Professional Documents

Culture Documents

Sinter Machine 1 - 05.07.2017 - Rev

Uploaded by

sujit55840 ratings0% found this document useful (0 votes)

14 views2 pagesOriginal Title

SINTER MACHINE 1_05.07.2017_REV.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pagesSinter Machine 1 - 05.07.2017 - Rev

Uploaded by

sujit5584Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

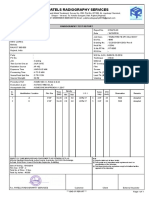

ELECTROSTEEL STEELS LIMITED Report Status

Bokaro Works, CBM Cell ALERT

OIL ANALYSIS SECTION

Wear Debris Analysis

Report

DATE: 9/2/2017

REPORT NO:WDA_SP_SM1_17-18 Q2

General:

Department Attention:1 Attention:2 Area

SINTER PLANT G C MAHTO SANJAY BORAL

Equipment Item Sample_ID Date of Sample

SINTER MACHINE 1 CC104S1458V2 7/5/2017

Wear Debris Analysis:

Wear PC(ppm) Normal RB Red Oxides Black Oxide Sand/Dirt Sphere

78 F N N F

Low Al St SW CH St WP Hi AL St WP Md Al St WP Brg. WP Brg Fat WP

0 0 0 0 0 0 0 38 F 16 F

Brg Pit WP Babbitt WP Cu WP Gear WP Gear Fatigue Gear Pit WP

0 0 0 0 0 0 0 0 24 F-M 0 0

Observation based on above analysis: (All numbers units are in microns wherever not stated)

1: Oil contaminated with debris/wear particles.

2:

Suggestion based on the above observation:

1: Centrifuge/filter the oil to avoid cascading wear.

2:

FEEDBACK FROM DEPARTMENT :

Abbreviations used:

1:Al: Alloy 2:St: Steel 3:SW: sliding wear 4:CH: Case Harden 5: Hi: High 6:Md: Medium 7:Brg: Bearing

8:Fat: Fatigue 9:Pit: Pitting 10:WP: wear particle: 11:PC: Particle Concentration 12:RB: Rubbing Wear

13:Cu: Copper 14:S Small 15:M: Marginal 16:NL: Near Large 17: NM: Near Marginal 18:L: Large 19:N:

Negligible 2: WPC: Wear Particle Concentration

(All records are in CBM cell and can be verified if required)

(CBM Cell)

You might also like

- Amal-18 Sta DDR#18 29-02-2020Document30 pagesAmal-18 Sta DDR#18 29-02-2020eng7mohamed7hashimNo ratings yet

- Boilers - Introduction, TypesDocument13 pagesBoilers - Introduction, Typessujit5584No ratings yet

- Bill of Quantity For Silo FoundationDocument6 pagesBill of Quantity For Silo Foundationlaxmi sunder libiNo ratings yet

- Dmgt307 Total Quality ManagementDocument252 pagesDmgt307 Total Quality ManagementAshu KunwarNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- RbamDocument35 pagesRbamTong Bbm100% (1)

- IIW/EWF Diploma in Welding QualificationDocument8 pagesIIW/EWF Diploma in Welding Qualificationreezman100% (1)

- X DIN 6885Document3 pagesX DIN 6885bee140676No ratings yet

- Ball Bearing Case Studies enDocument8 pagesBall Bearing Case Studies ensubodh ranjanNo ratings yet

- ME ProductCatalogDocument20 pagesME ProductCatalogNoman Abu-FarhaNo ratings yet

- Plano de SaturadorDocument6 pagesPlano de SaturadorRodrigo Andres CeledonNo ratings yet

- Dmgt525 Materials ManagementDocument202 pagesDmgt525 Materials ManagementArasu RajaNo ratings yet

- Cleaning Primary Reformer's Convection Section and Combustion Chamber's Firebrick CoatingDocument7 pagesCleaning Primary Reformer's Convection Section and Combustion Chamber's Firebrick CoatingakjayaNo ratings yet

- KELTEC Technolab CECOELDocument40 pagesKELTEC Technolab CECOELEber.CV100% (1)

- Uaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileDocument20 pagesUaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileABHIJITH M SNo ratings yet

- Equalizing Line Mbe 6 WTRDocument2 pagesEqualizing Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- 11C043F0300-5330 - 2 Calculation Carbon FilterDocument120 pages11C043F0300-5330 - 2 Calculation Carbon FilterLorenzoNo ratings yet

- D62 - 691 - 5 - C4-Specification Sheets PDFDocument26 pagesD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaNo ratings yet

- IIW Guidance For 3834Document20 pagesIIW Guidance For 3834Necati Dayı80% (5)

- Company Profile - Timur AutomationDocument26 pagesCompany Profile - Timur AutomationsabrinaNo ratings yet

- Oil Analysis ReportDocument2 pagesOil Analysis Reportsujit5584No ratings yet

- Magnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceDocument4 pagesMagnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceSulthan HanifNo ratings yet

- 107.8182.MPI - Pre.Unit.730395.Fuel TankDocument2 pages107.8182.MPI - Pre.Unit.730395.Fuel TankHerr DdimanNo ratings yet

- Patels Radiography Services RT ReportDocument1 pagePatels Radiography Services RT ReportRavi patelNo ratings yet

- Amal-18 Sta DDR#20 02-03-2020Document30 pagesAmal-18 Sta DDR#20 02-03-2020eng7mohamed7hashimNo ratings yet

- Amal-18 Sta DDR#23 05-03-2020Document30 pagesAmal-18 Sta DDR#23 05-03-2020eng7mohamed7hashimNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationKorneliusNo ratings yet

- Crown Cement Concrete & Building Products LTD.: Quality Assurance & Laboratory Department - Unit-6Document3 pagesCrown Cement Concrete & Building Products LTD.: Quality Assurance & Laboratory Department - Unit-6Hasan al MahmudNo ratings yet

- Feuille Des Donnees Cables F&G: ProjetDocument6 pagesFeuille Des Donnees Cables F&G: ProjetAshraf Ammar100% (1)

- Material Receiving Inspection SENDING ULN3 TO LPGU3Document30 pagesMaterial Receiving Inspection SENDING ULN3 TO LPGU3ReduddboyNo ratings yet

- Plate - ADocument9 pagesPlate - ASumit SinghNo ratings yet

- Inspection Report: General InformationDocument22 pagesInspection Report: General InformationShamsul AffendiNo ratings yet

- Rig: GD Chitra 15.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 711M. Present OperationDocument7 pagesRig: GD Chitra 15.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 711M. Present Operationongcchemist gd chitraNo ratings yet

- PR RepairDocument1 pagePR Repairaxis inspection solutionsNo ratings yet

- Amal-18 Sta DDR#19 01-03-2020Document30 pagesAmal-18 Sta DDR#19 01-03-2020eng7mohamed7hashimNo ratings yet

- Amal-18 Sta DDR#22 04-03-2020Document30 pagesAmal-18 Sta DDR#22 04-03-2020eng7mohamed7hashimNo ratings yet

- Laporan MT OK PABSHOP TRUBADocument8 pagesLaporan MT OK PABSHOP TRUBAAnda SilalahiNo ratings yet

- ISO Certified Company Final Inspection ReportsDocument20 pagesISO Certified Company Final Inspection ReportsSandeep MauryaNo ratings yet

- Atch Igt SPK DSDocument1 pageAtch Igt SPK DSSudar MyshaNo ratings yet

- Design Basis For Nht/Unit 02: SnamprogettiDocument2 pagesDesign Basis For Nht/Unit 02: Snamprogettimohsen ranjbarNo ratings yet

- Design Basis For Nht/Unit 02: SnamprogettiDocument2 pagesDesign Basis For Nht/Unit 02: Snamprogettimohsen ranjbarNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Amal-18 Sta DDR#25 07-03-2020Document30 pagesAmal-18 Sta DDR#25 07-03-2020eng7mohamed7hashimNo ratings yet

- Amal-18 Sta DDR#26 08-03-2020Document30 pagesAmal-18 Sta DDR#26 08-03-2020eng7mohamed7hashimNo ratings yet

- Virgo ValvesDocument26 pagesVirgo ValvesslavaNo ratings yet

- Amal-18 Sta DDR#24 06-03-2020Document30 pagesAmal-18 Sta DDR#24 06-03-2020eng7mohamed7hashimNo ratings yet

- 109.8181.MPI - Pre.Unit.730395.Cover RadiatorDocument2 pages109.8181.MPI - Pre.Unit.730395.Cover RadiatorHerr DdimanNo ratings yet

- Radiography OfferDocument1 pageRadiography OfferRavi patelNo ratings yet

- by Pass Line Mbe 6 WTRDocument2 pagesby Pass Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- Fwir Branch LineDocument10 pagesFwir Branch LineMuhamad Hifni SyahbanaNo ratings yet

- Amal-18 Sta DDR#21 03-03-2020Document30 pagesAmal-18 Sta DDR#21 03-03-2020eng7mohamed7hashimNo ratings yet

- Test Certificate: QR/BTC/01 ISO 9001:2015 CompanyDocument1 pageTest Certificate: QR/BTC/01 ISO 9001:2015 CompanyRai Singh MalhiNo ratings yet

- Amal-18 Sta DDR#8 19-02-2020Document30 pagesAmal-18 Sta DDR#8 19-02-2020eng7mohamed7hashimNo ratings yet

- Welding Procedure B69AWDocument2 pagesWelding Procedure B69AWMastram HatheshNo ratings yet

- Sos Sampling ReportDocument2 pagesSos Sampling Reportomar solimanNo ratings yet

- SOS Sampling ReportDocument2 pagesSOS Sampling ReportAsaisan AsaisanNo ratings yet

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomNo ratings yet

- AK2 - RevADocument13 pagesAK2 - RevAChirag ShahNo ratings yet

- Rig: GD Chitra 14.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 540M. Present OperationDocument7 pagesRig: GD Chitra 14.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 540M. Present Operationongcchemist gd chitraNo ratings yet

- Level Gauge Data SheetDocument4 pagesLevel Gauge Data SheetJKKNo ratings yet

- RT Report For CastingDocument1 pageRT Report For CastingSwarup mishraNo ratings yet

- F-04 (Ultrasonic Test.) (New) Dated. 25.03.2016 JOKA123Document52 pagesF-04 (Ultrasonic Test.) (New) Dated. 25.03.2016 JOKA123Himanshu SinghNo ratings yet

- NDT Request for Butt WeldsDocument3 pagesNDT Request for Butt WeldsFiras AlbaweiNo ratings yet

- ALL Specification Sheet ExcelDocument20 pagesALL Specification Sheet Exceladitya.ablazeexportNo ratings yet

- Colume Detile by Etabs 16Document2 pagesColume Detile by Etabs 16hedayatullahNo ratings yet

- Visual Inspection ReportDocument5 pagesVisual Inspection ReportOmar WardehNo ratings yet

- DSFSFSEDocument2 pagesDSFSFSEAniket KabadeNo ratings yet

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pages14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariNo ratings yet

- Two years Spares quote comparison for Nitrogen Generation PlantDocument2 pagesTwo years Spares quote comparison for Nitrogen Generation Plantsujit5584No ratings yet

- Tata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data SheetDocument6 pagesTata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data Sheetsujit5584No ratings yet

- SR No Package Details TBSL Scope - Civil Works Vender Scope-Civil WorksDocument1 pageSR No Package Details TBSL Scope - Civil Works Vender Scope-Civil Workssujit5584No ratings yet

- Jeevan Praman - Procedures For DLC Ver1 0Document6 pagesJeevan Praman - Procedures For DLC Ver1 0vineetkrsinghNo ratings yet

- 00 Hydrogen - 2Document6 pages00 Hydrogen - 2sujit5584No ratings yet

- 00 Hydrogen - 2Document6 pages00 Hydrogen - 2sujit5584No ratings yet

- 00 Hydrogen - 2Document6 pages00 Hydrogen - 2sujit5584No ratings yet

- AsDocument3 pagesAssujit5584No ratings yet

- Complete list of bearingsDocument28 pagesComplete list of bearingssujit5584No ratings yet

- 13 Sinter Plant-MM-Preventive Maintenence Schedule For EOT CraneDocument2 pages13 Sinter Plant-MM-Preventive Maintenence Schedule For EOT Cranesujit5584No ratings yet

- No-Alcohol Policy at Alstom TransportDocument5 pagesNo-Alcohol Policy at Alstom Transportsujit5584No ratings yet

- Boiler Tech SpecsDocument2 pagesBoiler Tech Specssujit5584No ratings yet

- DetailsDocument1 pageDetailssujit5584No ratings yet

- A Ad Haar Authentication User GuideDocument4 pagesA Ad Haar Authentication User GuideTathagat SarthakaNo ratings yet

- Culture L1 SolutionsDocument29 pagesCulture L1 Solutionssujit5584No ratings yet

- Ments On Offer of KirloskarDocument3 pagesMents On Offer of Kirloskarsujit5584No ratings yet

- 02 INTRODUCTION Sintering ProcessDocument3 pages02 INTRODUCTION Sintering Processsujit5584No ratings yet

- 14 LIst of Check ListDocument1 page14 LIst of Check Listsujit5584No ratings yet

- How To Read Your Oil Analysis ReportDocument7 pagesHow To Read Your Oil Analysis Reportswapneel_kulkarniNo ratings yet

- UTL-007-A4 Part-1ADocument20 pagesUTL-007-A4 Part-1Asujit5584No ratings yet

- Tata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data SheetDocument6 pagesTata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data Sheetsujit5584No ratings yet

- DESIGN CALCULATION FOR: Overhead Yard Pipework: PH-1, CSC : ISMB400 622.1 ISMB300Document3 pagesDESIGN CALCULATION FOR: Overhead Yard Pipework: PH-1, CSC : ISMB400 622.1 ISMB300sujit5584No ratings yet

- Environmental Pollution: Module - 4Document21 pagesEnvironmental Pollution: Module - 4sauravds7No ratings yet

- 03 Area of Sinter PlantDocument1 page03 Area of Sinter Plantsujit5584100% (1)

- Employment Form ESLDocument5 pagesEmployment Form ESLsujit5584No ratings yet

- Allahabad Bank (PO) 21.02.2010 Answer KeyDocument6 pagesAllahabad Bank (PO) 21.02.2010 Answer KeyumaannamalaiNo ratings yet

- Standard Maintenance Practice: Laser Beam Alignment of Circle Cooler Fan No.3 MotorDocument5 pagesStandard Maintenance Practice: Laser Beam Alignment of Circle Cooler Fan No.3 Motorsujit5584No ratings yet

- Advertisement For Assistant Competitive Examination-2014Document3 pagesAdvertisement For Assistant Competitive Examination-2014sujit5584No ratings yet

- 00 Hydrogen - 2Document6 pages00 Hydrogen - 2sujit5584No ratings yet

- DXCDDocument302 pagesDXCDPankajNo ratings yet

- Product Brochure PDFDocument16 pagesProduct Brochure PDFEswara ReddyNo ratings yet

- Ch15. Resource Requirements Planning - MRP & CRPDocument73 pagesCh15. Resource Requirements Planning - MRP & CRPJaishree PanwarNo ratings yet

- Automated Flow LinesDocument2 pagesAutomated Flow LinesNyanga-regina Nyamaropa Bende Chapatarongo-ruwangweNo ratings yet

- 2009 TDS Terramesh Galvanized & PVC AMDocument2 pages2009 TDS Terramesh Galvanized & PVC AMRobert Ibañez MendezNo ratings yet

- Compact SpinningDocument51 pagesCompact SpinningKathirrveluSubramainan100% (1)

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- A Review of Open Cast Coal Mining in IndiaDocument62 pagesA Review of Open Cast Coal Mining in IndiaAbhiram ReddyNo ratings yet

- PPG PMC Primetime Protective Vol3 10jan2012 en LRDocument16 pagesPPG PMC Primetime Protective Vol3 10jan2012 en LRsayyadsajidaliNo ratings yet

- Nanocomposites Synthesis, Structure, Properties and New Application OpportunitiesDocument39 pagesNanocomposites Synthesis, Structure, Properties and New Application OpportunitiesFkbs MalangNo ratings yet

- CP Abalaba 201704Document13 pagesCP Abalaba 201704Larasanto Cipta AgungNo ratings yet

- Winter Project ReportDocument23 pagesWinter Project ReportSARAVANANNo ratings yet

- ProblemsDocument1 pageProblemsvivek100% (1)

- Pagel - Grout 20 USA 20V12050Document4 pagesPagel - Grout 20 USA 20V12050some_guy89100% (1)

- Me440 - hw2Document6 pagesMe440 - hw2Enis DönmezNo ratings yet

- Paints Coatings and Adhesives - Industry Overview (April 2002) PDFDocument26 pagesPaints Coatings and Adhesives - Industry Overview (April 2002) PDFAbhineet Shrivastava100% (1)

- Production Planning: It's Meaning and Objectives!Document52 pagesProduction Planning: It's Meaning and Objectives!Gautam KocherNo ratings yet

- Oil and Gas Production Handbook Ed3x0 - Web - Part11Document2 pagesOil and Gas Production Handbook Ed3x0 - Web - Part11joshua_tan_31No ratings yet