Professional Documents

Culture Documents

TLV SJ3FX

Uploaded by

Álvaro Martínez FernándezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TLV SJ3FX

Uploaded by

Álvaro Martínez FernándezCopyright:

Available Formats

SDS U2000-132

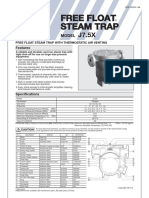

FREE FLOAT

STEAM TRAP

MODEL SJ3FX DUCTILE CAST IRON

FREE FLOAT STEAM TRAP WITH THERMOSTATIC AIR VENTING

Features

Reliable and durable steam trap with tight

shut-off for use on small to medium process

equipment. Models for horizontal or vertical

piping installation.

1. Self-modulating free float provides continuous,

smooth, low-velocity condensate discharge as

process loads vary.

2. Precision-ground float, constant water seal and

three-point seating design ensure a steam-tight

seal, even under no-load conditions.

3. Thermostatic capsule (X-element) with fail

open feature vents air automatically until close-

to-steam temperature.

4. Built-in screen with large surface area ensures

extended trouble-free operation.

5. Easy, inline access to internal parts simplifies Patented

cleaning and reduces maintenance costs.

Specifications

Model SJ3FNX SJ3FVX

Installation Horizontal Vertical

Connection Flanged

Size DN 15, 20, 25

Orifice No. 2, 5, 9, 14, 22

Maximum Operating Pressure (barg) PMO 2, 5, 9, 14, 22

Maximum Differential Pressure (bar) PMX 2, 5, 9, 14, 22

Maximum Operating Temperature (C) TMO 220

Subcooling of X-element Fill (C) up to 6

Type of X-element B

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS): Maximum Allowable Pressure (barg) PMA: 22 1 bar = 0.1 MPa

Maximum Allowable Temperature (C) TMA: 220

To avoid abnormal operation, accidents or serious injury, DO NOT use this product outside of the specification range.

CAUTION Local regulations may restrict the use of this product to below the conditions quoted.

No. Description Material DIN* ASTM/AISI*

q Body Ductile Cast Iron GGG40.3 0.7043 A395

w Cover Ductile Cast Iron GGG40.3 0.7043 A395

eMR Cover Gasket Fluorine Resin PTFE PTFE PTFE

rF Float Stainless Steel SUS316L 1.4404 AISI316L

tR Orifice

yMR Orifice Gasket Fluorine Resin PTFE PTFE PTFE

uR Air Vent Screen Stainless Steel SUS304 1.4301 AISI304

iR Main Screen Stainless Steel SUS430 1.4016 AISI430

Screen Holder (SJ3FNX) Cast Stainless Steel A351 Gr.CF8 1.4312

o

Screen Holder (SJ3FVX) Cast Stainless Steel SCS2A 1.4027 A743 Gr.CA40

!0MR Screen Holder Gasket Soft Iron SUYP 1.1121 AISI1010

!1 Orifice Plug Cast Stainless Steel A351 Gr.CF8 1.4312

!2MR Orifice Plug Gasket (SJ3FNX) Soft Iron SUYP 1.1121 AISI1010

!3 Drain Plug Carbon Steel SS400 1.0037 A6

!4R X-element Stainless Steel

!5R X-element Guide Stainless Steel SUS304 1.4301 AISI304

!6 X-element Cover Cast Stainless Steel A351 Gr.CF8 1.4312

!7R Air Vent Valve Seat Stainless Steel SUS420F 1.4028 AISI420F

!8 Cover Bolt Carbon Steel S45C 1.0503 AISI1045

!9R Spring Clip Stainless Steel SUS304 1.4301 AISI304

@0MR X-element Cover Gasket Fluorine Resin PTFE PTFE PTFE

@1 Nameplate Stainless Steel SUS304 1.4301 AISI304

* Equivalent materials

Replacement kits available: (M) maintenance parts, (R) repair parts, (F) float

Dimensions

SJ3FNX Flanged SJ3FNX Flanged (mm)

W L

L

Weight

DN DIN 2501 H1 W B

(kg)

PN25/40

15 6.0

150 177

20 157 100 6.4

25 160 184 6.9

H1

SJ3FVX Flanged SJ3FVX Flanged (mm)

W1 L

Weight

DN DIN 2501 W1 B1

(kg)

PN25/40

15 5.1

150

20 155 70 5.6

L

25 160 6.3

B1

Discharge Capacity

2000

Discharge Capacity (kg/h)

1000 14 22

9

5

2

700

500

300

200

100

0.1 0.3 0.5 1 2 3 4 5 7 9 10 14 20

22

Differential Pressure (bar) 1 bar = 0.1 MPa

1. Line numbers within the graph refer to orifice numbers.

2. Differential pressure is the difference between the inlet and outlet pressure of the trap.

3. Capacities are based on continuous discharge of condensate 6C below saturated steam

temperature.

4. Recommended safety factor: at least 1.5.

DO NOT use traps under conditions that exceed maximum differential pressure,

CAUTION as condensate backup will occur!

SDS U2000-132 Rev. 3 /2015

T Products for intended use only.

Specifications subject to change without notice.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Free Float Steam Trap: Model Ductile Cast Iron Cast IronDocument2 pagesFree Float Steam Trap: Model Ductile Cast Iron Cast IronSamerNo ratings yet

- Free Float Steam Trap: Model Stainless SteelDocument2 pagesFree Float Steam Trap: Model Stainless SteelJustin GentryNo ratings yet

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyNo ratings yet

- Trampa Tipo Balde JH7 TLVDocument2 pagesTrampa Tipo Balde JH7 TLVAriel InsaurraldeNo ratings yet

- Free Float Free Float Steam Trap Steam Trap: ModelDocument2 pagesFree Float Free Float Steam Trap Steam Trap: ModelAnonymous cb9s3t0qNo ratings yet

- E j75x0 HP - UnlockedDocument2 pagesE j75x0 HP - Unlockedahmadsweiti11No ratings yet

- Steam Trap: P46SRN/P46SRM/P46SRWDocument2 pagesSteam Trap: P46SRN/P46SRM/P46SRWGina FelyaNo ratings yet

- E l21s0 HPDocument2 pagesE l21s0 HPrinthusNo ratings yet

- U dr20x HP PDFDocument2 pagesU dr20x HP PDFRicardo SanchezNo ratings yet

- E ss1nh HPDocument2 pagesE ss1nh HPRigobertoMedinaNo ratings yet

- Valvula de MariposaDocument12 pagesValvula de MariposaErick HdezNo ratings yet

- StrainerDocument2 pagesStrainermayNo ratings yet

- Valve TableDocument2 pagesValve TablerendydunNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- Steam Trap Datasheet TLV Type P65SRNDocument2 pagesSteam Trap Datasheet TLV Type P65SRNAnonymous ThzA9zNo ratings yet

- TLV Tc1 Self Acting Temperature Regulator FlangedDocument2 pagesTLV Tc1 Self Acting Temperature Regulator FlangedSDP02No ratings yet

- Zero Loss Drain by QPPDocument2 pagesZero Loss Drain by QPPMod KaewdaengNo ratings yet

- Two Orifice Float Trap: DescriptionDocument4 pagesTwo Orifice Float Trap: DescriptionHiranthaNo ratings yet

- Ball Valves Jis10k Flanged End 0Document5 pagesBall Valves Jis10k Flanged End 0Royal BoardNo ratings yet

- NAF-Navalsteam Ball Valves FK 25.76 (2) GB: Primary CharacteristicsDocument2 pagesNAF-Navalsteam Ball Valves FK 25.76 (2) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- Safety Relief Valve VSEODocument4 pagesSafety Relief Valve VSEOShashank HNo ratings yet

- L1B02E2K9 Steam TrapDocument20 pagesL1B02E2K9 Steam Traparsa1aNo ratings yet

- Avk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300Document2 pagesAvk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300DanielSchwaskiNo ratings yet

- 400E EngineeringDocument8 pages400E EngineeringDenis Oliveira CostaNo ratings yet

- High Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFDocument2 pagesHigh Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFjayakumarNo ratings yet

- Lit RD10 ENDocument6 pagesLit RD10 ENlesonspkNo ratings yet

- Ball Three Pieces Steel A105 / A216 WCB 1000 PSIG: Pressure Temperature RatingsDocument2 pagesBall Three Pieces Steel A105 / A216 WCB 1000 PSIG: Pressure Temperature RatingsAlicia MartinezNo ratings yet

- Iron Wafer Type Check Valve: Kitz Cast Iron ValvesDocument1 pageIron Wafer Type Check Valve: Kitz Cast Iron ValvesAndy SetyawanNo ratings yet

- Yokogawa: Y/11AM Pneumatic Absolute Pressure Transmitter User's ManualDocument5 pagesYokogawa: Y/11AM Pneumatic Absolute Pressure Transmitter User's ManualRabah AmidiNo ratings yet

- Datasheet M35140Document1 pageDatasheet M35140gürkan yılmazNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve: Technical FeaturesMuhammad ElbarbaryNo ratings yet

- MDT 2021 Bro Yfe 10K FCDocument1 pageMDT 2021 Bro Yfe 10K FCsuwono radukNo ratings yet

- Model No 20501Document5 pagesModel No 20501Achmad HambaliNo ratings yet

- Wika Diaphragm Seal, Flange Connection Model 990.27Document4 pagesWika Diaphragm Seal, Flange Connection Model 990.27Syed Imtiaz HussainNo ratings yet

- Automatic Air and Gas Vents For Liquid Systems - AE44Document2 pagesAutomatic Air and Gas Vents For Liquid Systems - AE44Mohamed Osama El GendiNo ratings yet

- SY Y StranerDocument2 pagesSY Y StranerPhú Song LongNo ratings yet

- Check Valve DSDocument2 pagesCheck Valve DSsinamicsNo ratings yet

- Spirax BSA TDocument4 pagesSpirax BSA TNang DapiNo ratings yet

- Flush Diaphragm SealDocument2 pagesFlush Diaphragm SealSureshNo ratings yet

- Catalogo Asca Valvula RetencaoDocument2 pagesCatalogo Asca Valvula RetencaoMaurício Duarte de AndradeNo ratings yet

- 11.8a Ghibson GB015Document2 pages11.8a Ghibson GB015Shah Rizal AbidNo ratings yet

- (Steam Trap - Thermo) Yoshitake TD-10 NADocument2 pages(Steam Trap - Thermo) Yoshitake TD-10 NAAldeline SungahidNo ratings yet

- 84-90-001 Avk002ax Eni 432447Document3 pages84-90-001 Avk002ax Eni 432447Gotica ManagementNo ratings yet

- FK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsDocument2 pagesFK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsNguyen KhaNo ratings yet

- DFS (GS 06p01y01-E-E - 008)Document30 pagesDFS (GS 06p01y01-E-E - 008)tetioNo ratings yet

- SS-E-04 - RID Air ToqueDocument8 pagesSS-E-04 - RID Air ToqueagrovadoNo ratings yet

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- Ghibson GB015Document2 pagesGhibson GB015Jessicalba LouNo ratings yet

- Purgador BimetalicoDocument2 pagesPurgador BimetalicoEugenio DíazNo ratings yet

- Air Trap RL1090 - RL1290Document2 pagesAir Trap RL1090 - RL1290satphoenixNo ratings yet

- E SVGMD HPDocument2 pagesE SVGMD HPSylvio Santiago LimaNo ratings yet

- Technical Sheet DT300FDocument2 pagesTechnical Sheet DT300FMalik DaniyalNo ratings yet

- Medium Sized Coriolis Mass Flowmeter: Measurement & ControlDocument8 pagesMedium Sized Coriolis Mass Flowmeter: Measurement & ControlTeknik GresikNo ratings yet

- 1 Valvula Globo Con Fuelle Didtek Acero Carbono PDFDocument1 page1 Valvula Globo Con Fuelle Didtek Acero Carbono PDFjoaquin torrano veraNo ratings yet

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- Product Data Sheet Wouter Witzel - EVBS: GD200 01 04 Valves Rubber Lined - Centric EVBSDocument3 pagesProduct Data Sheet Wouter Witzel - EVBS: GD200 01 04 Valves Rubber Lined - Centric EVBSDerick MendozaNo ratings yet

- Data Sheet Purgador PT65-40Document2 pagesData Sheet Purgador PT65-40Douglas Tondello100% (1)

- Nonsociableness SummaryDocument3 pagesNonsociableness SummaryÁlvaro Martínez FernándezNo ratings yet

- Spectrofluorometric DiagramDocument2 pagesSpectrofluorometric DiagramÁlvaro Martínez FernándezNo ratings yet

- Phthisical SummaryDocument2 pagesPhthisical SummaryÁlvaro Martínez FernándezNo ratings yet

- Piperidid AnalysisDocument2 pagesPiperidid AnalysisÁlvaro Martínez FernándezNo ratings yet

- Asteraceae DiagramDocument2 pagesAsteraceae DiagramÁlvaro Martínez FernándezNo ratings yet

- Metafulminuric AnalysisDocument2 pagesMetafulminuric AnalysisÁlvaro Martínez FernándezNo ratings yet

- Pall Mall Gazette: Evening EditionDocument2 pagesPall Mall Gazette: Evening EditionÁlvaro Martínez FernándezNo ratings yet

- Fallout 3 Wasteland ChecklistDocument11 pagesFallout 3 Wasteland ChecklistÁlvaro Martínez FernándezNo ratings yet

- Info Iec60383-2 (Ed1.0) en D.imgDocument6 pagesInfo Iec60383-2 (Ed1.0) en D.imgÁlvaro Martínez FernándezNo ratings yet

- March/April 2016: Looking For Group The Marketplace What's Hitting The TableDocument22 pagesMarch/April 2016: Looking For Group The Marketplace What's Hitting The TableÁlvaro Martínez FernándezNo ratings yet

- Sttuvw Xyz ( - ) W Yw W - ( ( W y W y - y y (W - W W - )Document1 pageSttuvw Xyz ( - ) W Yw W - ( ( W y W y - y y (W - W W - )Álvaro Martínez FernándezNo ratings yet

- P018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Document9 pagesP018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Álvaro Martínez Fernández100% (1)

- Sherlock Holmes and The BabyDocument6 pagesSherlock Holmes and The BabyÁlvaro Martínez FernándezNo ratings yet

- 7010 - Data Sheet PDFDocument2 pages7010 - Data Sheet PDFÁlvaro Martínez FernándezNo ratings yet

- Fallout 3 Skill BooksDocument8 pagesFallout 3 Skill BooksÁlvaro Martínez FernándezNo ratings yet

- Rsstuv WX Yz ( - (Yv) (V (Yz X V) (V V X Z Z UDocument1 pageRsstuv WX Yz ( - (Yv) (V (Yz X V) (V V X Z Z UÁlvaro Martínez FernándezNo ratings yet

- METRICA V3 Aseguramiento de La CalidadDocument17 pagesMETRICA V3 Aseguramiento de La CalidadÁlvaro Martínez FernándezNo ratings yet

- Fallout 3 ChecklistDocument28 pagesFallout 3 ChecklistÁlvaro Martínez Fernández100% (1)

- Discover PragueDocument180 pagesDiscover PragueÁlvaro Martínez FernándezNo ratings yet

- Deefgh Ijk LMLN Lop JQH MJH RSTN P K TK H Ujv H TH N TH Uv LMSWWP X yDocument1 pageDeefgh Ijk LMLN Lop JQH MJH RSTN P K TK H Ujv H TH N TH Uv LMSWWP X yÁlvaro Martínez FernándezNo ratings yet

- 40K04L6MN 01: Kllmno PQR Stsu SVW Qxo Tqo Yw U U SZ (O - S) R ) (Document1 page40K04L6MN 01: Kllmno PQR Stsu SVW Qxo Tqo Yw U U SZ (O - S) R ) (Álvaro Martínez FernándezNo ratings yet

- London DirectoryDocument20 pagesLondon DirectoryÁlvaro Martínez Fernández100% (2)

- London Directory - London DirectoryDocument111 pagesLondon Directory - London DirectoryÁlvaro Martínez FernándezNo ratings yet

- Standard Design: Angle Seat Valve 7010Document2 pagesStandard Design: Angle Seat Valve 7010Álvaro Martínez FernándezNo ratings yet

- 7010 - High Temperature 220 - Data Sheet - USDocument6 pages7010 - High Temperature 220 - Data Sheet - USÁlvaro Martínez FernándezNo ratings yet

- 7031 - Data SheetDocument7 pages7031 - Data SheetÁlvaro Martínez FernándezNo ratings yet

- Installation, Operation and Maintenance Instructions: Hancock Forged Steel - Gate, Globe and Check ValvesDocument6 pagesInstallation, Operation and Maintenance Instructions: Hancock Forged Steel - Gate, Globe and Check ValvesÁlvaro Martínez FernándezNo ratings yet

- 7032 - Data SheetDocument9 pages7032 - Data SheetÁlvaro Martínez FernándezNo ratings yet

- Hot Spotet, Lista Me 31 Pikat Më Të Rrezikshme Mjedisore Në VendDocument5 pagesHot Spotet, Lista Me 31 Pikat Më Të Rrezikshme Mjedisore Në VendTelevizioni A1 ReportNo ratings yet

- The Ultimate Troubleshooting GuideDocument112 pagesThe Ultimate Troubleshooting Guidekishor reddyNo ratings yet

- Internship Report For Compounding Department at General Tyre & Rubber Company of PakistanDocument22 pagesInternship Report For Compounding Department at General Tyre & Rubber Company of PakistanZeeshan Zahid0% (1)

- List of Village Industries Schemes Under Purview of KVICDocument4 pagesList of Village Industries Schemes Under Purview of KVICPoornima Subramanian50% (2)

- Compressed Stabilised Earth Block: A Case Study ReportDocument2 pagesCompressed Stabilised Earth Block: A Case Study ReportShubham SrivastavaNo ratings yet

- SLMR 1912 09 15Document24 pagesSLMR 1912 09 15Russell HartillNo ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument3 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryRhobbie NolloraNo ratings yet

- Low Cost Materials For ConstructionDocument6 pagesLow Cost Materials For Constructionmedepalli jeevanNo ratings yet

- Mini Project StyereneDocument25 pagesMini Project StyereneMard Apik100% (1)

- Ferroelectric CeramicsDocument38 pagesFerroelectric CeramicsPalashbarikNo ratings yet

- Ipcc Waste ModelDocument98 pagesIpcc Waste ModelJayson VillezaNo ratings yet

- Civ E398 Mid 2 Fall 14Document10 pagesCiv E398 Mid 2 Fall 14Rajat GuptaNo ratings yet

- Soil Science Lab 5Document4 pagesSoil Science Lab 5Joshua Ruel NalzaroNo ratings yet

- A Seminar Report On: Production of Ball BearingDocument25 pagesA Seminar Report On: Production of Ball BearingParveen KumarNo ratings yet

- SM Lucena SignageDocument1 pageSM Lucena SignageconeyquNo ratings yet

- Anchor Flange CatalogDocument4 pagesAnchor Flange CatalogRockny2011No ratings yet

- Penetration and Softening PointDocument34 pagesPenetration and Softening PointLaxmikantNo ratings yet

- Chapter 2 MahoganyDocument2 pagesChapter 2 MahoganyRichelle DandoNo ratings yet

- Aluminum Crust BreakerDocument8 pagesAluminum Crust BreakersenamotoNo ratings yet

- Nomex Essential: Extreme Protection ColorDocument2 pagesNomex Essential: Extreme Protection ColorRobert AndrewNo ratings yet

- Trident Steel Pipe Catelouge 06.11Document4 pagesTrident Steel Pipe Catelouge 06.11Mohamed Mostafa AamerNo ratings yet

- IKO Ball Needle BRGDocument5 pagesIKO Ball Needle BRGjohnsonregoNo ratings yet

- Ec Clean - SdsDocument5 pagesEc Clean - SdsMary JosephineNo ratings yet

- Prestressed Tied Arch BridgesDocument18 pagesPrestressed Tied Arch BridgesTamaduianu IoanNo ratings yet

- The Gibbs Phase Rule RevisitedDocument3 pagesThe Gibbs Phase Rule Revisitedleizar_death640% (1)

- Lummus - EBOne Process PDFDocument2 pagesLummus - EBOne Process PDFJungmuk Lee0% (1)

- 10 Shear Strength of Soil PDFDocument84 pages10 Shear Strength of Soil PDFRajesh KhadkaNo ratings yet

- XTRACT: A Tool For Axial Force - Ultimate Curvature InteractionsDocument9 pagesXTRACT: A Tool For Axial Force - Ultimate Curvature InteractionscvlengNo ratings yet

- MAKINO U Series Doc ButtonDocument12 pagesMAKINO U Series Doc ButtonBharath SaravananNo ratings yet

- V2500 Capability ListDocument11 pagesV2500 Capability ListVuppala RavitejaNo ratings yet