Professional Documents

Culture Documents

Compressor MSV 20 SD Two Stages 175 Psig

Uploaded by

Joel Leandro Ibarra CoriaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressor MSV 20 SD Two Stages 175 Psig

Uploaded by

Joel Leandro Ibarra CoriaCopyright:

Available Formats

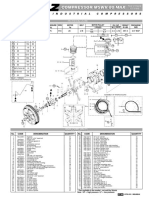

COMPRESSOR MSV 20 SD TWO STAGES

175 PSIG

C A S T I R O N I N D U S T R I A L C O M P R E S S O R S

TECHNICAL DATA

DISPLACEMENT MAX. PRESSURE RPM MOTOR BELT MOTOR PULLEY OIL CAP. WEIGHT DISCHARGE

MODEL

cfm psig hp l IN lbs SIZE

2 POLES 4 POLES

mm inch mm inch

MSV 20 SD 20 175 930 5 2-B 0,7 120 1/2" BSP

105 4.1 200 7.9

38

40 37

50

49

36

39

48

35

24 24

42 41

28

A 34

33

27 46 47

43

26 45 26

44

32

25 47 24

24 4

4 31

22

23

A

30

10 20

21

11 3 29

1

2 6 4

4 5

11

7 19

8

9

4 18

11 17

12 13

14 15 16

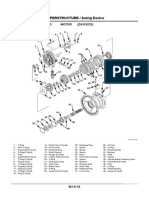

BARE PUMP'S PARTS

No. CODE DENOMINATION QUANTITY No. CODE DENOMINATION QUANTITY

1 709.0595-7 Flywheel 01 29 709.0545-0 LP connecting rod 01

2 * UNC 1/4" x 5/8" LT head screw 04 30 016.0022-2 LP 4" piston 01

3 709.0161-7 Flange cover 01 31 830.0274-3 LP ring 01

4 830.0275-1 Crankcase gasket 01 32 709.0540-0 LP cylinder 01

5 023.0048-6 Oil seal 01 33 709.0588-4 LP cylinder cover 01

6 019.0005-6 6207 bearing 01 34 007.0118-0 Filter element 01

7 * UNC 3/8" x 1" LT head screw 06 35 007.0116-0 Air filter 01

8 709.0544-2 Flange 01 36 003.0005-5 NPT 1/8" x 1/4" elbow 02

9 382.0107-7 6308 bearing 01 37 830.0340-5 1/4" crankcase breather tube 01

0

10 709.0163-3 Key 01 38 003.0113-2 90 MF 1/2" elbow 01

11 830.0375-8 Crankshaft 01 39 830.0296-4 Intercooler 01

12 709.0730-5 Counter weight 01 40 003.0008-0 0

90 MF 1/2" fitting 01

13 013.0467-4 UNC 3/16" x 7/8" LT Allen head screw 02 41 013.0287-6 LP concentric valve screw 01

14 709.0550-7 Crankcase 01 42 013.0040-7 HP concentric valve screw 01

15 830.0205-0 Oil drain tube 01 43 809.0212-3 LP concentric valve 01

16 709.0549-3 Crankcase cover 01 44 830.0175-5 LP concentric valve kit 01

17 830.0106-2 1/2" oil level sight 01 45 830.0277-8 HP concentric valve kit 01

18 * UNC 5/16" x 3/4" LT head screw 04 46 809.0321-9 HP concentric valve 01

19 830.0202-6 Oil level dipstick 01 47 830.0582-3 HP/LP concentric valve spring 02

20 830.0636-0 HP connecting rod with needle bearing 01 48 830.0599-8 1/4" ring 01

21 019.0028-0 Needle bearing 01 49 830.0603-0 5/8" ring 01

22 830.0633-0 HP 2.1/4" piston 01 50 003.0050-0 1/2" x 5/8" straight connection 02

23 830.0276-0 HP ring 01 - 709.0524-8 Pulley 105 mm 01

24 * UNC 3/8" x 7/8" LT head screw 19 - 709.0464-0 Pulley 200 mm 01

25 709.0541-8 HP cylinder 01

26 830.0294-8 Upper gasket 01 * Part available in the market - not sold by Schulz S.A.

27 709.0587-6 HP cylinder cover 01 Note: The standard motor pulley is supplied with a standard hole.

28 003.0108-6 0

45 MF 1/2" fitting 01 HP = high pressure

LP = low pressure

CT 169 JULY/00 025.0306-0

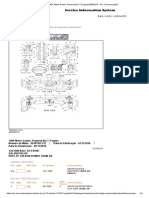

DIMENSIONS MAINTENANCE

WARNING

MSV 20 SD

H Turn off power before servicing and be sure the air tank is unloaded. These

instructions are based on normal operating conditions. If the compressor is

located in an exceedingly dusty area, increase the frequency of all

inspections.

DAILY

- Inspect the compressor visually.

G

- Check oil level and add some if necessary, before turning the

compressor on.

- Drain moisture from the piping system.

D - Be sure there is no excessive or unusual vibration or noise.

B C

F

WEEKLY

A

E - Remove and clean intake air filters; do not wash the filter element.

A B C D E F G H - Check V-belts for tightness. Belt tension should be adjusted to allow

approximately 3/8" to 1/2" (9 to 13 mm) deflection with normal thumb

mm 345 185 60 10,5 380 160 365 490

pressure.

inch 13.6 7.3 2.4 0.41 15 6.3 14.4 19.3 - Clean cylinders externally, cylinder head, motor, fan blade, tubing, and tank.

- Safety valve should be tested manually to see if it is working properly.

INSTALLATION AND OPERATION INSTRUCTIONS MONTHLY

- Check entire system for air leakage around fittings, etc by using water and

INSTALLATION AND LOCATION soap lather.

1. Installation: Install the compressor in a covered, well - Check the pressure switch operation.

ventilated area, free of dust, toxic gases, humidity or any

other kind of pollution. The compressor should be located no - Check for oil contamination and change it if necessary.

closer than 32" (800mm) from a wall or any other obstacle QUARTERLY

that could interfere with the air flow through the fan. This - Change the air filter element every 300 working hours or quarterly.

distance will also make maintenance easier. Place the (Whichever occurs first).

compressor on a leveled surface. Rotation of the flywheel

must be in the direction of the arrow cast into the flywheel. - Fasten cap screws and nuts as required.

The maximum ambient temperature recommended while - Change oil more frequently if compressor is located in a very dirty

working is 113F or 45C. If necessary, install an exhaust fan environment.

to guarantee fresh air and to dissipate heat. - On the 7 , 10 and 15 HP compressor pumps, the concentric valves must be

Before making the electrical connections, check oil level and inspected and cleaned between 800 and 1000 service hours.

top-up lubricating oil. For type of oil, see table at the end of

- WHILE RUNNING IN A PERIOD OF ABOUT 100 WORKING HOURS THE OIL

these instructions.

LEVEL SHOULD BE CAREFULLY CHECKED.

2. Electrical connection: The country's valid electrical

standards must be followed regarding Low Voltage Electrical ANNUALLY

Installation. - Test and calibrate the pressure switch, pressure gauge and safety valve

OPERATION according to their own technical standards. These parts must be removed

1. Initial start procedure: Before turning on the compressor, from the tank and pump to be tested.

check the crankcase oil level. It must be between the - Inspect and clean the suction and discharge valve(s) plate(s) every 1000 (one

dipstick's maximum and minimum marks, or in the middle of thousand) working hours (whichever occurs first), located between the

the OIL LEVEL SIGHT. As to the type of oil to be used and the cylinder and its cover and, if necessary, replace it (them) according to the

recommended change intervals, check at "Lubrication" and operation conditions.

as to its volume, check the Technical Data Table.

2. Start: Turn on the electrical start key and let your LUBRICATION

compressor run for about 10 (ten) minutes, what will keep - The first oil change should be made after 8 hours of operation.

the tank's internal pressure or compressed air around 20 - The second oil change after 40 hours of operation.

psig. This will optimize a homogeneous lubrication of the

parts.

- The third and following exchanges should be made after 200 hours of

operation, or 60 (sixty) days, whichever occurs first.

NOTE:

LIMITED WARRANTY Heavy Duty and multi-viscous oils are not adequate for Schulz air

compressor's lubrication. The same applies to oils that tend to emulsify.

All component parts on your SCHULZ compressor are

warranted to be free of defects in workmanship and material We recommend good industrial oil for air compressors, with rust and

for a period of one year. Transportation charges are oxidation inhibitors and high viscosity level (from 90 to 95), SAE or ISO, as

responsibility of the purchaser. This warranty extends to the indicated in the table below:

original purchaser of the compressor only. RECOMMENDED LUBRICANT OILS FOR SCHULZ AIR PUMPS

There are no express warranties except as contained in this AMBIENT TEMPERATURE 0F (0C)

limited warranty statement and implied warranties, 0

Below 32 F 32 0F to 68 0F 68 0F to 113 0F

including those of merchantability and fitness for a particular Below 0 0C 0 0C to 20 0C 20 0C to 45 0C

purpose, are limited to the period of warranty.

SAE 10W SAE 20W SAE 30

Our liability is limited solely to replacement of or or or

nonconforming parts as set forth herein and does not include ISO 32 ISO 68 ISO 100

any liability for any incidental, consequential, or other

damages of any kind. This warranty gives you specific legal

rights, and you may also have other rights that vary from DISTRIBUTOR

state to state.

Schulz of America, Inc.

320 A Northpoint Parkway

Acworth, GA 30102

Phone # (770) 529-4731 / 32

Fax # (770) 529-4733

E-mail: sales@schulzamerica.com

You might also like

- MSW 60 MaxDocument2 pagesMSW 60 MaxAlex SanchesNo ratings yet

- Compressor MSL 40 Max Two Stages 175 PsigDocument2 pagesCompressor MSL 40 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaNo ratings yet

- Compressor MSW 60 Max Two Stages 175 PsigDocument2 pagesCompressor MSW 60 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaNo ratings yet

- Arexdelta Om Us Cmyk Explode A31Document1 pageArexdelta Om Us Cmyk Explode A31Kitsuneiat IAT Celso HiroshiNo ratings yet

- La Meuse: BRUFACE - Geology and Engineering Geology Geotechnical Interpretation Nuclear Power Station of Tihange IDocument1 pageLa Meuse: BRUFACE - Geology and Engineering Geology Geotechnical Interpretation Nuclear Power Station of Tihange IAlbert NiyonzimaNo ratings yet

- Millermatic180 Parts ManualDocument6 pagesMillermatic180 Parts ManualAllan SalazarNo ratings yet

- Ryobi: 18 Volt Circular Saw Model No. P508 Repair SheetDocument4 pagesRyobi: 18 Volt Circular Saw Model No. P508 Repair SheetVictor Perez100% (1)

- 7Document50 pages7Manuel BritoNo ratings yet

- Gear Housing Lower 1 61 1Document3 pagesGear Housing Lower 1 61 1Андрей ШумиловNo ratings yet

- SUP031ODocument7 pagesSUP031OPhilippe Fabro-joaoNo ratings yet

- Parts List: JTR-MOL254/LBADocument74 pagesParts List: JTR-MOL254/LBAJoseNo ratings yet

- Quantum Energy Spinning E30ptiDocument1 pageQuantum Energy Spinning E30ptipikemanserbiaNo ratings yet

- FMOD Transition - Violin IIDocument2 pagesFMOD Transition - Violin IISergio de MiguelNo ratings yet

- D6R Track-Type Tractor Differential Steering 1RW00001-UP (MACHINE) POWERED BY 3306 Engine (SEBP2616 - 79) - Por Palabra ClaveDocument4 pagesD6R Track-Type Tractor Differential Steering 1RW00001-UP (MACHINE) POWERED BY 3306 Engine (SEBP2616 - 79) - Por Palabra ClaveDey MayNo ratings yet

- Especalogo Actros 4144K 45 8x4Document3 pagesEspecalogo Actros 4144K 45 8x4Manuel PomahualiNo ratings yet

- Pompa ve pump parts reference guideDocument24 pagesPompa ve pump parts reference guidecobrax100100% (1)

- Partner 351 Partner 370 Partner 390 I Partner 420Document7 pagesPartner 351 Partner 370 Partner 390 I Partner 420Ahmed AvdicNo ratings yet

- Master Manual Machine: X-Ergo Manual No: 119003: Edition 2005BDocument25 pagesMaster Manual Machine: X-Ergo Manual No: 119003: Edition 2005BПавел ХромовNo ratings yet

- RR Fs-5205aDocument26 pagesRR Fs-5205aEduar Drink LozanoNo ratings yet

- CE25MRTP - Tiller ArmDocument2 pagesCE25MRTP - Tiller ArmDavid VaquerizoNo ratings yet

- Repair Kits: "N" Version Ø 24mmDocument1 pageRepair Kits: "N" Version Ø 24mmAdan BarbasNo ratings yet

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 216Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 216Andi KaNo ratings yet

- PM Pe770 en 73001402755498334Document27 pagesPM Pe770 en 73001402755498334Callejas Polanco JavierNo ratings yet

- Servo XL-554-204XC $26 Fmfyce 20-05Document19 pagesServo XL-554-204XC $26 Fmfyce 20-05huangjia0517No ratings yet

- ManualDocument4 pagesManualEliel SouzaNo ratings yet

- Llustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700Document72 pagesLlustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700Michael RapinoNo ratings yet

- Part Book PC 200-8 m0-988Document313 pagesPart Book PC 200-8 m0-988hara tulisanNo ratings yet

- Ryobi 50Cc Chain Saw ITEM NO. RY5020 MFG. NO. 090840005 Repair SheetDocument7 pagesRyobi 50Cc Chain Saw ITEM NO. RY5020 MFG. NO. 090840005 Repair SheetAvila MatthNo ratings yet

- High Rate CommercialDocument8 pagesHigh Rate Commercialsidney_viegasNo ratings yet

- Eje Trasero 420d.Document4 pagesEje Trasero 420d.Ivan CastellanosNo ratings yet

- 1" Dr. Impact Wrench: Enjoy Your WorkDocument1 page1" Dr. Impact Wrench: Enjoy Your Workoficina soldaNo ratings yet

- Ingersoll Rand 235HDDocument2 pagesIngersoll Rand 235HDPedro Samuel Brito LopesNo ratings yet

- Service Manual & Parts List for 1600P-QC Sewing MachineDocument23 pagesService Manual & Parts List for 1600P-QC Sewing MachineMichele NordahlNo ratings yet

- TS GyratoryCrusher 8.5x11-PageResolutionDocument1 pageTS GyratoryCrusher 8.5x11-PageResolutionMaxx Ccoñas RamosNo ratings yet

- Massey Ferguson MF 1250 Tractor Service Parts Catalogue ManualDocument15 pagesMassey Ferguson MF 1250 Tractor Service Parts Catalogue Manualqlb898316No ratings yet

- SCEPTER GX SeriesDocument1 pageSCEPTER GX SeriesJose GutiérrezNo ratings yet

- Orange15021801jw SevDocument7 pagesOrange15021801jw SevMonete FlorinNo ratings yet

- C 330 C 331Document29 pagesC 330 C 331Flaco Depaulo CarlosNo ratings yet

- WA450-3 parts listDocument2 pagesWA450-3 parts listAnonymous cS9UMvhBqNo ratings yet

- TUMKALIPDocument32 pagesTUMKALIPtsbarzonNo ratings yet

- NEW SILVER 5.5-10 230-400-50-60 20-07-2017 1127340125 ING PartsDocument15 pagesNEW SILVER 5.5-10 230-400-50-60 20-07-2017 1127340125 ING PartsCarlos Ferreira100% (1)

- Service ManualDocument28 pagesService ManualJose Manuel Barradas100% (1)

- Pantalla Anterior Bienvenido: Cr461jeaDocument7 pagesPantalla Anterior Bienvenido: Cr461jeaLeonardo PerezNo ratings yet

- From Serial Number: 30101868: Unit 1 Illustrated Parts BreakdownDocument4 pagesFrom Serial Number: 30101868: Unit 1 Illustrated Parts BreakdownPrzemysław CNo ratings yet

- 14 SASURFLEADERSD CI4+30 03354.ja - enDocument1 page14 SASURFLEADERSD CI4+30 03354.ja - enddvNo ratings yet

- Fe1700 Mack Super LinerDocument2 pagesFe1700 Mack Super LinerLukas FaltusNo ratings yet

- PA LIne3 UpperDeckDocument1 pagePA LIne3 UpperDeckfrancisNo ratings yet

- Electric Tool Parts List: Hitachi Power ToolsDocument4 pagesElectric Tool Parts List: Hitachi Power ToolsJoe SchlueterNo ratings yet

- Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocument31 pagesAllison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz GalanNo ratings yet

- Rectifier Battery Test Every 6 MonthsDocument1 pageRectifier Battery Test Every 6 Monthshamed hassanNo ratings yet

- VKF11 21c1 Rev1Document1 pageVKF11 21c1 Rev1LorraineDaoustNo ratings yet

- Himno A La AlegriaDocument4 pagesHimno A La AlegriaBeltran Colque TrujilloNo ratings yet

- Gaggia Syncrony Logic Part Diagram PDFDocument8 pagesGaggia Syncrony Logic Part Diagram PDFАнтон Иванов100% (1)

- 5 Mitsubishi-OUTLANDER-2006-BODY-REPAIR-MANUAL-SYNTHETIC-RESIN-PARTSDocument4 pages5 Mitsubishi-OUTLANDER-2006-BODY-REPAIR-MANUAL-SYNTHETIC-RESIN-PARTSClodoaldo BiassioNo ratings yet

- MAC CAT 436 Parts ListDocument8 pagesMAC CAT 436 Parts ListquetzNo ratings yet

- Air Conditioner: Parts ListDocument4 pagesAir Conditioner: Parts ListDavid Lemos SanchezNo ratings yet

- E.T. - ViolaDocument3 pagesE.T. - ViolaOmarSalazarHidalgoNo ratings yet

- MANUALcentralQ7 S 2017Document7 pagesMANUALcentralQ7 S 2017Joel Leandro Ibarra CoriaNo ratings yet

- Manual Sc32.PDF Prenza Hidraulica GatesDocument16 pagesManual Sc32.PDF Prenza Hidraulica GatesEsteban Sándiga GrandaNo ratings yet

- Compressor Msii 52 ML Single Stage 120 PsigDocument2 pagesCompressor Msii 52 ML Single Stage 120 PsigJoel Leandro Ibarra CoriaNo ratings yet

- Compressor CSW 40 Max Two Stages 175 PsigDocument2 pagesCompressor CSW 40 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaNo ratings yet

- COMPRESSOR MSWV 80 MAX TWO STAGE 175 PSIG TECHNICAL DATADocument2 pagesCOMPRESSOR MSWV 80 MAX TWO STAGE 175 PSIG TECHNICAL DATAebebvetbNo ratings yet

- KD105 ManualDocument22 pagesKD105 ManualJoel Leandro Ibarra CoriaNo ratings yet

- Compressor MSL 15 Max Siingle StageDocument2 pagesCompressor MSL 15 Max Siingle StageJoel Leandro Ibarra CoriaNo ratings yet

- SOLDADURADocument25 pagesSOLDADURAJoel Leandro Ibarra CoriaNo ratings yet

- Compressor CSL 18 Max Single Stage 125 PsigDocument2 pagesCompressor CSL 18 Max Single Stage 125 PsigJoel Leandro Ibarra CoriaNo ratings yet

- ReleaseNotes PDFDocument21 pagesReleaseNotes PDFFrancisco Jose Arista QuinteroNo ratings yet

- Thor 175 C Safe1Document1 pageThor 175 C Safe1Joel Leandro Ibarra CoriaNo ratings yet

- PipelayerDocument1 pagePipelayerJoel Leandro Ibarra CoriaNo ratings yet

- Dimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofDocument1 pageDimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofJoel Leandro Ibarra CoriaNo ratings yet

- Dinset/Gasline: Outlet Points For Industrial GasesDocument2 pagesDinset/Gasline: Outlet Points For Industrial GasesJoel Leandro Ibarra CoriaNo ratings yet

- Dimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofDocument1 pageDimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofJoel Leandro Ibarra CoriaNo ratings yet

- Dimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofDocument1 pageDimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofJoel Leandro Ibarra CoriaNo ratings yet

- Dimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofDocument1 pageDimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofJoel Leandro Ibarra CoriaNo ratings yet

- Tuberia Astm A53 Grado A Grado BDocument6 pagesTuberia Astm A53 Grado A Grado BMedardo Silva50% (2)

- Lista de Articulos: 1 Electrodos Conarco GrupoDocument8 pagesLista de Articulos: 1 Electrodos Conarco GrupoJoel Leandro Ibarra CoriaNo ratings yet

- Alignment of Railway Track Nptel PDFDocument18 pagesAlignment of Railway Track Nptel PDFAshutosh MauryaNo ratings yet

- HVAC Master Validation PlanDocument51 pagesHVAC Master Validation Plannavas197293% (30)

- Bala Graha AfflictionDocument2 pagesBala Graha AfflictionNeeraj VermaNo ratings yet

- Why Choose Medicine As A CareerDocument25 pagesWhy Choose Medicine As A CareerVinod KumarNo ratings yet

- Managerial EconomicsDocument3 pagesManagerial EconomicsGuruKPONo ratings yet

- Gabinete STS Activity1Document2 pagesGabinete STS Activity1Anthony GabineteNo ratings yet

- Lewis Corporation Case 6-2 - Group 5Document8 pagesLewis Corporation Case 6-2 - Group 5Om Prakash100% (1)

- Inborn Errors of Metabolism in Infancy: A Guide To DiagnosisDocument11 pagesInborn Errors of Metabolism in Infancy: A Guide To DiagnosisEdu Diaperlover São PauloNo ratings yet

- Astm D7928 - 17Document25 pagesAstm D7928 - 17shosha100% (2)

- Propoxur PMRADocument2 pagesPropoxur PMRAuncleadolphNo ratings yet

- Indian Standard: Pla Ing and Design of Drainage IN Irrigation Projects - GuidelinesDocument7 pagesIndian Standard: Pla Ing and Design of Drainage IN Irrigation Projects - GuidelinesGolak PattanaikNo ratings yet

- CALCULUS PHYSICS MIDTERMDocument41 pagesCALCULUS PHYSICS MIDTERMMACARIO QTNo ratings yet

- Certification Presently EnrolledDocument15 pagesCertification Presently EnrolledMaymay AuauNo ratings yet

- Mpu 2312Document15 pagesMpu 2312Sherly TanNo ratings yet

- Guia de Usuario GPS Spectra SP80 PDFDocument118 pagesGuia de Usuario GPS Spectra SP80 PDFAlbrichs BennettNo ratings yet

- CS709 HandoutsDocument117 pagesCS709 HandoutsalexNo ratings yet

- Marshall Stability Test AnalysisDocument5 pagesMarshall Stability Test AnalysisZick Zickry50% (2)

- EIRA v0.8.1 Beta OverviewDocument33 pagesEIRA v0.8.1 Beta OverviewAlexQuiñonesNietoNo ratings yet

- Bengali (Code No - 005) COURSE Structure Class - Ix (2020 - 21Document11 pagesBengali (Code No - 005) COURSE Structure Class - Ix (2020 - 21Břîšťỹ ÃhmęđNo ratings yet

- Desana Texts and ContextsDocument601 pagesDesana Texts and ContextsdavidizanagiNo ratings yet

- Statistical Quality Control, 7th Edition by Douglas C. Montgomery. 1Document76 pagesStatistical Quality Control, 7th Edition by Douglas C. Montgomery. 1omerfaruk200141No ratings yet

- Extrajudicial Settlement of Estate Rule 74, Section 1 ChecklistDocument8 pagesExtrajudicial Settlement of Estate Rule 74, Section 1 ChecklistMsyang Ann Corbo DiazNo ratings yet

- HSSC English Model PaperDocument32 pagesHSSC English Model PaperMaryam Abdus SalamNo ratings yet

- Form 4 Additional Mathematics Revision PatDocument7 pagesForm 4 Additional Mathematics Revision PatJiajia LauNo ratings yet

- Big Joe Pds30-40Document198 pagesBig Joe Pds30-40mauro garciaNo ratings yet

- EXPERIMENT 4 FlowchartDocument3 pagesEXPERIMENT 4 FlowchartTRISHA PACLEBNo ratings yet

- Final Year Project (Product Recommendation)Document33 pagesFinal Year Project (Product Recommendation)Anurag ChakrabortyNo ratings yet

- THE DOSE, Issue 1 (Tokyo)Document142 pagesTHE DOSE, Issue 1 (Tokyo)Damage85% (20)

- Steps To Christ AW November 2016 Page Spreaad PDFDocument2 pagesSteps To Christ AW November 2016 Page Spreaad PDFHampson MalekanoNo ratings yet