Professional Documents

Culture Documents

CS Forging Requirements

Uploaded by

SanjayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CS Forging Requirements

Uploaded by

SanjayCopyright:

Available Formats

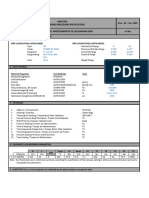

Name: CARBON STEEL FORGINGS

1 Quantity

2 Size / Dimensions Refer Sheet 2

3 Material Specification SA-266 Gr. II

4 General/Client Specification

5 Code/ Standard ASME Section II Part A Edition 2013

6 NACE MR0103 Required Not Required

7 Supply Condition Normalized As Rolled

Tempered Quenched

Accelerated Cooled As per Attached Specification

8 Steel making process Fully Killed Fine Grained

Vacuum Degassed

9 Impact Tests Required Not Required

11 Certification/Markings/ Identification As per Specification Others

12 Other Requirements:

1 Product Analysis

2 Simulated PWHT of test coupon

3 Tension Test for Specimen close to hub

4 UT as per A388

5 UT as per Div.2

6 Restricted Chemistry

7 Carbon Equivalent

8 Low Sulphur Steel

14 Additional Requirements

Hardness Maximum permissible value: 200 BHN

HIC test as per NACE TM 0284 Solution: B

Calcium Treated Steel

Maximum Columbium (Niobium) content can be up to 0.05% on heat analysis (Note D of Table 1, SA-20)

Design Code is ASME Sec. VIII Div. 2 Yes No

15 Other Miscellaneous Requirements

1. Magnetic Particle Testing Required Not Required

2. Repair by Welding is not permitted

3. Material Test Certificates as per EN10204 3.1 3.2

17 IBR Certification Required? Yes No

Design Pressure(= MAWP) MPa

Temperature F

Any Other Special Requirement

Attachments (If Any)

You might also like

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- TDC 006 - SS Threaded Couplings & Nipples - r0Document1 pageTDC 006 - SS Threaded Couplings & Nipples - r0samkarthik47No ratings yet

- Bharat Gears Limited: PREPARED BY Mr. YogendraDocument13 pagesBharat Gears Limited: PREPARED BY Mr. YogendraAnonymous lzxpjxNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- TDCDocument6 pagesTDCalex hutaurukNo ratings yet

- 3 2 Purchase Material SpecificationDocument1 page3 2 Purchase Material Specificationanon_376696588No ratings yet

- Sa 739Document3 pagesSa 739Elgen IgloriaNo ratings yet

- Fpso Piping Material Datasheet SO17033 PESDMCPF999001 A2 10 of 23Document1 pageFpso Piping Material Datasheet SO17033 PESDMCPF999001 A2 10 of 23alouisNo ratings yet

- Sa 387Document6 pagesSa 387ismaelarchilacastilloNo ratings yet

- MPS TemplateDocument4 pagesMPS TemplategaurangNo ratings yet

- 3.3. Oes-Td-Int-005-Fs-Mm02Document6 pages3.3. Oes-Td-Int-005-Fs-Mm02sumit kumarNo ratings yet

- BHEL, Tiruchirapalli-620014. Quality Assurance TECHNICAL DELIVERY CONDITION Product: Steel Castings. (Valves)Document7 pagesBHEL, Tiruchirapalli-620014. Quality Assurance TECHNICAL DELIVERY CONDITION Product: Steel Castings. (Valves)abdulNo ratings yet

- TDC0412 - Rev18 PDFDocument7 pagesTDC0412 - Rev18 PDFpl_arunachalam79No ratings yet

- Welded Nickel and Nickel-Cobalt Alloy Pipe: Standard Specification ForDocument5 pagesWelded Nickel and Nickel-Cobalt Alloy Pipe: Standard Specification ForZouhair BoukriNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- Asme SB-443Document11 pagesAsme SB-443coronado777No ratings yet

- 1206-1906 QapDocument2 pages1206-1906 QapSambit NayakNo ratings yet

- Astm A240 Ss316Document12 pagesAstm A240 Ss316Henky PramaNo ratings yet

- A 1021 - 01 - QtewmjetmdeDocument4 pagesA 1021 - 01 - QtewmjetmdeAdrian GonzalezNo ratings yet

- Tube CS179 - MPSDocument3 pagesTube CS179 - MPSgaurangNo ratings yet

- 44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESDocument5 pages44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESAvinash ShuklaNo ratings yet

- Astm B 444Document4 pagesAstm B 444Jamil SalmanNo ratings yet

- A 982 - 02 Perfiles de TurbinaDocument4 pagesA 982 - 02 Perfiles de Turbinaalucard375No ratings yet

- Sa 106 PDFDocument16 pagesSa 106 PDFRaju SkNo ratings yet

- Specification For Pressure Vessel Plates, Alloy Steel, Chromium-MolybdenumDocument6 pagesSpecification For Pressure Vessel Plates, Alloy Steel, Chromium-MolybdenumAnilNo ratings yet

- A1021 PDFDocument4 pagesA1021 PDFlilianaNo ratings yet

- SB-425 - ASME BPVC 2021 Sección II Part BDocument8 pagesSB-425 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- Sa 351Document6 pagesSa 351Anil0% (1)

- Specification For Seamless Copper Pipe, Standard SizesDocument8 pagesSpecification For Seamless Copper Pipe, Standard SizesVCNo ratings yet

- Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825 and N08221) Seamless Pipe and TubeDocument4 pagesNickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825 and N08221) Seamless Pipe and TubeRio WitcandraNo ratings yet

- UE-BHEL-054-MPP-03 Rev.01Document6 pagesUE-BHEL-054-MPP-03 Rev.01udayakarnaNo ratings yet

- Hdpe Bps Sab355Document1 pageHdpe Bps Sab355Benjamin Enmanuel Mango DNo ratings yet

- Steel Bars, Carbon, Hot-Wrought or Cold-Finished, Special Quality, For Pressure Piping ComponentsDocument3 pagesSteel Bars, Carbon, Hot-Wrought or Cold-Finished, Special Quality, For Pressure Piping ComponentsCK CkkouNo ratings yet

- Specification For Fire Pump - Part 7Document5 pagesSpecification For Fire Pump - Part 7Melisa MackNo ratings yet

- Sa 312 PDFDocument14 pagesSa 312 PDFAnilNo ratings yet

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocument1 pageDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarNo ratings yet

- TDC For Plates - SA 516 65Document3 pagesTDC For Plates - SA 516 65Renny DevassyNo ratings yet

- Smls Itp MpsDocument5 pagesSmls Itp MpsGabriel Caicedo RussyNo ratings yet

- SB 148Document4 pagesSB 148AnilNo ratings yet

- B705 Acpt1003Document3 pagesB705 Acpt1003taya1401No ratings yet

- Asme Sa-562-Sa-562M Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Titanium Forglass or Diffused Metallic Coatings PDFDocument4 pagesAsme Sa-562-Sa-562M Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Titanium Forglass or Diffused Metallic Coatings PDFElkin Dario Aguirre MesaNo ratings yet

- Nickel-Alloy (UNS N06625, N06219and N08825) Welded Pipe: Standard Specification ForDocument2 pagesNickel-Alloy (UNS N06625, N06219and N08825) Welded Pipe: Standard Specification ForGreg YeeNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Daison PaulNo ratings yet

- TDC For Flanges SA 105NDocument2 pagesTDC For Flanges SA 105NRenny DevassyNo ratings yet

- 5083 en MarineDocument1 page5083 en MarineBPP-Tech PythonNo ratings yet

- B 80 Â " 97 QJGWLTK3 PDFDocument11 pagesB 80 Â " 97 QJGWLTK3 PDFdjreyes04No ratings yet

- A 946 - 95 R00 QTK0NGDocument2 pagesA 946 - 95 R00 QTK0NGPRASANTH PRASANTHNo ratings yet

- ASME II A 1 (2015) .PDF ExtractDocument7 pagesASME II A 1 (2015) .PDF ExtractPedro Montes Marin100% (1)

- PDFsam - B 423 - 11 (2016)Document4 pagesPDFsam - B 423 - 11 (2016)mike.jensen0581No ratings yet

- Purchase Spec. For Tubes-Nonferrous (SB111 Uns C71500)Document6 pagesPurchase Spec. For Tubes-Nonferrous (SB111 Uns C71500)Daison PaulNo ratings yet

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarNo ratings yet

- Sa 276Document10 pagesSa 276ismaelarchilacastilloNo ratings yet

- Nickel-Iron-Chromium-Silicon Alloy Welded Tube: Standard Specification ForDocument2 pagesNickel-Iron-Chromium-Silicon Alloy Welded Tube: Standard Specification ForEduardoNo ratings yet

- Asme Section Ii A Sa-31Document4 pagesAsme Section Ii A Sa-31ksd2No ratings yet

- Purchase Spec. For Tubes (Sa213 TP321)Document5 pagesPurchase Spec. For Tubes (Sa213 TP321)Daison PaulNo ratings yet

- Sec. II A - SA - 209Document6 pagesSec. II A - SA - 209RamuAlagappanNo ratings yet

- Purchase Spec. For Pipes (Sa312 TP316L)Document5 pagesPurchase Spec. For Pipes (Sa312 TP316L)Daison PaulNo ratings yet

- Asme Sa 517 Astm A517 PDFDocument5 pagesAsme Sa 517 Astm A517 PDFBernathTurnipNo ratings yet

- Process Pipe Support Structure Design CalnDocument39 pagesProcess Pipe Support Structure Design CalnSanjayNo ratings yet

- Wind Load Calculation As Per Russia CodeDocument7 pagesWind Load Calculation As Per Russia CodeSanjay100% (1)

- CAESAR II Input Echo and OutputDocument264 pagesCAESAR II Input Echo and OutputSanjayNo ratings yet

- UpnDocument2 pagesUpnadrianNo ratings yet

- UpnDocument2 pagesUpnadrianNo ratings yet

- KHT Breech LockDocument8 pagesKHT Breech Locksumantra1976100% (1)

- MSS SP97Document2 pagesMSS SP97SanjayNo ratings yet

- Metal Inert Gas Welding-120526013715-Phpapp01Document2 pagesMetal Inert Gas Welding-120526013715-Phpapp01SanjayNo ratings yet

- Lecture Slides The Long Channel MOS Transistor IntroductionDocument7 pagesLecture Slides The Long Channel MOS Transistor IntroductionSwapna BharaliNo ratings yet

- Eee421: Power Electronics: Power Semiconductor Devices: MOSFETDocument9 pagesEee421: Power Electronics: Power Semiconductor Devices: MOSFETRafat ShamsNo ratings yet

- DishwasherDocument3 pagesDishwasherAnil Kumar SinghNo ratings yet

- List of InventorsDocument18 pagesList of InventorsJahnavi PatilNo ratings yet

- Inventors and Inventions Cheat SheetsDocument43 pagesInventors and Inventions Cheat SheetsbrunerteachNo ratings yet

- Ktu Manufacturing Technology PDFDocument5 pagesKtu Manufacturing Technology PDFseminarprojectNo ratings yet

- Heat Treatment of Steel PDFDocument8 pagesHeat Treatment of Steel PDFkaviatchennai100% (2)

- Tus Zonas Erróneas - Wayne DyerDocument112 pagesTus Zonas Erróneas - Wayne Dyersoky mezaNo ratings yet

- V MosfetDocument6 pagesV Mosfetsurbhi98No ratings yet

- BL4-738D SM Old BL Serger PDFDocument8 pagesBL4-738D SM Old BL Serger PDFDonnie AshleyNo ratings yet

- 25CrMo4Document1 page25CrMo4Hans GoetheNo ratings yet

- Scrapple From The AppleDocument4 pagesScrapple From The ApplefattfarrNo ratings yet

- COMP EYF Test Questions CH 01-The History of EngineerringDocument4 pagesCOMP EYF Test Questions CH 01-The History of EngineerringManuel Sanchez NoaNo ratings yet

- Cupola Furnace Mechanical EngineeringDocument8 pagesCupola Furnace Mechanical EngineeringMujahid Raza NooriNo ratings yet

- 9626 - ArDocument235 pages9626 - ArAbdallahNo ratings yet

- Electronic: Video Camera TubeDocument3 pagesElectronic: Video Camera TubefunmastiNo ratings yet

- 1985 Siliconix MOSPOWER Applications PDFDocument512 pages1985 Siliconix MOSPOWER Applications PDFGabrielitoNo ratings yet

- Nano + ArchitectureDocument7 pagesNano + ArchitectureBoneyPhilipNo ratings yet

- Feedstock Recycling and PyrolysisDocument27 pagesFeedstock Recycling and PyrolysisacornaimNo ratings yet

- Steels ExplainedDocument237 pagesSteels Explainedradou99100% (1)

- Microwind TutorialDocument87 pagesMicrowind Tutorialminajohn86% (7)

- Lecture3 MOS TransistorDocument12 pagesLecture3 MOS TransistorKartika MunirNo ratings yet

- Training Handbook ENGDocument391 pagesTraining Handbook ENGnagaNo ratings yet

- L&T Log SheetDocument10 pagesL&T Log SheetSrikant GanjiNo ratings yet

- ProjectionWelding JiangDocument23 pagesProjectionWelding JiangVimal KumarNo ratings yet

- Asic Interview QuestionsDocument2 pagesAsic Interview Questionspritam044No ratings yet

- 2015 - 01 - Fume Treatment Plant and Dedusting Sys Rev. 00 PDFDocument8 pages2015 - 01 - Fume Treatment Plant and Dedusting Sys Rev. 00 PDFElafanNo ratings yet

- Electrodo de Carbon PDFDocument2 pagesElectrodo de Carbon PDFAlfredo FloresNo ratings yet

- Chromate-Free Coated Hot-Dip Galvanized Steel Sheet JCDocument2 pagesChromate-Free Coated Hot-Dip Galvanized Steel Sheet JCaries26marchNo ratings yet

- Wilson Tool Wheel Tool WebinarDocument51 pagesWilson Tool Wheel Tool WebinarAndres Byke SepulvedaNo ratings yet