Professional Documents

Culture Documents

KF Ball Iom Series p3 m3

Uploaded by

Arifin ZakyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KF Ball Iom Series p3 m3

Uploaded by

Arifin ZakyCopyright:

Available Formats

SERIES P3/M3 Page: 1 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

INSTALLATION, OPERATION & MAINTENANCE MANUAL

KF SERIES P3/M3

THREE PIECE TRUNNION

MOUNTED BALL VALVE

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 2 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

CONTENTS

BILL OF MATERIALS -------------------------------------------------------------------------------------------------------------------------------------------------- 3

1) SCOPE------------------------------------------------------------------------------------------------------------------------------------------------------------ 6

2) INSTALLATION ------------------------------------------------------------------------------------------------------------------------------------------------ 6

3) OPERATION ---------------------------------------------------------------------------------------------------------------------------------------------------- 6

3.1) INITIAL START-UP/COMMISSIONING ---------------------------------------------------------------------------------------------------------------- 6

3.2) NORMAL OPERATING ACTIVITY ----------------------------------------------------------------------------------------------------------------------- 6

3.3) DOUBLE BLOCK AND BLEED OPERATION ------------------------------------------------------------------------------------------------------------ 7

3.4) BODY CAVITY RELIEVING SYSTEMS ------------------------------------------------------------------------------------------------------------------- 7

4) MAINTENANCE ----------------------------------------------------------------------------------------------------------------------------------------------- 7

5) RECONDITIONING -------------------------------------------------------------------------------------------------------------------------------------------- 7

6) REASSEMBLY -------------------------------------------------------------------------------------------------------------------------------------------------- 8

7) VALVE SERVICING INTERVALS ---------------------------------------------------------------------------------------------------------------------------- 9

8) VALVE MAINTENANCE GUIDE LINES -------------------------------------------------------------------------------------------------------------------- 9

8.1) ROUTINE MAINTENANCE -------------------------------------------------------------------------------------------------------------------------------- 9

8.2) VALVE FLUSH ------------------------------------------------------------------------------------------------------------------------------------------------ 9

8.3) VALVE CLEANING------------------------------------------------------------------------------------------------------------------------------------------- 9

8.4) EMERGENCY REPAIR -------------------------------------------------------------------------------------------------------------------------------------- 9

9) QUICK REFERENCE ----------------------------------------------------------------------------------------------------------------------------------------- 10

9.1) NEW INSTALLATION START-UP ------------------------------------------------------------------------------------------------------------------- 10

9.2) PROPER VALVE TESTING ------------------------------------------------------------------------------------------------------------------------------- 10

9.3) SHELL TESTING -------------------------------------------------------------------------------------------------------------------------------------------- 10

9.4) HYDROSTATIC SEAT TESTING ------------------------------------------------------------------------------------------------------------------------- 10

9.5) SUPPLEMENTAL AIR SEAT TEST ---------------------------------------------------------------------------------------------------------------------- 11

9.6) DOUBLE BLOCK AND BLEED (DBB) VALVES ------------------------------------------------------------------------------------------------------- 11

10) GEAR OPERATOR FIELD ADJUSTMENT --------------------------------------------------------------------------------------------------------------- 11

11) VALVE MAINTENANCE OVERVIEW -------------------------------------------------------------------------------------------------------------------- 11

12) LUBRICATION EQUIPMENT ------------------------------------------------------------------------------------------------------------------------------ 11

13) PROPER VALVE STORAGE -------------------------------------------------------------------------------------------------------------------------------- 11

14) TROUBLESHOOTING --------------------------------------------------------------------------------------------------------------------------------------- 12

Installation, Operation and Maintenance Manual

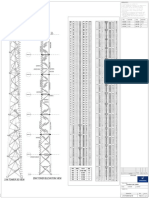

SERIES P3/M3 Page: 3 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

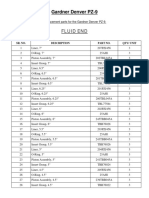

BILL OF MATERIALS

(P3/M3 Component Parts 2 FP 4 FP)

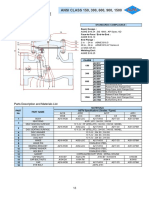

Class 150, 300, 600, 900, 1500 & 2500

1 Body

2 Adapter

3 Bonnet

4 Ball

5 Stem

6 Lower Trunnion

7 Seat assembly

8 Top cover

9 Seat springs

10 stem bearing

11 Lower Trunnion bearing

12 Adapter primary seal

13 Adapter sub seal

14 Bonnet primary seal

15 Bonnet Sub seal

16 Lower Trunnion primary seal

17 Lower trunnion sub seal

18 Stem seal

19 Stem sub seal

20 Seat seal

21 Seat seal backup

22 Seat sub seal

23 Stud, body

24 Nut, Body

25 Cap screw, bonnet

26 Cap screw, Top cover

27 Cap screw, Lower trunnion

28 Thrust bearing

29 Bleed/Drain valve

30 Injection Fitting

31 Ball check

36 Alignment pin, Bonnet

42 Antistatic Pin

43 Antistatic Spring

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 4 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

(P3/M3 Component Parts 6 FP 12 FP)

Class 150, 300 & 600

1 Body

2 Adapter

3 Bonnet

4 Ball

5 Stem

6 Lower Trunnion

7 Seat assembly

8 Top Cover

9 Seat Springs

10 stem Bearing

11 Lower Trunnion Bearing

12 Adapter Primary Seal

13 Adapter Sub Seal

14 Bonnet Primary Seal

15 Bonnet Sub Seal

16 Lower Trunnion Primary Seal

17 Lower Trunnion Sub Seal

18 Stem Seal

19 Stem Sub Seal

20 Seat Seal

21 Seat Seal Backup

22 Seat Sub Seal

23 Stud, Body

24 Nut, Body

25 Cap screw, Bonnet

26 Cap screw, Top cover

27 Cap screw, Lower trunnion

28 Thrust Bearing

29 Bleed/Drain valve

30 Injection Fitting

31 Ball Check

32 Drain Plug

34 Key

36 Alignment Pin, Bonnet

42 Antistatic Pin

43 Antistatic Spring

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 5 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

(P3/M3 Component Parts 6 FP 12 FP)

Class 900, 1500 & 2500

14 & Larger, All Classes

1 Body

2 Adapter

3 Bonnet

4 Ball

5 Stem

6 Trunnion Block

7 Seat Assembly

8 Top Cover

9 Seat Springs

10 Stem Bearing

11 Lower Trunnion Bearing

12 Adapter Primary Seal

13 Adapter Sub Seal

14 Bonnet Primary Seal

15 Bonnet Sub seal

16 Lower Trunnion Primary Seal

17 Lower trunnion sub seal

18 Stem Seal

19 Stem Sub Seal

20 Seat Seal

21 Seat Seal Backup

22 Seat Sub Seal

23 Stud, Body

24 Nut, Body

25 Cap screw, Bonnet

26 Cap screw, Top cover

28 Thrust Bearing

29 Bleed/Drain valve

30 Injection Fitting

31 Ball check

32 Drain Plug

34 Key

36 Alignment pin, Bonnet

46 Trunnion Block Pin

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 6 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

1) SKVC

SCOPE KF offers and optional gear operator with

hand wheel which can be field mounted.

The following instructions are very important Depending on size, some valves (6" bore and

for the maintenance, disassembling and larger) have gear operators mounted with

assembling of series P3 ball valve. exposed bolting. Installation of a gear operator

The instruction refers also to grease on these valves simply requires placing the

emergency seal valves with back-up rings for high operator over the stem, onto the top cover or

pressure services. bonnet and securing it with bolts.

Important! After attachment to the valve,

you must adjust the threaded "OPEN" and

"CLOSED" travel stops on the gear operator by

observing ball port and stem key position.

Complete assembly by installing covers. Failure to

set maximum open and closed positions

accurately may result in premature seat failure

due to throttling or pinched flow condition.

3) OPERATION

3.1) INITIAL START-UP/COMMISSIONING

Once the valve has been installed on the line it

shall be left either in fully open or fully closed

position depending on start-up / commissioning

operation

Important! Do not leave the valve in

half/partially open position for a long period of

time. Ensure that the pipeline is free of any debris

such as sand, tool, welding slag or weld splatter

and rod ends. This will damage the valve ball and

NAME PLATE INFORMATION seat during start-up/commissioning operations.

2) INSTALLATION 3.2) NORMAL OPERATING ACTIVITY

Install valve in system using proper size and KF Series P3 Ball Valves are recommended for

type mating flanges and appropriate gaskets (for on-off service only. Throttling (partial opening)

RF) or seal rings (for RTJ). Valve design allows for may cause excessive and non-uniform wear on

line flow in either direction. the seats, preventing tight shut-off. Series P3 Ball

Valves open by rotating stem or gear operator

SKVC P3 Ball Valves (6" bore and larger) are

Series hand wheel in a counter-clock-wise direction.

provided with mounting holes on a machined top Exact closed and open position is determined by

cover or bonnet surface for convenient actuator the radial location of the stem flats or keyway

or gear operator mounting. Consult factory for with respect to the fluid bore centerline of the

location and dimensions of these holes. body. When the stem flats or keyway are

perpendicular to the fluid bore, valve is closed.

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 7 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

Positive stops and arrow indication are provided 4) MAINTENANCE

on handles and gear operators.

Routine maintenance on Series P3 Ball Valves

3.3) DOUBLE BLOCK AND BLEED OPERATION consists of periodic grease injections through the

two seat lube fittings (30), one on the body and

KF Series P3 Ball Valves are well suited for one on the adapter. See exploded view on page

sealing fluids, concurrently, at both ends. The (3-5). General purpose grease, such as VAL-TEX

bleed valve (29) provides a safe and convenient 2000, is recommended for this service. Two

method for checking closed valve seat sealing pump strokes per fitting twice a year are

effectiveness as required for Double Block and adequate. The use of thick, very viscous grease

Bleed valves. may hamper designed sealing action and make

seat removal during any required disassembly

Caution! Before opening the bleed valve note more difficult. The stem journals are

orientation of the exhaust hole in the bleed valve permanently lubricated at the factory and

body. Stand clear of this direction when opening require no routine maintenance.

the bleed valve. Never remove bleed valve while

valve is exposed to line pressure. Note: The stem journal fitting is for sealant

injection to provide temporary sealing in the

3.4) BODY CAVITY RELIEVING SYSTEMS event of a stem seal failure (Seal weld Ball Valve

Sealant No. 5050, available from Seal weld Corp.,

Trunnion mounted ball valves do have a body Houston, Texas or Calgary, Alberta-Canada). Also,

cavity where pressure can be trapped into a in the event of internal seat/ball interface

closed volume. Under this circumstance any leakage, sealant may be injected through the two

increase of the contained fluid temperature or seat lube fittings to provide temporary sealing.

any degradation of the contained fluid can result

in an uncontrolled pressure increase of the Caution! The use of traditional "plug valve

trapped fluid to figures that are above the design sealant" may result in failure of seat and/or stem

pressures of the pressure equipment. seals and is not recommended.

To avoid the above scenario, all of the KF

trunnion mounted ball valves are provided with 5) RECONDITIONING

one of the following body cavity relieving

systems (depending on the design of the seats): KF Series P3 Ball Valves may be rebuilt after

removing the valve from the pipeline.

Self-Relieving Seats: The design of self-

relieving seat is such that when the pressure in Important! Prior to dissemble, valve must first

the body cavity exceeds the maximum cavity be isolated from system pressure and flow. Also,

pressure, the seat will automatically disconnect with the valve set at approximately half open,

from the ball and allow pressure equalization internal pressure must be bled to 0 psi through

between the body cavity and the pipeline. the ball cavity bleed valve (29). Finally, as a

safety precaution, remove the bleed valve

When one or both the seats are of the Self entirely.

Relieving type there is no need of any other type

of body cavity relieving systems. After observing the above precautions,

remove the valve from the pipeline. Operate the

ball to the "CLOSED" position. Removes handle,

retainer and stop plate. If the valve is equipped

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 8 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

with an actuator or gear operator, remove it. 6) REASSEMBLY

Also, remove the stem key (34). Remove any

accessories or hydraulic tubing. Use new replacement parts, as required. Use

a liberal amount of general purpose grease (such

Stand the valve on end, resting on one of the as Mystic JT-6) on seals and machined mating

adapters. Care should take during this step to surfaces. Fill the reliefs between stem O-rings

avoid scarring the raised sealing portion or ring with grease.

groove of the flange. Loosen the top cover, the

bonnet and Trunnion caps screws (25, 26, and Install seat assemblies and springs as far as

27). Remove the top cover (8). Pull the bonnet (3) possible, by hand, into seat pockets of body and

off, over the stem. Take the stem (5) out of the adapter. Take care to assure that O-ring seals are

valve. Remove the trunnion (6) (only for 2"FP to not pinched during assembly. Seat assemblies

12"FP size valve). There is a threaded hole in the must be placed deep enough into seat pockets so

end of the bonnet and trunnion, which may be that the wave springs are in contact with both

used to facilitate this extraction. body and seat. Insert stem assembly complete

with thrust bearing into lubricated stem journal.

Remove the nuts (24) from the studs on the (Note: A thin screwdriver or like tool will be

uppermost adapter. Carefully lift the adapter (2) required to depress the stem's side anti-static

off of the body. plunger in order to engage the plunger into the

stem journal.) Pull stem assembly through to full

Place Nylon lifting strap or rope through the engagement and rotate it to a closed position. 8"

ball port and lift the ball (4) straight out of the and above valves require that the keyway be

body. Care must be exercised to prevent the ball oriented radially toward the lube fitting in the

from being banged or scraped during this body.

procedure. Set the ball down on a clean surface

free of anything that might scar the ball finish. Place bearings in trunnion supports then

install this assembly on each trunnion of the ball.

Remove the trunnion support (7) (only 14"FP The blocks must be oriented such that the 5/16"

and larger sizes valves) form the ball. holes face toward the body and the tapered

edges conform to the mating body inside

Remove the nuts from the lower adapter. diameters. Carefully lower this assembly into the

Then, pull the body (1) off of the lower adapter. ball cavity of the body. (Note: A thin strip of steel

Remove the seats (7) and seat springs (9) from strap held in the ball's stem slot will depress the

the adapters. Take all the seals and back-up rings stem end plunger smoothly as the ball trunnion

off of the valve components clean the parts and blocks are lowered into position.) Assure this

inspect them for damage, wear or corrosion. assembly has reached its seated position within

Replace seals and other parts, as required. the body by noting engagement with trunnion

alignment pin (46). Place body seal in position on

Reassemble in reverse order. Use a liberal adapter pilot diameter then align adapter with

amount of general purpose grease (such as body studs such that flange end holes match

VAL-TEX 2000) on all seals and machined mating bodyMystic JT-6holes.

end flange ) After adapter is in contact

surfaces Fill the relief area between the O- with body fasten evenly and securely by

ring grooves with grease on the stem and tightening hex nuts in a cross-opposing order.

trunnion. A quality thread lubricant should be Complete assembly by adding stem bearing, stop

used when making up the adapter nuts. plate and retainer or gear operator assembly.

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 9 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

Clean the parts and inspect them for damage, 8.1) ROUTINE MAINTENANCE

wear and corrosion. Observe seat pocket bores,

stem seal bore and adapter seal area for rust pits The valve lubricants are designed for routine

and scale. If necessary, use fine emery for valve maintenance. It consists of injecting

removal of deposits on machined surfaces. Fine lubricant/sealant though the groove or channel

emery may also be used very lightly on the ball's inside the valve leading to seal points around the

spherical sealing surfaces. ball thus topping off the lubricant/sealant. The

Top Off quantity can vary greatly due to

Scratches or cuts on the sealing insert surface frequency of valve operation and service

of the seats are cause for replacement. Flush conditions. The lubricant is available in stick or

lube and sealant injection fittings and channels liquid from and should be free from heavy agent

with two or three pumps of grease while valve is such as PTFE, clay and wax. The most widely used

disassembled. Replace seals and other parts, as lubricant by manufacturers and users is

required. HYDROCARBON GREASE.

Reassemble in reverse order. Use a liberal 8.2) VALVE FLUSH

amount of general purpose grease (such as

Mystic JT-6) on all seals and machined mating Valve flush is a blend of synthetic oils. It works

surfaces. Fill the relief area between the stem through penetration by pressure and often

and lower trunnion O-ring grooves with grease. successful in softening hardened deposits of

Finally, assemble the adapter to the body and lubricants and sealants. It forms protective

uniformly tighten the adapter nuts. coating on the metal surface and impenetrable

barrier which will withstand high pressure and

7) VALVE SERVICING INTERVALS friction in server service demands.

Valve shall be inspected regularly during 8.3) VALVE CLEANING

operation and subjected to scheduled

maintenance. The operator is responsible for When the valve does not seal properly and

servicing the valve at regular intervals. The hard to turn, the valve cleaning is required. Valve

service intervals are determined by media in line, cleaners are the product that contains detergent,

temperature, pressure and number of cycles sealant and oils. It clears channel/passage where

during the operations. High pressure accelerates old grease may have been hardened, Inject

the loss of lubricants. cleaner through the lubrication channels, leaves

it for three-to-four hours. If possible, cycle the

8) VALVE MAINTENANCE GUIDE LINES valve to evenly distribute the cleaner in the ball-

seat contact area. This procedure is often

In order to guarantee efficient valve operation, successful in freeing seized or hard to turn valve.

the valve shall be inspected on regular basis

during the operation and subject to scheduled Note: Always displace the valve cleaner with

maintenance. All maintenance work shall be equal quantities of Lubricant/Sealant after

done by qualified personnel. Follow the grease cleaning.

gun or pump manufactures equipments

guidelines for proper use. Local regulations shall 8.4) EMERGENCY REPAIR

be strictly followed for the safety and health of

persons involved. A severe seat or ball damage may cause the

valve to leak. The valve sealants are designed to

stop a leaking valve. The sealant contains heavier

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 10 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

agent such as PTFE and clay in a grease base. The partially open. Testing pressure is 1.5 times MOP.

temporary seal can be achieved by injecting a Test duration are 2 min for 4 and under valves,

heavy sealant. Displace a heavy sealant after use 5 min for 6 to 10 valves, 15 min for 12 to 18

of a lighter lubricant/sealant to avoid valves and 30 min for 20 and larger.

complications. The valve which requires

continuous heavy sealant injections shall be I. Fit the vent valve and set it in open

either replaced or repaired immediately. position.

II. Operate the valve to the half-open

9) QUICK REFERENCE position.

III. Fill in the valve with the fluid (Venting the

9.1) NEW INSTALLATION START-UP air through the vent valve)

IV. Close the vent valve and apply pressure in

Valves are frequently damaged by debris accordance with max operating pressure

during hydro testing or start-up of a New of the pipeline.

Installation V. Visually check the outside of the ball

valve for possible deformations or

It is very important that the valve be in full leakage.

open position during this process. VI. Depressurize the valve.

If the valve is closed or partially open,

debris can damage the ball and find its 9.4) HYDROSTATIC SEAT TESTING

way into seat pockets

This can cause the valve to leak soon after Valves are to be subjected to a hydrostatic

start-up. seat test. There is to be no leakage under test

pressure. Test pressure is to be applied

9.2) PROPER VALVE TESTING successively to both sides of closed valve with

other side open to atmosphere. Testing pressure

I. Each valve is to be operated before and is 1.1 times MOP. Test durations are 2 min for 4

after testing for any unusual torque and under valves, 5 min for 6 and larger valves.

requirements.

II. Test pressure measuring devices are to be 1. Operate the valve to the fully close

either currently calibrated pressure gages position and open the vent valve.

or pressure transducers. 2. Pressurize one side in accordance with

III. Tests are to be made with ball and seat max operating pressure of the pipeline.

free of any sealant. 3. From the body vent, check for possible

IV. Fluid for shell and seat tests is to be water seat leakage.

with a corrosion inhibitor. 4. Repeat same operations as per points 2

V. Valves are to be substantially relieved of & 3 on opposite side of the valve.

air or gas when tested with liquid. 5. Depressurize the valve.

VI. Seat closure tests are to be conducted

after acceptable shell test. Note: For valve without a body vent or drain

connection, it is necessary to install on the

9.3) SHELL TESTING pipeline a control system to measure pressure

upstream and downstream the valve.

Prior to painting or other external coatings,

Valves is to be subjected to a hydrostatic shell

test. There is to be no leakage under the test

pressure when both ends are blanked and ball is

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 11 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

9.5) SUPPLEMENTAL AIR SEAT TEST for change in amount of flow out bleed

fitting. The objective is to find a position

Valves subjected to an 80psi air seat test shall where flow no longer comes from bleed

show no signs of visible leakage. fitting. At each check position, it is

necessary to allow some time to see if the

9.6) DOUBLE BLOCK AND BLEED (DBB) VALVES flow changes. If a position is not found to

stop leakage in the CW direction, turn hand

If the valve has DBB, the test shall be wheel CCW to see if the valve may have

performed as follows: been over-closing.

VII. If a position is found where leakage stops,

1. With the valve in half-open position, the turn the stop-screw CW until it hits snugly

valve shall be completely filled then tighten the lock nut.

2. The valve shall than be closed and the VIII. If a position is not found where leakage

valve vent opened to allow excess fluid stops, it can be concluded that the seat

to overflow from the cavity connection insert is damaged and repair is necessary.

3. Apply pressure on both the seats

simultaneously 11) VALVE MAINTENANCE OVERVIEW

4. Seat tightness shall be monitored from

the cavity connection Establish a valve Maintenance group

5. Depressurize the valve. Have a set valve servicing schedule

Service schedule is dependent on the

Note: For valve without a body vent or drain media and the number of times the

connection, the above test is not applicable valve is cycled

Valves should be lubricated at least one

10) GEAR OPERATOR FIELD ADJUSTMENT time every six months.

I. Locate closed stop adjustment screw on

12) LUBRICATION EQUIPMENT

gear operator. It is the screw on back of

gear case on same side of operator as the

Hydraulic hand guns are efficient for 4

hand wheel.

Bore and smaller

II. Operate ball valve to full closed, feel the

Hand guns require 50 Strokes to move 1oz

valve hit the stop.

of product

III. With pressure on closed ball valve, loosen

Air operated guns are the most efficient for

the lock nut on closed stop adjustment

6 bore and larger

screw then back out screw [CCW] 3 or 4

turns.

IV. Open bleed fitting on side (center) of ball 13) PROPER VALVE STORAGE

valve.

V. Line media will escape from bleed fitting INSIDE STORAGE

while evacuating ball cavity. Allow a minute

or two for body cavity to bleed down. If Ball valves should be in the full open

media continues to escape thru bleed position

fitting, leakage is confirmed. End connection protectors should be tight

VI. If leakage continues to be observed at to prevent ingress of moisture and debris.

bleed fitting, turn gear operator hand Valves should be left in original shipping

wheel clockwise (right) to further close the container (If possible).

ball valve. As hand wheel is turned, observe

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 12 of 13

THREE-PIECE TRUNNION Document Name: IOM-P3

Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

14) TROUBLESHOOTING

Adjust Gear Operator/Actuator Stops

Verify leakage (Block & Bleed) Occasionally, a stop set on a gear

Cycle the valve 3-6 Times operator may loosen causing the valve

Wipes the ball and often allows trapped to over or under level.

debris to travel downstream

Can free-up a stubborn seat

FAULT FINDING CORRECTION

Stroke the valve to the fully closed position.

Discharge the residual pressure left inside

Small leaks can be stopped by

the cavity through the drain valve and the

injecting sealant into grease

Internal vent plug (when provided).

nipples

Leakage Allow the system to stabilize for half an

Bad ones require replacement

hour minimum.

of seat seals.

If the valve is tight no water should drip out

the drain valve.

When any of the body flanged connections

External leaks can be stopped

Body Leakage drips verify the bolt tightening torque of the replacing body gaskets.

joint concerned.

A slight increase in the valve torque

requirement is natural during the valve life Inject lubricant grease through

and has been taken in account when the stem grease fitting.

If this operation does not bring

designing the operator device.

any benefit dismantle the

This torque increment tends to stabilize with stem/gland flange group and

Increase in

time. verify no galling, scores or

torque

Torque increasing rate that does not trend damages have occurred.

requirements If possible, remove the foreign

to stabilize can be caused by external affairs

such as sand / debris trapped between stem objects from the pipeline.

Verify that the operator is

and bonnet flange or foreign objects, left

correctly set and is delivering

into the pipeline that gets trapped between its nominal torque.

seats and ball.

Installation, Operation and Maintenance Manual

SERIES P3/M3 Page: 13 of 13

Document Name: IOM P3

THREE-PIECE TRUNNION Revision: 15333

MOUNTED BALL VALVE Release Date: 07/03/2015

Leakages from stem depend from damage of

primary and secondary seal on the Small leakages can be stopped

stem in case the grease injector is not or reduced injecting grease

between the two sealing areas. In this case sealant through the grease

the leakage is recorded through stem seal. injector.

Stem leakage

In case the grease injector is positioned

between the seals (primary and secondary) Big leakages require the

the leakage of primary seal can be recorded dismounting of the valve.

removing the grease injector or plug forecast

during the design stage.

If elastomeric seal material is

damaged it is substituted after

dismounting the vent and

Leakage through drains and vents caused by

drain.

damage of elastomeric seal material or when

In case there is any missing

minimum torque required is not achieved

Vent and torque the correct torque is

(wrong torque applied or threaded parts

drain leakage applied (after the verification of

damaged).

integrity for threaded area).

In this case there is a leakage of fluid or gas

Leak from the gasket seal can

from vent and drain.

require the dismounting of the

flange and substitution of

gasket seal.

Installation, Operation and Maintenance Manual

You might also like

- SECTION 6-Power End Repair Part PDFDocument46 pagesSECTION 6-Power End Repair Part PDFDidin Delgado100% (1)

- Annular Spherical Packing ElementsDocument21 pagesAnnular Spherical Packing Elementsjesus100% (1)

- ## - Powerful P&ID Development PDFDocument33 pages## - Powerful P&ID Development PDFAyman TermaniniNo ratings yet

- PC340, PC340LC-6K, PC340NLC-6K Hydraulic Excavator Shop Manual PDFDocument748 pagesPC340, PC340LC-6K, PC340NLC-6K Hydraulic Excavator Shop Manual PDFJozef100% (6)

- Regulator3 4 DSDocument4 pagesRegulator3 4 DSargaNo ratings yet

- Gardner Denver PZ-7 PZ7 PZG Mud Pump PartsDocument9 pagesGardner Denver PZ-7 PZ7 PZG Mud Pump PartsImran ShaikhNo ratings yet

- Gardner Denver PZ Mud Pump Parts ManualDocument6 pagesGardner Denver PZ Mud Pump Parts ManualKapil Agarwal100% (1)

- Empaquetaduras Bombas Triplex.Document40 pagesEmpaquetaduras Bombas Triplex.pabloasotoNo ratings yet

- DSA6 15M SidedoorDocument14 pagesDSA6 15M SidedoorДудла Станіслав100% (1)

- Grove B5Document32 pagesGrove B5walid100% (1)

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 pagesOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNo ratings yet

- DHV 6a Catalogue-FinalDocument16 pagesDHV 6a Catalogue-FinalJohn UrdanetaNo ratings yet

- Gardner-Denver@: Triplex PlungerDocument38 pagesGardner-Denver@: Triplex PlungerLibardo Alfonso Cadena Rodriguez100% (1)

- Saint Gobain Bushing Install RequirementsDocument21 pagesSaint Gobain Bushing Install RequirementsJeremy100% (1)

- Stripper Packer DSV4 3.06 1 VentanaDocument12 pagesStripper Packer DSV4 3.06 1 VentanaValeria Sanchez100% (1)

- 2a33687 Exl Back Pressure Relief Valve PDFDocument51 pages2a33687 Exl Back Pressure Relief Valve PDFEnrique HortaNo ratings yet

- Polypak SealDocument2 pagesPolypak SealZAMFERLENONo ratings yet

- Y Strainer CatalogDocument21 pagesY Strainer CatalogIrfan FahmiNo ratings yet

- Technical Description MPPUDocument10 pagesTechnical Description MPPUNinaNo ratings yet

- Farr KT7585Document132 pagesFarr KT7585wfcenda2603No ratings yet

- Baker Style 20 Setting Tool PDFDocument1 pageBaker Style 20 Setting Tool PDFDenier RubianoNo ratings yet

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 pagesSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoNo ratings yet

- Mud Gate ValveDocument16 pagesMud Gate ValvesudhisnairNo ratings yet

- M60es54 Na549y QC Man 001Document29 pagesM60es54 Na549y QC Man 001Riski Kurniawan67% (3)

- High Energy Mixing Injector - en - MANUALDocument10 pagesHigh Energy Mixing Injector - en - MANUALNiki Andriano100% (1)

- Anson Gate Valves, Manifolds, and TreesDocument9 pagesAnson Gate Valves, Manifolds, and TreesBala KrishnanNo ratings yet

- DSQ4 10M SidedoorDocument15 pagesDSQ4 10M SidedoorДудла СтаніславNo ratings yet

- Codes & Standards For Natural GasDocument13 pagesCodes & Standards For Natural Gasharikrishnanpd3327No ratings yet

- CASVDocument17 pagesCASVvegaronNo ratings yet

- PB DDM 026Document3 pagesPB DDM 026Jim SharpNo ratings yet

- 7.6 SingleDocument226 pages7.6 Singlewuillian barretoNo ratings yet

- 2020 Product CatalogDocument60 pages2020 Product CatalogGasim MohNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument15 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- Franks Cabot - Q02 - 09 de 17 - TRANSMISSION PDFDocument10 pagesFranks Cabot - Q02 - 09 de 17 - TRANSMISSION PDFcarlospais2No ratings yet

- SL Manual Lock 13 58 SHAFFER RAM BOP Page-6-10Document5 pagesSL Manual Lock 13 58 SHAFFER RAM BOP Page-6-10Richard EVNo ratings yet

- Mahle Bilge Water Separator Type PPT-BWS:MESB 5,0 - 5ppm Instruction ManualDocument183 pagesMahle Bilge Water Separator Type PPT-BWS:MESB 5,0 - 5ppm Instruction ManualIgors VrublevskisNo ratings yet

- Oil States Swab Cups PDFDocument2 pagesOil States Swab Cups PDFramudo ZNo ratings yet

- SPE - 22559 Advancements in Dynamic-Kill Calculations For Blowout Wells - G E KoubaDocument10 pagesSPE - 22559 Advancements in Dynamic-Kill Calculations For Blowout Wells - G E KoubaAsahel NuñezNo ratings yet

- Stripper TOT 2.50 10M DS34 TechMan1146Document13 pagesStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaNo ratings yet

- N2 Triplex Pump - 1Document6 pagesN2 Triplex Pump - 1Ibrahim AhmedNo ratings yet

- SRP PUMP ASSEMBLY Parts and Accessories CatalogueDocument52 pagesSRP PUMP ASSEMBLY Parts and Accessories Catalogue000No ratings yet

- M60eh44 Man 001Document40 pagesM60eh44 Man 001Riski KurniawanNo ratings yet

- V1S3 Traveling Block Manual 2015.4.17Document6 pagesV1S3 Traveling Block Manual 2015.4.17tavingus2No ratings yet

- KF Series Ball Valve PDFDocument20 pagesKF Series Ball Valve PDFbloggerparthiNo ratings yet

- A08012200E D en TPH400Document85 pagesA08012200E D en TPH400Doni Kurniawan100% (1)

- CLE14000DPcerev9 09 PDFDocument139 pagesCLE14000DPcerev9 09 PDFAdhie WaelacxhNo ratings yet

- ASME Bladder Accumulator DatasheetDocument3 pagesASME Bladder Accumulator DatasheetEng-Mohammed Salem100% (1)

- Technical Manual: 1:1 SeparatorDocument24 pagesTechnical Manual: 1:1 SeparatorAndres NavarroNo ratings yet

- Case Study VR Lubricator ToolDocument2 pagesCase Study VR Lubricator ToolVictorNo ratings yet

- 1PackerSystem PackerAccessories&tools PDFDocument21 pages1PackerSystem PackerAccessories&tools PDFAnand aashishNo ratings yet

- CamesaEMC Catalog 12-2013 7Document1 pageCamesaEMC Catalog 12-2013 7Gerardo LizardoNo ratings yet

- FH18 35(21)英文说明书Document16 pagesFH18 35(21)英文说明书ADM MTCNo ratings yet

- CT WKM Gate Saf T Seal 01 PDFDocument36 pagesCT WKM Gate Saf T Seal 01 PDFchonubobbyNo ratings yet

- C 06.C Wellhead DesignDocument6 pagesC 06.C Wellhead DesignJose David Hernandez OteroNo ratings yet

- Catalogue Smi PDFDocument24 pagesCatalogue Smi PDFegsge100% (1)

- Lufkin Mark IIDocument8 pagesLufkin Mark IIjulioramcaNo ratings yet

- Caja de Cambio John DeereDocument52 pagesCaja de Cambio John Deerenelson.oyanadel21No ratings yet

- Accelerated Multiplex Plunger Pumps PDFDocument20 pagesAccelerated Multiplex Plunger Pumps PDFJessica montesNo ratings yet

- H11 Cameron Floating Type Accumulator Package ManualDocument11 pagesH11 Cameron Floating Type Accumulator Package ManualEdmo VirgensNo ratings yet

- Parker HTR ActuatorDocument22 pagesParker HTR ActuatorYorkistNo ratings yet

- Model pl5 Service Manual PDFDocument31 pagesModel pl5 Service Manual PDFingcalderonNo ratings yet

- Batch Mixer ManualDocument40 pagesBatch Mixer ManualAndrew ArNo ratings yet

- WWW - Incar.tw-Kelly Spinner ManualDocument6 pagesWWW - Incar.tw-Kelly Spinner ManualSachin KumarNo ratings yet

- Triplex Pump: TPH 400 Main SpecificationsDocument2 pagesTriplex Pump: TPH 400 Main SpecificationsAttou Housseyn100% (1)

- Valvulas Cuerpo Soldado KFDocument10 pagesValvulas Cuerpo Soldado KFMiguel FNo ratings yet

- Omnirest Parts ListDocument20 pagesOmnirest Parts ListjmezapNo ratings yet

- Dungs Frs Gas Pressure RegulatorsDocument8 pagesDungs Frs Gas Pressure RegulatorsSandeep JajawaraNo ratings yet

- ASMEDocument77 pagesASMEJitendra BhosaleNo ratings yet

- Pressure Vessel Temperature Ratings For Group 1.3 Materials Per. ASME B16.5 Pipes Flanges and Flanged Fittings - Engineers EdgeDocument5 pagesPressure Vessel Temperature Ratings For Group 1.3 Materials Per. ASME B16.5 Pipes Flanges and Flanged Fittings - Engineers EdgeMuhammad AfzaalNo ratings yet

- Maverick Valves CatalogueDocument84 pagesMaverick Valves Cataloguer4mms3sNo ratings yet

- Forged Extended Gate ShortDocument2 pagesForged Extended Gate ShortAugusto Manuel Inga SánchezNo ratings yet

- SRG LPG Float Gauge Type 487: Container Connection Mounting Head MaterialsDocument1 pageSRG LPG Float Gauge Type 487: Container Connection Mounting Head Materialsalvaro_arcvNo ratings yet

- Catalogo ValvulaDocument1 pageCatalogo Valvulajcojedar2009No ratings yet

- TATA Valve ClassesDocument5 pagesTATA Valve ClassesIgnacio Moratinos CastañedaNo ratings yet

- API 570 Certification Module #1 Homework Open Book: Terms in This SetDocument4 pagesAPI 570 Certification Module #1 Homework Open Book: Terms in This SetNIMANo ratings yet

- TDS Crystar Saint-Gobain HiFlo - enDocument2 pagesTDS Crystar Saint-Gobain HiFlo - enSanja BjelicaNo ratings yet

- Wey Knife Gate Valve Model A3 W0 W1 W2 W3 PDFDocument4 pagesWey Knife Gate Valve Model A3 W0 W1 W2 W3 PDFcvfNo ratings yet

- Wafer Check Valves - O&MDocument4 pagesWafer Check Valves - O&MjayakumarNo ratings yet

- Erection PDFDocument3 pagesErection PDFmmm mmmNo ratings yet

- Grundfosliterature 4609696Document42 pagesGrundfosliterature 4609696Maaz JunaidiNo ratings yet

- Catalogue Armacon-Valve 20190522Document26 pagesCatalogue Armacon-Valve 20190522Scipp ZengNo ratings yet

- 501SHDocument2 pages501SHbhaskarbabaiNo ratings yet

- Frank Henry CatalogueDocument80 pagesFrank Henry CatalogueRio de MarioNo ratings yet

- Kemper DistributionDocument16 pagesKemper Distributionerminhusagic2308No ratings yet

- Ci Sluice Valve PN 1.6Document1 pageCi Sluice Valve PN 1.6rajanNo ratings yet

- Pressure Measurement Part2Document7 pagesPressure Measurement Part2salemNo ratings yet

- Cast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Document3 pagesCast Steel Swing Check Valve: ANSI CLASS 150, 300, 600, 900, 1500Andri AjaNo ratings yet

- Assembly - FlayerDocument8 pagesAssembly - FlayerIbrahim MesfinNo ratings yet

- PDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia SeparatorDocument8 pagesPDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia Separatorhgag selimNo ratings yet

- Orifice Plate - Multi-Holes: DatasheetDocument10 pagesOrifice Plate - Multi-Holes: DatasheetMarcelo PellizzaNo ratings yet