despiece Pulsar 200NSDocument84 pagesDespiece Pulsar 200NSCocoman Seba Cuentas67% (6)

- FlyweelDocument6 pagesFlyweelTalebNo ratings yet

- CADET Catalogue - 1Document14 pagesCADET Catalogue - 1Алмаз КенжетаевNo ratings yet

- M SR 0008 PDFDocument2 pagesM SR 0008 PDFMoh DeBrNo ratings yet

- Hyg Dx77a ManualDocument14 pagesHyg Dx77a Manualve7eoeNo ratings yet

- Davis VP2 Manual Temp STN Rev ADocument12 pagesDavis VP2 Manual Temp STN Rev AphilaskNo ratings yet

- The Chair SuspensionDocument8 pagesThe Chair SuspensionChris BrookesNo ratings yet

- Anchor Bolt CalculationDocument4 pagesAnchor Bolt CalculationYash SutharNo ratings yet

- X ( J / ËEÚŒ ( EÚ - EÚ Æ ( Æ "I HDocument8 pagesX ( J / ËEÚŒ ( EÚ - EÚ Æ ( Æ "I HTuna garadaNo ratings yet

- ASSESSMENT G8 TLE q2Document2 pagesASSESSMENT G8 TLE q2Maria Chelo AgosNo ratings yet

- Mp20X FBW - Mp20X FBW Fixed (D843) Parts Manual: Yale Europe Materials Handling LimitedDocument204 pagesMp20X FBW - Mp20X FBW Fixed (D843) Parts Manual: Yale Europe Materials Handling LimitedMoysess Oliver100% (3)

- Weights and Loads - ElfaDocument2 pagesWeights and Loads - ElfaEtibar AliyevNo ratings yet

- Zintek 200 Spec SheetDocument6 pagesZintek 200 Spec SheetellisforheroesNo ratings yet

- TAYTAY BID FORM - OdsDocument42 pagesTAYTAY BID FORM - OdsDavid Raphael CaÑaresNo ratings yet

- Machinists Screw JackDocument3 pagesMachinists Screw Jackmauri_ros100% (1)

- Tectos Falsos Stretch Caracteristicas TecnicasDocument37 pagesTectos Falsos Stretch Caracteristicas TecnicasVadymNo ratings yet

- Model FCDocument23 pagesModel FCLeandroNo ratings yet

- Wire Jacketing Nylon FirestoneDocument14 pagesWire Jacketing Nylon FirestoneAndres Valencia MiraNo ratings yet

- OTA Fiberglass Pipe Shaver 2020Document10 pagesOTA Fiberglass Pipe Shaver 2020Ralf Woolf100% (1)

- Elora Tool Catalogue E90Document532 pagesElora Tool Catalogue E90ivanrahadiyanNo ratings yet

- Vergokan 2017 Cable LadderDocument115 pagesVergokan 2017 Cable LadderAlin MoicaNo ratings yet

- Question Bank 03062016Document7 pagesQuestion Bank 03062016Babu NarayananNo ratings yet

- Screw PointDocument2 pagesScrew PointGaurav RelanNo ratings yet