Professional Documents

Culture Documents

Plate Heat Exchangers

Uploaded by

amini_mohiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plate Heat Exchangers

Uploaded by

amini_mohiCopyright:

Available Formats

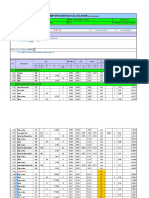

Technical Specification ZGFDC

Client.

Plate Heat Exchangers Unit 05 KERMANSHAH

05-ME-EC Doc. n P999-05-ME-EC-000 Spcifications Summary

000 Etabli. par: SZ Rv. Page

Spcifications Summary Date : 21/01/2015 A 1/1

Repre Dsignation N Date N Date N Date N Date N Date N Date

E0513A/B Mash heater A 21/01/2015 B C D E F

E0515 Mash degazing condenser A 21/01/2015 B C D E F

E0521 Alcoholized water heater A 21/01/2015 B C D E F

P999-05-ME-EC-000-RevA-Plate Heat Exchangers.xlsm

Technical Specification Client :

ZGFDC

Plate Heat Exchangers Unit 05 KERMANSHAH

05-ME-EC Doc n : P999-05-ME-EC-E0513A/B

Mash heater Made by : SZ Rev. Page

E0513A/B Date : 21/01/2015 A 1

Unit : 05 Quantity : 2

date rev designation Design Ver. App. date rev designation Design Ver. App.

21/1/15 A First Edition SZ PG JT D

B E

C F

HOT SIDE COLD SIDE

PROCESS SPECIFICATIONS

- Fluid . Type Process condensate Fermented mash

. Dry Matter 0,0% 14% % weight

- Vapor flowrate - - kg/h

- Liquid flowrate 19 185 75 197 kg/h

- Specific Weight 968 1 000 kg/m

- Viscosity cPo

- Specific Heat 1 0,9 kcal/kgC

- Thermal conductibility kcal/mhC

- Latent Heat - - kcal/kg

- Inlet Temperarture 88 50 C

- Outlet Temperature 52,7 60 C

- Working Pressure bar g.

- Maxi permitted pressure drop 0,5 0,5 bar

- Fouling resistance 10000xm3.h.C/kcal

EXCHANGER PERFORMANCES

- Heat exchanged 676 774 kcal/h

- Mean temperature difference 11 C

- Heat transfert area m2

- O.H.T.C. . Clean /Service kcal/m2.h.C

- Calculated pressure drop bar

MECHANICAL CHARACTERISTICS

- Plate material / thickness Stainless Steel 316 / 0,5 mini / mm

- Space between plates Large mm

- Sealing material (gasket) EPDM Clip on

- Connections . Material / ND Stainless Steel Stainless Steel / mm

- Flange rating ANSI 150 lbs (or ISO PN 20)

- Pressure design . Design / Test 10 10 bar g.

- Design Temperature 120 120 C

SUPPLIER DATA

- Supplier

- Model

- Number of passes

- Relative direction of the fluids

- No. of plates

- Extension capacity (+ plates)

- Nozzle orientation

- Overall length x width x height

- Liquid Volume

- Net Weight . Empty / Operation

Observations :

Please indicate speed of fluid beteween plates

A is running B is in stand-by / cleaning

P999-05-ME-EC-000-RevA-Plate Heat Exchangers.xlsm

Technical Specification Client :

ZGFDC

Plate Heat Exchangers Unit 05 KERMANSHAH

05-ME-EC Doc n : P999-05-ME-EC-E0515

Mash degazing condenser Made by : SZ Rev. Page

E0515 Date : 21/01/2015 A 1

Unit : 05 Quantity : 1

date rev designation Design Ver. App. date rev designation Design Ver. App.

21/1/15 A First Edition SZ PG JT D

B E

C F

HOT SIDE COLD SIDE

PROCESS SPECIFICATIONS

- Fluid . Type Mash degazing Cooling water

. Alcohol % 59,2% 0% % vol.

- Vapor flowrate 1321,35 - kg/h

- Liquid flowrate - 50 740 kg/h

- Specific Weight 0,375 / 863 1 000 kg/m

- Viscosity cPo

- Specific Heat 1 kcal/kgC

- Thermal conductibility kcal/mhC

- Latent Heat 384 - kcal/kg

- Inlet Temperarture 59 28 C

- Outlet Temperature 59 38 C

- Working Pressure bar g.

- Maxi permitted pressure drop 0,5 bar

- Fouling resistance 10000xm3.h.C/kcal

EXCHANGER PERFORMANCES

- Heat exchanged 507 398 kcal/h

- Mean temperature difference 26 C

- Heat transfert area m2

- O.H.T.C. . Clean /Service kcal/m2.h.C

- Calculated pressure drop bar

MECHANICAL CHARACTERISTICS

- Plate material / thickness Stainless Steel 316 / 0,5 mini / mm

- Space between plates mm

- Sealing material (gasket) EPDM Clip on

- Connections . Material / ND Stainless Steel Stainless Steel / mm

- Flange rating ANSI 150 lbs (or ISO PN 20)

- Pressure design . Design / Test 10 10 bar g.

- Design Temperature 120 120 C

SUPPLIER DATA

- Supplier

- Model

- Number of passes

- Relative direction of the fluids

- No. of plates

- Extension capacity (+ plates)

- Nozzle orientation

- Overall length x width x height

- Liquid Volume

- Net Weight . Empty / Operation

Observations :

WARNING : 5% uncondensable in mash degazing

P999-05-ME-EC-000-RevA-Plate Heat Exchangers.xlsm

Technical Specification Client :

ZGFDC

Plate Heat Exchangers Unit 05 KERMANSHAH

05-ME-EC Doc n : P999-05-ME-EC-E0521

Alcoholized water heater Made by : SZ Rev. Page

E0521 Date : 21/01/2015 A 1

Unit : 05 Quantity : 1

date rev designation Design Ver. App. date rev designation Design Ver. App.

21/1/15 A First Edition SZ PG JT D

B E

C F

HOT SIDE COLD SIDE

PROCESS SPECIFICATIONS

- Fluid . Type Spent feints alcoholized water

. Alcohol % 0,0% 10% % vol.

- Vapor flowrate - - kg/h

- Liquid flowrate 13 750 3 750 kg/h

- Specific Weight 1 000 1 000 kg/m

- Viscosity cPo

- Specific Heat 1 0,97 kcal/kgC

- Thermal conductibility kcal/mhC

- Latent Heat - - kcal/kg

- Inlet Temperarture 82 20 C

- Outlet Temperature 67 75 C

- Working Pressure bar g.

- Maxi permitted pressure drop 0,5 0,5 bar

- Fouling resistance 10000xm3.h.C/kcal

EXCHANGER PERFORMANCES

- Heat exchanged 200 063 kcal/h

- Mean temperature difference 21 C

- Heat transfert area m2

- O.H.T.C. . Clean /Service kcal/m2.h.C

- Calculated pressure drop bar

MECHANICAL CHARACTERISTICS

- Plate material / thickness Stainless Steel 316 / 0,5 mini / mm

- Space between plates mm

- Sealing material (gasket) EPDM Clip on

- Connections . Material / ND Stainless Steel Stainless Steel / mm

- Flange rating ANSI 150 lbs (or ISO PN 20)

- Pressure design . Design / Test 10 10 bar g.

- Design Temperature 120 120 C

SUPPLIER DATA

- Supplier

- Model

- Number of passes

- Relative direction of the fluids

- No. of plates

- Extension capacity (+ plates)

- Nozzle orientation

- Overall length x width x height

- Liquid Volume

- Net Weight . Empty / Operation

Observations :

P999-05-ME-EC-000-RevA-Plate Heat Exchangers.xlsm

You might also like

- TEMA Sheet Heat Exchanger SpecificationDocument3 pagesTEMA Sheet Heat Exchanger SpecificationSonNguyenNo ratings yet

- NIOEC standard specification for concrete used for fireproofingDocument9 pagesNIOEC standard specification for concrete used for fireproofingamini_mohiNo ratings yet

- Rigid Pipeline DesignDocument123 pagesRigid Pipeline DesignAditya Prasad100% (1)

- Schedule basement renovation project with Innovative DreamworksDocument59 pagesSchedule basement renovation project with Innovative DreamworksAnni FipNo ratings yet

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNo ratings yet

- Cooling Water CalculationDocument20 pagesCooling Water CalculationShahzaibUsman100% (1)

- D-STEAM SIZING FOR VAPORIZING AMMONIADocument2 pagesD-STEAM SIZING FOR VAPORIZING AMMONIAVinh Do ThanhNo ratings yet

- Boiler Commissioning & Functional Testing - Quality AssuranceDocument1 pageBoiler Commissioning & Functional Testing - Quality Assurancebandithaguru6338No ratings yet

- A7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsDocument5 pagesA7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsMudabbir Shan AhmedNo ratings yet

- REFREG CHARGE CALCDocument12 pagesREFREG CHARGE CALCKhadija MirajNo ratings yet

- Shell and Tube Heat Exchanger Design CalculationsDocument6 pagesShell and Tube Heat Exchanger Design CalculationsnileshNo ratings yet

- Design of a Double Pipe Heat Exchanger CalculationsDocument2 pagesDesign of a Double Pipe Heat Exchanger CalculationsSaqib RaoufNo ratings yet

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssNo ratings yet

- P103e Gas Scrubbing PlantsDocument12 pagesP103e Gas Scrubbing PlantsAswad Ali100% (1)

- F.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellDocument9 pagesF.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellVINOD KAMBLENo ratings yet

- Cooling Tower Makeup Water TankDocument3 pagesCooling Tower Makeup Water TankDota Ng100% (1)

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- UtilityDocument8 pagesUtilityAmit JainNo ratings yet

- Air Cooled Heat Exchanger !Document17 pagesAir Cooled Heat Exchanger !RehinaNo ratings yet

- Liquid Distributor DesignDocument3 pagesLiquid Distributor Designanon_414493592No ratings yet

- Insulation Thickness & Heat LossDocument5 pagesInsulation Thickness & Heat Losszahid nawazNo ratings yet

- Is 14164 2008Document45 pagesIs 14164 2008Pukhraj DagaNo ratings yet

- Electrcial Room Ventilation System Calculation: X 1.005 X 5 Airflow (m3/hr)Document2 pagesElectrcial Room Ventilation System Calculation: X 1.005 X 5 Airflow (m3/hr)psjjoshiNo ratings yet

- Chiller Size CalculatorDocument4 pagesChiller Size CalculatormpokeNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- Spec - Chiller Lắp Đặt ChillerDocument42 pagesSpec - Chiller Lắp Đặt ChillerBay MưaNo ratings yet

- Air Cooled Heat Exchanger CourseDocument2 pagesAir Cooled Heat Exchanger Courserodrigoperezsimone100% (1)

- Design of EquipmentDocument14 pagesDesign of EquipmentNaeem KhanNo ratings yet

- Shell and Tube VaporizerDocument17 pagesShell and Tube VaporizercontinentalflossNo ratings yet

- Design of A Vapor-Liquid SeparatorDocument2 pagesDesign of A Vapor-Liquid SeparatorpowerveeNo ratings yet

- Central Gas Consumption Calculation (SNG / NG) : Company LogoDocument4 pagesCentral Gas Consumption Calculation (SNG / NG) : Company Logoshameelpt66No ratings yet

- Typical Process / Facility Water Balance CalculationDocument5 pagesTypical Process / Facility Water Balance CalculationYesi CeballosNo ratings yet

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Document1 pageTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456No ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- Gas (Amine) Sweetening Process - Jonell Filtration Applications GasSweet 1015Document2 pagesGas (Amine) Sweetening Process - Jonell Filtration Applications GasSweet 1015Bob PeppingNo ratings yet

- Pipe DimensionDocument7 pagesPipe DimensionLily NurdianaNo ratings yet

- Process Calculation ManualDocument13 pagesProcess Calculation ManualDHAVAL PANCHALNo ratings yet

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsDocument9 pagesReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- Disturbance FactorDocument46 pagesDisturbance FactorBossNo ratings yet

- Agitator SizingDocument4 pagesAgitator SizingArbee AquinoNo ratings yet

- Calculation of Heat and Mass BalanceDocument16 pagesCalculation of Heat and Mass BalanceHEMANTNo ratings yet

- Expansion Tank Capacity Calculation SheetDocument5 pagesExpansion Tank Capacity Calculation SheetDEX TERRNo ratings yet

- BE. Heat Exchangers.Document97 pagesBE. Heat Exchangers.Gannavarapu KrishnaNo ratings yet

- Heat Exchanger CalcDocument34 pagesHeat Exchanger Calcميثة الغيثيةNo ratings yet

- Alkali Boil Out Procedure - Rev-1Document10 pagesAlkali Boil Out Procedure - Rev-1vahab shaikNo ratings yet

- Spreadsheet Calculates Nitrogen Purging Requirements for Storage TankDocument7 pagesSpreadsheet Calculates Nitrogen Purging Requirements for Storage TankWickyNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument40 pagesShell and Tube Heat Exchanger DesignamiyachemNo ratings yet

- Steam Tracing Specification ChartDocument1 pageSteam Tracing Specification Chartgpskumar22No ratings yet

- Steam CalculationDocument27 pagesSteam CalculationRAVI KUMAR CarpenterNo ratings yet

- Final Energy Balance-Vizag DT 9-6-18Document6 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNo ratings yet

- AF84C8 Excel Template Prelim Double Pipe Heat Exchanger Design Us UnitsDocument8 pagesAF84C8 Excel Template Prelim Double Pipe Heat Exchanger Design Us Unitss111_sunilNo ratings yet

- Ps 50 Bypass Calculations 13.3.17Document10 pagesPs 50 Bypass Calculations 13.3.17Deepak JoyNo ratings yet

- Carbon Filter CatalogueDocument2 pagesCarbon Filter CatalogueTanveer Alam Ansari100% (1)

- Nawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFDocument29 pagesNawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFAhmed AbidNo ratings yet

- Data Sheet-Bandar - Dayyer - MACDocument1 pageData Sheet-Bandar - Dayyer - MACmeisamNo ratings yet

- Data Sheet-Bandar - Dayyer - BACDocument1 pageData Sheet-Bandar - Dayyer - BACmeisamNo ratings yet

- VALVE SPECSDocument3 pagesVALVE SPECSazitaggNo ratings yet

- Kcj450lal BXXXDocument4 pagesKcj450lal BXXXShaiveeNo ratings yet

- NSDL Project Technical Data Sheet for 541-Ton Air-Cooled ChillerDocument3 pagesNSDL Project Technical Data Sheet for 541-Ton Air-Cooled ChillerVenu GopalNo ratings yet

- NT2212GKV2 925CD02Document2 pagesNT2212GKV2 925CD02Rajeesh P RaviNo ratings yet

- AMI Organics LTD Unit II 100 TRDocument18 pagesAMI Organics LTD Unit II 100 TRVatsal VermaNo ratings yet

- STEAM TABLE FORMULATION AND VERIFICATIONDocument8 pagesSTEAM TABLE FORMULATION AND VERIFICATIONcemal gümrükçüoğluNo ratings yet

- RIELLO P en RGDDocument10 pagesRIELLO P en RGDReggie HarvirNo ratings yet

- Nioec230 02 Eb Me P0207 A0Document9 pagesNioec230 02 Eb Me P0207 A0amini_mohiNo ratings yet

- NIOEC Site Conditions SpecificationDocument7 pagesNIOEC Site Conditions Specificationamini_mohiNo ratings yet

- Nioec230 02 Eb Me P0207 A0Document9 pagesNioec230 02 Eb Me P0207 A0amini_mohiNo ratings yet

- Nioec230 02 Eb Me P0207 A0Document9 pagesNioec230 02 Eb Me P0207 A0amini_mohiNo ratings yet

- 1117 Ed 00 PL SP 007 A3Document8 pages1117 Ed 00 PL SP 007 A3amini_mohiNo ratings yet

- Nioec SP 00 04 PDFDocument21 pagesNioec SP 00 04 PDFamini_mohiNo ratings yet

- Nioec SP 00 03 PDFDocument11 pagesNioec SP 00 03 PDFamini_mohiNo ratings yet

- Nioec SP-10-13Document7 pagesNioec SP-10-13amini_mohiNo ratings yet

- Nioec SP 00 02 PDFDocument13 pagesNioec SP 00 02 PDFamini_mohi100% (1)

- Nioec SP 00 03 PDFDocument11 pagesNioec SP 00 03 PDFamini_mohiNo ratings yet

- 1117 Ed 00 PL SP 005 A2Document5 pages1117 Ed 00 PL SP 005 A2amini_mohiNo ratings yet

- Nioec SP 00 02 PDFDocument13 pagesNioec SP 00 02 PDFamini_mohi100% (1)

- Nioec SP 00 05 PDFDocument8 pagesNioec SP 00 05 PDFamini_mohiNo ratings yet

- Process Design of Fuel Systems: NIOEC-SP-00-65Document34 pagesProcess Design of Fuel Systems: NIOEC-SP-00-65amini_mohiNo ratings yet

- Plant Technical & Equipment Manuals (Engineering Dossiers) : NIOEC-SP-00-60Document28 pagesPlant Technical & Equipment Manuals (Engineering Dossiers) : NIOEC-SP-00-60amini_mohi100% (1)

- 1117 Ed 00 PL SP 013 A1 PDFDocument5 pages1117 Ed 00 PL SP 013 A1 PDFamini_mohiNo ratings yet

- Design Criteria For Process and MechanicsDocument47 pagesDesign Criteria For Process and Mechanicsamini_mohi50% (2)

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specificationsamini_mohiNo ratings yet

- WPS & PQR Training PDFDocument316 pagesWPS & PQR Training PDFamini_mohiNo ratings yet

- 1117 Ed 00 PL SP 004 A1 PDFDocument8 pages1117 Ed 00 PL SP 004 A1 PDFamini_mohiNo ratings yet

- 1117 Ed 00 PL SP 002.a2Document5 pages1117 Ed 00 PL SP 002.a2amini_mohiNo ratings yet

- 1117 Ed 00 PL SP 013 A1 PDFDocument5 pages1117 Ed 00 PL SP 013 A1 PDFamini_mohiNo ratings yet

- Datasheet For Pressure Indicator: Serial 05 Project Pro. Part Scope Dis. Doc. Rev. Igat6 D PL IN DSH 0007Document4 pagesDatasheet For Pressure Indicator: Serial 05 Project Pro. Part Scope Dis. Doc. Rev. Igat6 D PL IN DSH 0007amini_mohiNo ratings yet

- Specification For Instrument Cable: Pecification For Nstrument AbleDocument18 pagesSpecification For Instrument Cable: Pecification For Nstrument Ableamini_mohiNo ratings yet

- Specification For Pressure TransmitterDocument15 pagesSpecification For Pressure Transmitteramini_mohiNo ratings yet

- Temperature Instrument SpecificationDocument14 pagesTemperature Instrument Specificationamini_mohiNo ratings yet

- Datasheet For Pig Signaler: DSH Serial 05 Project Pro. Part Scope Dis. 0002 Igat6 D PL IN Doc. RevDocument22 pagesDatasheet For Pig Signaler: DSH Serial 05 Project Pro. Part Scope Dis. 0002 Igat6 D PL IN Doc. Revamini_mohiNo ratings yet

- Specification For Temperature Safety Valve: S T S VDocument17 pagesSpecification For Temperature Safety Valve: S T S Vamini_mohiNo ratings yet

- Datasheet For Pressure Transmitter: Serial 05 Project Pro. Part Scope Dis. Doc. Rev. Igat6 D PL IN DSH 0001Document4 pagesDatasheet For Pressure Transmitter: Serial 05 Project Pro. Part Scope Dis. Doc. Rev. Igat6 D PL IN DSH 0001amini_mohiNo ratings yet

- OECSwceDocument12 pagesOECSwceChristopher WeeksNo ratings yet

- Dudley Renovation Exploded DiagramsDocument2 pagesDudley Renovation Exploded DiagramsStudioAPLANo ratings yet

- RENAN ResumeDocument2 pagesRENAN ResumeAlbert AbilarNo ratings yet

- Segmental Bridge Construction ProcessDocument14 pagesSegmental Bridge Construction Processbadam zadran100% (1)

- Jawaban Plan and Schedule OperationDocument2 pagesJawaban Plan and Schedule OperationAhmad NaswianNo ratings yet

- 415b - Universal Locking SystemDocument29 pages415b - Universal Locking SystemAbish KhanNo ratings yet

- (2017 Nilforoush Et Al.) - Influence of Surface Reinforcement, Member Thickness and Cracked Concrete On Tensile Capacity of Anchor BoltsDocument14 pages(2017 Nilforoush Et Al.) - Influence of Surface Reinforcement, Member Thickness and Cracked Concrete On Tensile Capacity of Anchor BoltsmanoelmangabeiraNo ratings yet

- MBH Catalogue 2019Document56 pagesMBH Catalogue 2019Anonymous 1oWzM3No ratings yet

- DAIKIN VAM VRV HVE ModelDocument5 pagesDAIKIN VAM VRV HVE ModelPads PrietoNo ratings yet

- Simple Connections in Steel StructuresDocument13 pagesSimple Connections in Steel StructuresSetup ComputerNo ratings yet

- Material Finish GuideDocument7 pagesMaterial Finish GuideRomie CubalNo ratings yet

- Bosch Washing Machine WAS32461GB 90004608573Document6 pagesBosch Washing Machine WAS32461GB 90004608573David GoldNo ratings yet

- Gs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralDocument2 pagesGs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralmustafaNo ratings yet

- Dislocations: Edge, Screw, Slip Systems & CharacteristicsDocument27 pagesDislocations: Edge, Screw, Slip Systems & CharacteristicspavankcvsNo ratings yet

- Type of Vaults Used: Rectangular Large Span Vault 15m X 8m Resting On Four CornersDocument2 pagesType of Vaults Used: Rectangular Large Span Vault 15m X 8m Resting On Four CornersHarshali PatilNo ratings yet

- GE Circuit Breaker EnclosuresDocument8 pagesGE Circuit Breaker Enclosuresdiscovery198No ratings yet

- Catalog 3800 Quick Coupling ProductsDocument229 pagesCatalog 3800 Quick Coupling ProductsANKUSH PARMARNo ratings yet

- Performance Evaluation of The Bending Strength of Larch CLTDocument12 pagesPerformance Evaluation of The Bending Strength of Larch CLTSỹ PhạmNo ratings yet

- 2 - Compressibility of SoilsDocument34 pages2 - Compressibility of SoilsKatherine Shayne YeeNo ratings yet

- How Does Contact With Aluminum Affect Concrete - Concrete Construction MagazineDocument1 pageHow Does Contact With Aluminum Affect Concrete - Concrete Construction MagazineHerdisNo ratings yet

- Republic of the Philippines site and building plansDocument5 pagesRepublic of the Philippines site and building plansDean DumaguingNo ratings yet

- SM 17Document152 pagesSM 17Sebastian TataranNo ratings yet

- Presentation DokaDocument20 pagesPresentation DokabetungurarnoldNo ratings yet

- SIM (3) - EIM 10-CMG - Week 4-5 - Q1Document12 pagesSIM (3) - EIM 10-CMG - Week 4-5 - Q1Genelyn NarcisoNo ratings yet

- VSL - Multistrand Post TensioningDocument15 pagesVSL - Multistrand Post TensioningkmabdNo ratings yet

- Foundation DesignDocument2 pagesFoundation Designhemantmech09No ratings yet

- Group 15 : Relief Valves AccessoriesDocument4 pagesGroup 15 : Relief Valves AccessoriesLPG Equipment Consulting and ServicesNo ratings yet

- Air Fiter - Regulator SB10Document3 pagesAir Fiter - Regulator SB10Abhishek SinghNo ratings yet