Professional Documents

Culture Documents

AMETank Product Brochure

Uploaded by

SYedZYnAle0 ratings0% found this document useful (0 votes)

195 views6 pagesAMETank Product Brochure

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAMETank Product Brochure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

195 views6 pagesAMETank Product Brochure

Uploaded by

SYedZYnAleAMETank Product Brochure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

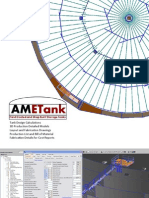

AMETank

Field Erected and Shop Built Storage Tanks

Engineering Application Software

Tank Design Calculations

3D Production Detailed Models

Layout and Fabrication Drawings

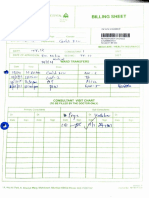

Production List and Bill of Material

Fabrication Details for Cost Reports

Rapid Design and Detailing Easy to use Graphical User Interface

AMETank enables the rapid configuration, design, and AMETank supports a fully interactive 3D graphical user

detailing of above-ground shop-built and field-erected interface.

storage tanks.

The configuration and layout of the tank shell, floor, roof

Design calculations conforming to API 650, API 620, and structure, and subsystems is facilitated through

AWWA, and EN 14015 are supported. intuitive menus with options customized specifically for

tank design.

Design calculations for shell courses, floors, roofs,

structures, anchors, nozzles, manways, and cleanout A complete design can be configured and detailed in less

doors are supported. Calculations include seismic, than two hours including the automatic generation of:

internal and external pressures, and wind loading for

new as well as corroded conditions. Design reports Tank 3D geometry with production details.

include calculation formulation and details in US or

SI units. To-scale drawings including general arrangements,

fabrication details, assembly layout, weld and X-Ray

Throughout the system minimum sizes are calculated maps.

for various conditions and used for defaults as well as Components fabrication list, bill of material, weight

validation of user inputs. reports, and cost data.

Tank Design Layouts and Configurations Stairs, Ladders, Platforms, & WindGirders

A wide range of storage tank designs and configurations Configuration and detailing of radial and spiral stairways

are supported. with intermediate platforms are supported. Single and

double stringers designs, and various types of hand

Roof layouts include self and structurally supported, railings and posts are included.

single and multi-bay flat, cone, umbrella, and dome with

knuckle design. Roofs with stiffeners welded on plates Ladders with cages, climbing devices, safety cables, gates,

are supported. removable start ladders, and intermediate platforms, with

bolted or welded clips are supported. Internal rolling and

Roof structures include various configurations for hinged ladders for floating roof access can be configured.

columns, girders, rafters, and brackets. Single and double

deck, external and internal floating roofs are supported. Wind girders with variable sections and different

structural attachments are supported. Wind girder railings

Shell courses, stiffening rings, and anchor chairs can be and integration with optional access from stairways are

configured with various dimensions and types. supported.

Bottom types include sloped or shoveled with staggered or Roof walkways and platforms with different railing

ribbon layout with optional annular ring. Plates can be lap configurations and attachments are supported.

or butt welded with or without backing bars.

Internal and External Appurtenances Layout Fabrication Drawings and Reports

Piping subsystems for multi-level sampling, overflow, The plates layout and fabrication details for shells,

draw-off, diffusers, foaming, and pumping are supported. floors, and all roof types including designs with

The subsystems include various configurations and knuckle edge plates are provided. Details include

options for weirbox, structural attachment, end flanges, plate dimensions, overlaps, and welds types. Output

among others. for NC machines is supported.

Manways with optional davit arm, hinges, handles Shell weld maps, and shell roll out drawings, with

attached to shells and roofs are provided. Rectangular details including appurtenances, stairs, ladders, and

and circular hatches, cleanouts, vents, couplings, and other systems are supported.

nozzles with flanges, elbows and other attachments and

configurations are supported. Detailed assembly and components fabrication

drawings for all substructures, appurtenances, ladders,

Liquid level gauges and gauge poles can be integrated. platforms, stairs, and any other subsystems are

Scaffolding cable supports, lifting lugs, grounding lugs, supported.

tray supports, baffles, and hundreds of other internal and 3D geometry, drawings, bill of material, weights, and

external appurtenances are supported. cost data can be edited within AMETank or exported.

Tank Rapid Design and Detailing Environment

From configuration and design to 3D geometry, detailed bill of

material, purchase list, cost data, and to-scale fabrication and

layout drawings, in two hours.

Within minutes design changes can be made to modify, add, or

delete features. The 3D geometry, drawings, bill of material, TECHNOSOFT

plate cut data, and cost reports are automatically updated.

Custom and easy to use graphical interface. AMETank can be

mastered in two days of training.

AMETank and AMPreVA Sales and Contact Information

AMETank is developed by TechnoSoft and is marketed For more information about AMETank contact:

globally through a network of reseller. In addition to

API 650, API 620, AWWA, and API 653 AMETank TECHNOSOFT

Release 11, planned for end of 2017, will support API 579. 11180 Reed Hartman Hwy.

Cincinnati, OH 45242

For Pressure Vessels design and detailing refer to AMPreVA,

a TechnoSoft product. Visit ampreva.technosoft.com Phone: 1-513-985-9877

AMETank@technosoft.com

www.AMETank.com

Copyrights TechnoSoft Inc.

You might also like

- Preva: Pressure Vessels and Heat ExchangersDocument6 pagesPreva: Pressure Vessels and Heat ExchangersTrishul Nath PallayNo ratings yet

- Freeboard Claculation For Stoarage Tanks As Per Api-650 12Th Edition V V D D H H K K Q Q I IDocument2 pagesFreeboard Claculation For Stoarage Tanks As Per Api-650 12Th Edition V V D D H H K K Q Q I IAnonymous JWI6rqt100% (1)

- Secondary Condensate B API650 Sloshing Impact RoofDocument22 pagesSecondary Condensate B API650 Sloshing Impact RoofFrancisco OrtuzarNo ratings yet

- Add any change made in the sheet with new revision NoDocument16 pagesAdd any change made in the sheet with new revision Nochenfs27531No ratings yet

- Rectangular Tanks:: Rectangle Tank DesignDocument23 pagesRectangular Tanks:: Rectangle Tank Designshna jabarNo ratings yet

- Design ReportDocument22 pagesDesign Reportamit_saxena_10No ratings yet

- Design of Reinforced Concrete RING BEAM FOUNDATIONDocument2 pagesDesign of Reinforced Concrete RING BEAM FOUNDATIONnirmal suthar100% (1)

- S 101 Sodium Chloride Silo Specification Sheet and DesignDocument8 pagesS 101 Sodium Chloride Silo Specification Sheet and DesignBenedick Jayson MartiNo ratings yet

- Rect TankDocument6 pagesRect TankSasikumar JothiNo ratings yet

- 3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankDocument4 pages3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankNurul HudaNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- Bar Bending Schedule OF Box CulvertDocument1 pageBar Bending Schedule OF Box CulvertvishalNo ratings yet

- WELDED TANKS FOR OIL STORAGE tablesDocument2 pagesWELDED TANKS FOR OIL STORAGE tablesGerman DiBaccoNo ratings yet

- AMETank 14 Release Notes 14.3 2021 03 12Document3 pagesAMETank 14 Release Notes 14.3 2021 03 12Pierre DibNo ratings yet

- Design and Study of Floating Roofs For Oil Storage TanksDocument12 pagesDesign and Study of Floating Roofs For Oil Storage TanksDavid RodriguesNo ratings yet

- Sap2000 Egitim 2 GKTDocument32 pagesSap2000 Egitim 2 GKTAlp KuzubasiogluNo ratings yet

- Ldo Storage Tank Calculation 170Document6 pagesLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- Chapter 3: Tank DesignDocument4 pagesChapter 3: Tank Designevrim77No ratings yet

- 7-12-0006 Rev6 (Angle Leg Support)Document2 pages7-12-0006 Rev6 (Angle Leg Support)sumit kumarNo ratings yet

- Ibc 16Document114 pagesIbc 16Luis Fernando BaqueNo ratings yet

- Permastore Capacity ChartDocument3 pagesPermastore Capacity ChartMangatur SimamoraNo ratings yet

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikash Kumar Singh100% (1)

- SABP Q 008 Concrete Masonry WallsDocument22 pagesSABP Q 008 Concrete Masonry Wallsaseptman1No ratings yet

- RectangularTanks 25-3-2015Document98 pagesRectangularTanks 25-3-2015Sary LimNo ratings yet

- Codeware Interface 2018 Installation GuideDocument20 pagesCodeware Interface 2018 Installation GuideRaul GonzaloNo ratings yet

- Ametank 10.9 Release Notes Focus on Fixes and UpdatesDocument8 pagesAmetank 10.9 Release Notes Focus on Fixes and UpdatesvikramNo ratings yet

- Curriculam Vitae: - Since Aug 2011 To Till DateDocument6 pagesCurriculam Vitae: - Since Aug 2011 To Till DatechetanmaleNo ratings yet

- Autopipe Vessel Guide 1-5Document5 pagesAutopipe Vessel Guide 1-5fiuto_rights_1404802No ratings yet

- Api - 650 - 2007 - 40Document1 pageApi - 650 - 2007 - 40Raul GonzaloNo ratings yet

- Build A Tank VesselDocument18 pagesBuild A Tank VesselMiguel EspinozaNo ratings yet

- Design and Analysis of Tank Ring Wall Fo PDFDocument3 pagesDesign and Analysis of Tank Ring Wall Fo PDFsatyakamNo ratings yet

- Composite Tank FinalDocument30 pagesComposite Tank FinalAmru AmruteshNo ratings yet

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraNo ratings yet

- AWWA D100 Tension TableDocument1 pageAWWA D100 Tension Tablejojo_323No ratings yet

- Tank Design: EN 1993 4 2 Eurocode 3Document31 pagesTank Design: EN 1993 4 2 Eurocode 3אחמד סלאח כאמלNo ratings yet

- Waste Water Equalising Tank Anchor Chair DetailsDocument4 pagesWaste Water Equalising Tank Anchor Chair DetailsShaheed HossainNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuNo ratings yet

- 134004-SEP-MEC-DAT-0004 Rev.B2 PDFDocument11 pages134004-SEP-MEC-DAT-0004 Rev.B2 PDFDhakshina KNo ratings yet

- Calcs 6Document5 pagesCalcs 6Jedmar Flynn LimenNo ratings yet

- Design and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankDocument5 pagesDesign and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankGRD JournalsNo ratings yet

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocument6 pagesStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNo ratings yet

- FINITE ELEMENT ANALYSIS OF STEEL STORAGE TANKDocument8 pagesFINITE ELEMENT ANALYSIS OF STEEL STORAGE TANKBala SutharshanNo ratings yet

- RectangularDocument6 pagesRectangularhgag selimNo ratings yet

- IIT Hyderabad Faculty Housing Design CalculationsDocument33 pagesIIT Hyderabad Faculty Housing Design CalculationssmijusNo ratings yet

- Tank 14m x12 M HeightDocument60 pagesTank 14m x12 M Heighthgag selim100% (1)

- CR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFDocument3 pagesCR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFInamullah KhanNo ratings yet

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- KDS 41 17 00 2019Document75 pagesKDS 41 17 00 2019Suso IglesiasNo ratings yet

- 125 128Document4 pages125 128Majdi JerbiNo ratings yet

- Excel Fatigue AnalysisDocument11 pagesExcel Fatigue AnalysisAli GhNo ratings yet

- AMETank PDFDocument6 pagesAMETank PDFMadan Yadav50% (2)

- AMETank BrochureDocument6 pagesAMETank BrochureOscar A. Martínez CastroNo ratings yet

- Amp RevaDocument6 pagesAmp RevajavilapiedraNo ratings yet

- Sepl Esr GSRDocument4 pagesSepl Esr GSRSyed Mohd MehdiNo ratings yet

- AVEVA OutfittingDocument8 pagesAVEVA OutfittingrevelacionesNo ratings yet

- STAAD - Foundation SDocument2 pagesSTAAD - Foundation Safzaalahmad6043No ratings yet

- Safe BrochureDocument21 pagesSafe BrochuremindoiuNo ratings yet

- Chapter02.Structural Design Using STAAD PRODocument22 pagesChapter02.Structural Design Using STAAD PROSiddharth Chetia100% (3)

- Structural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkFrom EverandStructural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkRating: 3 out of 5 stars3/5 (1)

- UOP 300-E-03 D Shell Side Nozzle Load Flange Rating As Per Code Case 2901 CalculationsDocument12 pagesUOP 300-E-03 D Shell Side Nozzle Load Flange Rating As Per Code Case 2901 CalculationsSYedZYnAle100% (1)

- 100 E02eDocument12 pages100 E02eSYedZYnAleNo ratings yet

- Saudization PlanningDocument4 pagesSaudization PlanningSYedZYnAle100% (1)

- Nozzel LoadDocument6 pagesNozzel LoadSYedZYnAleNo ratings yet

- QG20 Career 20 FairDocument7 pagesQG20 Career 20 FairKarthik ChockkalingamNo ratings yet

- PC Version Help Manual V2Document5 pagesPC Version Help Manual V2Alyani KornerNo ratings yet

- ASME PTB 10 2015 Guide For ASME Section VIII Division 1 Stamp Holders 1 PDFDocument111 pagesASME PTB 10 2015 Guide For ASME Section VIII Division 1 Stamp Holders 1 PDFmarcoNo ratings yet

- PV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2Document15 pagesPV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2SYedZYnAleNo ratings yet

- Allowable loads on pressure vessel nozzlesDocument1 pageAllowable loads on pressure vessel nozzlesSYedZYnAleNo ratings yet

- For Pressure Vessels and Columns (Bidding Stage)Document2 pagesFor Pressure Vessels and Columns (Bidding Stage)SYedZYnAleNo ratings yet

- Threaded Half CouplingDocument1 pageThreaded Half CouplingwhngomjNo ratings yet

- Rams Is Organization ChartDocument1 pageRams Is Organization ChartSYedZYnAleNo ratings yet

- Form 4Document5 pagesForm 4SYedZYnAleNo ratings yet

- Modular Unit Doubles Gasoline Output PTQ Technology in Action FeatureDocument1 pageModular Unit Doubles Gasoline Output PTQ Technology in Action FeatureSYedZYnAleNo ratings yet

- Data Overview - Sr. Project EngineerDocument1 pageData Overview - Sr. Project EngineerSYedZYnAleNo ratings yet

- Standard Drawing For Stationary Equipment (1) - 2Document76 pagesStandard Drawing For Stationary Equipment (1) - 2SYedZYnAleNo ratings yet

- Body Flange To Be Replaced by Dished Head As Mentioned in DOCUMENT MISA-1836-001-V - 1 AND MISA-1836-001-V - 2Document1 pageBody Flange To Be Replaced by Dished Head As Mentioned in DOCUMENT MISA-1836-001-V - 1 AND MISA-1836-001-V - 2SYedZYnAleNo ratings yet

- CEPCI June 2017 IssueDocument1 pageCEPCI June 2017 IssueEsteban Wong Muñoz97% (31)

- Resignation LetterDocument1 pageResignation LetterSYedZYnAleNo ratings yet

- American Structural ShapesDocument16 pagesAmerican Structural ShapesSYedZYnAleNo ratings yet

- Common Liquid and Gas DataDocument2 pagesCommon Liquid and Gas Dataabhi_mohit2005No ratings yet

- Net Positive Suction Head or NPSHDocument4 pagesNet Positive Suction Head or NPSHsateesh chandNo ratings yet

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (3)

- Version 5.10 CAESAR II Applications GuideDocument302 pagesVersion 5.10 CAESAR II Applications GuideBin XiangNo ratings yet

- Structural Design of Steel Bins - Gerard XavierDocument77 pagesStructural Design of Steel Bins - Gerard XavierNicolas Valle100% (9)

- VD-SRU-V-004-100-Rev ADocument51 pagesVD-SRU-V-004-100-Rev ASYedZYnAleNo ratings yet

- ATM Tank Calc (Converted)Document5 pagesATM Tank Calc (Converted)rahul84803No ratings yet

- Descon Engineering Corporate Presentation 2016Document23 pagesDescon Engineering Corporate Presentation 2016SYedZYnAle100% (1)

- Introduction Computer NetworkingDocument42 pagesIntroduction Computer NetworkingAtul SinghNo ratings yet

- 132 KVDocument32 pages132 KVWan Zamani Wan AbdullahNo ratings yet

- Fra - New Format 01Document4 pagesFra - New Format 01paras pantNo ratings yet

- BPP Coursework Cover Sheet: (Please Attach The Confirmation of Any Extension Received)Document19 pagesBPP Coursework Cover Sheet: (Please Attach The Confirmation of Any Extension Received)Amber PreetNo ratings yet

- Corporate Law Object ClauseDocument34 pagesCorporate Law Object ClausedaariyakNo ratings yet

- Human Resources, Job Design, and Work MeasurementDocument82 pagesHuman Resources, Job Design, and Work Measurementsaira khanNo ratings yet

- Anjali Kailash ChourasiyaDocument4 pagesAnjali Kailash ChourasiyaSatish VirasNo ratings yet

- Heating curve graph for benzeneDocument2 pagesHeating curve graph for benzeneBluematwo TwoNo ratings yet

- Failure Analysis of A Diesel Engine Crankshaft: Zhiwei Yu, Xiaolei XuDocument9 pagesFailure Analysis of A Diesel Engine Crankshaft: Zhiwei Yu, Xiaolei XuAnonymous LfeGI2hMNo ratings yet

- Formulir Management Review MeetingDocument5 pagesFormulir Management Review MeetingShella MustikaNo ratings yet

- Patient Medication Management: DRUG STUDY University of Cebu Medical CenterDocument1 pagePatient Medication Management: DRUG STUDY University of Cebu Medical CenterMemcom SolutionNo ratings yet

- February 17, 2012 Strathmore TimesDocument28 pagesFebruary 17, 2012 Strathmore TimesStrathmore TimesNo ratings yet

- Introduction To Machine Maintenance and InstallationDocument43 pagesIntroduction To Machine Maintenance and Installationmynor8josh8juarez100% (1)

- Gantrail Installation BrochureDocument6 pagesGantrail Installation BrochurenanesculNo ratings yet

- Process SynthesisDocument30 pagesProcess Synthesismiza adlin100% (1)

- ITEC 90: Key Networking ConceptsDocument3 pagesITEC 90: Key Networking ConceptsMark Nathan BatulaNo ratings yet

- Entrepreneurs Are Great WorksheetsDocument9 pagesEntrepreneurs Are Great WorksheetsSilvia MontesNo ratings yet

- Interim Payment CertificatesDocument3 pagesInterim Payment CertificatesRanjith100% (1)

- M0000561 sch100 v1.4 IngDocument20 pagesM0000561 sch100 v1.4 IngLenin Romero100% (1)

- Philippine Education Department's GSP Action PlanDocument2 pagesPhilippine Education Department's GSP Action PlanCharie P. Gracia100% (1)

- Level 4Document7 pagesLevel 4Tudor PricopNo ratings yet

- Chem ChinaDocument18 pagesChem Chinamfarhad2No ratings yet

- OSOT Checklist for New VISTAsDocument2 pagesOSOT Checklist for New VISTAscrimsonstained7No ratings yet

- MIESDocument4 pagesMIESSumit YadavNo ratings yet

- STOCKS PLUNGE FOR THIRD DAYDocument2 pagesSTOCKS PLUNGE FOR THIRD DAYEhsan KarimNo ratings yet

- Opencv: Object Classification - in The Object Classification, We Train A Model On A Dataset ofDocument9 pagesOpencv: Object Classification - in The Object Classification, We Train A Model On A Dataset ofSrinadh ShaikNo ratings yet

- A Gunsmiths Tale of 82G Accuracy WorkDocument7 pagesA Gunsmiths Tale of 82G Accuracy WorkwellfedirishmanNo ratings yet

- Chapter 9 Performance Management and AppraisalDocument48 pagesChapter 9 Performance Management and AppraisalAbir HasanNo ratings yet

- Lok AdalatDocument11 pagesLok Adalatsweetykrsh50% (2)

- Healy World Compensation Plan Global 22 en EUDocument32 pagesHealy World Compensation Plan Global 22 en EUTamara Alvarado CastilloNo ratings yet

- Asynchronous vs Synchronous Serial Data CommunicationDocument6 pagesAsynchronous vs Synchronous Serial Data CommunicationVasthav KalluriNo ratings yet