Professional Documents

Culture Documents

Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed Lubrication

Uploaded by

Raphael LinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed Lubrication

Uploaded by

Raphael LinoCopyright:

Available Formats

Lubricants in industrial gears

MDI-170-B-EN 12.01.2010

LUBRICANTS IN INDUSTRIAL GEARS

1. SIGNIFICANCE OF LUBRICATION ................................................................................... 2

2. LUBRICATION METHODS ................................................................................................. 2

2.1 BATH LUBRICATION ............................................................................................................ 2

2.2 SPLASH LUBRICATION ........................................................................................................ 2

2.3 GREASE LUBRICATION ....................................................................................................... 2

2.4 PRESSURE-FEED LUBRICATION ........................................................................................... 2

3. LUBRICATION IN EXTREME SITUATIONS....................................................................... 2

3.1 OIL HEATING ..................................................................................................................... 2

3.2 OIL COOLING ..................................................................................................................... 3

3.2.1 Bath and splash lubrication ......................................................................................... 3

3.2.2 Pressure-feed lubrication............................................................................................. 3

3.3 COLD START ..................................................................................................................... 4

4. HANDLING AND DISPOSING OF LUBRICANTS .............................................................. 4

5. APPROVED LUBRICANTS ................................................................................................ 5

Moventas Santasalo Oy 1(9)

Lubricants in industrial gears

MDI-170-B-EN 12.01.2010

1. SIGNIFICANCE OF LUBRICATION

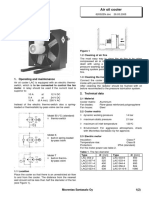

To secure the appropriate lubrication of a gear 2.4 Pressure-feed lubrication

assembly, it is of primary importance that its

The structure, size, use and cooling requirement of

lubrication and the related observation and

the gear may require pressure-feed lubrication. In

maintenance tasks have been properly arranged.

pressure-feed lubrication, the oil pipeline of the gear

The main task of lubrication is to form an oil film is connected to a central lubrication system, or a

between the working flanks of the gear teeth of a dedicated lubrication pump is located close to the

gear wheel to prevent metal contact and to lubricate gear. The lubrication pump may be shaft-operated,

the bearings and seals. which means that it gets its operating power directly

Other lubrication functions include: from the gear shaft, or it may have a dedicated

electric engine.

reducing friction and the resultant power loss

The equipment level in pressure-feed lubrication is

transfer heat away from the tooth contact and determined by the demand level, supervision and

bearings gear cooling requirements of the machine being

minimise wear and tear operated. It is also possible to connect a standard

lubrication unit to the gear and equip it with a water

prevent the entry of impurities into the lubricated or air cooling unit.

parts

3. LUBRICATION IN EXTREME

move impurities and wear-down particles away

SITUATIONS

reduce vibration

3.1 Oil heating

protect the parts from corrosion

If a gear is located outdoors or in a non-heated

The thickness of the oil film depends for example on location, the gear manufacturer must be notified of

the surface pressure of the gear tooth, the viscosity this and of the temperature variations. The usual

of the oil and the pitch line velocity. If the oil film fails problem at low temperatures is the supply of oil to the

repeatedly during operation, the working flank of the item requiring lubrication because of the high

tooth becomes damaged. viscosity of the oil.

Information pertaining to the viscosity and amount of An oil heater is a resistor element located in the oil

the gear lubrication oil is presented per application compartment of the gear and thread-mounted in the

either in the plate attached to the gear and/or in the wall of the gear housing. If required, the resistor

dimensional drawing of the gear. Oil types approved element can be detached for cleaning. In this case,

for use in industrial gears are presented in section 5. the gear oil must be removed first.

When using oil types not presented in the above

There is a thermostat for controlling the oil heater.

appendix, consult with the gear manufacturer first.

The thermostat must be programmed in such a way

2. LUBRICATION METHODS as to power on the oil heater if the temperature in the

gears falls below the pour point in bath or splash

2.1 Bath lubrication lubricated gears or below the temperature listed in

In bath lubrication, the oil surface is raised high Table 1 for pressure-feed-ubricated gears.

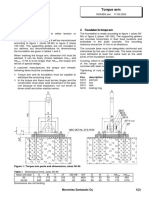

enough to submerge the tooth contact and the rolling Table 1. Minimum temperatures (C) with different oil

elements of the bearings in oil. Bath lubrication is qualities in pressure-feed-lubricated gears at or

suitable only for very slow-rotating gear wheels with a above which the oil viscosity value <2000 cSt occurs.

low pitch line velocity.

2.2 Splash lubrication ISO VG class 680 460 320 220 150 100

In splash lubrication, the gear wheels are partially

submersed in oil. Tooth contact is lubricated with the Mineral oil +25 +20 +15 +10 +5

oil splashing from the gear wheels or conveyed with

the teeth. The bearings are lubricated with oil Synthetic oil +15 +10 +5 0 -5

splashing from the gear wheels. Splash lubrication is In pressure-lubricated gears, the viscosity of the

suitable for relatively slow-rotating gear wheels. lubrication oil must be <2000 cSt at the start-up

2.3 Grease lubrication temperature.

The use of grease lubrication is limited almost solely The high end of the thermostat is set to power the

to the lubrication of bearings and seals if the bearing unit off at a temperature of +8..+10 C above the

structure of a gear assembly requires that. abovementioned power-on temperature.

Moventas Santasalo Oy 2(9)

Lubricants in industrial gears

MDI-170-B-EN 12.01.2010

Table 2 presents oil viscosity as a function of temperature.

Mineral oils Synthetic PAO oils

-25 -20-15-10 -7 Po ur poi nt [C]

-40 -40 - 35 -30 Pour point [C]

3000

3000 220 460

2000

2000 1 50 3 20 Viscosi ty i nde x

150 32 0 68 0 Vi scosity index

VI=90...100 VI=140...180

220 460 1000 ISO VG

1 000

ISO VG

500 500

200 200

150 150

1 00 100

40 40

Visc osity V iscosity

2

2

[mm / s] [mm /s]

10 10

-20 -10 0 10 20 30 40 50 60 70 80 90 1 00

-20 -10 0 10 20 30 40 50 60 70 80 90 100

Gear unit

s lubricating temperat ure of oil T L [C] Gear unit

s lubricating temperature of oil TL [ C]

Table 2

3.2 Oil cooling MPa (10 bar). The direction of flow of the water is

insignificant in the water cooling coil unit.

The gear manufacturer must be notified of above-

normal operating temperatures and temperature The flow amount of the water cooling coil unit must

variations. If the operating temperature of the oil is be adjusted so that the temperature of the oil

higher than the designed temperature, the oil compartment in the gear does not exceed +80 C.

viscosity falls too low. This may result in decreased There must be a thermometer in the oil compartment

lubrication film thickness, potential metal contact, of the gear for monitoring the temperature.

surface wear and damage. 3.2.2 Pressure-feed lubrication

3.2.1 Bath and splash lubrication The operating temperature of a gear with pressure-

The highest allowed operating temperature of bath feed lubrication is normally at most +80 C measured

and splash-lubricated gears is normally +90 C at the gears bearing housing.

measured at the gear s bearing housing. In special Gear cooling may be enhanced as follows:

cases the highest allowable operating temperature

use a water-cooled oil cooler

may be +100 C. If the gear s operating power

exceeds the thermal power, the above normal use an air-cooled oil cooler

operating temperature will be exceeded unless the An air-cooled oil cooler must be located in a dust-free

gear cooling is enhanced. environment.

Gear cooling may be enhanced as follows: The input side of a water-cooled oil cooler must have

a thermostat-controlled water valve. The greatest

place a water cooling coil unit in the gear

s oil

allowed operating pressure of the water is 1 MPa (10

compartment

bar). The direction of water flow marked in the oil

place one or two fans on the input shaft of the cooler must be adhered to.

gear In water-cooled oil coolers, the water volume must be

Fans are not recommended in dusty or humid adjusted with a thermostat so that the temperature of

environments. the oil entering the gear is +45..+55 C.

The input side of the water cooling coil unit must If the gear has an air-cooled oil cooler, it must be

have a thermostat-controlled water valve. The thermostat-controlled and control the operation of the

greatest allowed operating pressure of the water is 1

Moventas Santasalo Oy 3(9)

Lubricants in industrial gears

MDI-170-B-EN 12.01.2010

fan engine so that the temperature of the oil entering

the gear is +45...+55 . use the closest matching oil of a thinner oil group

3.3 Cold start use different oil for winter and summer

In a cold start situation, the viscosity of the lubrication environments

oil must be <2000 cSt at the start-up temperature for

the pressure-feed-lubricated gears. For bath and

use an oil heater

splash-lubricated gears, the start-up temperature use a synthetic polyalphaolephin-based (PAO)

must be higher than the pour point of the lubrication oil

oil. If this is not the case, the seals, bearings and In case of a temporary start-up temperature decrease

gear wheels will not be lubricated at all. (e.g., downtime), start-up problems in pressure-feed-

If the viscosity of the selected oil exceeds the allowed lubricated gear wheels can be reduced by allowing

viscosity at the start-up temperature, the following the electric engine pump to run through the

measures can be performed with the gear downtime.

manufacturer s permission:

4. HANDLING AND DISPOSING OF LUBRICANTS

Lubrication oils are hazardous waste and dangerous

to the environment. National laws and regulations

must be adhered to in their handling and disposal.

Moventas Santasalo Oy 4(9)

Lubricants in industrial gears

MDI-170-B-EN 12.01.2010

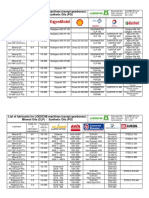

5. APPROVED LUBRICANTS

The lubricant table below lists the lubricants approved for Moventas Santasalo Oy

s industrial gear wheels.

Mineral oils

ISO VG AGMA Viscosity Pour point

Company Oil types

class number cSt / 40 C C

Aral Degol BG 150 plus 150 -12

BP Energol GR-XP 150 149 -12

Castrol Alpha SP 150 150 -21

Castrol Alpha MAX 150 150 -23

Castrol Optigear BM 150 150 -18

Castrol Tribol 1100/150 146 -27

150 4EP Chevron Meropa WM 150 150 -27

Fuchs Renolin CLP 150 150 -24

Fuchs Renolin CLP 150 PLUS 150 -24

Fuchs Lubritech Gearmaster CLP 150 150 -24

Klber Klberoil GEM 1-150 N 150 < -10

Lubrication 604 ALMASOL Vari- 150 -24

Engineers Purpose Gear Lubricant

Lukoil Steelo 150 150 -15

Mobil Mobilgear XMP 150 150 -27

Mobil Mobilgear 600 XP 150 150 -24

Neste Vaihteisto 150 EP 150 -21

Petro Canada Ultima EP 150 150 -33

Shell ------- -- --

Statoil Loadway EP 150 140 -27

Total ------- -- --

Total Carter XEP 150 150 -27

Aral Degol BG 220 plus 220 -15

BP Energol GR-XP 220 210 -9

Castrol Alpha SP 220 220 -21

Castrol Alpha MAX 220 220 -23

Castrol Optigear BM 220 220 -15

Castrol Tribol 1100/220 214 -24

220 5EP Chevron Meropa WM 220 220 -21

Fuchs Renolin CLP 220 220 -24

Fuchs Renolin CLP 220 PLUS 220 -24

Fuchs Lubritech Gearmaster CLP 220 220 -21

Klber Klberoil GEM 1-220 N 220 < -10

Lubrication 607 ALMASOL Vari- 220 -24

Engineers Purpose Gear Lubricant

Lukoil Steelo 220 220 -15

Mobil Mobilgear XMP 220 220 -24

Mobil Mobilgear 600 XP 220 220 -24

Neste Vaihteisto 220 EP 220 -24

Petro Canada Ultima EP 220 220 -27

Shell Omala F 220 220 -18

Statoil Loadway EP 220 225 -21

Total Carter VP/CS 220 220 -21

Total Carter XEP 220 220 -24

Aral Degol BG 320 plus 320 -9

BP Energol GR-XP 320 311 -9

Castrol Alpha SP 320 320 -21

Castrol Alpha MAX 320 320 -23

320 6EP Castrol Optigear BM 320 320 -15

Castrol Tribol 1100/320 331 -21

Chevron Meropa WM 320 320 -18

Fuchs Renolin CLP 320 320 -14

Moventas Santasalo Oy 5(9)

Lubricants in industrial gears

MDI-170-B-EN 12.01.2010

Fuchs Renolin CLP 320 PLUS 320 -18

Fuchs Lubritech Gearmaster CLP 320 320 -15

320 6EP Klber Klberoil GEM 1-320 N 320 < -10

Lubrication 605 ALMASOL Vari- 320 -18

Engineers Purpose Gear Lubricant

Lukoil Steelo 320 320 -15

Mobil Mobilgear XMP 320 320 -18

Mobil Mobilgear 600 XP 320 320 -24

Neste Vaihteisto 320 EP 320 -12

Petro Canada Ultima EP 320 320 -21

Shell Omala F 320 320 -15

Statoil Loadway EP 320 337 -18

Total Carter VP/CS 320 320 -18

Total Carter XEP 320 320 -18

Aral Degol BG 460 plus 460 -18

BP Energol GR-XP 460 432 -

Castrol Alpha SP 460 460 -6

Castrol Alpha MAX 460 460 -9

Castrol Optigear BM 460 460 -12

Castrol Tribol 1100/460 460 -21

460 7EP Chevron Meropa WM 460 460 -15

Fuchs Renolin CLP 460 460 -12

Fuchs Renolin CLP 460 PLUS 460 -14

Fuchs Lubritech Gearmaster CLP 460 460 -12

Klber Klberoil GEM 1-460 N 460 -10

Lubrication 608 ALMASOL Vari- 460 -15

Engineers Purpose Gear Lubricant

Lukoil Steelo 460 460 -15

Mobil Mobilgear XMP 460 460 -12

Mobil Mobilgear 600 XP 460 460 -15

Neste Vaihteisto 460 EP 460 -15

Petro Canada Ultima EP 460 460 -15

Shell Omala F 460 460 -9

Statoil Loadway EP 460 440 -12

Total Carter VP/CS 460 460 -12

Total Carter XEP 460 460 -12

Aral Degol BG 680 plus 680 -12

BP Energol GR-XP 680 710 -

Castrol Alpha SP 680 680 -6

Castrol ------- -- --

Castrol Optigear BM 680 680 -9

Castrol Tribol 1100/680 690 -18

680 8EP Chevron ------- -- --

Fuchs Renolin CLP 680 680 -10

Fuchs Renolin CLP 680 PLUS 680 -17

Fuchs Lubritech Gearmaster CLP 680 680 -12

Klber Klberoil GEM 1-680 N 680 -5

Lubrication 609 ALMASOL Vari- 680 -15

Engineers Purpose Gear Lubricant

Lukoil Steelo 680 680 -15

Mobil Mobilgear XMP 680 680 -9

Mobil Mobilgear 600 XP 680 680 -9

Neste Vaihteisto 680 EP 680 -12

Petro Canada Ultima EP 680 680 -15

Shell ----- -- --

Statoil Loadway EP 680 645 -9

Total Carter VP/CS 680 680 -9

Total Carter XEP 680 680 -9

Moventas Santasalo Oy 6(9)

Lubricants in industrial gears

MDI-170-B-EN 12.01.2010

Mineral oils for paper machine use

ISO VG AGMA Viscosity Pour point

Company Oil types

class number cSt / 40 C C

Esso Teresstic N 220 220 -12

BP Energol PM 220 220 -18

Mobil DTE PM 220 -6

220 5EP Neste-Exxon Paperikone 220D 220 -12

Petro Canada SEPRO XL 220 218 -21

Petro Canada ULTIMA EP 220 220 -27

Texaco PMO Premium 220 220 -18

Texaco PMO Ashless 220 220 -18

Synthetic polyalphaolephin-based oils

ISO VG AGMA Viscosity Pour point

Company Oil types

class number cSt / 40 C C

Aral Degol PAS 150 150 -39

BP Enersyn EP-XF 150 150 -48

Castrol Alphasyn EP 150 150 -48

Castrol ------- -- --

150 4EP Castrol Optigear Synthetic X 150 146 -39

Castrol Tribol 1510/150 155 -45

Fuchs Renolin Unisyn CLP 150 150 -45

Klber Klbersynth GEM 4 150 N 150 -40

Mobil Mobilgear SHC XMP 150 150 -48

Mobil Mobil SHC 629 150 -42

Neste Vaihteisto S 150 EP 150 -42

Petro Canada Enduratex Synthetic EP 150 150 -54

Shell Omala HD 150 150 -54

Statoil Mereta 150 150 -57

Total Carter SH 150 148 -45

Aral Degol PAS 220 220 -39

BP Enersyn EP-XF 220 220 -42

Castrol Alphasyn EP 220 220 -42

Castrol Optigear Synthetic A 220 210 -36

220 5EP Castrol Optigear Synthetic X 220 218 -33

Castrol Tribol 1510/220 220 -42

Fuchs Renolin Unisyn CLP 220 220 -42

Klber Klbersynth GEM 4 220 N 220 -40

Mobil Mobilgear SHC XMP 220 220 -45

Mobil Mobil SHC 630 220 -42

Neste Vaihteisto S 220 EP 220 -48

Petro Canada Enduratex Synthetic EP 220 223 -48

Shell Omala HD 220 220 -48

Statoil Mereta 220 220 -48

Total Carter SH 220 220 -45

Moventas Santasalo Oy 7(9)

Lubricants in industrial gears

MDI-170-B-EN 12.01.2010

Aral Degol PAS 320 320 -39

BP Enersyn EP-XF 320 320 -30

Castrol Alphasyn EP 320 320 -36

Castrol Optigear Synthetic A 320 330 -36

320 6EP Castrol Optigear Synthetic X 320 325 -33

Castrol Tribol 1510/320 330 -39

Fuchs Renolin Unisyn CLP 320 320 -42

Klber Klbersynth GEM 4 320 N 320 -35

Mobil Mobilgear SHC XMP 320 335 -38

Mobil Mobil SHC 632 320 -39

Neste Vaihteisto S 320 EP 320 -48

Petro Canada Enduratex Synthetic EP 320 323 -42

Shell Omala HD 320 320 -45

Statoil Mereta 320 320 -42

Total Carter SH 320 314 -42

Aral Degol PAS 460 460 -39

BP Enersyn EP-XF 460 460 -36

Castrol Alphasyn EP 460 460 -36

Castrol Optigear Synthetic A 460 463 -30

Castrol Optigear Synthetic X 460 459 -27

460 7EP Castrol Tribol 1510/460 460 -33

Fuchs Renolin Unisyn CLP 460 460 -39

Klber Klbersynth GEM 4 460 N 460 -30

Mobil Mobilgear SHC XMP 460 460 -36

Mobil Mobil SHC 634 460 -39

Neste Vaihteisto S 460 EP 460 -45

Petro Canada Enduratex Synthetic EP 460 501 -42

Shell Omala HD 460 460 -42

Statoil Mereta 460 460 -39

Total Carter SH 460 455 -30

ARAL ----- -- --

BP ----- -- --

Castrol ----- -- --

Castrol ----- -- --

Castrol ----- -- --

Castrol Tribol 1510/680 680 -30

Fuchs Renolin Unisyn CLP 680 680 -33

680 8EP Klber Klbersynth GEM 4 680 N 680 -30

Mobil Mobilgear SHC XMP 680 680 -30

Mobil Mobil SHC 636 68 -39

Neste Vaihteisto S 680 EP 680 -35

Petro Canada ----- -- --

Shell Omala HD 680 680 -39

Statoil Mereta 680 680 -39

Total Carter SH 680 676 -21

Synthetic polyalphaolephin-based oils for paper machine use

ISO VG AGMA Viscosity Pour point

Company Oil types

class number cSt / 40 C C

Castrol Optisynth HT 220 220 -39

Mobil SHC PM 220 225 -36

220 5EP

Neste Lamda 220 ZF 220 -45

Texaco Paper Machine Oil Premium

Moventas Santasalo Oy 8(9)

Lubricants in industrial gears

MDI-170-B-EN 12.01.2010

Roller bearing greases

Operating temperature -30..+100 C NLGI 2 (EP)

Fluency point

Company Grease type Penetration

C

Aral Aralub HLP2 265/295 180

BP Energrease LS-EP 265/295 195

Castrol Tribol 3785/220-1,5 265/295 >180

Castrol Longtime PD 2 265/295 260

Castrol Tribol 4020/220-2 265/295 260

Chevron Dura-Lith EP2 265/295 185

Elf Epexa EP2 265/295 207

Exxon Beacon EP2 265/295 190

Gulf Gulfcrown EP 2 265/295 180

Klber CENTOPLEX 2EP 265/295 190

Mobil Mobilux EP2 265/295 190

Neste Allrex EP 2 265/295 198

Shell Alvania Grease EP2 265/295 180

Statoil Uniway EP2N 270/280 185

Teboil Multi-purpose EP 265/295 185

Texaco Multifak EP2 265/295 186

Total Multis EP2 265/295 190

Lubrication of hot-running cone bearings (>80 C) NLGI 2 (EP)

Fluency point

Company Grease type Penetration

C

Castrol Tribol 3785/220-1,5 265/295 >180

Castrol Tribol 4020/220-2 265/295 260

Castrol Tribol 4747/220-2 265/295 >250

Klber Klberplex BE 31-102 265/295 190

Shell Albida Grease EP2 265/295 260

Teboil Multi-purpose HT 265/295 260

Lubrication of slow-rotating, axial, spherical pressure bearings NLGI 0..1 (EP)

Fluency point

Company Grease type Penetration

C

Castrol Molub-Alloy 9141-1 310/340 >230

Castrol Olista Longtime 1 310/340 >180

Castrol Optipit 245/275 300

Castrol Tribol 3020/1000-1 265/295 260

Klber STABURAGS NBU 30 245/275 220

Klber Klberplex BEM 41-141 310/345 250

Moventas Santasalo Oy 9(9)

You might also like

- Process Plant Insulation & Fuel Efficiency: Pdhonline Course M156 (4 PDH)Document76 pagesProcess Plant Insulation & Fuel Efficiency: Pdhonline Course M156 (4 PDH)satishchemeng75% (4)

- Awwa Hdpe PDFDocument37 pagesAwwa Hdpe PDFRaphael LinoNo ratings yet

- Blast Design and AnalysisDocument63 pagesBlast Design and AnalysisriprapNo ratings yet

- Heat ExchangerDocument17 pagesHeat ExchangerMedariTrinadh100% (2)

- Total - LUB - Industrial Apps - 2013 PDFDocument20 pagesTotal - LUB - Industrial Apps - 2013 PDFAzhar1109100% (1)

- Construction Lube Apps 18 Jan 16Document46 pagesConstruction Lube Apps 18 Jan 16José Cesário NetoNo ratings yet

- Report On Engine LubricationDocument9 pagesReport On Engine LubricationJitesh MhatreNo ratings yet

- Ubricants Brand ComparisonDocument6 pagesUbricants Brand ComparisonUtkarshNo ratings yet

- Lubricant Base Stocks: OutlineDocument23 pagesLubricant Base Stocks: OutlineJahmia Coralie100% (1)

- Is 13656 2002 PDFDocument24 pagesIs 13656 2002 PDFSiddharth GuptaNo ratings yet

- Splash Lubrication PDFDocument32 pagesSplash Lubrication PDFRajender KumarNo ratings yet

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezNo ratings yet

- HiTEC-419 PDSDocument2 pagesHiTEC-419 PDSSong Hum KangNo ratings yet

- Hitech Therm 60Document16 pagesHitech Therm 60Sales Support100% (1)

- Timken Lubricants: Timken Grease Interchange GuideDocument2 pagesTimken Lubricants: Timken Grease Interchange GuideChristian CotteNo ratings yet

- Ama Machine ManualDocument97 pagesAma Machine ManualmersiumNo ratings yet

- Corrosion in Crude Distillation Overhead System A ReviewDocument10 pagesCorrosion in Crude Distillation Overhead System A ReviewSalem GarrabNo ratings yet

- High Temperature Grease: DescriptionDocument2 pagesHigh Temperature Grease: Descriptionvicky kNo ratings yet

- Fundamentals of Lubrication: © INFINEUM INTERNATIONAL LIMITED 2019. All Rights ReservedDocument32 pagesFundamentals of Lubrication: © INFINEUM INTERNATIONAL LIMITED 2019. All Rights ReservedSiva KulanjiNo ratings yet

- Base Stocks 基础油Document18 pagesBase Stocks 基础油Yesica RozoNo ratings yet

- PETROLENE Product CatalogueDocument45 pagesPETROLENE Product CatalogueOscar Vargas GuerreroNo ratings yet

- Lubricant BasestocksDocument37 pagesLubricant BasestocksmaiatostiNo ratings yet

- Viscosity and Viscosity ModifiersDocument37 pagesViscosity and Viscosity ModifiersmaiatostiNo ratings yet

- Moly GreaseDocument2 pagesMoly GreaseDivyanshu SharmaNo ratings yet

- Disperse Dyes Used Polyester DyeingDocument23 pagesDisperse Dyes Used Polyester DyeingPratik Minj100% (3)

- BurnerDocument33 pagesBurnertoficNo ratings yet

- ATF LubricantDocument35 pagesATF LubricantTung NguyenNo ratings yet

- Shell Risella X 420 GtL Technical White Oil Data SheetDocument2 pagesShell Risella X 420 GtL Technical White Oil Data SheetHUM CIREBON DFLTS100% (1)

- Knife Edges and PivotsDocument8 pagesKnife Edges and PivotsYineth100% (3)

- Gear OilsDocument3 pagesGear OilsPurchase ZenoilNo ratings yet

- Velvex Industrial Oil - Nandan Petrochem LTDDocument27 pagesVelvex Industrial Oil - Nandan Petrochem LTDNandan Petrochem Ltd0% (1)

- SYNTHETIC GEAR OIL SPECDocument4 pagesSYNTHETIC GEAR OIL SPECdfbdfbfdbfbNo ratings yet

- Shell Melina S30: Performance, Features & BenefitsDocument2 pagesShell Melina S30: Performance, Features & BenefitsStefas DimitriosNo ratings yet

- Applying Food-Grade Gear Oils in Tobacco ProcessingDocument6 pagesApplying Food-Grade Gear Oils in Tobacco ProcessingMitar JocanovicNo ratings yet

- Product Information Navigo 6 So: DescriptionDocument2 pagesProduct Information Navigo 6 So: DescriptionCOMITYNo ratings yet

- Global Industrial Gear Oil MarketDocument16 pagesGlobal Industrial Gear Oil MarketSanjay MatthewsNo ratings yet

- Synthetic Gear Oil SelectionDocument9 pagesSynthetic Gear Oil Selectionsmallik3No ratings yet

- Engine Oil ChartDocument1 pageEngine Oil ChartprsovNo ratings yet

- Flender Gear Units: Double-Screw-Extruder Gear UnitDocument110 pagesFlender Gear Units: Double-Screw-Extruder Gear UnitAmirmasoudNo ratings yet

- Comparison of Shell Gadus S5 V100 2 Vs Tribol GR 100Document1 pageComparison of Shell Gadus S5 V100 2 Vs Tribol GR 100Hirendra GodeNo ratings yet

- High-Speed Bearing Grease Berutox FB 22Document1 pageHigh-Speed Bearing Grease Berutox FB 22Mauricio SánchezNo ratings yet

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Document42 pagesTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiNo ratings yet

- Cat Helimax 2016 Esp 1Document74 pagesCat Helimax 2016 Esp 1HKM IngenierosNo ratings yet

- En Additin RC 2540Document3 pagesEn Additin RC 2540Dinesh babuNo ratings yet

- Ss Mobilith SHCDocument2 pagesSs Mobilith SHCFarrukh JamalNo ratings yet

- Global DHD 1Document15 pagesGlobal DHD 1sanbao72No ratings yet

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Document8 pagesList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaNo ratings yet

- Synthetic Cross Reference GuideDocument1 pageSynthetic Cross Reference Guideالمشري بدوNo ratings yet

- Klüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain BearingsDocument4 pagesKlüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain Bearingsphucdc095041No ratings yet

- Shell - Rimula - R4 X 15W40 - Construction ColombiaDocument1 pageShell - Rimula - R4 X 15W40 - Construction ColombiaJorge Arrieta Torres100% (1)

- Klübersynth GE 46-1200 EN enDocument4 pagesKlübersynth GE 46-1200 EN enkarenglzNo ratings yet

- STLE ORG:BOK:LS:Additives:Boundary Lubricity Additives TLT Article Sept09Document8 pagesSTLE ORG:BOK:LS:Additives:Boundary Lubricity Additives TLT Article Sept09Dr. Stan Wardel BA, MA, MChem, MBA, DPhil, DSc.No ratings yet

- MAN 270 Diesel Engine Oil: Products For The Specification Approved by NameDocument2 pagesMAN 270 Diesel Engine Oil: Products For The Specification Approved by NameSyed JunaidNo ratings yet

- Copi Brochure Cover Update v8 en InteractiveDocument8 pagesCopi Brochure Cover Update v8 en InteractiveMuh HabzNo ratings yet

- Flender Gear UnitsDocument74 pagesFlender Gear Unitssdk00No ratings yet

- MIL-L-2105D Downloaded Gear Oil SpecDocument17 pagesMIL-L-2105D Downloaded Gear Oil Speckamal arabNo ratings yet

- Viscosity ClassificationsDocument6 pagesViscosity ClassificationsDarmawan PutrantoNo ratings yet

- Aceites Lubricantes para Motores Diesel Sep-2015Document28 pagesAceites Lubricantes para Motores Diesel Sep-2015Carlos Andres BonillaNo ratings yet

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshNo ratings yet

- Innovations in Lube Marketing: Indian Perspective Challenges & Way AheadDocument27 pagesInnovations in Lube Marketing: Indian Perspective Challenges & Way AheadBhagyesh DokeNo ratings yet

- Loesche List of Lubricants 03 2015 - enDocument6 pagesLoesche List of Lubricants 03 2015 - enphucdc095041No ratings yet

- Gulf Marine Corporate Presentation Ppt2009 07Document22 pagesGulf Marine Corporate Presentation Ppt2009 07Philippe-Andre BoileauNo ratings yet

- Flender Gearbox Lubricant 7300 (En)Document28 pagesFlender Gearbox Lubricant 7300 (En)samer salamehNo ratings yet

- Maintenance Tips On OilDocument12 pagesMaintenance Tips On OilAndrea StoneNo ratings yet

- En Additin RC 93210Document2 pagesEn Additin RC 93210Dinesh babuNo ratings yet

- HP Lubes GuideDocument196 pagesHP Lubes GuideJen Ekx100% (1)

- 6 Cyl and Packing LubricationDocument10 pages6 Cyl and Packing LubricationMohamed Nagim Cheikh AhmedNo ratings yet

- L3206en PDFDocument2 pagesL3206en PDFRaphael LinoNo ratings yet

- 5 - Equivalencia de Normas PERNOSDocument1 page5 - Equivalencia de Normas PERNOSRaphael LinoNo ratings yet

- Mdi 110en PDFDocument2 pagesMdi 110en PDFRaphael LinoNo ratings yet

- enDocument2 pagesenRaphael LinoNo ratings yet

- Pressure lubrication unit connectionsDocument2 pagesPressure lubrication unit connectionsRaphael LinoNo ratings yet

- Use and Maintenance of Gear UnitDocument4 pagesUse and Maintenance of Gear UnitRaphael LinoNo ratings yet

- Corrosion Protection and StorageDocument3 pagesCorrosion Protection and StorageRaphael LinoNo ratings yet

- MDI 165EN - InstallingDocument5 pagesMDI 165EN - InstallingRaphael LinoNo ratings yet

- MDI 120EN - Safety GuideDocument6 pagesMDI 120EN - Safety GuideRaphael LinoNo ratings yet

- Assembly Report: Gear Unit: Manuf. Number: DriveDocument1 pageAssembly Report: Gear Unit: Manuf. Number: DriveRaphael LinoNo ratings yet

- Use and Maintenance of Gear UnitDocument4 pagesUse and Maintenance of Gear UnitRaphael LinoNo ratings yet

- Corrosion Protection and StorageDocument3 pagesCorrosion Protection and StorageRaphael LinoNo ratings yet

- M062210 Tech SpecDocument1 pageM062210 Tech SpecRaphael LinoNo ratings yet

- Mdi 110enDocument2 pagesMdi 110enRaphael LinoNo ratings yet

- M062210 Part ListDocument4 pagesM062210 Part ListRaphael LinoNo ratings yet

- enDocument2 pagesenRaphael Lino100% (1)

- MDI 120EN - Safety GuideDocument6 pagesMDI 120EN - Safety GuideRaphael LinoNo ratings yet

- 2577910.dimensional DrawingDocument1 page2577910.dimensional DrawingRaphael LinoNo ratings yet

- L3206en PDFDocument2 pagesL3206en PDFRaphael LinoNo ratings yet

- M062210 - Manual Cover SheetDocument1 pageM062210 - Manual Cover SheetRaphael LinoNo ratings yet

- enDocument2 pagesenRaphael LinoNo ratings yet

- Shaft Driven Pump Operation DirectionsDocument1 pageShaft Driven Pump Operation DirectionsRaphael LinoNo ratings yet

- L3206ENDocument2 pagesL3206ENRaphael LinoNo ratings yet

- enDocument1 pageenRaphael LinoNo ratings yet

- Safety Valve Durgo: 2. Ensure The Valve FunctionsDocument1 pageSafety Valve Durgo: 2. Ensure The Valve FunctionsRaphael LinoNo ratings yet

- Visual Differential Pressure Indicator: Type FPC V 10 VMDocument1 pageVisual Differential Pressure Indicator: Type FPC V 10 VMRaphael LinoNo ratings yet

- enDocument2 pagesenRaphael LinoNo ratings yet

- Astm A105Document1 pageAstm A105Raphael LinoNo ratings yet

- Romacon & Hegawa CatalogueDocument60 pagesRomacon & Hegawa CataloguePhattapoom RoopngamNo ratings yet

- Parallel Session ICMIA Update 12 NovDocument4 pagesParallel Session ICMIA Update 12 NovnagatozzNo ratings yet

- FM 200 Properties Uses Storage HandlingDocument16 pagesFM 200 Properties Uses Storage HandlingAfsal NangathanNo ratings yet

- Hamworthy Flue Gas Generator PLC ControlledDocument3 pagesHamworthy Flue Gas Generator PLC ControlledHARISHNo ratings yet

- AASHTO M 320-10 Performance Graded Asphalt BinderDocument7 pagesAASHTO M 320-10 Performance Graded Asphalt BinderplavingalneemaNo ratings yet

- An Empirical Model To Calculate The Threads Stripping of A Bolt Installed in A Tapped PartDocument4 pagesAn Empirical Model To Calculate The Threads Stripping of A Bolt Installed in A Tapped Partparag7676No ratings yet

- Sikadur 30 PDFDocument5 pagesSikadur 30 PDFDarwin SyahputraNo ratings yet

- Tutorial 1Document4 pagesTutorial 1Kevin TanNo ratings yet

- Mohammed Et Al. (2022) - Graphene-CelluloseDocument8 pagesMohammed Et Al. (2022) - Graphene-CellulosealhassanNo ratings yet

- Crane Packing ListDocument2 pagesCrane Packing Listmanas3sNo ratings yet

- MiniPAC Manual REV 4.3 July 25 2012Document78 pagesMiniPAC Manual REV 4.3 July 25 2012zfo302No ratings yet

- Glitter Laser Machines CashDocument5 pagesGlitter Laser Machines CashAns JoaquinNo ratings yet

- Magnetic Effects of Electric Current ( (Term I)Document15 pagesMagnetic Effects of Electric Current ( (Term I)Tapas BanerjeeNo ratings yet

- SkinnySelectKevlar 4841Document1 pageSkinnySelectKevlar 4841Carlos Manuel Leonardo Vargas NavaNo ratings yet

- MSDS M.E.KDocument94 pagesMSDS M.E.KqNo ratings yet

- Marten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsDocument391 pagesMarten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsJed MansouriNo ratings yet

- Operating and Maintenance InstructionsDocument8 pagesOperating and Maintenance InstructionsRaja TouseefNo ratings yet

- CT - L1, L2Document9 pagesCT - L1, L2Rohna IqbalNo ratings yet

- VIBRATORY ROLLER OPERATOR'S MANUALDocument43 pagesVIBRATORY ROLLER OPERATOR'S MANUALkadaimamak100% (1)

- STEEL & PIPES for AFRICA price listDocument1 pageSTEEL & PIPES for AFRICA price listWynand Van ZylNo ratings yet

- Shower Tile - Over Tray Installation Guide Wet Area Solutions (Aust) Pty LTDDocument4 pagesShower Tile - Over Tray Installation Guide Wet Area Solutions (Aust) Pty LTDpaulnidNo ratings yet

- Social Icons: C-80 GradeDocument3 pagesSocial Icons: C-80 GradeEdward OropezaNo ratings yet

- Global Energy Balance in The Exchanger and Losses StudyDocument4 pagesGlobal Energy Balance in The Exchanger and Losses StudyJames Clerk MaxwellNo ratings yet