Professional Documents

Culture Documents

Sl3sl4 Stop Light Switch

Uploaded by

Hassan ShathakCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sl3sl4 Stop Light Switch

Uploaded by

Hassan ShathakCopyright:

Available Formats

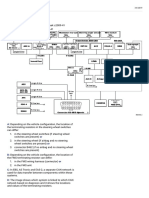

SD-06-1800

Bendix SL-3 & SL-4 Stop Light Switch

MACHINE

SCREWS

7

TERMINAL 2 TERMINAL 9

VENT PLUG 10

COVER 8

COVER 1

TERMINAL SPRING 11

CONNECTOR 7

CONTACT CONTACT

STRIP 12

CONTACTS PISTON

13 GASKET

PLUNGER 4 SPRING 3

15

WASHER 5 O-RING

DIAPHRAGM 14 BODY

BODY DIAPHRAGM 6

FIGURE 1 - SL-3 STOP LIGHT SWITCH FIGURE 2 - SL-4 STOP LIGHT SWITCH

DESCRIPTION PREVENTIVE MAINTENANCE

The stop light switch is an electro-pneumatic switch and Important: Review the Bendix Warranty Policy before

operates in conjunction with the brake valve and stop lights performing any intrusive maintenance procedures. A warranty

by completing the electrical circuit when a brake application may be voided if intrusive maintenance is performed during

is made. the warranty period.

No two vehicles operate under identical conditions; as a

OPERATION

result, maintenance intervals may vary. Experience is a

When a brake application is made, air pressure from the valuable guide in determining the best maintenance interval

brake valve enters the cavity below the diaphragm. At for air brake system components. At a minimum, the SL-3/

approximately 5 psi, the air pressure underneath the SL-4 switch should be inspected every 6 months or 1500

diaphragm overcomes the force of the spring and moves operating hours, whichever comes first, for proper operation

the piston or plunger until the contact points close completing and electrical connections. Should the SL-3/SL-4 switch

the stop light electrical circuit and lighting the stop lights. not meet the elements of the operational tests noted in this

document, further investigation and service of the valve may

be required.

Downloaded from www.Manualslib.com manuals search engine

TESTING FOR SERVICEABILITY CLEANING AND INSPECTION

OPERATING TEST Clean all metal parts in cleaning solvent. Wipe rubber parts

1. Apply the brake valve and note that the stop light lights dry with cloth.

before the delivery pressure reaches 7 psi.

Inspect contact points for pits or wear. If pitting is not too

2. Release the brake valve and note that the stop light goes severe, the points may be reconditioned by filing with a

off. distributor point file. If points cannot be reconditioned, they

LEAKAGE TEST should be replaced. The contact strip in the SL-4 switch

1. With the brakes fully applied, no leakage is permitted at may be turned over to use the other side of the contacts.

the stop light switch. If the stop light switch does not Check the spring for signs of deterioration; Replace if

function as described or if leakage is excessive, it is discolored. The spring in the SL-3 switch carries the current

recommended that it be replaced with a new unit or of the electrical circuit involved; consequently, in the case of

repaired with genuine Bendix parts available at authorized excessive current, as might be caused by a short, the spring

Bendix parts outlets. will be overheated and ruined.

REMOVING Inspect cover and body. If cracked or damaged, replace.

1. Disconnect electrical connections at the stop light switch. Only genuine Bendix service parts should be used for

2. Disconnect air line to the stop light switch. replacement.

3. Remove the stop light switch. ASSEMBLY

INSTALLING (SL-3 Switch) (Figure 1)

1. Install in a convenient location for servicing. 1. Insert terminal screws (2) in cover (1), making sure the

2. Install with pipe tap pointing to the ground and keep it terminal connector (7) is properly positioned.

high for adequate drainage. 2. Secure terminal screws with washers and nuts, or

3. Connect the stop light switch in series in the stop light terminal clips, as the case may be.

circuit. 3. Place diaphragm (6) in body.

4. Keep the stop light switch terminals away from frame 4. Position contact plunger (4) on diaphragm.

members to avoid grounding. 5. Position spring (3) on plunger.

5. Connect the pipe tap to the brake chamber supply line 6. Place washer (5) on diaphragm and screw cover (1)

so that the stop light switch will operate whether the into body. Torque to 30 foot pounds. Make certain the

foot or hand valve is applied. vent hole in the cover is open.

DISASSEMBLY (SL-4 Switch) (Figure 2)

(SL-3 SWITCH) 1. Position terminals (9) in cover (8) and secure with washers

1. Place hex portion of body in a vise. and nuts or terminal clips. Place vent plug (10) in cover.

2. Using a large end wrench on cover flats, turn cover (1) 2. Place o-ring diaphragm (14) and piston (13) in body.

in a counterclockwise direction and remove from body. O-ring diaphragm should be installed with its flat side

adjacent to the piston.

3. Remove terminal nuts, terminals (2) and terminal

connector (7) from cover. 3. Place gasket (15) in place on body and contact strip

(12) on piston (13).

4. Remove spring (3), plunger (4), washer (5) and

diaphragm (6) from body. 4. Position cover assembly on gasket and secure with

machine screws. Torque to 20 inch pounds.

(SL-4 SWITCH)

1. Remove two machine screws (7) and remove cover (8). TEST OF REBUILT STOP LIGHT SWITCH

2. Remove terminal nuts and terminals (9) from cover. Both operating and leakage tests, as indicated under section

headed Testing for Serviceability, must be made after

3. Remove the vent plug (10) from cover.

rebuilding or repairing the stop light switch. The switch must

4. Remove spring (11), contact strip (12), piston (13) and meet the following specifications;

o-ring diaphragm (14) from body.

1. No leakage is permissible at the stop light switch with

the brakes applied.

2. The stop light switch contact should close with not more

than 7 pounds of air pressure.

2

Downloaded from www.Manualslib.com manuals search engine

PRECAUTIONARY NOTE: 5. Following the vehicle manufacturers

recommended procedures, deactivate the electrical

WARNING! PLEASE READ AND FOLLOW system in a manner that safely removes all

THESE INSTRUCTIONS TO AVOID electrical power from the vehicle.

PERSONAL INJURY OR DEATH: 6. Never exceed manufacturers recommended

pressures.

When working on or around a vehicle, the following 7. Never connect or disconnect a hose or line

general precautions should be observed at all times. containing pressure; it may whip. Never remove a

1. Park the vehicle on a level surface, apply the component or plug unless you are certain all

parking brakes, and always block the wheels. system pressure has been depleted.

Always wear safety glasses. 8. Use only genuine Bendix replacement parts,

2. Stop the engine and remove ignition key when components and kits. Replacement hardware,

working under or around the vehicle. When tubing, hose, fittings, etc. must be of equivalent

working in the engine compartment, the engine size, type and strength as original equipment and

should be shut off and the ignition key should be be designed specifically for such applications and

removed. Where circumstances require that the systems.

engine be in operation, EXTREME CAUTION should 9. Components with stripped threads or damaged

be used to prevent personal injury resulting from parts should be replaced rather than repaired. Do

contact with moving, rotating, leaking, heated or not attempt repairs requiring machining or welding

electrically charged components. unless specifically stated and approved by the

3. Do not attempt to install, remove, disassemble or vehicle and component manufacturer.

assemble a component until you have read and 10. Prior to returning the vehicle to service, make

thoroughly understand the recommended certain all components and systems are restored

procedures. Use only the proper tools and observe to their proper operating condition.

all precautions pertaining to use of those tools.

11. For vehicles with Antilock Traction Control (ATC),

4. If the work is being performed on the vehicles air

the ATC function must be disabled (ATC indicator

brake system, or any auxiliary pressurized air

lamp should be ON) prior to performing any vehicle

systems, make certain to drain the air pressure from

maintenance where one or more wheels on a drive

all reservoirs before beginning ANY work on the

axle are lifted off the ground and moving.

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

Downloaded from www.Manualslib.com manuals search engine

4 BW1593 2006 Bendix Commercial Vehicle Systems LLC All rights reserved. 7/2006 Printed in U.S.A.

Downloaded from www.Manualslib.com manuals search engine

You might also like

- 821F - 921F Catalogo de PartesDocument912 pages821F - 921F Catalogo de Partesjose juan100% (12)

- Governor D-2 Service ManualDocument4 pagesGovernor D-2 Service ManualLuis Eduardo Albarracin Rugeles100% (1)

- Lead-Acid Battery TechnoLogiesDocument366 pagesLead-Acid Battery TechnoLogiesRoger Roger86% (7)

- Nissan Skyline R32 Engine ManualDocument580 pagesNissan Skyline R32 Engine ManualEminence Imports100% (6)

- 5.12 Bop Es 15MDocument30 pages5.12 Bop Es 15MJavier Rivas50% (2)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Technical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Document16 pagesTechnical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Riski KurniawanNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- RSP-1000 Maintenance Guide for Low Torque Plug ValvesDocument13 pagesRSP-1000 Maintenance Guide for Low Torque Plug ValvesAnonymous 45Ile4No ratings yet

- Detergent Powder Manufacturing Business Plan Sample - MuvsiDocument9 pagesDetergent Powder Manufacturing Business Plan Sample - MuvsiMomar Talla Diaw0% (1)

- AASHTO M 325-08 (2012) - Stone Matrix Asphalt (SMA) PDFDocument5 pagesAASHTO M 325-08 (2012) - Stone Matrix Asphalt (SMA) PDFGuilhermeNo ratings yet

- Bomba de EspumaDocument16 pagesBomba de EspumaArmandoAndreNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Astec Product Catlogue PDFDocument23 pagesAstec Product Catlogue PDFProject MarsysNo ratings yet

- High VoltageDocument28 pagesHigh VoltageDileep DudiNo ratings yet

- .Setup Myho Tel - Co M: Room Inspection ChecklistDocument2 pages.Setup Myho Tel - Co M: Room Inspection ChecklistXamantha Marie Porio EriveraNo ratings yet

- Gas Conditioning & Processing - GLOMACSDocument5 pagesGas Conditioning & Processing - GLOMACSCHO ACHIRI HUMPHREYNo ratings yet

- Lubricador CiegoDocument2 pagesLubricador CiegoMARIO100% (1)

- Current SSPC Standards June2019Document7 pagesCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- t4 Hitech 03-06Document364 pagest4 Hitech 03-06Nicoleta Costea100% (1)

- Table of Contents For MBA ProjectDocument1 pageTable of Contents For MBA ProjectramevsNo ratings yet

- Sl5ds2 Switch and Check ValveDocument4 pagesSl5ds2 Switch and Check ValveHassan ShathakNo ratings yet

- TFP220 11 2014Document8 pagesTFP220 11 2014ioan cristian cotorobaiNo ratings yet

- CanadianTire 3 Gallon Compressor 0581290-En-FrDocument49 pagesCanadianTire 3 Gallon Compressor 0581290-En-FrDuc LeVanNo ratings yet

- Maintain Fire ExtinguishersDocument4 pagesMaintain Fire ExtinguishersNego1975No ratings yet

- PCR Autolube Intecs PDFDocument27 pagesPCR Autolube Intecs PDFstrong holdNo ratings yet

- OPERATION MANUAL WIRELESS REMOTE CONTROLLERDocument18 pagesOPERATION MANUAL WIRELESS REMOTE CONTROLLERSicologo CimeNo ratings yet

- R12 r14 내용Document6 pagesR12 r14 내용moviecinema1111No ratings yet

- Well Control EquipmentDocument18 pagesWell Control Equipmentفؤاد ابوزيدNo ratings yet

- tfp342 Ty5151Document4 pagestfp342 Ty5151Raúl Antonio MacíasNo ratings yet

- Bendix SR-5 Trailer Spring Brake ValveDocument10 pagesBendix SR-5 Trailer Spring Brake ValvePaola Rosado SotoNo ratings yet

- Km35 Series: Installation, Care & Use ManualDocument7 pagesKm35 Series: Installation, Care & Use Manualheri setyawanNo ratings yet

- Models AH, C, B, CB and Scullery B Quick Setup Instructions: Model Ah Rear ViewDocument2 pagesModels AH, C, B, CB and Scullery B Quick Setup Instructions: Model Ah Rear ViewmarkthadNo ratings yet

- Posh Solus Mkii Basin Mixer 9502635 Tech WarrantyDocument3 pagesPosh Solus Mkii Basin Mixer 9502635 Tech WarrantymainpersonNo ratings yet

- C06000 - BRO - EN - A4 - V3 - VIPRsDocument8 pagesC06000 - BRO - EN - A4 - V3 - VIPRscerberusdodoNo ratings yet

- Air Governor TrucksDocument4 pagesAir Governor TrucksMaldwin MenorcaNo ratings yet

- Bendix TC-7 Trailer Control Brake Valve: DescriptionDocument4 pagesBendix TC-7 Trailer Control Brake Valve: DescriptionSebastian OlayaNo ratings yet

- AFV-019D PreviewDocument5 pagesAFV-019D Preview翟明辉No ratings yet

- Series III-L Valve: Installation and Operating Instructions For Barksdale Heavy Duty Integrated Actuator ValveDocument11 pagesSeries III-L Valve: Installation and Operating Instructions For Barksdale Heavy Duty Integrated Actuator ValveranjithNo ratings yet

- Installation Instructions: WarningDocument2 pagesInstallation Instructions: WarningMohamed Karim ABAOUBNo ratings yet

- Thermosiphon seal supply system overviewDocument4 pagesThermosiphon seal supply system overviewkeyur1109No ratings yet

- Chuck PartsDocument12 pagesChuck Partselgenedy98No ratings yet

- Inground Pool Skimmer Instructions: Operation For All SkimmersDocument3 pagesInground Pool Skimmer Instructions: Operation For All SkimmersRAKESH REDDYNo ratings yet

- Oil level regulator assembly drawingDocument2 pagesOil level regulator assembly drawingChí Khang NguyễnNo ratings yet

- Liquefied Gas SolutionDocument12 pagesLiquefied Gas SolutioncerberusdodoNo ratings yet

- RHBU2 2 Way Hydraulic Pressure SensorDocument6 pagesRHBU2 2 Way Hydraulic Pressure Sensoralan minayaNo ratings yet

- C15 & C20 Series Inline Flow Switch: FeaturesDocument2 pagesC15 & C20 Series Inline Flow Switch: FeaturesJavier AffifNo ratings yet

- Bomba Neumatica Milton RoyDocument8 pagesBomba Neumatica Milton RoyGuillermo de la Fuente SantiagoNo ratings yet

- Hvac Equipment Hanging Detail 1: SD SDDocument1 pageHvac Equipment Hanging Detail 1: SD SDSami KhouryNo ratings yet

- Parveen: Technical ManualDocument16 pagesParveen: Technical ManualDEATH ASSASSIN GAMERNo ratings yet

- Air Lock Relay: MIL Controls LimitedDocument2 pagesAir Lock Relay: MIL Controls Limitedsumit kumarNo ratings yet

- Bendix E-2-E-3 BRAKE VALVES User ManualDocument4 pagesBendix E-2-E-3 BRAKE VALVES User ManualVOLVONo ratings yet

- 4 in WL Bop & RiserDocument19 pages4 in WL Bop & RisersambhajiNo ratings yet

- Actuator Instruction Manual - RCEL015-250Document2 pagesActuator Instruction Manual - RCEL015-250Josue Reyes GironNo ratings yet

- MODELS 373LAV, 376CAV Downflow/Horizontal and 383kav, 395cav Upflow Gas FurnaceDocument12 pagesMODELS 373LAV, 376CAV Downflow/Horizontal and 383kav, 395cav Upflow Gas Furnacemark jenkins100% (1)

- Daikin VRV-X Installation ManualDocument44 pagesDaikin VRV-X Installation ManualTangtang SatangNo ratings yet

- algapdfDocument22 pagesalgapdfDaniel BahamondeNo ratings yet

- NE/SA556: Dual TimerDocument11 pagesNE/SA556: Dual TimerRicardo LimonNo ratings yet

- Sullivan Palatek: User'S ManualDocument22 pagesSullivan Palatek: User'S ManualjulioNo ratings yet

- ACK250Document6 pagesACK250karthegreNo ratings yet

- D-2 Governor (SD-01-503)Document4 pagesD-2 Governor (SD-01-503)emmanuelNo ratings yet

- Service N ValveDocument30 pagesService N ValvemecambNo ratings yet

- How to Maintain Your S2-250 MotorcycleDocument201 pagesHow to Maintain Your S2-250 MotorcycleyisusyisusNo ratings yet

- 2006 Swinger Shock Service Manual - Rev NC PDFDocument45 pages2006 Swinger Shock Service Manual - Rev NC PDFMuad DibNo ratings yet

- High Chiept PCR & Maint - BWPDocument27 pagesHigh Chiept PCR & Maint - BWPMuhammadSyarifudinNo ratings yet

- IOM - LSEC LSEH L Series Industrial Revesered Hub CouplingsDocument8 pagesIOM - LSEC LSEH L Series Industrial Revesered Hub CouplingsJhon SanabriaNo ratings yet

- Vda050710sdsm Rev1122Document10 pagesVda050710sdsm Rev1122Pkk Siam Rayong co-saleNo ratings yet

- Maintain CONSEP Separator with Proper Inspection and ServiceDocument4 pagesMaintain CONSEP Separator with Proper Inspection and ServicecarlosegomezfNo ratings yet

- Pressure Loss in Bends and Fittings ModelDocument31 pagesPressure Loss in Bends and Fittings ModelMayuresh ChavanNo ratings yet

- Manual Auto Start "Deep Sea 3110"controller: Control Panel Type Cm2 Electric DiagramDocument6 pagesManual Auto Start "Deep Sea 3110"controller: Control Panel Type Cm2 Electric Diagramsuroto abimanyuNo ratings yet

- Hand Signal-2Document1 pageHand Signal-2Hassan ShathakNo ratings yet

- Relay 5Document1 pageRelay 5Hassan ShathakNo ratings yet

- Load ChartDocument9 pagesLoad ChartHassan ShathakNo ratings yet

- Relay 7Document1 pageRelay 7Hassan ShathakNo ratings yet

- Hand Signal-6Document1 pageHand Signal-6Hassan ShathakNo ratings yet

- Hand Signal-1Document1 pageHand Signal-1Hassan ShathakNo ratings yet

- Hand Signal-3Document1 pageHand Signal-3Hassan ShathakNo ratings yet

- Hand Signal-5Document1 pageHand Signal-5Hassan ShathakNo ratings yet

- Hand Signal-4Document1 pageHand Signal-4Hassan ShathakNo ratings yet

- Parts List for Volvo Transmission RepairkitDocument2 pagesParts List for Volvo Transmission RepairkitHassan ShathakNo ratings yet

- Y243558 en 000Document2 pagesY243558 en 000Hassan ShathakNo ratings yet

- Y294093 en 000Document2 pagesY294093 en 000Hassan ShathakNo ratings yet

- Y115383 en 001Document2 pagesY115383 en 001Hassan ShathakNo ratings yet

- Y011355 en 002Document2 pagesY011355 en 002Hassan ShathakNo ratings yet

- Parts List 9730010200 PDFDocument2 pagesParts List 9730010200 PDFHassan ShathakNo ratings yet

- Y011355 en 002Document2 pagesY011355 en 002Hassan ShathakNo ratings yet

- WABCO - Technical Sheet - 973 001 010 0Document2 pagesWABCO - Technical Sheet - 973 001 010 0Hassan ShathakNo ratings yet

- Tamil Nadu Loyal V 2948058a PDFDocument10 pagesTamil Nadu Loyal V 2948058a PDFHassan ShathakNo ratings yet

- 9730 XXDocument8 pages9730 XXHassan ShathakNo ratings yet

- Emsisoft - How To Stop DjvuDocument3 pagesEmsisoft - How To Stop Djvumiki1222No ratings yet

- 9730010100Document1 page9730010100Hassan ShathakNo ratings yet

- 973001950Document1 page973001950Hassan ShathakNo ratings yet

- Performance of Poltical PartiesDocument5 pagesPerformance of Poltical PartiesHassan ShathakNo ratings yet

- Print PreviewDocument2 pagesPrint PreviewHassan ShathakNo ratings yet

- KAU Faculty of Sciences Stats Dept Textbook ReferencesDocument1 pageKAU Faculty of Sciences Stats Dept Textbook ReferencesHassan ShathakNo ratings yet

- Performance of Poltical PartiesDocument13 pagesPerformance of Poltical PartiesHassan ShathakNo ratings yet

- 1 Cover PageDocument3 pages1 Cover PageHassan ShathakNo ratings yet

- 6 List of SymbolsDocument1 page6 List of SymbolsHassan ShathakNo ratings yet

- 3 AbstractDocument1 page3 AbstractHassan ShathakNo ratings yet

- LM W2340aDocument52 pagesLM W2340aBruno Alexander MachadoNo ratings yet

- Pbadupws - Nrc.gov Docs ML0731 ML073190432Document57 pagesPbadupws - Nrc.gov Docs ML0731 ML073190432Ashish MahtoNo ratings yet

- 5kv CableDocument2 pages5kv Cableencarn1092No ratings yet

- Washing Machine: User's ManualDocument36 pagesWashing Machine: User's Manualsam alNo ratings yet

- Analysis and Economical Design of Water TanksDocument6 pagesAnalysis and Economical Design of Water TanksBTENo ratings yet

- 1 D 713224192Document1 page1 D 713224192Jaganathan KrishnanNo ratings yet

- SPC Series: Polyester Pleated CartridgesDocument2 pagesSPC Series: Polyester Pleated CartridgesElizabethNo ratings yet

- Chem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodheaDocument16 pagesChem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodhearahmanNo ratings yet

- 05-Coke Drum DesignDocument9 pages05-Coke Drum DesignGeorge J AlukkalNo ratings yet

- Steel Specification ComparisonsDocument1 pageSteel Specification Comparisonssmith willNo ratings yet

- CU-22L Tissue Culture Chamber: Lighting SystemDocument2 pagesCU-22L Tissue Culture Chamber: Lighting SystemAjay KumarNo ratings yet

- W.A.T.T.: Design Project Check ListDocument2 pagesW.A.T.T.: Design Project Check ListDhanya Geethanjali SasidharanNo ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet

- Ap SSR 2018Document448 pagesAp SSR 2018swarnalatha100% (1)

- Categorization-Classification Table - 12052017Document2 pagesCategorization-Classification Table - 12052017Sho Delos AngelesNo ratings yet

- SushmaDocument4 pagesSushmaapi-25885200No ratings yet

- 8100 Series Brochure PDFDocument12 pages8100 Series Brochure PDFHeny MarthaNo ratings yet

- Thermal Power Plant Report: Coal Handling, Boilers, Turbines & MoreDocument66 pagesThermal Power Plant Report: Coal Handling, Boilers, Turbines & MoreAdityaSinghNo ratings yet

- Ca 450 en 1609Document2 pagesCa 450 en 1609Randolf WenholdNo ratings yet

- 413 PDFDocument10 pages413 PDFanaklanangNo ratings yet