Professional Documents

Culture Documents

KE TPRE SOP TK 607 SOP For Management of Toolkits

Uploaded by

Shaharyar WaliullahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KE TPRE SOP TK 607 SOP For Management of Toolkits

Uploaded by

Shaharyar WaliullahCopyright:

Available Formats

The Karachi Electric Limited

TPRE (Distribution)

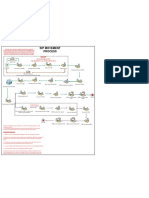

Standard Operating Procedure SOP # : KE / TPRE / SOP / TK / 607

Management of Toolkit for Various Jobs in KE Dist. Network

PREPARED, REVIEWED AND APPROVED

Name Designation Dept Signature

Approved By

Chief HSEQ & Special

Amir Zafar DS&P

Distribution Project

Azhar Hussain Advisor TPRE

Jamil Gul Shaikh Advisor E&C

Humayun Saghir

Head R-I

Sheikh

Muhammad Siddiq Head R-II

Arshad Iftikhar Head R-III

Rashid Hussain Head R-IV

Imdad Afzal Deputy Director IM

Azhar Masud Deputy Director MM

Usman Ahmed Khan GM Procurement

Adnan Shaikh GM Meter

Reviewed By

Irfan Azam /

GM TPRE

Obedullah Tufail

Prepared By

Sakhawat Ali /

DM / AM TPRE

Abdul Ghaffar

Rev. Date Page #.

Page 1 of 5

00 July 26, 2016

The Karachi Electric Limited

TPRE (Distribution)

Standard Operating Procedure SOP # : KE / TPRE / SOP / TK / 607

Management of Toolkit for Various Jobs in KE Dist. Network

Index

1. SOP No. KE/TPRE/TK/607 (Rev 00) dated July 26, 2016

Rev. Date Page #.

Page 2 of 5

00 July 26, 2016

The Karachi Electric Limited

TPRE (Distribution)

Standard Operating Procedure SOP # : KE / TPRE / SOP / TK / 607

Management of Toolkit for Various Jobs in KE Dist. Network

Standard Operating Procedure for

Management of Toolkit for Various Jobs in KE Distribution Network

Rev. Date Page #.

Page 3 of 5

00 July 26, 2016

The Karachi Electric Limited

TPRE (Distribution)

Standard Operating Procedure SOP # : KE / TPRE / SOP / TK / 607

Management of Toolkit for Various Jobs in KE Dist. Network

0.0 Foreword

0.1 This SOP has been prepared by Technical Process Re-Engineering (TPRE) Department

0.2 This SOP is subject to revision as and when required.

1.0 Objective

1.1 This SOP defines the procedure and guideline for the procurement and management of toolkit for

various jobs on site, as and when required. The standard toolkit has been prepared for various gangs

/ teams for smooth, safe and comfortable performance of work.

2.0 Scope

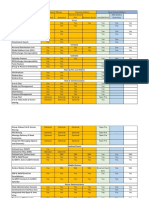

2.1 Eleven numbers of standard toolkits have been developed for lineman, jointer, fitter and meter

installation team working at site. List has been mentioned as follows:

Serial Number Toolkit User Department / Section

1 Lineman HT Mains

2 Lineman HT Operation

3 Lineman HT Underground

4 Lineman LT Network

5 Lineman (HT ABC) E&C

6 Lineman (LT ABC) E&C / IBCs

7 Fitter HT Network

8 Fitter LT Network

9 Jointer HT Underground

10 Jointer LT Underground / IBCs

11 Meter Installation Team Meter Department / IBCs

3.0 Procedure:

3.1 Accumulative material requisition (MR) shall be prepared by taking demand from all concerned

users as per their need and requirement and shall be forwarded to material management (MM)

3.2 MM shall evaluate the MR and the same shall be forwarded to inventory management (IM)

department for creation of purchase requisition (PR)

Rev. Date Page #.

Page 4 of 5

00 July 26, 2016

The Karachi Electric Limited

TPRE (Distribution)

Standard Operating Procedure SOP # : KE / TPRE / SOP / TK / 607

Management of Toolkit for Various Jobs in KE Dist. Network

3.3 IM department after preparation of PR, shall forward it to procurement for procurement as per

procedure

3.4 After tendering and receiving of technical and commercial submittal of toolkit from prequalified

vendors, the technical submittal along with sample shall be forwarded to TPRE for technical

evaluation (TE) comprising of all requirements as mentioned in relevant specs

3.5 After successful technically approved vendor from TPRE, the toolkits shall be procured and

provided to respective user as per their need and requirement

4.0 Responsibility and Issuance Mechanism:

4.1 Toolkit will be issued to the concerned departmental head after proper documentation on SAP. The

same will then be given to the concerned line managers for issuing it to the authorized field staff.

4.2 Authorized field staff such as lineman, fitter, jointer, AOC supervisors etc. are responsible to take

care of all the tools and equipment issued.

4.3 Any missing tool has to be reported immediately to the concerned head of department. For major

tools like ratchets, crimping machine, power master etc., missing of tool has to be reported along

with FIR to the concerned departmental head.

5.0 Duration for Replacement of Tools / Equipments:

5.1 In case of any loss / damage of any tool in the toolkit, the separate MR for only that specific tool

with item / material code will be generated for procurement after approval from concerned GM.

5.2 The damaged tool / equipment shall be submitted / credited in central store before issuance of new

one.

5.3 In case of loss of toolkit item, a proper justification will be submitted to head of department (HOD)

and the new MR will be generated with the approval of concerned GM

6.0 Toolkit Check:

6.1 The use of toolkit item shall follow the safety procedure and practices

6.2 After finish of work / prior to leave from site, all tool items shall be checked and packed properly

Rev. Date Page #.

Page 5 of 5

00 July 26, 2016

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ybersecurity ISK Ssessment: ACME Technologies, LLCDocument15 pagesYbersecurity ISK Ssessment: ACME Technologies, LLCStephen Wilcox100% (2)

- 11KV Network Manual - V.1Document215 pages11KV Network Manual - V.1Shaharyar Waliullah80% (5)

- CSS Beginners Guide (2017-18) PDFDocument66 pagesCSS Beginners Guide (2017-18) PDFSaad Ahsan100% (1)

- LT ABC Line Isolation: (KE/TPRE/SOP/605)Document15 pagesLT ABC Line Isolation: (KE/TPRE/SOP/605)Shaharyar WaliullahNo ratings yet

- LineDocument4 pagesLineShaharyar WaliullahNo ratings yet

- English (P&C) (11) Subjective-2016Document2 pagesEnglish (P&C) (11) Subjective-2016atif RazzaqNo ratings yet

- Sip Movement Process: No Tracking/control No Deadlines For Clearing The FilesDocument2 pagesSip Movement Process: No Tracking/control No Deadlines For Clearing The FilesShaharyar WaliullahNo ratings yet

- PublicDocument1 pagePublicShaharyar WaliullahNo ratings yet

- Consumer Service Manual - NEPRADocument66 pagesConsumer Service Manual - NEPRAstubborn002No ratings yet

- 11KV Network Manual - V.0Document232 pages11KV Network Manual - V.0Shaharyar Waliullah0% (1)

- Brochure 3Document2 pagesBrochure 3Shaharyar WaliullahNo ratings yet

- Lec01 - Introduction To ESDDocument24 pagesLec01 - Introduction To ESDShaharyar WaliullahNo ratings yet

- Engro 25 10amDocument2 pagesEngro 25 10amShaharyar WaliullahNo ratings yet

- Sop # Ke-Tpre-Sop-606 (Sop For HT ABC Line Isolation)Document16 pagesSop # Ke-Tpre-Sop-606 (Sop For HT ABC Line Isolation)Shaharyar WaliullahNo ratings yet

- Embedded Assignment 01Document6 pagesEmbedded Assignment 01Shaharyar WaliullahNo ratings yet

- Model United Nations in Nust-Pnec (Muninp)Document19 pagesModel United Nations in Nust-Pnec (Muninp)Shaharyar WaliullahNo ratings yet

- ESD Lab02Document8 pagesESD Lab02Shaharyar WaliullahNo ratings yet

- Compressive Wireless Data Transmissions UnderDocument9 pagesCompressive Wireless Data Transmissions UnderShaharyar WaliullahNo ratings yet

- Inter-Router Wireless Scalable Express Channels ForDocument8 pagesInter-Router Wireless Scalable Express Channels ForShaharyar WaliullahNo ratings yet

- Tanhai K Safar MeinDocument1 pageTanhai K Safar MeinShaharyar WaliullahNo ratings yet

- Transducers Updated SlidesDocument88 pagesTransducers Updated SlidesShaharyar WaliullahNo ratings yet

- Transmission of Adaptive MPEG Video OverDocument12 pagesTransmission of Adaptive MPEG Video OverShaharyar WaliullahNo ratings yet

- 004 1 EE 232 Signals and SystemsDocument2 pages004 1 EE 232 Signals and SystemsShaharyar WaliullahNo ratings yet

- On Measuring Memory Length of The ErrorDocument6 pagesOn Measuring Memory Length of The ErrorShaharyar WaliullahNo ratings yet

- Dengue PresentationDocument1 pageDengue PresentationShaharyar WaliullahNo ratings yet

- Irfan Ahmed (UrfiDocument1 pageIrfan Ahmed (UrfiShaharyar WaliullahNo ratings yet

- IBCC Equilence Form For O/A Levels.Document5 pagesIBCC Equilence Form For O/A Levels.Hubbak Khan100% (1)

- Cplusplus4c Ebooks StlbookDocument95 pagesCplusplus4c Ebooks StlbookAZOGTHOTHNo ratings yet

- Hello My Name Is Ali and I Am 8 Years Old .How Are You?Document1 pageHello My Name Is Ali and I Am 8 Years Old .How Are You?Shaharyar WaliullahNo ratings yet

- Final Pre Medical Gaz Annual 2013 Part IIDocument103 pagesFinal Pre Medical Gaz Annual 2013 Part IIShaharyar WaliullahNo ratings yet

- General - Introduction - ZWCAD 2021Document22 pagesGeneral - Introduction - ZWCAD 2021Trung ĐứcNo ratings yet

- Standardized Design Environment and Methodologies Enable Simultaneous Implementation of 28nm Designs With A Single FlowDocument31 pagesStandardized Design Environment and Methodologies Enable Simultaneous Implementation of 28nm Designs With A Single FlowAnand Parakkat ParambilNo ratings yet

- Restaurant Automation System: Software Requirements SpecificationDocument12 pagesRestaurant Automation System: Software Requirements SpecificationPrasannajit sahooNo ratings yet

- Big Data Ibm 2014Document33 pagesBig Data Ibm 2014John DoeNo ratings yet

- SD01 - Solution Design Document BPIDocument113 pagesSD01 - Solution Design Document BPIqkhan2000100% (1)

- Software Measurement: Function Point Analysis (Albrect)Document5 pagesSoftware Measurement: Function Point Analysis (Albrect)Badsector CkNo ratings yet

- QIM Integration With Audit Management & Quality ManagementDocument7 pagesQIM Integration With Audit Management & Quality ManagementAbhijeet MhatreNo ratings yet

- List of Information Technology (IT) Companies in NoidaDocument17 pagesList of Information Technology (IT) Companies in NoidaDigital ServiceNo ratings yet

- Daniel Roe:, MS, PMP, CLSSBBDocument6 pagesDaniel Roe:, MS, PMP, CLSSBBAmlinsys IncNo ratings yet

- R Market - Page 4Document22 pagesR Market - Page 4Sebastian GhermanNo ratings yet

- Passenger Flow Detection Management Platform (English Version)Document14 pagesPassenger Flow Detection Management Platform (English Version)Mafosk8No ratings yet

- Appointment Scheduling (DAS) ADMIN GUIDE EWM940Document19 pagesAppointment Scheduling (DAS) ADMIN GUIDE EWM940raviNo ratings yet

- Yerra Solutions Global KM Expert Group KM UTBMS Code SetDocument9 pagesYerra Solutions Global KM Expert Group KM UTBMS Code SetsubscriptionNo ratings yet

- Bizathon 8 Notes by RitoDocument18 pagesBizathon 8 Notes by RitoVanama TejaNo ratings yet

- E-Commerce U4 PDFDocument12 pagesE-Commerce U4 PDFMunavalli Matt K SNo ratings yet

- Managing The IT Procurement Process - MDocument12 pagesManaging The IT Procurement Process - MEli RayNo ratings yet

- Accounts Receivable and Credit Collection ReportDocument27 pagesAccounts Receivable and Credit Collection Reportbob2nkongNo ratings yet

- E-Government Literature ReviewDocument4 pagesE-Government Literature Reviewxvszcorif100% (1)

- Blockchain SCMDocument21 pagesBlockchain SCMTrí NghiênNo ratings yet

- Commerce Major Syllabus For U.G. (Session 2021-22) 171Document33 pagesCommerce Major Syllabus For U.G. (Session 2021-22) 171ALANKRIT TRIPATHINo ratings yet

- Ems Muthu and NarenDocument11 pagesEms Muthu and NarenRejones 7No ratings yet

- SE3201 - Software Design and ArchitectureDocument6 pagesSE3201 - Software Design and Architectureنوره داعجNo ratings yet

- Microsoft Office 2010 Product Key Full Crack Download (Latest)Document1 pageMicrosoft Office 2010 Product Key Full Crack Download (Latest)Lamsaaf MohamedNo ratings yet

- 5 Emails To Trigger An Instant Buying Frenzy From Your ListDocument20 pages5 Emails To Trigger An Instant Buying Frenzy From Your ListMidnight SunNo ratings yet

- Profile Summary: Sindhu RaoDocument3 pagesProfile Summary: Sindhu RaoVijay SamuelNo ratings yet

- Innovation and Product Development British English Teacher Ver2Document4 pagesInnovation and Product Development British English Teacher Ver2kitmengNo ratings yet

- Zimbra Feature ComparisonDocument4 pagesZimbra Feature ComparisonKanthanathan SNo ratings yet

- Project On AnalysisDocument33 pagesProject On Analysismohamed samiNo ratings yet

- Memo - RCSP DocumentationDocument3 pagesMemo - RCSP DocumentationMaria LeeNo ratings yet