Professional Documents

Culture Documents

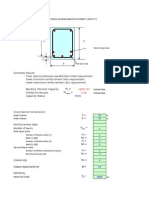

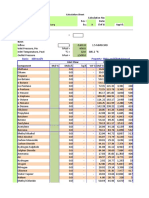

Material Properties

Uploaded by

CelineKevinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Properties

Uploaded by

CelineKevinCopyright:

Available Formats

Material Chemical Composition Physical Properties Mechanical Properties Thermal Properties

Tensile strength : 655 Mpa

Yield strength : 415 Mpa

Bulk modulus : (typical for steel) 140 Gpa

Shear modulus : (typical for steel) 80 Gpa

Elastic modulus : 190-210 Gpa

Poisson's ratio : 0.27-0.30 Thermal expansion co-efficient

Steel (4140) Cr (0.8-1.1), Mn (0.75-1.0),C (0.38-0.43), Density 7.85 g/cm3 Elongation at break (in 50 mm) : 25.7% (@ 0-100C/32-212F) : 12.2

Si (0.15-0.30), S (0.04), P (0.035) melting point 1416C m/mC Thermal conductivity

Hardness, Brinell : 197 (@ 100C) : 42.6 W/mK

Hardness, Knoop : 219

Hardness, Rockwell B : 92

Hardness, Rockwell C : 13

Hardness, Vickers : 207

Machinability (based on AISI 1212 as 100 machinability) : 65

Tensile strength : 6517 Mpa

Yield strength : 4827 Mpa

Elastic modulus : 110-125 Gpa Thermal expansion co-efficient

Ti (89.85-94), Al (4-6), Sn (2-3), Fe ( Density 4.48 g/cm3 shear modulus : 48 Gpa (@0.000-100C/32-212F): 9.40

Ti (5Al-

0.50) , O ( 0.20) , C ( 0.10), N( 0.30), melting point 1590 Elongation Break : 15% m/mC5.22 in/inF Thermal

2.5Sn)

H ( 0.15), Other ( 0.30) C Hardness, Brinell : 320 conductivity : 7.80 W/mK54.1

BTU in/hr.ft.F

Hardness, Knoop : 363

Hardness, Rockwell C : 36

Hardness Vickers : 349

Tensile Strength @ Room Temp., psi :100,000 500,000

Atomic weight : 183.85 Tensile Strength @ 500 C, psi : 75,000 200,000

Thermal Conductivity @ 20 C

g/ g atom

Tensile Strength @ 1000 C, psi : 50,000 75,000 (cal/cm/C/sec) : 0.40

W pure - Density :19.25 g.cm-3

Linear Coefficient of

melting point : 3410C Hardness, Brinell : 2570

Expansion per C : 4.3 x 10E-6

Boiling point : 5530C Hardness ,Vicker : 3430

Poissons Ratio : 0.284

Tensile strength : 372-517 MPa

Yield strength (depending on temper) : 88.0-483 MPa

Thermal expansion co-efficient

Density : 8.94 g/cm3 Elongation at break (in 381 mm) : 45%

(@20-300C/68-572F) : 16.2

Cu (71500) Cu (0.7), Ni (0.3) melting point : Elastic modulus : 117 GPa

m/mC Thermal conductivity

1171C Poissons ratio : 0.34 (@20C/ 68F ) : 29 W/mK

Machinability (UNS C36000 (free-cutting brass) = 100) : 20

Shear modulus : 57.0 GPa

Al (balance), Mg (0.8-1.2), Si(0.4 0.8), Ultimate Tensile (T=0) : 110-152 Mpa Co-Efficient of Thermal

Density: 2.7 g/cm3 0.2% Proof Stress (T=0) : 65-110(MPa)

iron (Max. 0.7), copper (0.15-0.40), Zn Expansion (20-100C): 23.5x10-

Al 6061 Melting Point: Approx

(Max. 0.25), Ti (Max. 0.15), Mn (Max. Brinell Hardness (500kg load, 10mm ball, T=0) : 30-33 6 m/m.C Thermal

580C

0.15), Cr (0.04-0.35), other (0.05) Conductivity: 173 W/m.K

elongation (50mm dia, T-0) : 14-16%

Hardness, Brinell : 111

Hardness, Knoop (Converted from Brinell hardness) :129

C (0.17 - 0.230 %), Fe(99.08 - 99.53 %),

Hardness, Rockwell B(Converted from Brinell hardness) :64

Hardness, Vickers (Converted from Brinell hardness) : 115

C (0.17 - 0.230 %), Fe(99.08 - 99.53 %), Tensile Strength, Ultimate : 394.72 MPa

steel 1020 Mn (0.30 - 0.60 %), P ( 0.040 %), S ( density : 7.87 g/cc Tensile Strength, Yield : 294.74 MPa

0.050 %) Elongation at Break (in 50 mm) : 36.5 %

Reduction of Area : 66.0 %

Modulus of Elasticity (Typical for steel) : 200 GPa

Bulk Modulus (Typical for steel) : 140 GPa

Poissons Ratio : 0.290

Melting point : 231.96 tensile strength : 220 Mpa Thermal expansion co-efficient

C boiling point : 2602 Modulus of elasticity : 41.6 Gpa (@-50C/-58F) : 5.40 m/mC

tin pure

C density : 5.765 Shear modulus : 15.6 Gpa Thermal conductivity : 63.2

g/cm3 Hardness, Brinell : 2.3 W/mK

melting point : elastic (Young's) modulus : 80 to 125 GPa

Thermal conductivity : 21.6 W m-

Pure Ti 3,000 F Poisson's ratio : 0.287 to 0.391 1.K-1

density : 4.51g/cc Tensile strength ; 240 MPa -1400 MPa

Tensile strength : 900 MPa

Poissons ratio : 0.35

Density : 16.65 g/cm3 Modulus of elasticity : 186 GPa Co-Efficient of Thermal

Melting point : 2850 Shear modulus : 186 GPa Expansion : 6.50 m/mC

Pure Ta

C Boiling point : Hardness, Brinell : 195 Thermal Conductivity: 54.4

6000 C Hardness, rockwell B: 92 W/mK

Hardness, Rockwell C : 12

Hardness Vickers : 200

Tensile strength : 10 to 30 GPa

Shear strength (torsional strain rate 0.25/s) : 500MPa Imperial

Modulus Elasticity : 330 Gpa Imperial

Poissons Thermal expansion coefficient

Pure Mo Density : 0.3 g/cm melting pointratio : 0.38

: 2,623 C

Hardness, Brinell : 225 (@20C/68F) : 5.35 m/mC

Thermal conductivity : 138

Hardness, rockwell B: 98

W/mK

Hardness, Rockwell C : 19

Hardness Vickers : 230

You might also like

- Structural SpecsDocument42 pagesStructural SpecsJosh Jaymes MasseNo ratings yet

- T500 VeeyesDocument5 pagesT500 VeeyesTimothy TaylorNo ratings yet

- Stress Analysis ReportDocument123 pagesStress Analysis ReportNOXOLO PETUNIA SAMBONo ratings yet

- Note of Use of The Linear Solver in AsterDocument28 pagesNote of Use of The Linear Solver in AsterTran TuyenNo ratings yet

- KFHC TPB Reguler ZfactorDocument9 pagesKFHC TPB Reguler ZfactorIlhamRifaldiNo ratings yet

- Yanbu: Export Refinery ProjectDocument5 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Yanbu: Export Refinery ProjectDocument6 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Yanbu: Export Refinery ProjectDocument7 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Boundary Layer CalculatorDocument10 pagesBoundary Layer CalculatorTint TigerNo ratings yet

- APEx Tutorial WorkbookDocument31 pagesAPEx Tutorial WorkbookmusaveerNo ratings yet

- Specific Heat Chart of WaterDocument2 pagesSpecific Heat Chart of WaterDaud IfadahNo ratings yet

- Direction Numbers of Component Vectors A B CDocument2 pagesDirection Numbers of Component Vectors A B CMessy CoolNo ratings yet

- Gawish SPE Paper PDFDocument11 pagesGawish SPE Paper PDFEdsonNo ratings yet

- Jet Reynolds Number Nozzle-Plate SpacingDocument2 pagesJet Reynolds Number Nozzle-Plate SpacingBurak GülenNo ratings yet

- Report PDFDocument98 pagesReport PDFYuri PaixãoNo ratings yet

- Compressor+Dryer+CO remover+CO2 ScrubberDocument7 pagesCompressor+Dryer+CO remover+CO2 ScrubberZohaib AliNo ratings yet

- LP - FlashDocument6 pagesLP - FlashvikramNo ratings yet

- Steel PropertiesDocument26 pagesSteel PropertiesLutfy AzanNo ratings yet

- Pipe Properties FullDocument16 pagesPipe Properties FullJuan P RuizNo ratings yet

- AntoineDocument64 pagesAntoinealexis19714aNo ratings yet

- BWB Synopsis ReportDocument37 pagesBWB Synopsis ReportMidhun MvNo ratings yet

- ANSYS AIM DocumentationDocument306 pagesANSYS AIM DocumentationWilder Molina100% (2)

- fouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594Document27 pagesfouling factor 중량 비체적: ft^2/Btu m^2/Kcal lb/ft kg/m lb/ft^3 kg/m^3 0.3689556791 1.4881889764 16.018732594김종민No ratings yet

- Calculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesDocument5 pagesCalculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesselisenNo ratings yet

- Hydroulics Calculation and Gas PropertiesDocument4 pagesHydroulics Calculation and Gas PropertiesMubarizNo ratings yet

- List Files in A FolderDocument12 pagesList Files in A Foldervincent02hk_57881301No ratings yet

- Heat Transfer SummaryDocument23 pagesHeat Transfer SummaryDaniel GarcíaNo ratings yet

- Calalang, Louise Anne E. EXAM # 1-SE533 AT P. 164 Single Degree of Freedom PropertiesDocument1,713 pagesCalalang, Louise Anne E. EXAM # 1-SE533 AT P. 164 Single Degree of Freedom PropertiesRenzel EstebanNo ratings yet

- Natural Gas Homework2Document42 pagesNatural Gas Homework2Khanz KhanNo ratings yet

- Fan Static Pressure CalculationsDocument3 pagesFan Static Pressure CalculationskarthickNo ratings yet

- Carbon Steel and Alloy Steel FastenersDocument2 pagesCarbon Steel and Alloy Steel FastenersagnisivadasanNo ratings yet

- Yanbu: Export Refinery ProjectDocument8 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- BoltDocument39 pagesBoltHarmeet SinghNo ratings yet

- Chapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument23 pagesChapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallselisenNo ratings yet

- IGIP&IOIP Calculation ResultsDocument9 pagesIGIP&IOIP Calculation ResultsDonny Ridwan PrihadiNo ratings yet

- Blank Calc Template - Steel Tools1Document656 pagesBlank Calc Template - Steel Tools1magdy.kamel6528No ratings yet

- Bk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Document34 pagesBk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Anonymous bHh1L1No ratings yet

- Yanbu: Export Refinery ProjectDocument6 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Centre of Stiffness Calculation: Ground FloorDocument91 pagesCentre of Stiffness Calculation: Ground FloorPoshan DhunganaNo ratings yet

- Deu PointDocument2 pagesDeu PointP.S.J.SarmaNo ratings yet

- Beam CalculationDocument49 pagesBeam CalculationRobin Charles SamuelNo ratings yet

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document36 pagesMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Karina RoquelNo ratings yet

- Firetube Heaters: FIG. 8-31 Convection HeaterDocument7 pagesFiretube Heaters: FIG. 8-31 Convection Heatery149487No ratings yet

- Effectiveness - NTU CurvesDocument31 pagesEffectiveness - NTU CurvesLoken Rizal0% (1)

- Inches-Kips Inches-Kips: U Z MaxDocument3 pagesInches-Kips Inches-Kips: U Z MaxRosendo Olguera AlejandroNo ratings yet

- 2.2 Manual Calculation of Materials and Energy Balances 2.2.1 Mass Balance Plant Complete If The Amount That Targeted Is AchievedDocument34 pages2.2 Manual Calculation of Materials and Energy Balances 2.2.1 Mass Balance Plant Complete If The Amount That Targeted Is AchievedmmbmnbmnbNo ratings yet

- Compressor Selection: Semi-Hermetic Reciprocating CompressorsDocument2 pagesCompressor Selection: Semi-Hermetic Reciprocating CompressorsMohammed ElhakeemNo ratings yet

- Jumadiao, Yra Marielle M. Exercise 9: Heat Balance and Theoretical Flame Temperature GivenDocument4 pagesJumadiao, Yra Marielle M. Exercise 9: Heat Balance and Theoretical Flame Temperature GivenJanelle M. JumadiaoNo ratings yet

- Fluent VofDocument27 pagesFluent VofSungki JungNo ratings yet

- Oilproperties.Xls: Γ Api +131 - 5 Ρ Γ R Γ Γ ADocument3 pagesOilproperties.Xls: Γ Api +131 - 5 Ρ Γ R Γ Γ ATifano KhristiyantoNo ratings yet

- Yanbu: Export Refinery ProjectDocument6 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Paper Sukanta Azad - 11 PDFDocument6 pagesPaper Sukanta Azad - 11 PDFAgung SiswahyuNo ratings yet

- Mass Balance (Final)Document26 pagesMass Balance (Final)Adeel AhmedNo ratings yet

- Basis: Basis: 100 Mol/h Property: GPSA and Elliott ManualDocument6 pagesBasis: Basis: 100 Mol/h Property: GPSA and Elliott ManualsterlingNo ratings yet

- CS46 - Basic Immersion Firetube ModelDocument22 pagesCS46 - Basic Immersion Firetube ModelYasin YILDIZNo ratings yet

- Astm A193Document1 pageAstm A193Ramesh SelvarajNo ratings yet

- Aluminum Bronze, UNS C61300: Component Wt. %Document3 pagesAluminum Bronze, UNS C61300: Component Wt. %AbbasNo ratings yet

- ATA Heet: LSS Chipper KnifeDocument2 pagesATA Heet: LSS Chipper KnifeX800XL100% (1)

- Tugas Sistem PerpipaanDocument15 pagesTugas Sistem PerpipaanAfif ZenaNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data SheetMECHA ENGINEEERINGNo ratings yet

- Simbol Oil GreaseDocument3 pagesSimbol Oil GreaseCelineKevinNo ratings yet

- Eni OSO 32: Eni OSO 32 Is A High Performance Antiwear Hydraulic Oil, Specifically Designed To Meet The MostDocument2 pagesEni OSO 32: Eni OSO 32 Is A High Performance Antiwear Hydraulic Oil, Specifically Designed To Meet The MostCelineKevinNo ratings yet

- Eni Arnica 46 PDFDocument2 pagesEni Arnica 46 PDFAnibal RiosNo ratings yet

- 17 181 FirstSolar Thompson PDFDocument33 pages17 181 FirstSolar Thompson PDFGideon Oyibo0% (1)

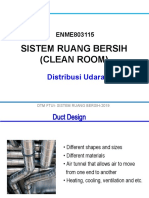

- Sistem Ruang Bersih (Clean Room) : Distribusi UdaraDocument48 pagesSistem Ruang Bersih (Clean Room) : Distribusi UdaraCelineKevinNo ratings yet

- Agip Atf Ii D: Characteristics (Typical Figures)Document1 pageAgip Atf Ii D: Characteristics (Typical Figures)CelineKevinNo ratings yet

- 1275 EnuDocument2 pages1275 EnuJan HendriksNo ratings yet

- CV Samples PDFDocument4 pagesCV Samples PDFCelineKevinNo ratings yet

- Plunger Pumps Pompe A Pistoni Bombas de EmbolosDocument8 pagesPlunger Pumps Pompe A Pistoni Bombas de EmbolosCelineKevinNo ratings yet

- Centrifugal Fan and BlowerDocument34 pagesCentrifugal Fan and BlowerCelineKevinNo ratings yet

- CV Samples PDFDocument4 pagesCV Samples PDFCelineKevinNo ratings yet

- MT Salary List (Last Update 2017 Nov) PDFDocument19 pagesMT Salary List (Last Update 2017 Nov) PDFCelineKevinNo ratings yet

- Guide To Electric Motor Bearing LubricationDocument7 pagesGuide To Electric Motor Bearing LubricationUber_Konstruktor100% (2)

- MT Salary List (Last Update 2017 Nov) PDFDocument19 pagesMT Salary List (Last Update 2017 Nov) PDFCelineKevinNo ratings yet

- BlankDocument1 pageBlanknarkooNo ratings yet

- Foote Sandifer Reprint PDFDocument18 pagesFoote Sandifer Reprint PDFCelineKevinNo ratings yet

- Foote Sandifer Reprint PDFDocument18 pagesFoote Sandifer Reprint PDFCelineKevinNo ratings yet

- Foote Sandifer Reprint PDFDocument18 pagesFoote Sandifer Reprint PDFCelineKevinNo ratings yet

- BlankDocument1 pageBlanknarkooNo ratings yet

- Foote Sandifer Reprint PDFDocument18 pagesFoote Sandifer Reprint PDFCelineKevinNo ratings yet

- Foote Sandifer Reprint PDFDocument18 pagesFoote Sandifer Reprint PDFCelineKevinNo ratings yet

- (MEKFLU) 11 PR - 05 - Celine Kevin - 1606904516Document3 pages(MEKFLU) 11 PR - 05 - Celine Kevin - 1606904516CelineKevinNo ratings yet

- UploadDocument1 pageUploadCelineKevinNo ratings yet

- Review: Normal, Shear & Moment DiagramsDocument21 pagesReview: Normal, Shear & Moment DiagramsrevandifitroNo ratings yet

- HeiDocument1 pageHeiCelineKevinNo ratings yet

- Askelandphulenotes Ch01printableDocument24 pagesAskelandphulenotes Ch01printableShivashankrappa BalawatNo ratings yet

- Tugas1 Celine Kevin 1606904516Document3 pagesTugas1 Celine Kevin 1606904516CelineKevinNo ratings yet

- Slide AssignmentDocument9 pagesSlide AssignmentWan Madihah MahmodNo ratings yet

- Journal of Applied Polymer Science Volume 103 Issue 5 2007 (Doi 10.1002/app.25468) Sergul Acikalin Gulmus Ulku Yilmazer - Effect of The Surface Roughness and Construction Material On Wall Slip inDocument7 pagesJournal of Applied Polymer Science Volume 103 Issue 5 2007 (Doi 10.1002/app.25468) Sergul Acikalin Gulmus Ulku Yilmazer - Effect of The Surface Roughness and Construction Material On Wall Slip inMohamed MostafaNo ratings yet

- Manual - BigMuff - Green RussianDocument10 pagesManual - BigMuff - Green RussianBen KussauerNo ratings yet

- ALUPEX BrochureDocument5 pagesALUPEX BrochureTamas PapikNo ratings yet

- Lab Report On Climate ChangeDocument3 pagesLab Report On Climate ChangecmsbballNo ratings yet

- Unit V - Metrology and Instrumentation NotesDocument34 pagesUnit V - Metrology and Instrumentation NotesmanisekNo ratings yet

- BEEngGuideYKStyleG16075EG1 517Document116 pagesBEEngGuideYKStyleG16075EG1 517HemantSharmaNo ratings yet

- Accelerator Design For Proton Therapy: OutlineDocument8 pagesAccelerator Design For Proton Therapy: OutlineriomjNo ratings yet

- Usm Stis 2011 - Bahasa InggrisDocument16 pagesUsm Stis 2011 - Bahasa InggrisAhmad Pique Baisuni100% (1)

- World Standard Sheet LinesDocument4 pagesWorld Standard Sheet LinesAlejandro RubianoNo ratings yet

- AC Power Plugs and Sockets PDFDocument31 pagesAC Power Plugs and Sockets PDFZercNo ratings yet

- ValProbe ManualDocument91 pagesValProbe ManualRicardo AugustoNo ratings yet

- EC ElectromagneticsDocument51 pagesEC ElectromagneticsNilamani Umashankar JenaNo ratings yet

- John Zink Company Overview Markets Served TODD Products & Technologies Case StudiesDocument21 pagesJohn Zink Company Overview Markets Served TODD Products & Technologies Case Studieshamid vahedil larijaniNo ratings yet

- Lect 2Document25 pagesLect 2Mahmoud El-MahdyNo ratings yet

- Eng Sicor Catalogue GearlessDocument52 pagesEng Sicor Catalogue GearlessEmeka Pius OramunwaNo ratings yet

- Technip Introduces New Diving Support Vessel Deep ExplorerDocument2 pagesTechnip Introduces New Diving Support Vessel Deep Explorermuhammad ilyasNo ratings yet

- UCMP Unit 1Document16 pagesUCMP Unit 1Sreedhar ReddyNo ratings yet

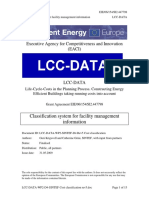

- Lcc-Data Cost Classification enDocument15 pagesLcc-Data Cost Classification enkoscoloi365No ratings yet

- KSG 5K DMDocument2 pagesKSG 5K DMGirasolar solarNo ratings yet

- SLOvenia Invites You!Document28 pagesSLOvenia Invites You!Finance100% (1)

- Dams: Parts, PakistanDocument22 pagesDams: Parts, PakistanEnigmatic Yousafzai100% (1)

- Enedict Oliman Ineda: Curriculum VitaeDocument6 pagesEnedict Oliman Ineda: Curriculum VitaeDaryll SanjoseNo ratings yet

- Mobildrive Series 4-15-16-30 - Technical Manual (230v - 50 HZ - Dbq26-En - Rev 01)Document133 pagesMobildrive Series 4-15-16-30 - Technical Manual (230v - 50 HZ - Dbq26-En - Rev 01)DMike67% (3)

- 1559038005845442000Document171 pages1559038005845442000Patel IbrahimNo ratings yet

- An Experimental Study On Usage of Hollow Glass Spheres (HGS) For Reducing Mud Density in Geothermal DrillingDocument7 pagesAn Experimental Study On Usage of Hollow Glass Spheres (HGS) For Reducing Mud Density in Geothermal DrillingifebrianNo ratings yet

- CHEM 397 Experiment QDocument20 pagesCHEM 397 Experiment QazinthepantsNo ratings yet

- Atoms, Electron Structure and Periodicity HWDocument14 pagesAtoms, Electron Structure and Periodicity HWLuke WilliamsonNo ratings yet

- Advanced Power System-I (Department Elective-I)Document4 pagesAdvanced Power System-I (Department Elective-I)Palak AriwalaNo ratings yet

- Ingersoll Rand RR150rv5C DocumentationDocument23 pagesIngersoll Rand RR150rv5C DocumentationSergei KurpishNo ratings yet