Professional Documents

Culture Documents

Dual Pressure Nitric Acid Process Simulation Results ProSim PDF

Uploaded by

lucasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dual Pressure Nitric Acid Process Simulation Results ProSim PDF

Uploaded by

lucasCopyright:

Available Formats

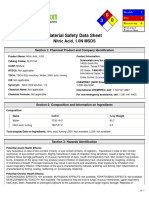

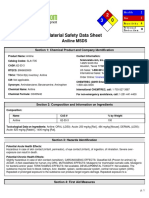

PROSIMPLUS HNO3 APPLICATION EXAMPLE

DUAL-PRESSURE NITRIC ACID

MANUFACTURING PROCESS

INTEREST OF THIS EXAMPLE

This example corresponds to the simulation of a manufacturing unit of nitric acid by a dual-pressure process. It is a

rather traditional process of nitric acid industrial production. The main modules specific to the simulator ProSimPlus

HNO3 are implemented: absorption column of nitrous vapors, nitrous vapors condensers, oxidation reactors, heat

exchangers with oxidation volumes, nitrous vapor compressors, etc.

The particular points which are detailed in this example are:

The use of a constraint management module in order to reach a specification and the management of

information streams;

The use of an information stream to split a heat exchanger between a temperature set point and a simple

exchanger in order to avoid a stream recycling.

ACCESS Free-Internet Restricted to ProSim clients Restricted Confidential

CORRESPONDING PROSIMPLUS HNO3 FILE HNO3 dual pressure process.pmp

Reader is reminded that this use case is only an example and should not be used for other purposes. Although this example is based on actual case it

may not be considered as typical nor are the data used always the most accurate available. ProSim shall have no responsibility or liability for damages

arising out of or related to the use of the results of calculations based on this example.

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 2 / 25

TABLE OF CONTENTS

1. PROCESS MODELING 3

1.1. Process description 3

1.2. Process flow diagram 5

1.3. Specifications 5

1.4. Components 6

1.5. Thermodynamic model 6

1.6. Operating conditions 7

1.7. "Hints and Tips" 13

1.7.1. Constraints and Recycles modules 13

1.7.2. Information stream handler module 14

1.7.3. Heat exchanger splitting 15

1.7.4. Changing of the thermodynamic model 15

2. RESULTS 16

2.1. Comments on results 16

2.2. Mass and energy balances 17

2.3. Column C101 profiles 22

2.4. Column C102 profiles 24

3. REFERENCES 25

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 3 / 25

1. PROCESS MODELING

1.1. Process description

This example is extracted from the publications [1] and [2], which describe the process summarily.

The manufacture of nitric acid includes three principal stages:

Oxidation of ammonia:

4 NH3 5 O 2 4 NO 6 H2 O

Condensation of the water of combustion and oxidation of nitric oxide

H2 O gaz H2 O liq.

2 NO O 2 2 NO 2 N2 O 4

Absorption of nitrogen dioxide and Nitrogen Tetroxide:

3 NO 2 H2 O 2 HNO 3 NO

N2 O 4 1/ 2O 2 H2 O 2 HNO 3

The mathematical modeling of chemical equilibrium and kinetics of the above reactions are complex and secondary

reactions occur, in particular the formation of N2O3:

NO NO 2 N2 O 3

The dual-pressure process (pressure of the absorption appreciably higher than that of catalytic combustion) rest on

the reaction:

3 NO 2 H2 O 2 HNO 3 NO

The principal characteristic of this reaction is that, each time two molecules of nitric acid are formed, there is also

production of a nitric oxide molecule NO, that it is required to oxide in NO2 then to absorb and so on. These

successive oxidations are done mainly in gas phase, in absorption towers where are in parallel carried out the

reaction of formation of the nitric acid and that of oxidation of NO:

NO 1/ 2 O 2 NO 2

This process is characterized mainly by the use:

of two different pressures for oxidation from ammonia and the absorption of nitrogen oxides, which ensures a

high nitrogen yield and low consumption of platinum;

of a system of high-output absorption which, combined with the high pressure of operation, makes it possible

to obtain a final low NOx content of tail gas (lower than 150 ppm in volume).

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 4 / 25

The process diagram is provided hereafter.

The liquid ammonia is vaporized by cooling water (E101), then heated (E102), filtered and sent in a mixer air-

ammonia (M101). The filtered atmospheric air is compressed (K101), then is divided into two currents, the primary

air (HP Air S2) which goes to the mixer air-ammonia (M101) and secondary air which goes to the bleacher (C102).

The air-ammonia mixture is directed towards the NH3 converter (R101).

The model of the reactor takes into account three reactions:

4 NH3 5 O 2 4 NO 6 H2 O

4 NH3 3 O 2 2 N2 6 H2 O

2 NH3 2 O 2 N2 O 3 H2 O

The gas after combustion contains nitrogen oxides, nitrogen and oxygen. Its significant heat content is recovered in

a series of exchangers (E107, E106, E108, E105, E109). After condensation (E110), a large quantity of acid with

weak concentration is formed and sent to the absorption tower (C101). The gas mixed with secondary air is

compressed (K102) and is cooled (E104 and E111). The gas and the acid are directed on the perforated plates of

the absorption column (C101) equipped in particular with cooling coils. Process water is introduced at the top and

the acid with the desired concentration is recovered at its bottom. This acid then goes to the bleaching column

(C102) equipped with plates. There is a stripping by secondary air (Air S2). The outgoing gases at the top of the

C101 absorber are sent in a series of gas-gas heat exchangers (E103, E104, E105 and E106), then in an expander

(T101) and finally in the stack.

In parallel, steam is produced by heat recovery. For that feed water is preheated (E109 and E108) then steam is

produced in the boiler (E112) and is overheated (E113). Part of this steam is turbinated (T102) to bring mechanical

power necessary to the process before being condensed (E114). For simplification purposes, that is not

represented on the diagram below, but in practice the two compressors (K101 and K102) are placed on the same

shaft as the turbines (T101 and T102).

The objective of this process is to produce 1.000 T/day of nitric acid (equivalent 100%) to a concentration of 58%

mass. The oxygen contents of tail gases are fixed at 2,5% in volume (mol.). The temperature at exit of the burner is

fixed at 890 C.

The process water feed flowrate, as well as the ammonia and air feed flowrates are automatically adjusted in order

to ensure this production.

On the level of the production of steam, the unit produces steam at 15 bars.

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 5 / 25

1.2. Process flow diagram

Dual-pressure process flow diagram

1.3. Specifications

The specifications imposed on the process are as follows:

Production of 1000 Tons/day (equivalent 100%) of nitric acid with 58% mass.

Production of 30 bars steam

The oxygen content of tail gas is fixed at 2.5% in volume (mol.)

The temperature at the output of the burner is fixed at 890 C

Mechanical energy required by the two compressors for air (K101) and NOx (K102) is provided by the

turbines of tail gas (T101) and 30 bars steam (T102)

One also seeks to optimize the energy production by recoveries between hot streams and cold streams.

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 6 / 25

1.4. Components

Properties of components involved in the simulation are taken from the specific HNO3 database, provided with

ProSimPlus HNO3 software. Nine components are taken into account:

Water (H2O)

Nitric oxide (NO)

Nitrogen dioxide (NO2)

Nitrogen Tetroxide (N2O4)

Nitrogen(N2)

Oxygen (O2)

Nitric Acid (HNO3)

Ammonia (NH3)

Nitrous oxide (N2O)

1.5. Thermodynamic model

For the main part of the process the thermodynamic model taken into account is the default model of the software

ProSimPlus HNO3 (see User's manual - chapter 2).

Two exceptions to that:

- at the level of the bleaching column, the model of Engels is used. Indeed, this model is particularly

adapted to the concentrated strong acids. Furthermore, this model must be modified in order to use

the same enthalpy basis as the HNO3 specific model :

H*=DH0f, ideal gas, 25C, 1 atm.

- at the level of the production of steam, a specific model for water and steam is used.

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 7 / 25

1.6. Operating conditions

Process feeds

Ammonia Air Process water Water for steam

(NH3) (LP AIR) (Water) (Water Utility S2)

Temperature (C) 10 25 20 20

Pressure (bar) 14 1 10 15

Adjusted so as to Adjusted so as to

Adjusted so as to satisfy

Total flow rate (t/d) satisfy the satisfy the 1 130

the specifications

specifications specifications

Reactor R101

Operating parameters Value

Type of reactor simple

Ammonia conversion rate (%) 5 O2 + 4 NH3 6 H2O + 4 NO 96.2

3 O2 + 4 NH3 6 H2O + 2N2 3.7

2 O2 + 2 NH3 3 H2O + N2O 0.1

Pressure drop (bar) 0.05

Output temperature adiabatic

Heat exchangers

Output Pressure drop Oxidation

Name Type 3

temperature (C) (bar) volume (m )

E101 Cooler/Heater Dew temp. 8 -

E102 Cooler/Heater 80 0.05 -

E103a Cooler/Heater 70 0.05 -

E103b Simple heat exchanger - 0.05 -

E104a Cooler/Heater 125 0.05 1.8

E104b Simple heat exchanger - 0.05 -

E105a Cooler/Heater 180 0.05 1.8

E105b Simple heat exchanger - 0.05 -

E106a Cooler/Heater 290 0.05 1.8

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 8 / 25

E106b Simple heat exchanger - 0.05 -

E107 Cooler/Heater 440 0.05 -

E108a Cooler/Heater 220 0.05 1.8

E108b Simple heat exchanger - 0.05 -

E109a Cooler/Heater 110 0.05 1.8

E109b Simple heat exchanger - 0.05 -

E112 Cooler/Heater Dew temp. 0.05 -

E113 Simple heat exchanger - 0.05 -

E114 Cooler/Heater Dew temp. 0.05 -

For the heat exchangers in which the chemical reactions are taken into account (reaction volume not equal to

zero), one adopts:

- a plug flow pattern

- an oxidation efficiency of 1

- the calculation of the oxidation reaction rate by the model of Koukolik

- the calculation of the dimerization equilibrium constant by the model of Koukolik.

Condenser E110

Operating parameters Value

Length of the tubes (m) 6

Number of tubes 840

Vapors flow Inside the tubes

Internal diameter of the tubes (mm) 25.4

Cooling water temperature (C) 15

Cooling water flow rate (t/d) 9000

Flow direction Counter-current

2

Overall heat exchange coefficient (kcal/h/m /K) 300

Moreover, one adopts:

- the calculation of the oxidation reaction rate by the model of Koukolik

- the calculation of the dimerization equilibrium constant by the model of Koukolik

- the calculation of the constant of absorption of N2O4 in water by the method based on the

equation of Miller (bubble caps).

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 9 / 25

Condenser E111

Operating parameters Value

Length of the tubes (m) 6

Number of tubes 250

Vapors flow Inside the tubes

Internal diameter of the tubes (mm) 25.4

Cooling water temperature (C) 15

Cooling water flow rate (t/d) 6 500

Flow direction Counter-current

2

Overall heat exchange coefficient (kcal/h/m /K) 600

Moreover, one adopts:

- the calculation of the oxidation reaction rate by the model of Koukolik

- the calculation of the dimerization equilibrium constant by the model of Koukolik

- the calculation of the constant of absorption of N2O4 in water by the method based on the

equation of Miller (bubble caps).

Compressor K101

Operating parameters Value

Isentropic efficiency 0,845

Mechanical efficiency 1

Discharge pressure (bar) 4.6

Taking into account of the chemical reaction no

Compressor K102

Operating parameters Value

Isentropic efficiency 0,795

Mechanical efficiency 1

Discharge pressure (bar) 10

Taking into account of the chemical reaction yes

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 10 / 25

Moreover, one adopts:

- the calculation of the oxidation reaction rate by the model of Koukolik

- the calculation of the equilibrium constant for the N2O3 formation by the model of Miller.

Oxidation volumes

Oxidation volume Pressure drop Temperature

Nom 3

(m ) (bar) (C)

O101 20 0.0125 Adiabatic

O102 25 0.0125 Adiabatic

O103 20 0.0125 Adiabatic

O104 20 0.0125 85

Moreover, one adopts:

- a plug-flow pattern

- an oxidation efficiency of 1

- the calculation of the oxidation reaction rate by the model of Koukolik

- the calculation of the dimerisation equilibrium constant by the model of Koukolik

Column C101

Operating parameters Value

Type of column Plate oxido-absorption column

Number of stages 30

25

Weak acid feed stage

(stages numbered from top to bottom)

Column diameter (m) 5

Diameter of the holes (mm) 5

Free section 4.82 %

Pressure drop in the column (bar) 0,8

Output temperature of the acid in the bottom (C) 25

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 11 / 25

Temperature Temperature

Stage Oxidation Stage Oxidation

3 3

C) volume (m ) (C) volume (m )

1 (top) 22 23.2 16 33 11.6

2 - 23.2 17 35 11.6

3 - 23.2 18 37 11.6

4 - 23.2 19 38 11.6

5 - 23.2 20 38 11.6

6 - 23.2 21 39 11.6

7 - 23.2 22 40 11.6

8 - 23.2 23 40 11.6

9 - 23.2 24 40 11.6

10 - 23.2 25 40 11.6

11 - 23.2 26 41 11.6

12 - 23.2 27 42 11.6

13 - 23.2 28 43 11.6

14 - 23.2 29 44 11.6

15 31 23.2 30 (bottom) 45 11.62

Moreover, one adopts:

- the calculation of the temperature profile in the column from the provided temperatures

- the dissolution of NOx is not taken into account and for NOx in liquid phase the oxidation of

NO is taken to 0%

- the calculation of the oxidation reaction rate by the model of Koukolik

- the calculation of the dimerisation equilibrium constant by the model of Koukolik

- the calculation of the equilibrium of the system nitrogen oxideswaternitric acid by the

equation of Zhidkov

- the efficiency of oxidation of each plate is equal to 1

- the hydrodynamic model on each plate is that of a plug-flow reactor

- the absorption efficiency on each plate is calculated by the equation of Atroshenko 3 with a

height of liquid on the trays of 10 cm.

Column C102

Operating parameters Value

Type of column Absorber

Number of theoretical stages 5

Overhead pressure (bar) 4.2

Pressure drop in the column (bar) 0.2

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 12 / 25

Pump P101

Operating parameters Value

Exhaust pressure (bar) 11

Volumetric efficiency 0.65

Mechanical efficiency 1

Expander T101

Operating parameters Value

Discharge pressure (bar) 1

Isentropic efficiency 0.83

Turbine T102

Operating parameters Value

Discharge pressure (bar) 1.05

Isentropic efficiency 0.85

Valve V101

Operating parameters Value Comments

Three way

Type of valve

valve

Splitting rate for the stream This rate will be adjusted in

80

AIR HP2 (%) order to reach the specifications

Valve V102

Operating parameters Value Comments

Three way

Type of valve

valve

This rate will be adjusted in order to

Splitting rate of the stream

90 expand sufficient steam to balance the

Steam S5 (%)

power required by the compressors

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 13 / 25

1.7. "Hints and Tips"

1.7.1. Constraints and Recycles modules

It is possible with ProSimPlus HNO3 to implement on the same flowsheet several modules of constraint

management. Here for example, for clarification of the diagram of simulation purposes, two modules of constraint

management are implemented:

- one for the process itself: SPEC01

- the other for the production of steam: SPEC02

The implementation of several modules of constraint management affects the order of calculation of the modules

(list of calculation automatically determined in ProSimPlus HNO3) and the convergence of each cycle, but does not

have any influence on the results obtained when convergence is reached. This possibility can be used in certain

very complex cases to facilitate convergence of flowsheets, or like here in order to simplify the representation of the

process.

The operation of the modules of Constraint Management in ProSimPlus HNO3 is described at the level of the user's

manual and illustrated in the application example of ProSimPlus E02 (Cyclohexane Plant).

In this case, at the level of the module SPEC01, 4 specifications (constraints) are imposed:

- the partial mass flowrate of pure nitric acid produced in bleaching column C102 bottom is fixed at

1000 T/d (measurement module MEAS03)

- the mass composition of the produced nitric acid (bleaching column C102 bottom) is fixed at 58%

(measurement module MEAS01)

- the oxygen volume composition (molar) in tail gas (TG S6) is fixed at 2.5% (measurement module

MEAS04)

- the output temperature of the reactor R101 (stream PG01) is fixed at 890C (measurement module

MEAS02)

With ProSimPlus HNO3, the module Constraint Management module SPEC01 then will adjust 4 parameters

simultaneously (action variables) to satisfy these specifications:

- ammonia feed flowrate (feed module NH3 feed)

- air feed flowrate (feed module Air feed)

- process water feed flowrate (feed module Process water feed)

- the value of the splitting ratio of the air in V101 valve between the air used the reactor R101 and the

air used in the bleaching column C102.

Moreover, this module SPEC01 also manages the convergence of the recycling streams.

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 14 / 25

1.7.2. Information stream handler module

At the module of constraint management SPEC02 level, the turbinated steam flowrate is adjusted by action on the

opening of the valve V102, in order to balance the power consumption of the compressors K101 and K102 with that

produced by the turbines T101 and T102. For that, several Information stream handler modules are implemented.

The Information stream handler module makes it possible in ProSimPlus HNO3 to make simple operations on a

information stream: to add (B) or of to withdraw (C) a constant, to multiply (A and P=1) or to divide (A and P=-1) its

content by a constant or to raise at power (P). The result of this operation is available in the information stream

leaving the Information stream handler module:

P

Output = A * (Input) + B C

In this formulation, A, B, C and P are constants fixed by the user. Entering several information streams in a

Information stream handler module and exploiting their position in the parameter area of the module it is possible to

make them take the place of constant A, B, C and P and thus to make operations between several information

streams (see below).

While implementing several modules of this type it is thus possible to make more complicated operations. For more

complex calculations on the information streams it is however recommended to implement a Windows Script

module.

Here, the Information stream handler module H102 receives in entry:

- power of the K102 compressor as value to be handled (WK102)

- power of the K101 compressor as additive factor (B)

A and P are fixed at 1 and C at 0. Thus the leaving information stream (Power compressors) will contain the total

power consumed by the two compressors.

In the same way, the Information stream handler module H103 receives in entry:

- power produced by the T101 turbine as value to be handled (WT101)

- power produced by the T102 turbine as additive factor (B)

A and P are fixed at 1 and C at 0. Thus the leaving information stream (Power turbines) will contain the total power

produced by the two turbines.

These two information streams (Power compressors and Power turbines) are then sent towards the Information

stream handler module H104 to make the sum of them. The stream Power compressors as value to be handled

and the stream Power turbines as additive factor (B). A and P are fixed at 1 and C at 0. Thus the leaving information

stream (Power difference) will contain the difference between the power of the turbines (negative) and that of the

compressors (positive). This information stream Power difference is then sent towards the module SPEC02 which

will take in charge to make converge towards zero the value of Power difference by action on the rate of division of

the V102 valve.

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 15 / 25

1.7.3. Heat exchanger splitting

In this example, most of the heat exchangers are simulated by uncoupling the hot stream and the cold stream. This

modeling of a heat exchanger between two streams makes it possible to avoid a recycling stream which would

penalize calculations by uncoupling the heat exchanger in two parts. This modeling is illustrated in the example of

application of ProSimPlus E02 (Cyclohexane Plant).

1.7.4. Changing of the thermodynamic model

In order of insure the consistency in the calculation of the enthalpies between the column C101 (oxido-absorption)

and the column C102 (bleacher) which are using different thermodynamic models (HNO3 specific for the first and

Engels for the latter), it is necessary to insert on the C102 inlet stream (Acid S1+S2) a dummy module which will

allow to change the thermodynamic model. The unit operation generally used for this purpose is a Cooler/Heater in

which the output temperature is taken equal to the inlet temperature. Thus only the enthalpy is recalculated. The

heat duty printed in the simulation report must be, of course, ignored as it corresponds only to the difference in the

enthalpies calculated by both models. In the present case, both models give enthalpy values which are very close

(deviation < 0.7 %), however this deviation must be multiplied by the value of the flowrate, that could lead, by the

end, to have some influence on the column C102.

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 16 / 25

2. RESULTS

2.1. Comments on results

The sequence of calculation (the order of calculation of the modules) is generated automatically. At the level of

recycling, no stream is initialized and ProSimPlus HNO3 chooses to make converge the stream Air S3.

The convergence of the first cycle is obtained in 4 iterations, that is to say 20 runs in the Maximum Cyclic Network.

The convergence of the second module of specification is obtained in 1 iteration, that is to say 4 passages in the

Maximum Cyclic Network.

When convergence is reached, the values obtained of the various parameters adjusted automatically by

ProSimPlus HNO3 to reach the specifications are as follows:

- ammonia feed flowrate: 283.616 t/d

- air feed flowrate: 4999.89 t/d

- process water feed flowrate: 367.240 t/d

- air splitting ratio in V101 valve:

air used in the R101 reactor: 83.83 %

air used in the C102 bleaching column: 16.17 %.

Regarding the absorption column (C101), convergence is obtained in 9 iterations, without any initialization.

Regarding the bleaching column (C102), it converges in 2 iterations, also without any initialization.

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 17 / 25

2.2. Mass and energy balances

Streams Acid S1 Acid S1+S2 Acid S2 Acid S3 Acid S4

From E111 Acids mixer C101 Dummy E110

To Acids mixer Dummy Acids mixer C102 P01

Partial flows t/d t/d t/d t/d t/d

WATER 110.330629 719.0267179 608.696089 719.0267179 209.963131

NITRIC OXIDE 0 0 0 0 0

NITROGEN DIOXIDE 0 0.171242013 0.171242013 0.171242013 0

NITROGEN 0 26.5555056 26.5555056 26.5555056 0

TETROXIDE

NITROGEN 0 0 0 0 0

OXYGEN 0 0 0 0 0

NITRIC ACID 50.70934 1002.750981 952.0416409 1002.750981 48.4400512

AMMONIA 0 0 0 0 0

NITROUS OXIDE 0 0 0 0 0

Total flow t/d 161.039969 1748.504446 1587.464477 1748.504446 258.403182

Total flow kmol/h 288.70913 2338.240064 2049.530933 2338.240064 517.643508

Temperature C 91.9381166 52.59991071 45 52.59991071 81.6451604

Pressure bar 9.89999732 9.899997325 9.899997325 9.899997325 4.21249886

Enthalpic flow kcal/h -18692289.6 -143427975 -124735685 -142520016 -34196144.9

Vapor fraction 0 0 0 0 0

Streams Acid S5 AIR S1 AIR S2 AIR S3 Condensate

s

From P01 V101 E103a C102 E114

To C101 E103a C102 K102 >>>>

Partial flows t/d t/d t/d t/d t/d

WATER 209.963131 9.150953613 9.150953613 4.436011318 959.536085

NITRIC OXIDE 0 0 0 0 0

NITROGEN DIOXIDE 0 0 0 22.50500389 0

NITROGEN 0 0 0 4.222192633 0

TETROXIDE

NITROGEN 0 613.4532114 613.4532114 613.2970848 0

OXYGEN 0 186.0172684 186.0172684 185.7742049 0

NITRIC ACID 48.4400512 0 0 2.755109167 0

AMMONIA 0 0 0 0 0

NITROUS OXIDE 0 0 0 0 0

Total flow t/d 258.403182 808.6214333 808.6214333 832.9896067 959.536085

Total flow kmol/h 517.643508 1175.820719 1175.820719 1188.483363 2219.26197

Temperature C 81.9068606 215.7343361 70 47.07917229 99.6325065

Pressure bar 10.999997 4.599998757 4.54999877 4.199998865 0.99999973

Enthalpic flow kcal/h -34193628.8 359264.567 -852795.401 -300693.485 1220318.93

Vapor fraction 0 1 1 1 1

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 18 / 25

Streams HP AIR1 HP AIR2 LP AIR NH3 NH3 S2

From K101 V101 >>>> >>>> E101

To V101 Mixer K101 E101 E102

Air+NH3

Partial flows t/d t/d t/d t/d t/d

WATER 56.5824732 47.43151958 56.5824732 0 0

NITRIC OXIDE 0 0 0 0 0

NITROGEN DIOXIDE 0 0 0 0 0

NITROGEN 0 0 0 0 0

TETROXIDE

NITROGEN 3793.12379 3179.670583 3793.123794 0 0

OXYGEN 1150.18801 964.1707389 1150.188007 0 0

NITRIC ACID 0 0 0 0 0

AMMONIA 0 0 0 283.6165392 283.616539

NITROUS OXIDE 0 0 0 0 0

Total flow t/d 4999.89427 4191.272841 4999.894275 283.6165392 283.616539

Total flow kmol/h 7270.37281 6094.552088 7270.372806 693.8895752 693.889575

Temperature C 215.734336 215.7343361 25 10 9.36352185

Pressure bar 4.59999876 4.599998757 0.992984732 13.99999622 5.99999838

Enthalpic flow kcal/h 2221416.32 1862151.757 -7563428.45 -11101866.5 -7703546.38

Vapor fraction 1 1 1 0 1

Streams NH3 S3 Nitric Acid PG00 PG01 PG02

Production

From E102 MEAS03 Mixer MEAS02 E107

Air+NH3

To Mixer >>>> R101 E107 E106a

Air+NH3

Partial flows t/d t/d t/d t/d t/d

WATER 0 723.7416218 47.43151958 497.4541587 497.454159

NITRIC OXIDE 0 0 0 480.7134005 480.713401

NITROGEN DIOXIDE 0 0.000204006 0 0 0

NITROGEN 0 0 0 0 0

TETROXIDE

NITROGEN 0 0.155163048 3179.670583 3188.301177 3188.30118

OXYGEN 0 0.242766129 964.1707389 308.053362 308.053362

NITRIC ACID 0 999.9960371 0 0 0

AMMONIA 283.616539 0 283.6165392 0 0

NITROUS OXIDE 0 0 0 0.36648111 0.36648111

Total flow t/d 283.616539 1724.135792 4474.889381 4474.88858 4474.88858

Total flow kmol/h 693.889575 2335.689738 6788.441663 6961.740584 6961.74058

Temperature C 80 51.93127648 198.0812614 889.9999211 440

Pressure bar 5.94999839 4.399998811 4.599998757 4.54999877 4.49999878

Enthalpic flow kcal/h -7280058.65 -143072111 -5417906.89 -5417908.71 -30796025.4

Vapor fraction 1 0 1 1 1

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 19 / 25

Streams PG03 PG04 PG05 PG06 PG07

From E106a O101 E108a O102 E105a

To O101 E108a O102 E105a OXI 03

Partial flows t/d t/d t/d t/d t/d

WATER 497.454159 497.4541587 497.4541587 497.4541587 497.454159

NITRIC OXIDE 471.416336 376.4039363 368.8073881 282.2212567 277.264103

NITROGEN DIOXIDE 14.2542765 159.9260257 171.5512153 304.2980458 311.662956

NITROGEN 2.8829E-05 0.001757513 0.02363313 0.0310847 0.2665072

TETROXIDE

NITROGEN 3188.30118 3188.301177 3188.301177 3188.301177 3188.30118

OXYGEN 303.096121 252.435043 248.3845261 202.2163753 199.573196

NITRIC ACID 0 0 0 0 0

AMMONIA 0 0 0 0 0

NITROUS OXIDE 0.36648111 0.36648111 0.36648111 0.36648111 0.36648111

Total flow t/d 4474.88858 4474.88858 4474.88858 4474.88858 4474.88858

Total flow kmol/h 6955.28559 6889.317386 6884.033172 6823.912763 6820.36439

Temperature C 290 325.3800873 220 252.7245814 180

Pressure bar 4.4499988 4.437498801 4.387498814 4.374998818 4.32499883

Enthalpic flow kcal/h -38871910.2 -38871910.2 -44442115.9 -44442115.9 -48230234.8

Vapor fraction 1 1 1 1 1

Streams PG08 PG09 PG10 PG11 PG13

From OXI 03 E109a E110 O104 K102

To E109a E110 O104 K102 E104a

Partial flows t/d t/d t/d t/d t/d

WATER 497.454159 497.4541587 280.5665562 280.5665562 285.002567

NITRIC OXIDE 228.148186 223.6229539 222.0586562 150.6022616 150.602262

NITROGEN DIOXIDE 387.010908 387.5943842 338.5782304 439.0036651 496.534591

NITROGEN 0.22332033 6.57795939 22.62660588 31.75847658 0.95470962

TETROXIDE

NITROGEN 3188.30118 3188.301177 3188.301177 3188.301177 3801.59826

OXYGEN 173.384348 170.9714722 163.9877533 125.8868524 311.661057

NITRIC ACID 0 0 0 0 2.75510917

AMMONIA 0 0 0 0 0

NITROUS OXIDE 0.36648111 0.36648111 0.36648111 0.36648111 0.36648111

Total flow t/d 4474.88858 4474.888587 4216.48546 4216.48547 5049.47504

Total flow kmol/h 6786.2826 6780.263058 6230.243037 6176.495317 7380.83997

Temperature C 198.72224 110 81.64516041 85 192.339758

Pressure bar 4.31249883 4.262498848 4.212498862 4.199998865 9.9999973

Enthalpic flow kcal/h -48230234.8 -52799109.1 -25845022.8 -27112834.5 -21102233.3

Vapor fraction 1 1 1 1 1

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 20 / 25

Streams PG14 PG15 Steam S1 Steam S2 Steam S3

From E104a E111 E112 E113 V102

To E111 C101 E113 V102 T102

Partial flows t/d t/d t/d t/d t/d

WATER 285.002567 167.4230739 1130 1130 959.536085

NITRIC OXIDE 123.490504 119.2119249 0 0 0

NITROGEN DIOXIDE 525.913527 458.7435962 0 0 0

NITROGEN 13.1436659 49.85086208 0 0 0

TETROXIDE

NITROGEN 3801.59826 3801.598262 0 0 0

OXYGEN 297.204935 288.4858539 0 0 0

NITRIC ACID 2.75510917 2.755109167 0 0 0

AMMONIA 0 0 0 0 0

NITROUS OXIDE 0.36648111 0.36648111 0 0 0

Total flow t/d 5049.47505 4888.435163 1130 1130 959.536085

Total flow kmol/h 7356.4965 7023.045811 2613.519249 2613.519249 2219.26197

Temperature C 125 91.93811658 197.8505116 393.1981727 393.198173

Pressure bar 9.94999731 9.899997325 14.84999599 14.799996 14.799996

Enthalpic flow kcal/h -25332332.1 -12128773.1 2743214.284 7808092.881 6630218.48

Vapor fraction 1 1 1 1 1

Streams Steam S4 Steam S5 TG S1 TG S2 TG S3

From T102 V102 C101 E103b E104b

To E114 >>>> E103b E104b E105b

Partial flows t/d t/d t/d t/d t/d

WATER 959.536085 170.4639145 7.154859967 7.154859967 7.15485997

NITRIC OXIDE 0 0 2.334332508 2.334332508 2.33433251

NITROGEN DIOXIDE 0 0 3.129031469 3.323380347 3.35275238

NITROGEN 0 0 0.223896879 0.029547791 0.00017573

TETROXIDE

NITROGEN 0 0 3801.598262 3801.598262 3801.59826

OXYGEN 0 0 111.7994054 111.7994054 111.799405

NITRIC ACID 0 0 0.000525795 0.000525795 0.00052579

AMMONIA 0 0 0 0 0

NITROUS OXIDE 0 0 0.36648111 0.36648111 0.36648111

Total flow t/d 959.536085 170.4639145 3926.606795 3926.606795 3926.60679

Total flow kmol/h 2219.26197 394.257276 5823.063828 5823.151838 5823.16514

Temperature C 128.789291 393.1981727 22 51.83759596 155.728602

Pressure bar 1.04999972 14.799996 9.099997541 9.049997554 8.99999757

Enthalpic flow kcal/h 1777553.49 1177874.405 -978694.335 233365.6391 4463464.37

Vapor fraction 1 1 1 1 1

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 21 / 25

Streams TG S4 TG S5 TG S6 Water Water Utility

S2

From E105b E106b MEAS04 >>>> >>>>

To E106b T101 >>>> C101 E109b

Partial flows t/d t/d t/d t/d t/d

WATER 7.15485997 7.154859967 7.154859967 367.2407048 1130

NITRIC OXIDE 2.33433251 2.334332508 2.334332508 0 0

NITROGEN DIOXIDE 3.35291791 3.352927815 3.352927815 0 0

NITROGEN 1.0196E-05 2.89804E-07 2.89804E-07 0 0

TETROXIDE

NITROGEN 3801.59826 3801.598262 3801.598262 0 0

OXYGEN 111.799405 111.7994054 111.7994054 0 0

NITRIC ACID 0.00052579 0.000525795 0.000525795 0 0

AMMONIA 0 0 0 0 0

NITROUS OXIDE 0.36648111 0.36648111 0.36648111 0 0

Total flow t/d 3926.60679 3926.606795 3926.606795 367.2407048 1130

Total flow kmol/h 5823.16521 5823.165218 5823.165218 849.3722577 2613.51925

Temperature C 247.85697 439.3442294 171.0302931 20 20

Pressure bar 8.94999758 8.899997595 0.99999973 9.999997298 14.9999959

Enthalpic flow kcal/h 8251581.95 16327464.53 5089518.327 -58071654.3 -27707366.3

Vapor fraction 1 1 1 0 0

Streams Water Utility Water utility

S3 S4

From E109b E108b

To E108b E112

Partial flows t/d t/d

WATER 1130 1130

NITRIC OXIDE 0 0

NITROGEN DIOXIDE 0 0

NITROGEN 0 0

TETROXIDE

NITROGEN 0 0

OXYGEN 0 0

NITRIC ACID 0 0

AMMONIA 0 0

NITROUS OXIDE 0 0

Total flow t/d 1130 1130

Total flow kmol/h 2613.51925 2613.519249

Temperature C 116.833991 198.0095633

Pressure bar 14.949996 14.89999597

Enthalpic flow kcal/h -23138491.9 -17568286.2

Vapor fraction 0 0.07331793

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 22 / 25

2.3. Column C101 profiles

Heat duty

-1.1E+07

-1.0E+07

-9.0E+06

-8.0E+06

-7.0E+06

Heat duty (kcal/h)

-6.0E+06

-5.0E+06

-4.0E+06

-3.0E+06

-2.0E+06

-1.0E+06

0.0E+00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Tray

NOx vapor mass flowrates

800

700

600

NOx mass flowrates (t/d)

500

400

300

200

100

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Tray

NO NO2 N2O4 NOx (NO+NO2+2N2O4)

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 23 / 25

Amount of NOx amount (ppmv)

90000

80000

70000

60000

NOx amount (ppmv)

50000

40000

30000

20000

10000

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Tray

Liquid mass fractions

0.7

0.6

0.5

Mass fraction

0.4

0.3

0.2

0.1

0.0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Tray

HNO3 NOx

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 24 / 25

2.4. Column C102 profiles

Liquid mass-fractions

0.60

0.58

0.56

0.54

Mass-fraction

0.52

0.50

0.48

0.46

0.44

0.42

0.40

1 2 3 4 5

Stage

WATER NITRIC ACID

Vapor mass-fractions

0.030

0.025

0.020

Mass-fraction

0.015

0.010

0.005

0.000

1 2 3 4 5

Stage

NITROGEN DIOXIDE NITROGEN TETROXI

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

Dual-pressure nitric acid manufacturing process

Version : December 2011 Page : 25 / 25

3. REFERENCES

[1] Badoual C.

Acide Nitrique

Techniques de l'Ingnieur, trait de Gnie des Procds

[2] Clarke Stephen I. and Mazzafro William J.

Nitric Acid

Kirk-Othmer Encyclopedia of Chemical Technology, 4th edition

[3] Joulia X.

"Contribution au dveloppement d'un programme gnral de simulation. Application l'analyse du

fonctionnement d'un atelier de production d'acide nitrique"

Thse INPT 1981

Copyright 2011 ProSim, Labge, France - Tous droits rservs www.prosim.net

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Design of An Plant For Manufacturing of AcetaldehydeDocument4 pagesDesign of An Plant For Manufacturing of AcetaldehydeClaudio Martinez BernalNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Understand your company's strengths, weaknesses, opportunities and threats with a SWOT analysisDocument1 pageUnderstand your company's strengths, weaknesses, opportunities and threats with a SWOT analysislucasNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Zhi Jiang 2008Document10 pagesZhi Jiang 2008lucasNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Chapter 3Document13 pagesChapter 3lucasNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Introduction to Acrylic Acid: Properties, Production, and UsesDocument262 pagesIntroduction to Acrylic Acid: Properties, Production, and Useslucas100% (6)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Correction Economic AnalysisDocument18 pagesCorrection Economic AnalysislucasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Economic AnalysisDocument10 pagesEconomic AnalysislucasNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- EiS CLO2 PLO8 Rubric Assign1Document1 pageEiS CLO2 PLO8 Rubric Assign1lucasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- CompanyDocument1 pageCompanylucasNo ratings yet

- EiS CLO2 PLO8 Rubric Assign1Document1 pageEiS CLO2 PLO8 Rubric Assign1lucasNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Ber 69-7Document3 pagesBer 69-7lucasNo ratings yet

- CompetitorDocument1 pageCompetitorlucasNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- EiS CLO2 PLO8 Rubric Assign1Document1 pageEiS CLO2 PLO8 Rubric Assign1lucasNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- How to Store Maize Flour for Long PeriodsDocument1 pageHow to Store Maize Flour for Long PeriodslucasNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- IdfcDocument2 pagesIdfclucasNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Nitric Acid PDFDocument6 pagesNitric Acid PDFshella168No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- BS en 10181-2019Document16 pagesBS en 10181-2019Federico De Martini100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Reaction Kinetics of Ammonia & Nitric AcidDocument116 pagesReaction Kinetics of Ammonia & Nitric AcidMonica Garcia100% (1)

- Topic 1 - 2Document9 pagesTopic 1 - 2hello niaNo ratings yet

- Food and Chemical Toxicology: Mustafa Soylak, Ayse AydinDocument7 pagesFood and Chemical Toxicology: Mustafa Soylak, Ayse Aydinlox agencyNo ratings yet

- Aromatic CompoundDocument256 pagesAromatic CompoundLuc LeNo ratings yet

- 2022 - Skema Bab7 - Kadar Tindak BalasDocument14 pages2022 - Skema Bab7 - Kadar Tindak BalasNa Ainul A'rifNo ratings yet

- Nitrogen and Its Compound (Chapter 19)Document26 pagesNitrogen and Its Compound (Chapter 19)SIVANESVARAN100% (6)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- (BS en 1233 - 1997) - Water Quality. Determination of Chromium. Atomic Absorption Spectrometric Methods.Document14 pages(BS en 1233 - 1997) - Water Quality. Determination of Chromium. Atomic Absorption Spectrometric Methods.Hector Cardenas100% (1)

- Set A Multiple Choice Questions Metals and Non-MetalsDocument7 pagesSet A Multiple Choice Questions Metals and Non-MetalsskandhaNo ratings yet

- Spoor-M. 1992 Modeling and Stochastic Simulation of The Reactions and Absorption of NOx in Water MSC PDFDocument124 pagesSpoor-M. 1992 Modeling and Stochastic Simulation of The Reactions and Absorption of NOx in Water MSC PDFDongO Jung100% (1)

- EuSalt AS008-2005 Potassium - Flame Atomic Absorption Spectrometric MethodDocument4 pagesEuSalt AS008-2005 Potassium - Flame Atomic Absorption Spectrometric MethodRuth Patinggi LPNo ratings yet

- Chemical Resistance ChartDocument12 pagesChemical Resistance ChartMatt SlowikowskiNo ratings yet

- Thermodynamic Considerations in The Interactions of Nitrogen Oxides and Oxy Acids in The AtmosphereDocument5 pagesThermodynamic Considerations in The Interactions of Nitrogen Oxides and Oxy Acids in The AtmosphereKing Ray TabalbaNo ratings yet

- CHAPTER 2 Acid Base and SaltDocument37 pagesCHAPTER 2 Acid Base and SaltRaghav ParasharNo ratings yet

- Solved Topical and Yearly (READANDWRITE PDFDocument275 pagesSolved Topical and Yearly (READANDWRITE PDFabdul majeed100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Modul Defra Ting 4 StudentDocument37 pagesModul Defra Ting 4 StudentCikFasyareena MaoNo ratings yet

- Kimia 2Document4 pagesKimia 2AmiRul SaLimi SAyutiNo ratings yet

- Hummer's MethodDocument1 pageHummer's MethodPrajwal Bikram Thapa0% (1)

- 9.2.19 - 972 - 25 PDFDocument1 page9.2.19 - 972 - 25 PDFLêXuânThắngNo ratings yet

- Maasai Mara University.: Food Crops Research Institute Kisii CentreDocument50 pagesMaasai Mara University.: Food Crops Research Institute Kisii CentreChilaNo ratings yet

- Oxidation of Benzoin Into Benzil (N°39) : Tatiana Pachova BSC 2, Chemistry Assistant: Chandan Dey Sciences Ii - Lab. ADocument4 pagesOxidation of Benzoin Into Benzil (N°39) : Tatiana Pachova BSC 2, Chemistry Assistant: Chandan Dey Sciences Ii - Lab. ARabiaNo ratings yet

- Bachmann Process For RDXDocument4 pagesBachmann Process For RDXjoshuaericksonNo ratings yet

- Ammonium Sulfate Unsuitable as Fire RetardantDocument3 pagesAmmonium Sulfate Unsuitable as Fire RetardantXiwen Huang100% (1)

- Design Project On Nitric Acid ProductionDocument170 pagesDesign Project On Nitric Acid ProductionKamran Malik75% (8)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Msds AnilinDocument6 pagesMsds Anilinikaa70No ratings yet

- Lab Report Exp 1 Organic ChemistryDocument7 pagesLab Report Exp 1 Organic ChemistrydzikranNo ratings yet

- EXP 7 Nitration - Methylbenzoate SP2008Document3 pagesEXP 7 Nitration - Methylbenzoate SP2008nabila_yahya_2No ratings yet

- Geochemical Analyses For Mapping Geological Processes - Webinar Handout PDFDocument98 pagesGeochemical Analyses For Mapping Geological Processes - Webinar Handout PDFFrancisco AlfaroNo ratings yet

- E841.18173 Copper in Iron OresDocument4 pagesE841.18173 Copper in Iron OresStefania HernandezNo ratings yet