Professional Documents

Culture Documents

1245 F A0 0001

Uploaded by

Eugene Francis CastroOriginal Title

Copyright

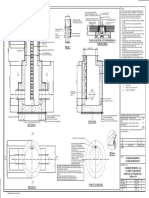

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1245 F A0 0001

Uploaded by

Eugene Francis CastroCopyright:

Available Formats

DRAWING LIST PROJECT DECLARATION GENERAL NOTES NOTES FOR CLEAN AGENT SYSTEMS SPRINKLER DESIGN CRITERIA FIRE

PROJECT DECLARATION GENERAL NOTES NOTES FOR CLEAN AGENT SYSTEMS SPRINKLER DESIGN CRITERIA FIRE PROTECTION SYSTEM DESIGN CRITERIA NOTES:

1. ALL DIMENSIONS AND SIZES ARE IN MILLIMETERS AND LEVELS ARE IN METERS UNLESS

S/N SHEET NUMBER SHEET NAME SHEET SIZE SCALE

TYPE OF OCCUPANCY : MULTIPLE TYPE OCCUPANCY 1. THE PROTECTION SYSTEM HAS BEEN DESIGNED IN ACCORDANCE OTHERWISE NOTED. DO NOT SCALE THE DRAWINGS.

1. NO DIMENSIONS ARE TO BE SCALED FROM THIS DRAWING. 1. THE DESIGN, INSTALLATION AND TESTING OF CLEAN AGENT SYSTEMS SHALL

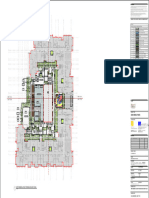

2. ANY DISCREPANCIES FOUND SHOULD BE REPORTED TO THE RESPONSIBLE ARCHITECT OR

1 1245-F-A0-0001 GENERAL NOTES, LEGENDS, ABBREVIATIONS, & DRAWINGS LIST A0 NTS BE DONE BY THE QCDD APROVED SPECIALIST CONTRACTOR IN ACCORDANCE

FIRE FIGHTING LAYOUT 2. ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE STATED. WITH THE AUTHORITY REGULATIONS AND NFPA 2001 STANDARDS. RESTAURANT MECH., PLANT, SAUNA & WITH THE FOLLOWING CODES & REGULATIONS: ENGINEER IMMEDIATELY.

AREA OF OPERATION PARKING CORRIDORS BED ROOMS VOID SPACES 3. IT IS THE RESPONSIBILITY OF THE CONTRACTOR OR BUILDERS TO ASCERTAIN AND

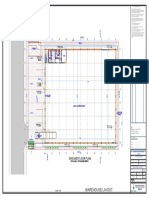

2 1245-F-A0-0002 SITE DEVELOPMENT PLAN FIRE FIGHTING SYSTEM LAYOUT A0 AS SHOWN SITTING SERVICE RM. STEAM BATH

3. BUILDER TO CHECK ALL DIMENSIONS AT SITE PRIOR TO CONSTRUCTION, 2. ONLY CLEAN AGENTS SPECIFICALLY APPROVED BY THE QATAR CIVIL DEFENSE OH1 LH LH LH LH OH1 OH2 NFPA 10 STANDARD FOR PORTABLE FIRE EXTINGUISHER CONFIRM THAT ALL DIMENSIONS SHOWN IN THESE DRAWINGS SHALL COMPLY WITH THE

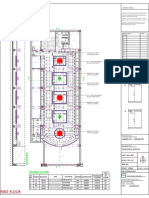

3 1245-F-A0-0003 SCHEMATIC RISER DIAGRAM FIRE FIGHTING SYSTEM LAYOUT A0 NTS HAZARD CLASSIFICATION

ASSEMBLY OR FABRICATION OF ALL WORKS. SHALL BE USED. NFPA 13 STANDARD FOR THE INSTALLATION OF AUTOMATIC SPRINKLER SITE DIMENSIONS AND LEVELS PRIOR TO PREPARING DRAWINGS AND EXECUTING THE

4 1245-F-A0-0004 BUILDING SECTION - A FIRE FIGHTING SYSTEM LAYOUT A0 1:150 DESIGN DENSITY (gpm/ft) 0.15 0.10 0.10 0.10 0.10 0.15 0.20

NFPA 14 STANDARD FOR THE INSTALLATION OF STANDPIPE AND HOSE SYSTEM WORKS.

5 1245-F-A0-0005 BUILDING SECTION - B FIRE FIGHTING SYSTEM LAYOUT A0 1:150 4. ALL WORKS ARE TO BE CARRIED OUT TO Q.C.S. AND OTHER RELEVANT CODES 3. CLEAN AGENT STORAGE CONTAINERS SHALL NOT BE STORED WITHIN THE AREA PER SPRINKLER 1500 1500 1500 1500 1500 1500 1500 NFPA 16 STANDARD FOR INSTALLATION OF FOAM-WATER SPRINKLER AND FOAM-WATER

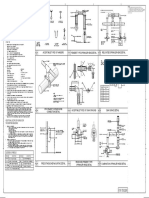

6 1245-F-A0-0006 TYPICAL INSTALLATION DETAILS FIRE FIGHTING SYSTEM LAYOUT A0 NTS OF CONSTRUCTIONS. PROTECTED ENCLOSURE. THEY SHALL BE EASILY ACCESSIBLE AND WITHIN COVERAGE (ft) 4. ALL WORKS ARE TO BE CARRIED OUT TO Q.C.S. AND OTHER RELEVANT CODES OF

SPRAY SYSTEM

2000mm FROM THE MAIN ENTRANCE OF THE PROTECTED ENCLOSURE. DESIGN AREA OF 130 225 225 225 225 130 130 CONSTRUCTIONS.

7 1245-F-A0-0007 FIRE PUMP ROOM "PLANS & PERSPECTIVE" FIRE FIGHTING A0 AS SHOWN SPRINKLER OPERATION (ft) NFPA 20 STANDARD FOR THE INSTALLATION OF STAIONARY PUMPS FOR FIRE PROTECTION

SYSTEM LAYOUT 5. THIS DRAWING IS TO BE READ FOR FIRE PROTECTION OF ALL SERVICES. NFPA 22 STANDARD FOR WATER TANKS FOR PRIVATE FIRE PROTECTION 5. THIS DRAWING SHOULD BE READ IN CONJUNCTION WITH THE OTHER RELEVANT

4. A MANUAL MECHANICAL MEANS OF DISCHARGING THE REQUIRED AGENT TYPE OF SPRINKLER UPRIGHT PENDENT PENDENT PENDENT UPRIGHT UPRIGHT PENDENT

8 1245-F-A0-0008 FIRE PUMP ROOM "SECTIONS" FIRE FIGHTING SYSTEM LAYOUT A0 AS SHOWN NFPA 72 NATIONAL FIRE ALARM CODE ARCHITECTURAL, STRUCTURAL, MECHANICAL AND ELECTRICAL DRAWING AND ALL

9 1245-F-A0-0009 GENERATOR & FUEL TANK ROOM FOAM WATER SPRINKLER A0 AS SHOWN

PROJECT DESCRIPTION 6. CONTRACTOR SHALL BE RESPONSIBLE FOR COORDINATION OF ALL SERVICES. SHALL BE PROVIDED ON THE STORAGE CONTAINER. TYPE OF K-FACTOR 5.6(80) 5.6(80) 5.6(80) 5.6(80) 5.6(80) 5.6(80) 5.6(80) NFPA 96 STANDARD FOR VENTILATION CONTROL AND FIRE PROTECTION OF COMMERCIAL RELEVANT SECTIONS OF THE SPECIFICATIONS.

DELUGE SYSTEM LAYOUT TEMPERATURE RATING (C) 79C 68C 68C 68C 68C 68C 141C COOKING OPERATIONS 6. EXACT LOCATION & DETAIL OF ELECTRO-MECHANICAL OPENING SHALL BE COORDINATED

7. ALL PORTABLE TYPE FIRE EXTINGUISHERS SHALL BE LISTED AND COMPLY 5. CLEAN AGENT SYSTEMS SHALL BE OPERATED AUTOMATICALLY BY A QCD NFPA 101 STANDARD FOR LIFE SAFETY CODE

10 1245-F-A0-0010 BASEMENT-1 CABLE TRENCH AUTOMATIC FIRE EXTINGUISHING A0 AS SHOWN TYPE OF RESPONSE STANDARD QUICK RESP. QUICK RESP. QUICK RESP. QUICK RESP. QUICK RESP. QUICK RESP. WITH ELECTRO-MECHANICAL ENGINEER.

WITH THE REQUIREMENTS OF NFPA 10. APPROVED AUTOMATIC DETECTION SYSTEM. NFPA 2001 STANDARD ON CLEAN AGENT FIRE EXTINGUISHING SYSTEM

SYSTEM LAYOUT 7. DIMENSION AND LOCATION OF SERVICES COORDINATED WITH RESPECTIVE ARCHITECTURAL

HOSE STREAM 100 GPM NFPA 2010 STANDARD FOR FIXED AEROSOL FIRE EXTINGUISHING SYSTEM

11 1245-F-A0-0011 B1 & TYP.B2-B4 ELEC. RM. & B1 PLC/MCC RM. AUTOMATIC FIRE A0 AS SHOWN 8. THE FIRE PUMP SHALL BE UL LISTED, FM APPROVED TYPE, QCDD APPROVED 6. THE CONTROL PANEL SHALL BE LOCATED EXTERNAL TO THE PROTECTED AND SERVICES DRAWINGS PRIOR TO COMMENCEMENT OF ANY WORK. ANY DISCREPANCY

MINIMUM DURATION 60 MINUTES

EXTINGUISHING SYSTEM AND SHALL COMPLY WITH THE REQUIREMENTS OF NFPA 20. ENCLOSURE AND LOCATED NEAR THE MAIN ENTRANCE TO THE PROTECTED FOUND SHOULD BE BROUGHT TO THE NOTICE OF THE CONCERNED ENGINEER.

12 1245-F-A0-0012 GROUND FLR. MV RM. & ELEC. RM. AUTOMATIC FIRE A0 AS SHOWN ENCLOSURE. THE CONTROL PANEL SHALL BE CONNECTED TO THE BUILDING 2. SPRINKLER IS DESIGNED TO THE FOLLOWING HAZARD CLASS SYSTEM.

EXTINGUISHING SYSTEM LAYOUT 9. ALL PIPES ABOVE GROUND SHALL BE GALVANIZED STEEL ERW SCHEDULE 40 MAIN FIRE ALARM SYSTEM THROUGH AN INTERFACE MODULE AND SHALL

CALCULATION OF EFFECTIVE FIRE WATER STORAGE CAPACITY

13 1245-F-A0-0013 1ST,TYP. 2ND-29TH,& RF ELEC. RM. AUTOMATIC FIRE A0 AS SHOWN TO ASTM A 53 GRADE. PROVIDE ALARM.

FIRE PUMP CAPACITY 1000 GPM @ 295 PSI TYPE OF OCCUPANCY

EXTINGUISHING SYSTEM LAYOUT MACHINE ROOM

14 1245-F-A0-0014 BASEMENT-1 TRANSFORMER ROOM CLEAN AGENT FIRE A0 AS SHOWN 10. ALL ISOLATING CONTROL VALVES SHALL BE UL LISTED, QCDD APPROVED 7. GAS DISCHARGED AND FAULT INDICATIONS ON THE MAIN PANEL. GAS 60,000 GALLONS

EXTINGUISHING SYSTEM LAYOUT INDICATING VALVES AND SHALL BE PROVIDED WITH SUPERVISORY SWITCHES DISCHARGE SHALL ONLY OCCUR AFTER A PREDETERMINED TIME DELAY TO BE STORAGE CAPACITY REQUIRED FOR 60MIN PUMP OPERATION HAZARD CLASS OF PROTECTION ORDINARY HAZARD GROUP-1

227,124.7 LITERS

15 1245-F-A0-0015 BASEMENT-1 LV ROOM CLEAN AGENT FIRE EXTINGUISHING A0 AS SHOWN CONNECTED TO THE BUILDING MAIN FIRE ALARM SYSTEM THROUGH AN APPROVED BY THE QCD. THE TIME DELAY SHALL BE INTERRUPTED BY THE

INTERFACE MODULE. OPERATION OF THE ABORT SWITCH AND SHALL RE-COMMENCE ON RELEASE 227.12 m

SYSTEM LAYOUT MIN. DESIGN DENSITY OF DISCHARGE 0.15 GPM / FT

OF THE ABORT SWITCH. THE MINIMUM DELAY SHALL BE 20 SECONDS. FIRE WATER STORAGE TANK AREA HEIGHT VOLUME

16 1245-F-A0-0016 BASEMENT-1 MAIN TELECOM ROOM CLEAN AGENT FIRE A0 AS SHOWN

11. ALL ABOVE GROUND PIPES 50mm AND LESS IN DIAMETER SHALL BE JOINED

EXTINGUISHING SYSTEM LAYOUT ASSUMED AREA OF OPERATION 1500 FT

WITH THREADED CONNECTIONS. 8. AT LEAST ONE MANUAL RELEASE PUSH BUTTON SHALL BE PROVIDED * CONCRETE FIRE WATER STORAGE TANK-1 WITH GRP LINING 45.00 m 3.90 m 175.5 m

17 1245-F-A0-0017 GRND. FLR. FCC & SECURITY CLEAN AGENT FIRE EXTINGUISHING A0 AS SHOWN EXTERNAL TO THE PROTECTED ENCLOSURE AND MOUNTED WITHIN 1.5M OF

SYSTEM LAYOUT 12. ALL ABOVE GROUND PIPES LARGER THAN 50mm IN DIAMETER SHALL BE JOINED THE MAIN ENTRANCE. SUBJECT TO THE SIZE AND CONFIGURATION OF THE * CONCRETE FIRE WATER STORAGE TANK-2 WITH GRP LINING 43.00 m 3.90 m 167.7 m MAX. AREA COVERAGE PER SPRINKLER 130 FT

18 1245-F-A1-0001 BASEMENT-4 FIRE FIGHTING SYSTEM LAYOUT A0 AS SHOWN WITH ROLL GROOVED TYPE COUPLINGS. PROTECTED ENCLOSURE, MORE THAN ONE MANUAL RELEASE PUSH BUTTON CLEARANCE PROVIDED AT THE BOTTOM OF THE VORTEX PLATE 0.15 m 3.90m-1.15m

19 1245-F-A1-0002 BASEMENT-3 FIRE FIGHTING SYSTEM LAYOUT A0 1:100 MAY BE REQUIRED. OPERATION OF THE MANUAL PUSH BUTTON SHALL CAUSE TYPE OF SPRINKLER QUICK RESPONSE 68C, NPT, RED

13. FLEXIBLE COUPLINGS SHALL BE USED IN ALL PIPE JOINTS AS PER NFPA INSTANT RELEASE OF THE CLEAN AGENT. CLEARANCE FROM THE SOFFIT OF SLAB TO WATER LEVEL 1.15 m EF HT=2.60m

20 1245-F-A1-0003 BASEMENT-2 FIRE FIGHTING SYSTEM LAYOUT A0 1:100

21 1245-F-A1-0004 BASEMENT-1 FIRE FIGHTING SYSTEM LAYOUT A0 1:100 STANDARDS.

THE EFFECTIVE HEIGHT OF WATER COLUMN INSIDE THE TANK EF HT=2.60m ORIFICE SIZE 1/2"

9. AN ABORT SWITCH THAT INTERRUPTS THE COUNTDOWN DELAY TIMER SHALL

22 1245-F-A1-0005 GROUND FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100

14. THE FIRE FIGHTING SYSTEM SHALL BE INSTALLED STRICTLY IN ACCORDANCE BE PROVIDED WITHIN THE PROTECTED ENCLOSURE AND MOUNTED WITHIN AREA HEIGHT VOLUME

23 1245-F-A1-0006 1ST FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 WITH THE REQUIREMENTS OF NFPA 10, NFPA 13, NFPA 14, NFPA 16, NFPA 20, 1.5M OF THE MAIN ENTRANCE. SUBJECT TO THE SIZE AND CONFIGURATION OF ORIFICE K-FACTOR 5.6 (gpm/psi)

24 1245-F-A1-0007 2ND FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 NFPA 22, NFPA 24, NFPA 25, NFPA 96, NFPA 2001, & NFPA 2010. THE PROTECTED ENCLOSURE, MORE THAN ONE ABORT SWITCH MAY BE THE EFFECTIVE VOLUME WATER STORAGE TANK-1 45.00 m 2.60 m 117.00 m

25 1245-F-A1-0008 TYP. 3RD-7TH & 9TH FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 REQUIRED. CONTINUOUS OPERATION OF THE ABORT SWITCH SHALL BE THE EFFECTIVE VOLUME WATER STORAGE TANK-2 43.00 m 2.60 m 111.80 m MIN. DURATION OF WATER SUPPLY 60 MINUTES

26 1245-F-A1-0009 8TH FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 15. THE SUCTION LINE OF THE PUMPS SHALL BE DETERMINED IN CONJUNCTION REQUIRED TO INTERRUPT THE COUNTDOWN TIMER. RELEASE OF THE ABORT

27 1245-F-A1-0010 10TH FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 WITH PUMPS SELECTION. SWITCH SHALL RESET THE COUNTDOWN TIMER TO GAS DISCHARGE. THE EFFECTIVE VOLUME OF WATER SHALL BE 228.80 m (60,442.58 gallons)

INSIDE HOSE FLOW 100 GPM

28 1245-F-A1-0011 11TH FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 60,442.58

16. THE PIPES SIZES SHALL BE BASED ON HYDRAULIC CALCULATION HOWEVER 10. "DO NOT ENTER - GAS DISCHARGED" ILLUMINATED SIGNS SHALL BE EXTERNAL 60.44 MINUTES =

29 1245-F-A1-0012 TYP. 12TH-18TH FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 AREA STATEMENT CONTRACTOR SHALL SUBMIT CALCULATION BASED ON ACTUAL PUMP TO THE PROTECTED ENCLOSURE AND MOUNTED ABOVE ALL ENTRANCES SO

DURATION OF USAGE

1000 3. FIRE HOSE REEL SHALL BE AS PER BELOW REQUIREMENT:

30 1245-F-A1-0013 19TH FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 CAPACITY AND ACTUAL SITE CONDITION IN ORDER TO IDENTIFY PRESSURE AS TO BE VISIBLE TO ANY PERSON ENTERING. THE LETTERING SHALL BE A

31 1245-F-A1-0014 20TH FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 LIMITS AS PER NFPA STANDARD. MINIMUM OF 50MM HIGH. IT SHALL BE VISIBLE AT ALL TIMES OF THE DAY. THE PUMP SCHEDULE

32 1245-F-A1-0015 TYP. 21ST-28TH FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 ILLUMINATION SHALL BE ACTIVATED BY A PRESSURE SWITCH FITTED TO THE TYPE OF OCCUPANCY MACHINE ROOM

33 1245-F-A1-0016 29TH FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 17. ALL OS&Y GATE VALVE SHALL BE INDICATING TYPE WITH A TAMPER SWITCH. DISCHARGE PIPING. "EVACUATE NOW - GAS DISCHARGE" ILLUMINATED SIGNS MOTOR CAPACITY

UNIT TOTAL

SHALL BE PROVIDED ABOVE THE EXITS OF THE PROTECTED ENCLOSURE. THE EQUIPMENT QTY EACH LOCATION HOSE REEL SYSTEM 100 GPM

34 1245-F-A1-0017 ROOF FLOOR FIREFIGHTING SYSTEM LAYOUT A0 1:100 No. HEAD PSIG

18. OS&Y GATE VALVE WITH TAMPER SWITCH, BUTTERFLY VALVE WITH LETTERING SHALL BE A MINIMUM OF 50MM HIGH. IT SHALL BE VISIBLE AT ALL AMPS. PHASE

35 1245-F-A1-0018 MACHINE ROOM LEVEL FIREFIGHTING SYSTEM LAYOUT A0 1:100 H.P. VOLTS HERTZ G.P.M

MOTORIZED DAMPER, FLOW SWITCH, ALARM CHECK VALVE ASSEMBLY TIMES OF THE DAY. ILLUMINATION SHALL BE ACTIVATED BY ON (FULL LOAD)

PRESSURE SWITCH, SPECIAL SYSTEM RELEASING PANELS, FIRE PUMP COMMENCEMENT OF THE DISCHARGE TIME DELAY.

FP-1 FIRE ELECTRIC PUMP (DUTY) 1 250 415 676 3 50 1000 295 BASEMENT-1

EQUIPMENT AND VALVES

CONTROLLERS (ELEC., DIESEL, JOCKEY) SHALL BE INTERFACED WITH BUILDING

MAIN FIRE ALARM SYSTEM THROUGH AN INTERFACE MODULE. 11. ALL ENCLOSURES PROTECTED BY CLEAN AGENTS SYSTEMS MUST BE SYMBOL DESCRIPTION ABBREVIATION

SUBJECTED TO AN ENCLOSURE INTEGRITY TEST. THE TEST MUST BE FP-2 FIRE DIESEL PUMP (STANDBY) 1 282 1000 295 BASEMENT-1

19. THE CONTRACTOR SHALL BE FULLY RESPONSIBLE FOR CARRYING OUT OF ALL CONDUCTED BY A QUALIFIED TESTER ACCEPTABLE TO THE QCD. THE TEST ALARM CHECK VALVE ACV

FIRE DETECTION AND PROTECTION, FIRE HOSE REEL/SPRINKLER WORK AS PER SHALL VERIFY THE ABILITY OF THE PROTECTED ENCLOSURE TO MAINTAIN THE FP-3 JOCKEY PUMP 1 30 415 81 3 50 50 335 BASEMENT-1 GATE VALVE GV

SPECIFICATION AND DRAWINGS IN ADDITION TO CIVIL DEFENSE REQUIREMENT. MINIMUM DESIGN CONCENTRATION FOR 10 MINUTES.THE ENCLOSURE TEST

CONTRACTOR SHALL INCLUDE IN THE PRICING ALL ITEMS WHICH ARE MUST BE WITNESSED BY THE QCD. THIS IS A PRE-CONDITION FOR ISSUE BE OS&Y VALVE WITH TAMPER SWITCH OS&Y

INDICATED ON THE ITEMS REQUIRED TO FULFILL THE REQUIREMENTS OF Q.C.S WITNESSED BY THE QCD. THIS IS A PRE-CONDITION FOR ISSUE OF THE

FUEL TANK SCHEDULE PER DIESEL ENGINE

BUTTERFLY VALVE WITH SUPERVISORY SWITCH BV

IN ADDITION TO CIVIL DEFENSE AUTHORITY BUT SPECIFICALLY NOT BUILDING'S FIRE SAFETY CERTIFICATE. EFFECTIVE --

MENTIONED IN THE DRAWING/SPECIFICATION. LOCATION TANK CAPACITY EFFECTIVE CAPACITY MINIMUM TANK SIZE NON RETURN VALVE / CHECK VALVE

DURATION -- NRV/CV

12. COMPLETE AREA OF THE ROOM TO BE PROTECTED WITH THE CLEAN AGENT

PRESSURE RELIEF VALVE RV

20. FIRE FIGHTING CONTRACTOR SHALL INCLUDE PRV WHEREVER PRESSURE SYSTEM INCLUDING ROOM SPACE, CEILING VOID, CABLE TRENCHES, AND ETC. BASEMENT-1 1 GAL / HP 2.46 m 2.35 m 18.44 Hrs.

EXCEEDS 12 BAR. WASTE CONE WAC

21. 1" PRV SHALL BE INSTALLED IN THE FIRE HOSE REEL WHEREVER THE CLEAN AGENT SYSTEM SEQUENCE OF OPERATION FIRE WATER TANK SCHEDULE FLOAT VALVE FLV

PRESSURE EXCEEDS 7 BAR. TEST AND DRAIN VALVE T&D

TYPE OF EFFECTIVE

LOCATION CONSTRUCTION NO. OF COMPARTMENT EFFECTIVE DURATION

22. ALL THE EQUIPMENT AND DEVICES USED FOR FIRE SAFETY-FIRE FIGHTING I-AUTOMATIC OPERATION: CAPACITY FLUSHING CONNECTION FLC

SYSTEM SHALL BE LISTED FOR SUCH PURPOSES AND APPROVED TYPE BY THE A. ACTIVATION OF ANY ONE OF THE DETECTOR IN EITHER CIRCUIT WITHIN THE REINFORCED 228.80 m

BASEMENT-1 2 Nos. 60.44 MINUTES CONCENTRIC REDUCER CR

QCDD. AFFECTED AREA SHALL; CONCRETE ( 60,442.58 gallons )

FOAM FIRE EXTINGUISHING SYSTEM FIRE PUMP SEQUENCE OF OPERATION AUTOMATIC AIR RELEASE VALVE AAV

23. THE CONTRACTOR TO REPLACE ONLY EQUIPMENTS THAT ARE NOT POSSIBLE 1. ILLUMINATE "ALARM" INDICATOR ON THE CONTROL PANEL AND

SEQUENCE OF OPERATION TO BRING BACK IN WORKING CONDITION. WHERE EVER, POSSIBLE THE DISPLAY CUSTOM MESSAGE FOR PROPER ZONE INDICATION.

FIRE PUMP ROOM REQUIREMENT 2-WAY 4" BREECHING INLET OR 4-WAY 6"

BREECHING INLET WITH CABINET BI2W / BI4W

1. FIRE PUMP SET CONSIST OF 3-PUMPS ( MAIN ELECTRICAL, DIESEL PUMP (SAME FLOW RATES ) EXISTING FIRE FIGHTING EQUIPMENTS SHALL BE REFURBISH AND USED. 2. ACTIVATE STROBE/HORN INSIDE (1ST STAGE ALARM). PG

PRESSURE GAUGE PG

AND A JOCKEY PUMP ) ENCLOSURE ENCLOSURE RATING

SEQUENCE OF OPERATION: 3. SEND PRE-ALARM SIGNAL TO MAIN FIRE ALARM PANEL. LOCATION DIMENSION

24. ALL SPRINKLER WORK SHALL CONFORM TO THE LATEST REQUIREMENTS OF CONSTRUCTION WALLS DOOR WINDOW WATER FLOW SWITCH WFS

ELECTRICALLY CONTROLLED FOAM DELUGE SYSTEM REQUIRES AN ELECTRIC SOLENOID VALVE COMPATIBLE

WITH SYSTEM RELEASING PANEL. AN EMERGENCY RELEASE VALVE IS PROVIDED FOR MANUAL OVERRIDE IN 2. ALL FIRE PUMP HAS IT'S OWN UL LISTED CONTROL PANEL COMPLETE WITH CONTROL WIRING, THE NFPA-13 AND ALL LOCAL AUTHORITIES AND AGENCIES HAVING REINFORCED

PRESSURE SWITCHES, POWER SUPPLY ETC... JURISDICTION. 1ST BASEMENT RECTANGULAR 2Hrs. 1.5Hrs. N.A. PG

FLOOR CONTROL VALVE ASSEMBLY FCVA

CASE OF MALFUNCTION OF THE RELEASING CONTROL PANEL. B. SUBSEQUENT OPERATION OF A "CROSS-ZONED" DETECTOR WITHIN THE CONCRETE

AFFECTED AREA SHALL; PG PG

1. WHEN THE RELEASING CONTROL PANEL DETECTS AN ALARM THRU SMOKE AND HEAT DETECTOR. 3. ALL FIRE PUMP SETS SHALL BE PREPARED TO WORK AUTOMATICALLY AND TO BE ACTUATED 25. IN ALL AREAS CONTRACTOR SHALL VERIFY AND INCLUDE FOR ANY ADDITIONAL 6" PRESSURE REDUCING VALVE PRVS

SUMMARY OF MATERIAL SPECIFICATION

DISCLAIMER: The CAD data is being supplied only to assist in production of the Sub-Consultant/Trade Contractor's work. It may contain some discrepancies and hence it should always be cross-checked with other relevant documents applying due diligence. Users are solely responsible for anything they produce using all or part of

PG PG

2. RELEASE CIRCUIT WILL ENERGIZE THE SOLENOID ACTUATOR IN THE DELUGE VALVE. BY PRESSURE SWITCH. SPRINKLER HEADS FOR CO-ORDINATION OF HEADS WITH FINAL INTERIOR 1. ILLUMINATE "PRE-DISCHARGE" INDICATOR ON THE CONTROL PANEL STATION (WITH BYPASS)

3. IT WILL ALLOWS THE VALVE TO OPEN AND WATER FLOW INTO THE SYSTEM PIPING TO FOAM DESIGNERS REQUIREMENTS. AND DISPLAY CUSTOM MESSAGE FOR PROPER ZONE INDICATION. OBLIQUE FLANGE TYPE LANDING VALVE LV-1

PROPORTIONER. 4. FIRE PUMP - PRESSURE SETTING SHALL BE ON PRE CALCULATED AND ACCURATE TO SUITE 2. ACTIVATE STROBE/HORN OUTSIDE (2ND STAGE ALARM).

THE SYSTEM REQUIREMENTS. 26. CONTRACTOR SHALL PERFORM & SUBMIT HYDRAULIC CALCULATIONS & SHOP OBLIQUE FLANGE TYPE LANDING VALVE LV-2

4. FOAM PROPORTIONER MIXED THE WATER AND THE SOLUTION TO CREATE FOAM AND FLOW INTO 3. SEND SIGNAL TO CLOSE ASSOCIATED DAMPERS AND SHUT DOWN MATERIAL DESCRIPTION WITH BUILT-IN PRV

THE OPEN FOAM SPRINKLER. DRAWINGS PRIOR TO COMMENCING THE INSTALLATION WORK. HVAC WITHIN THE HAZARD AREA. FLOW METER FLM

5. THE SEQUENCE OF OPERATION FOR THE THREE PUMPS SHALL BE AS FOLLOWS : 4. DEACTIVATE MAGNETICALLY HELD DOOR. 1. FIRE PUMPS HORIZONTAL SPLIT CASE PUMPS

IMPORTANT NOTICE ! THE DETAILED SEQUENCE OF OPERATION DESCRIBED BELOW IS SPECIFICALLY 27. ALL PIPING SHALL RUN CLOSE TO BEAMS, WALLS AND SLABS, SQUARE TO 5. ACTUATE CIRCUIT TO ENERGIZE 0-30 SECOND ADJUSTABLE 2. PIPING GALVANIZED ERW STEEL Sch. 40 INSPECTOR TEST CONNECTION

WITH ORIFICE PLATE ITC

WRITTEN FOR YOUR APPLICATION. OTHER SYSTEM'S OPERATION MAY DIFFER GREATLY DEPENDING ON THE ON DETECTION OF PRESSURE REDUCTION IN THE SYSTEM PRESSURE LOWER THAN BUILDING CONSTRUCTION, CONCEALED ABOVE HUNG CEILING AND WITHIN "EVACUATION TIMER".

THE START POINT OF JOCKEY PUMPS THEN FURRED SPACES. 3. VALVES(GATE & CHECK) OS&Y, GEAR OPERATED BUTTERFLY VALVE / SWING CHECK VALVE

SYSTEM'S REQUIREMENTS AND PARTICULARS OF THE PROJECTS. ALWAYS REFER TO THE SEQUENCE OF 6. ENABLE SYSTEM ABORT SEQUENCE.

MECHANICAL ALARM GONG MAG

OPERATION PROVIDED WITH 7. SEND ALARM SIGNAL TO MAIN FIRE ALARM PANEL. 4. FLOW / TAMPER SWITCHES VANE TYPE- LISTED FLOW SWITCH / TAMPER SWITCH

YOUR UNIT FOR PRECISE INFORMATION. THE HEAT AND SMOKE DETECTORS ARE WIRED ON TWO ZONES FOR THE JOCKEY PUMP SHALL BE ACTUATED FIRST TO COMPENSATE THE REDUCTION IN 28. SPRINKLER SYSTEM SHALL BE PROVIDED IN ALL SPACES IN THE BUILDING OR

OPERATION IN CROSSED ZONES MODE. PRESSURE. AS OTHERWISE REQUIRED. C. AFTER PRE-SET TIME DELAY SEQUENCE, THE FOLLOWING SHALL OCCUR; 5. SPRINKLERS STANDARD & QUICK RESPONSE

SURFACE MOUNTED FIRE HOSE REEL CABINET CONSISTING OF:

6. CONTROL PANELS UL-LISTED/ FM-APPROVED

THE ACTIVATION OF EITHER DETECTION ZONES WILL CAUSE THE FOLLOWING: AS PRESSURE IN THE SYSTEM CONTINUOUSLY DECREASE BELOW THE STARTING 29. PROVIDE FIRE EXTINGUISHER IN ALL LOCATIONS OF FIRE HOSE REEL OR FIRE 1. ACTUATE CIRCUIT TO RELEASE THE CLEAN AGENT SYSTEM INTO THE UPPER COMPARTMENT

POINT OF MAIN ELECTRICAL PUMP, THE JOCKEY PUMP CAN'T MEET THE SYSTEM HOSE REEL IN CABINET AND ALSO IN ALL OTHER LOCATIONS AS PER NFPA-10. AFFECTED AREA. 7. DRIVERS & CONTROLLERS UL-LISTED/ FM-APPROVED 1 NO. 25mm X 30 MTRS. LONG RUBBER AUTOMATIC

ON THE CONTROL PANEL ANNUNCIATOR: DEMAND AND THE MAIN ELECTRICAL PUMP SHALL BE ACTUATED AUTOMATICALLY TO (COVERAGE: 200m.sq. - LIGHT HAZARD: 150m.sq ORDINARY HAZARD) OR AS 2. ILLUMINATE "RELEASE" INDICATOR ON THE CONTROL PANEL AND

1" x 30 MTR. FIRE HOSE REEL AS PER EN 671-1 IN STEEL CABINET HOSE REEL FHRC-01

1. THE ZONE IN ALARM WILL BE DISPLAYED. MEET THE SYSTEM DEMAND. THE ELECTRIC PUMP WILL STOP AUTOMATICALLY AFTER SHOWN IN DRAWINGS. DISPLAY CUSTOM MESSAGE FOR DISCHARGE INDICATION. 8. HOSE & HOSE REELS W/ CABINETS

1 NO. 25mm GATE VALVE

2. THE ALARM LED WILL FLASH ALL THE STARTING CAUSES HAVE RETURN TO NORMAL AND 10 MINUTE MINIMUM RUN 3. ENERGIZE VISUAL INDICATOR (STROBE LIGHT) OUTSIDE THE HAZARD 9. BREECHING INLETS TWIN TYPE 4-WAY BREECHING INLET WITH 6" OUTLET 1 NO. 25mm PRESSURE REDUCING VALVE

3. THE LOCAL BUZZER WILL SOUND. TIME HAS ELAPSED. 30. FOR AREAS WHERE FALSE CEILING VOID IS MORE THAN 800 mm IN HEIGHT, IN WHICH OCCURED WITH STROBE/HORN.

FHRC-01 LOWER COMPARTMENT

CONTRACTOR SHALL SUPPLY UPRIGHT AND/OR PENDENT SPRINKLERS AS PER 10.AIR RELEASE VALVE 1" AIR RELEASE VALVE 1 NO. 4.5 KG. DRY POWDER FIRE EXTINGUISHER

SYSTEM OUTPUT ACTIVATION: IN CASE OF ELECTRICAL POWER SUPPLY FAILED, DIESEL PUMP SHALL BE ACTUATED NFPA -13 IRRESPECTIVE OF THE DRAWINGS. II-MANUAL OPERATION:

1. AN ALARM CONTACT FOR THE ALARM TRANSMISSION TO THE MAIN FIRE ALARM BUILDING PANEL AUTOMATICALLY TO COMPENSATE THE REQUIRED DEMAND TILL FINISHING THE FIRE 11. DRAINS TEST & DRAIN CONNECTION (UL/FM)

ACTIVATION OF MANUAL RELEASE STATION SHALL DUPLICATE THE "CROSS-ZONED

WILL BE ACTIVATED. FIGHTING PROCESS THEN SWITCH OFF THE DIESEL PUMP MANUALLY. 31. CONRACTOR SHALL COORDINATE WITH OTHER SERVICES TO IDENTIFY THE DETECTION" SEQUENCE DESCRIBED ABOVE EXCEPT TIME DELAY AND ABORT 12. SPECIAL SYSTEMS CLEAN AGENT SYSTEM, AEROSOL SYSTEM, FOAM SYSTEM

2. AN ALARM SIGNALLING CIRCUIT WILL BE ACTIVATED. ACTUAL OBSTRUCTIONS AT SITE. ADDITIONAL SPRINKLERS SHOULD BE FUNCTIONS. RECESSED MOUNTED FIRE HOSE REEL CABINET CONSISTING OF:

TO GUARANTEE THE PROPER AND EFFICIENT SEQUENCE OF OPERATION PROVIDED BELOW THE FIXED OBSTRUCTIONS MORE THAN 1200mm WIDE

THE ACTIVATION OF BOTH DETECTION ZONES (CROSSED ZONES) WILL CAUSE THE FOLLOWING: WITHOUT VARIATIONS CLAIM. III-ABORT OPERATION: UPPER COMPARTMENT

THE FOLLOWING PRESSURE SETTING VALUE TO BE ARRANGED AS RECOMMENDED BY IF ABORT SWITCH IS ACTIVATED WITHIN PRE-DISCHARGE PERIOD, THE FOLLOWING 1 NO. 25mm X 30 MTRS. LONG RUBBER AUTOMATIC

ON THE CONTROL PANEL ANNUNCIATOR: NFPA-20 : 32. SPRINKLERS LOCATED AT LOW LEVELS OR CRITICAL HEIGHT BELOW 2.20 SHALL OCCUR; HOSE REEL FHRC-02

1. THE ZONES IN ALARM WILL BE DISPLAYED. METERS SHALL BE EQUIPPED WITH SPRINKLER GUARDS.

1 NO. 25mm GATE VALVE

FIRE EXTINGUISHER TYPE AND SCHEDULE

the provided CAD data. CAD data is not intended to be issued to any third party without AEB's written consent for the same. In providing you with this CAD data, AEB does not assume any liability whatsoever unless expressed otherwise.

2. THE ALARM LED WILL FLASH 1. THE JOCKEY PUMP PRESSURE STOP POINT SHALL BE = MAIN PUMP CHURN PRESSURE + THE 1. ILLUMINATE "ABORT" INDICATOR ON THE CONTROL PANEL AND 1 NO. 25mm PRESSURE REDUCING VALVE

3. THE LOCAL BUZZER WILL SOUND. MINIMUM STATIC SUPPLY PRESSURE 33. A MINIMUM OF 40mm FLUSHING CONNECTION MUST BE PROVIDED AT THE END DISPLAY CUSTOM MESSAGE FOR PROPER ZONE INDICATION. LOWER COMPARTMENT

4. THE RELEASE LED WILL ILLUMINATE OF EACH CROSS-MAIN SECTION. 2. RELEASE OF GAS IS HELD IF ABORT SWITCH IS PRESSED NFPA 10- 2013 EDITION TABLE 6.2.1.1 FHRC-02 1 NO. 4.5 KG. DRY POWDER FIRE EXTINGUISHER

5. THE DISCHARGE LED WILL ILLUMINATE 2. THE JOCKEY PUMP START POINT SHALL BE AT LEAST 10 PSI LESS THAN THE JOCKEY PUMP CONTINUOUSLY. FIRE EXTINGUISHER SIZE AND PLACEMENT FOR CLASS-A HAZARD:

STOP POINT. 34. SPRINKLER SYSTEMS SHALL HAVE INSPECTOR TEST CONNECTION FITTED TO 3. AGENT WILL RELEASE IF ABORT SWITCH IS DEACTIVATED AND

SYSTEM OUTPUT ACTIVATION: THE MOST REMOTE SPRINKLER(S) ON EACH FLOOR/ZONE. AN ORIFICE TO COUNTDOWN IS COMPLETED.

3. THE ELECTRICAL FIRE PUMP START POINT SHALL BE 5 PSI LESS THAN THE JOCKEY PUMP SIMULATE A SINGLE SPRINKLER OPERATION SHALL BE FITTED TO THE END OF LIGHT ORDINARY EXTRA SURFACE MOUNTED FIRE HOSE REEL CABINET CONSISTING OF:

1. AN ALARM CONTACT FOR THE ALARM TRANSMISSION TO THE MAIN FIRE ALARM BUILDING PANEL (LOW)

CRITERIA (MODERATE) (HIGH)

WILL BE ACTIVATED. START POINT. USE ADDITIONAL 10 PSI INCREMENTS FOR EACH ADDITIONAL PUMP. IT.

HAZARD HAZARD HAZARD UPPER COMPARTMENT

2. AN ALARM SIGNALLING CIRCUIT WILL BE ACTIVATED. OCCUPANCY OCCUPANCY OCCUPANCY

FIRE PUMP PRESSURE SETTING: 35. FIRE DRAIN RISERS , PIPING & ALL WATER PIPING MATERIAL INSIDE PUMP 1 NO. 25mm X 30 MTRS. LONG RUBBER AUTOMATIC

3. THE RELEASE CIRCUIT WILL BE ACTIVATED AND THE CAF DISCHARGE WILL OCCUR.

ROOM SHALL BE ERW GALVANIZED STEEL PIPE SCHEDULE 40. HOSE REEL

4. THE DISCHARGE CONTACT WILL BE ACTIVATED FOR AUXILIARY FUNCTION. MINIMUM RATED SINGLE EXTINGUISHER 2-A 2-A 2-A

JOCKEY PUMP STOP PRESSURE 335 PSI 1 NO. 25mm GATE VALVE

MAXIMUM FLOOR AREA PER UNIT OF "A" 3,000 FT2 1,500 FT2 1,000 FT2 FHRC-03

36. INTERFACING OF FIRE ALARM SYSTEM SHALL BE DONE BY THE FIRE ALARM 1 NO. 25mm PRESSURE REDUCING VALVE

THE ACTIVATION OF ELECTRICAL EMERGENCY MANUAL RELEASE

JOCKEY PUMP START PRESSURE 325 PSI CONTRACTOR. MAXIMUM FLOOR AREA FOR EXTINGUISHER 11,250 FT2 11,250 FT2 11,250 FT2 LOWER COMPARTMENT

STATION WILL CAUSE THE FOLLOWING:

1 NO. 4.5 KG. DRY POWDER FIRE EXTINGUISHER

MAXIMUM TRAVEL DISTANCE TO EXTINGUISHER 75 FT 75 FT 75 FT FHRC-03 1 NO. 65mm LANDING VALVE

ON THE CONTROL PANEL ANNUNCIATOR: ELEC. FIRE PUMP START PRESSURE 320 PSI 37. All FIREFIGHTING PIPES FOR FIRE SAFETY APPLICATION PENETRATING THRU

1. THE ZONE IN ALARM (MANUAL PULL) WILL BE DISPLAYED. WALLS AND SLABS SHALL BE SEALED WITH FIRE RETARDANT MATERIAL WITH 1 NO. 65mm X 30 MTRS. FIRE HOSE WITH NOZZLE

2. THE ALARM LED WILL FLASH DIESEL FIRE PUMP START PRESSURE 310 PSI RATING OF NOT LESS THAN THE FIRE RATING OF THE WALL OR SLAB BEING

SPRINKLERS IN CONCEALED CEILING NFPA 10- 2013 EDITION TABLE 6.3.1.1

FIRE EXTINGUISHER SIZE AND PLACEMENT FOR CLASS-B HAZARD:

3. THE LOCAL BUZZER WILL SOUND. PENETRATED. AND RAISED FLOOR SPACES RECESSED MOUNTED FIRE HOSE REEL CABINET CONSISTING OF:

4. THE RELEASE LED WILL ILLUMINATE. NOTE: BASIC MAXIMUM

38. PROVISION FOR EXPLOSION PREVENTION SHALL BE INSTALLED IF THE TYPE OF UPPER COMPARTMENT

5. THE DISCHARGE LED WILL ILLUMINATE TYPE OF MINIMUM TRAVEL

TRANSFORMER TO BE USED ARE OIL FILLED. 1 NO. 25mm X 30 MTRS. LONG RUBBER AUTOMATIC

PUMP CHURN PRESSURE TO BE VERIFIED AT SITE BY THE SPECIALIST CONTRACTOR AS 1. CONCEALED CEILING AND FLOOR SPACES NOT EXCEEDING 400mm IN DEPTH HAZARD EXTINGUISHER DISTANCE TO HOSE REEL

SYSTEM OUTPUT ACTIVATION: PER THE ACTUAL FIRE PUMP SELECTION. FIRE PUMP PRESSURE SETTINGS TO BE NEED NOT BE PROTECTED BY SPRINKLER. RATING EXTINGUISHER

39. THE EXHAUST PIPE SHALL BE COVERED WITH HIGH TEMPERATURE 1 NO. 25mm GATE VALVE

1. AN ALARM CONTACT FOR THE ALARM TRANSMISSION TO THE MAIN FIRE ALARM BUILDING PANEL UPDATED ACCORDINGLY. FHRC-04

INSULATION. 5-B 30 FT 1 NO. 25mm PRESSURE REDUCING VALVE

WILL BE ACTIVATED. 2. CONCEALED CEILING AND FLOOR SPACES EXCEEDING 400mm BUT NOT LIGHT

LOWER COMPARTMENT

2. AN ALARM SIGNALING CIRCUIT WILL BE ACTIVATED. EXCEEDING 800mm IN DEPTH AND DO NOT CONTAIN COMBUSTIBLE MATERIAL (LOW) 10-B 50 FT A 11/05/17 ISSUED FOR TENDER KAS

40. CLEAN AGENT SYSTEM SHALL COMPLY WITH NFPA 2001 AND INTEGRITY TEST 1 NO. 4.5 KG. DRY POWDER FIRE EXTINGUISHER

3. THE RELEASE CIRCUIT WILL BE ACTIVATED AND THE CAF DISCHARGE WILL OCCUR. NEED NOT BE PROTECTED BY SPRINKLERS.

DIESEL ENGINE FUEL TANK CAPACITY SHALL BE CONDUCTED IN THE PRESENCE OF QCDD AUTHORIZED 10-B 30 FT FHRC-04 1 NO. 65mm LANDING VALVE

4. THE DISCHARGE CONTACT WILL BE ACTIVATED FOR AUXILIARY FUNCTION. ORDINARY

(DIESEL PUMP) REPRESENTATIVES. 3. CONCEALED CEILING AND FLOOR SPACES EXCEEDING 400mm BUT NOT (MODERATE) 1 NO. 65mm X 30 MTRS. FIRE HOSE WITH NOZZLE NO. DATE DESCRIPTION APPROVED

20-B 50 FT

THE ACTIVATION OF MECHANICAL EMERGENCY MANUAL STATION EXCEEDING 800mm IN DEPTH AND CONTAINING COMBUSTIBLE MATERIAL AEB STAMP PLANNING APPROVAL

INSIDE THE FOAM DELUGE SYSTEM WILL CAUSE THE FOLLOWING: ENGINE DRIVEN FIRE PUMP FUEL TANK CAPACITY 650 GALS. 41. CLEAN AGENT SYSTEM PIPES SHALL BE SEAMLESS BLACK STEEL SCHEDULE 80 SHALL BE PROTECTED BY SPRINKLERS INSTALLED ON THE EXTENDED BASIS. EXTRA 40-B 30 FT FIRE EXTINGUISHERS & FIRE BLANKET:

GRADE-B PAINTED WITH RED PAINT. THE FITTINGS SHALL BE SUITABLE TO SCH. SPRINKLER PROTECTION MAY BE OMITTED WHERE THE SPACE IS (HIGH) 80-B 50 FT

ON THE CONTROL PANEL ANNUNCIATOR: DIESEL DRIVEN FIRE PUMP 1000 GPM 80 PIPES AND IN ACCORDANCE WITH NFPA 2001. SUBDIVIDED BY FIRE AND DRAUGHT STOPS AT INTERVALS NOT EXCEEDING SYMBOL DESCRIPTION CLASS CAPACITY

1. THE ZONE IN ALARM (WATERFLOW) WILL BE DISPLAYED. 15m IN ANY DIRECTION.

TOTAL HEAD 295 PSI 42. CLEAN AGENT FIRE EXTINGUISHING SYSTEM SHALL BE SUPER-PRESSURIZED PFE DRY POWDER FIRE EXTINGUISHER ABC 4.5 KG.

2. THE ALARM LED WILL FLASH CLASS-C LOCATION:

3. THE LOCAL BUZZER WILL SOUND. AT 500PSI AND INSTALLED,TESTED AND COMMISSIONED IN ACCORDANCE WITH 4. CONCEALED CEILING AND FLOOR SPACES EXCEEDING 800mm SHALL BE C 4.5 KG.

CLASS C EXTINGUISHERS ARE REQUIRED WHERE ENERGIZED ELECTRICAL EQUIPMENT IS POTENTIALLY DIRECTLY INVOLVE IN PFE CLEAN AGENT FIRE EXTINGUISHER

4. THE DISCHARGE LED WILL ILLUMINATE DIESEL ENGINE HORSEPOWER 282 BHP NFPA-2001-(2012). PROTECTED BY SPRINKLER INSTALLED IN ACCORDANCE WITH THE

OR SURROUNDS ELECTRICAL EQUIPMENT. NORMALLY CLASS C FIRES ARE IN DIRECT LOCATION OF CLASS A OR CLASS B FIRES,

REQUIREMENT FOR THE PARTICULAR HAZARD. PFE WET CHEMICAL FIRE EXTINGUISHER K 6 LT.

THE EXTINGUISHER SHALL BE SIZED PER THE CLASS A OR CLASS B HAZARD.

SYSTEM OUTPUT ACTIVATION: FUEL CONSUMPTION 43. THE SPECIALIZED CONSULTANT FOR CLEAN AGENT FIRE EXTINGUISHING AND

35.25 Gal/Hr FB FIRE BLANKET N/A 6' X 6'

1. AN ALARM CONTACT FOR THE ALARM TRANSMISSION TO THE MAIN FIRE ALARM BUILDING PANEL (=282 Bhp x 1Gal / Hp-8Hr) AUTOMATIC FIRE SUPPRESSION SYSTEM SHALL SUBMIT DETAILED DRAWING

CLASS-D LOCATION:

WILL BE ACTIVATED. AND CALCULATION FOR QCD APPROVAL PRIOR TO WORK COMMENCEMENT.

FIRE EXTINGUISHERS FOR CLASS D LOCATION SHALL NOT BE LOCATED MORE THAN 75 FT. FROM THE HAZARD.

2. AN ALARM SIGNALLING CIRCUIT WILL BE ACTIVATED. AS PER NFPA 20, 11.4.2.1 FUEL TANK CAPACITY, DIESEL ENGINE DRIVE FUEL

SIZE DETERMINATION FOR CLASS D LOCATIONS IS BASED ON THE SPECIFIC COMBUSTIBLE METAL, PARTICLE SIZE, SPRINKLER HEADS CONSULTANT:

3. THE CAF DISCHARGE WILL OCCUR AND THE DISCHARGE CONTACT WILL BE ACTIVATED FOR SUPPLY TANK(S) SHALL HAVE A CAPACITY AT LEAST EQUAL TO 1 GAL. PER 44. THE SPECIALIZED CONSULTANT FOR FIRE SUPPRESSION SYSTEM SHALL

AREA TO BE COVERED, AND MANUFACTURER RECOMMENDATIONS.

AUXILIARY FUNCTION. HORSEPOWER, PLUS 5 PERCENT VOLUME FOR EXPANSION AND 5 PERCENT SUBMIT DETAILED DRAWING AND CALCULATION FOR QCD APPROVAL PRIOR TO SYMBOL DESCRIPTION K-FACTOR

VOLUME FOR SUMP. WORK COMMENCEMENT.

AUTOMATIC DISCHARGE

CLASS-K LOCATION:

UPRIGHT SPRINKLER HEAD 5.6 Arab Engineering Bureau

45. THE KITCHEN HOOD SHALL BE PROVIDED WITH FIRE SUPPRESSION SYSTEM BY CLASS K HAZARDS SHALL HAVE A FIRE EXTINGUISHER LOCATED WHERE IS A POTENTIAL FOR A FIRE INVOLVING COMBUSTIBLE COOKING AEB HEADQUARTERS:

THE DELUGE FOAM SYSTEM DISCHARGE WILL OCCUR FOR 10 MINUTES. AT THE END OF FUEL TANK VOLUME

564 Gals. THE SPECIALIZED CONTRACTOR. . MEDIA (VEGETABLE OR ANIMAL OILS AND FATS). THE EXTINGUISHER SHALL BE LOCATED NOT MORE THAN 30 FT. FROM THE HAZARD. UPRIGHT SPRINKLER HEAD 8.0 P.O. Box 1148 Doha, Qatar Tel +974 4406 88 88 Fax +974 4447 78 68

THE SOAK TIMER, THE DELUGE FOAM SYSTEM DISCHARGE WILL AUTOMATICALLY STOP. (1 GAL/HP / 8 HR. X 282 HP X 16HR. OPERATION) Email aeb@aeb-qatar.com Web www.aeb-qatar.com

THE RELEASE LED WILL THEN START FLASHING. CONCEALED PENDENT HIGH TEMPERATURE SPRINKLER HEAD 5.6 OTHER BRANCHES:

SUMP & EXPANSION 10% 46. SPECIAL TYPE OF FIRE SUPPRESSION SYSTEMS LIKE, CLEAN AGENT SYSTEM, ABU DHABI * MANILA * KUALA LUMPUR * MUSCAT

FOAM DELUGE SYSTEM, KITCHEN HOOD SYSTEM, AEROSOL SYSTEM, & ETC. TO PENDENT SPRINKLER HEAD 5.6

KITCHEN HOOD FIRE PROTECTION MINIMUM TANK SIZE 620.4 Gals.

(SAY 650 Gals.)

BE DESIGNED, CALCULATED, & VERIFIED BY THE SPECIALIST CONTRACTOR. PROJECT :

SEQUENCE OF OPERATION 18.44 Hrs.

THERE SHALL BE NO VARIATION CLAIMS IN THIS REGARD. CONCEALED PENDENT SPRINKLER HEAD 5.6

PROPOSED QATAR AIRWAYS RESIDENTIAL TOWER

DURATION OF USE SIDEWALL SPRINKLER HEAD 5.6

( AT FULL TANK ) 47. GRP LINING SHALL BE PROVIDED ON ALL INTERNAL WALLS INSIDE THE FIRE (4B+G+29 FLOORS)

D:\REVIT FILES\1245-16_MF_QA RES.TOWER_CF_AEB_R17_Wilson.rvt

FIRE IS DETECTED BY THE MECHANICAL LINK, OR ELECTRIC LINEAR HEAT DETECTION CABLE, OR THE SYSTEM IS WATER TANKS.

MANUALLY ACTIVATED BY A REMOTE PULL STATION. ABBREVIATION OWNER :

QATAR AIRWAYS

THE CONTROL SYSTEM ACTIVATED PRESSURIZED AGENT STORAGE CONTAINERS. RN RISER NIPPLE UP PIPE UP

SITE :

T/B PIPE TO BELOW PIPE DIAMETER AL DAFNA, WEST BAY DOHA, QATAR

THE FUEL SUPPLY IS SHUT DOWN BY INTERFACING SOLENOID VALVE.

FUEL TANK BUND WALL CALCULATION T/A PIPE TO ABOVE DP DRAIN PIPE

TITLE :

THE FIRE ALARM SYSTEM IS ACTIVATED BY AN INTERFACING MODULE.

F/A PIPE FROM ABOVE WSP WET STANDPIPE

GENERAL NOTES, LEGENDS, ABBREVIATIONS,

PLOTTED DATE: 11/05/2017 8:07:40 AM

MINIMUM TANK SIZE IN GALLONS 650 gals.

THE WET CHEMICAL AGENT, DESIGNED SPECIFICALLY FOR THE CHALLENGES POSED BY OIL AND GREASE IN A

KITCHEN ENVIRONMENT, IS PROPELLED THROUGH THE SYSTEM PIPING BY THE STORED PRESSURE

F/B PIPE FROM BELOW SRP SPRINKLER PIPE & DRAWINGS LIST FIRE FIGHTING LAYOUT

MINIMUM TANK SIZE IN CUBIC METERS 2.46 m DRAWN BY : DESIGN BY : CHECKED BY : APPROVED BY :

CONTAINER. DN PIPE DOWN HRP HOSE REEL PIPE WLC SP MH KAS

THE WET CHEMICAL AGENT DISCHARGES FROM STRATEGICALLY POSITIONED NOZZLES PROTECTING THE REQUIRED BUND WALL CAPACITY 2.46 m DATE : SCALE @ A0:

HOOD, DUCT AND APPLIANCES APC AGENT QUICKLY SUPPRESSES THE FLAMES AND FORMS A PROTECTIVE NOVEMBER 2016 NTS.

LAYER THAT NOT ONLY EXTINGUISHES THE FIRE, BUT ALSO PREVENT RE-IGNITION. ADDING 20% SAFETY FACTOR 2.95 m REVISION

PROJECT NO : DRAWING NO :

TOTAL BUND WALL CAPACITY L = 2.50 m W = 1.50 m H = 0.80 m V = 3.00 m 1245-16 1245-F-A0-0001 A

You might also like

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- 2015 0526 DWG Fire DDSetDocument16 pages2015 0526 DWG Fire DDSetnadiruuzaman sizanNo ratings yet

- Ar Main MajlisDocument32 pagesAr Main MajlisAli BaiasiNo ratings yet

- PORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairDocument34 pagesPORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairHarleen KlairNo ratings yet

- Demolition Notes General Notes General Notes: Creative Structures ServicesDocument1 pageDemolition Notes General Notes General Notes: Creative Structures ServicesHanif KhanNo ratings yet

- ISB - CM2150 - Without Aftertreatment - 4022080Document1 pageISB - CM2150 - Without Aftertreatment - 4022080Gustavo Rodriguez CanteNo ratings yet

- Ttag NTC Sds Mep DP MB 00 1Document1 pageTtag NTC Sds Mep DP MB 00 1Đỗ Thanh HùngNo ratings yet

- Job PortfolioDocument43 pagesJob PortfolioHarleen KlairNo ratings yet

- Atk GLW XX DR Ew 000007Document1 pageAtk GLW XX DR Ew 000007BEN BENNo ratings yet

- GADGopalpurROB1 3kmDocument2 pagesGADGopalpurROB1 3kmAnurag sharmaNo ratings yet

- Plumbing Permit Drawings PDFDocument3 pagesPlumbing Permit Drawings PDFJeremy BoyceNo ratings yet

- MP 1101Document1 pageMP 1101omar.engworkNo ratings yet

- General Specifications Legends and Symbols: Phase 6Document1 pageGeneral Specifications Legends and Symbols: Phase 6inno de los santosNo ratings yet

- Ttag NTC Sds Mep DP MB 01Document1 pageTtag NTC Sds Mep DP MB 01Đỗ Thanh HùngNo ratings yet

- For Tender: NotesDocument5 pagesFor Tender: NotesTeam RelentlessNo ratings yet

- St-Hidd-01 Security Room DetailsDocument1 pageSt-Hidd-01 Security Room Detailsmhazarath murariNo ratings yet

- General Slab On Ground Concrete Concrete Continued Chemical AnchorsDocument12 pagesGeneral Slab On Ground Concrete Concrete Continued Chemical AnchorsJelenaNo ratings yet

- Drawings Electric Forklift Charging StationsDocument14 pagesDrawings Electric Forklift Charging StationsRafael de la cruzNo ratings yet

- Zoleta Residence - Structural PlansDocument5 pagesZoleta Residence - Structural PlansJc SulitNo ratings yet

- v9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFDocument1 pagev9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFEllyella ElormNo ratings yet

- Sample Structural DrawingDocument1 pageSample Structural DrawingCherish Taguinod Aliguyon100% (1)

- General Notes:: Finishes To Architects Details Finishes To Architects DetailsDocument1 pageGeneral Notes:: Finishes To Architects Details Finishes To Architects DetailsAnonymous qEPNPwANo ratings yet

- (0030) Salman Town Solar Project Solar SMDBDocument6 pages(0030) Salman Town Solar Project Solar SMDBSavio SunnyNo ratings yet

- Sesb ModelDocument1 pageSesb ModelYon Chen LangNo ratings yet

- L&T Hydrocarbon Engineering: Approved For ConstructionDocument6 pagesL&T Hydrocarbon Engineering: Approved For ConstructionAnthony MayNo ratings yet

- Uci Mce Stru D S-20.6Document1 pageUci Mce Stru D S-20.6Thanh Đạt NguyễnNo ratings yet

- AE 036411 001 INDEX For Drawing and Equipment PDFDocument1 pageAE 036411 001 INDEX For Drawing and Equipment PDFjulius100% (1)

- 1ST Flr-LightingDocument1 page1ST Flr-LightingAnu GraphicsNo ratings yet

- 2020-276P Attachment 6.2-Architectural Drawings PDFDocument14 pages2020-276P Attachment 6.2-Architectural Drawings PDFanomenusNo ratings yet

- Location Plan SCALE-1:2000: Datum 2Document1 pageLocation Plan SCALE-1:2000: Datum 2SHRADDHA GHUGENo ratings yet

- Fa 3RDDocument1 pageFa 3RDAhmed KhalilNo ratings yet

- FP-01 Front PageDocument1 pageFP-01 Front PageBerlin Andrew SionNo ratings yet

- A B C D: Reinforcement Detail of Roof LevelDocument1 pageA B C D: Reinforcement Detail of Roof LevelSampath S. WickramanayakaNo ratings yet

- StrucDocument3 pagesStrucAlvin DeliroNo ratings yet

- 9 Jones ST - Building Review - 200227 - PL PDFDocument8 pages9 Jones ST - Building Review - 200227 - PL PDFLeonardo Jr. SasingNo ratings yet

- See Detail 1: NotesDocument1 pageSee Detail 1: NotesYazan MohammadNo ratings yet

- Annex 02Document12 pagesAnnex 02rukshan jayasingheNo ratings yet

- General Notes:: SSL +72.910 MDocument1 pageGeneral Notes:: SSL +72.910 MAnonymous qEPNPwANo ratings yet

- Catch Basin Detail: LegendsDocument1 pageCatch Basin Detail: LegendsM VlogNo ratings yet

- H85 J BA-430471 001: Field Design ChangeDocument11 pagesH85 J BA-430471 001: Field Design ChangeKarim Abd El HamidNo ratings yet

- 19088-PS1-AR-005-009 Beira-Control Room - Typical Concrete Ramp Section Rev 0Document1 page19088-PS1-AR-005-009 Beira-Control Room - Typical Concrete Ramp Section Rev 0Delfino Bernardo ViegasNo ratings yet

- FS0654-DOD-XX-01-DR-P-4004 - First Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-01-DR-P-4004 - First Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

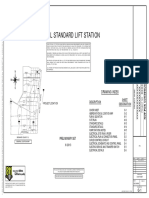

- Wws Typical Standard Lift StationDocument13 pagesWws Typical Standard Lift StationkingdbmNo ratings yet

- Tenant Protection Plan Notes Per 2014 Code 28-104.8.4 As Modified by Nyc Ll154 of 2017Document8 pagesTenant Protection Plan Notes Per 2014 Code 28-104.8.4 As Modified by Nyc Ll154 of 2017Leonardo Jr. SasingNo ratings yet

- Structual Plan 2-Storey ResidentialDocument9 pagesStructual Plan 2-Storey ResidentialMark Christian EsguerraNo ratings yet

- Epc For Rumaitha/Shanayel Facilities - Phase Iii: ADCO Contract No.: 15678.01 / EC 10884 ADCO Project No.: P44010Document2 pagesEpc For Rumaitha/Shanayel Facilities - Phase Iii: ADCO Contract No.: 15678.01 / EC 10884 ADCO Project No.: P44010suleman.shahNo ratings yet

- S1 Structural NotesDocument1 pageS1 Structural NotesRaynz PatronNo ratings yet

- Restrictive LayoutDocument7 pagesRestrictive LayoutMamelucoNo ratings yet

- PB4784 C205 Ar DR 37412 - 4.0Document1 pagePB4784 C205 Ar DR 37412 - 4.0amrNo ratings yet

- Mta-001 20Document1 pageMta-001 20MuhammadMursaleenNo ratings yet

- KIL2189 - 200 - 0001 - REV08 - Proposed LayoutDocument1 pageKIL2189 - 200 - 0001 - REV08 - Proposed LayoutNiemNo ratings yet

- GC ST 09 RevisedDocument1 pageGC ST 09 Revisedmhazarath murariNo ratings yet

- PlanDocument8 pagesPlanMark Christian EsguerraNo ratings yet

- 4124 Ai Du 21130i046s01 Is01 - Checkprint - DineshDocument1 page4124 Ai Du 21130i046s01 Is01 - Checkprint - Dineshamit bagchiNo ratings yet

- Aq 211101 001Document1 pageAq 211101 001Qudsi NayazNo ratings yet

- Appendix - B DrawingsDocument7 pagesAppendix - B DrawingsShreekant KeraiNo ratings yet

- Jeg Tower: Proposed 22-Storey Office Building Jeg Development CorpDocument1 pageJeg Tower: Proposed 22-Storey Office Building Jeg Development CorpErwin ObenzaNo ratings yet

- Warehouse: HHI-7H-7030-SA-200-05-C205-01 HHI-7H-7030-SA-200-05-C205-02Document1 pageWarehouse: HHI-7H-7030-SA-200-05-C205-01 HHI-7H-7030-SA-200-05-C205-02amrNo ratings yet

- Seismic Behavior of Large Panel Precast Concrete Walls - Analysis and ExperimentDocument25 pagesSeismic Behavior of Large Panel Precast Concrete Walls - Analysis and ExperimenttilaNo ratings yet

- Design Anlaysis of Cantilever BeamDocument6 pagesDesign Anlaysis of Cantilever BeamDannyDurhamNo ratings yet

- Diagrid, Prada Boutique AoyamaDocument4 pagesDiagrid, Prada Boutique AoyamastefanNo ratings yet

- Systems of Wiring: Shresth Sarthak Vashisht Raviraj Saurabh Prakhar PrabalDocument22 pagesSystems of Wiring: Shresth Sarthak Vashisht Raviraj Saurabh Prakhar PrabalPrabal SethiNo ratings yet

- Individual Assignment SMG504Document12 pagesIndividual Assignment SMG504Ammar HakimNo ratings yet

- Concept and Basic, Details Engg InfoDocument2 pagesConcept and Basic, Details Engg InfomgkvprNo ratings yet

- DR - Fixit Pidicrete - CF BRLDocument1 pageDR - Fixit Pidicrete - CF BRLnickdash09No ratings yet

- Urban Floods Chennai Report NGT Sep2021Document55 pagesUrban Floods Chennai Report NGT Sep2021Vaishnavi Jayakumar100% (1)

- Final ProjectDocument6 pagesFinal Projectbrian samNo ratings yet

- Tablas Weldolets, ThredoletsDocument44 pagesTablas Weldolets, ThredoletsIng TelloNo ratings yet

- Reinforced Concrete Design According To ACI 318M 19 Ver 4 0 El KatebDocument43 pagesReinforced Concrete Design According To ACI 318M 19 Ver 4 0 El KatebanonymNo ratings yet

- Zonal RegulationsDocument73 pagesZonal RegulationsSudhakar MuruganNo ratings yet

- Structural SpecificationsDocument71 pagesStructural SpecificationsFatima EberoNo ratings yet

- Design and Analysis of A Ladder FrameDocument14 pagesDesign and Analysis of A Ladder FrameNandan PoojaryNo ratings yet

- Hire Charges of EquipmentDocument1 pageHire Charges of EquipmentDEEPAKNo ratings yet

- D10TDocument2 pagesD10TjoseluisyalicoNo ratings yet

- Seminar Topic EditedDocument2 pagesSeminar Topic Editedhitheshds1999No ratings yet

- AH36Document3 pagesAH36Abu ZahidNo ratings yet

- Career Path Unit 2Document14 pagesCareer Path Unit 2Temuujin NaidandorjNo ratings yet

- DE Sem 5Document24 pagesDE Sem 5Yamin Devgadhwala100% (1)

- ALC-10488-2-Wall Adapter PlateDocument2 pagesALC-10488-2-Wall Adapter Plateusgl-scbd3639No ratings yet

- Standard Data Book For RoadsDocument1,082 pagesStandard Data Book For RoadsMonjit Gogoi100% (4)

- A Study of Measures To Improve Constructability - 2006Document16 pagesA Study of Measures To Improve Constructability - 2006Adilson Rodrigues RosaNo ratings yet

- Timber DistortionDocument14 pagesTimber DistortionThomas SmithNo ratings yet

- Pressure Vessel InspectionDocument3 pagesPressure Vessel InspectionSpectex dubaiNo ratings yet

- Slim Floor: Long Carbon Europe Sections and Merchant BarsDocument36 pagesSlim Floor: Long Carbon Europe Sections and Merchant BarstankeanleongNo ratings yet

- SECTION 16050 Basic Electrical Materials and MethodsDocument18 pagesSECTION 16050 Basic Electrical Materials and MethodsAyman SaberNo ratings yet

- Aldo RossiDocument35 pagesAldo RossiShiva Kumar SNo ratings yet

- Checklist For Dismantling & Preservation of Existing MEP Works-FinalDocument2 pagesChecklist For Dismantling & Preservation of Existing MEP Works-FinalMohammed Javid100% (1)

- Rimska ArhitekturaDocument11 pagesRimska ArhitekturadebbronnerfilesNo ratings yet