Professional Documents

Culture Documents

Inspection Procedure: Zig Zag

Uploaded by

Ali Ben AmorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Procedure: Zig Zag

Uploaded by

Ali Ben AmorCopyright:

Available Formats

PPE INSPECTION

Inspection procedure

This document describes

In addition to routine checks for each use, PPE should regularly undergo a thorough inspection by a the steps for a thorough PPE

competent person. inspection.

Petzl recommends an inspection every 12months and after any exceptional event in the life of the product.

Record the result of each step

in the inspection

PPE inspection should be done with the manufacturer's instructions available for reference. record.

Download the instructions at PETZL.COM

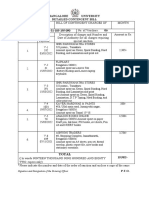

ZIG ZAG

D22

1. Known product history

Any PPE showing unexpected degradation should be quarantined, pending a thorough inspection.

The user should:

- Provide precise information on the usage conditions.

- Report any exceptional event regarding his PPE.

(Examples:fall or fall arrest, use or storage at extreme temperatures, modification outside manufacturer's

facilities,etc.).

2. Preliminary observations

Verify the presence and legibility of the serial number and the CE mark.

Verify that the product lifetime has not been exceeded.

Compare with a new device to verify there are no modifications or missing elements.

3. Checking the release lever

Check the condition of Check for wear from the rope passing Check the effectiveness of the return spring.

the release lever (marks, through the device.

deformation, cracks,etc.). If there is significant wear, do the rope-

grabbing test detailed in step7.

PPE INSPECTION - Inspection procedure - ZIGZAG D22 (010113) 1/3

4. Inspecting the friction chain

x12 x12

Check the condition of the friction chain x4

elements: x12 x12

- Rivets (cracks, deformation, x4

corrosion,etc.)

- Links (cracks, deformation, corrosion,

fouling,etc.).

- Release lever (wear, deformation,

corrosion, fouling,etc.).

- Bars (wear, deformation, corrosion,

fouling,etc.).

x12 x12

x4

Verify that the friction chain extends and compresses

freely. If necessary, clean with soap and water and lubricate

lightly (ex. graphite powder).

Inspect each link individually to verify there are no rough

spots in their rotation.

5. Inspecting the frame, sheave and swivel

Check the condition of Check the edges of the

the frame and rivets (marks, attachment hole for wear

deformation, cracks, caused by connectors.

corrosion, absence of

play,etc.).

x2 x5 x8 x12

x3 x6 x9 x14

x4 x7 x10 x16

Check the condition Verify that the sheave

of the sheave (marks, turns freely.

deformation, corrosion,

absence of foreign

bodies,etc.).

Check the Verify that the swivel

condition of the turns freely and that there

swivel (cracks, is no play between the

deformation,etc.). swivel and the frame (if

necessary lubricate with

graphite powder).

PPE INSPECTION - Inspection procedure - ZIGZAG D22 (010113) 2/3

6. Inspecting the alignment of the elements

Hold the ZIGZAG out in front

of you, by the release lever,

with the chain extended. Note

the alignment of the elements

and of the frame.

7. Function test:grabbing the rope

Use the different rope

diameters recommended by

the manufacturer (11.5 to

13mm).

Install the ZIGZAG in single

mode on an anchor at very

low height (see the chapter

on Compatibility / Rope

compatibility test in the

product instructions).

When hanging from the

ZIGZAG in simple mode, there STOP STOP

! !

should be no slippage.

Verify that the ZIGZAG slides

upward when the rope below

the device is pulled.

8. Function test:release under load

Install the ZIGZAG in normal

work configuration (double

mode), and hang from it at a

very low height.

Verify that pressure on the

release lever allows smooth

! sliding and control of the rope.

PPE INSPECTION - Inspection procedure - ZIGZAG D22 (010113) 3/3

You might also like

- Inspection Procedure: Grillon LanyardDocument5 pagesInspection Procedure: Grillon LanyardUlviyye ElesgerovaNo ratings yet

- Verif EPI Poulies Procedure ENDocument3 pagesVerif EPI Poulies Procedure ENaliya azharNo ratings yet

- Verif EPI GRIGRI Procedure enDocument3 pagesVerif EPI GRIGRI Procedure eninternetNo ratings yet

- Verif Epi Protraxion Procedure enDocument4 pagesVerif Epi Protraxion Procedure eninternetNo ratings yet

- Inspection Procedure: Professional HarnessesDocument9 pagesInspection Procedure: Professional Harnesseschanks498No ratings yet

- Verif EPI Harnais SPORT Procedure enDocument4 pagesVerif EPI Harnais SPORT Procedure enisacc palacios gamarraNo ratings yet

- Verif EPI Bloqueur Procedure EN PDFDocument6 pagesVerif EPI Bloqueur Procedure EN PDFdsn_sarmaNo ratings yet

- SOP Overhead Crane-Rev.1Document5 pagesSOP Overhead Crane-Rev.1RonniNo ratings yet

- Chain InspectionDocument4 pagesChain Inspectionadhi nrNo ratings yet

- Y-Strainer IOM Rev A (03!26!18)Document6 pagesY-Strainer IOM Rev A (03!26!18)Dominic V. PantigNo ratings yet

- Miller Lanyard Inspection and Maintenance Proceedure PDFDocument2 pagesMiller Lanyard Inspection and Maintenance Proceedure PDFUlviyye ElesgerovaNo ratings yet

- PIRMH Chain Inspection PIDocument4 pagesPIRMH Chain Inspection PIRicardoNo ratings yet

- Verif EPI Degaines Procedure enDocument2 pagesVerif EPI Degaines Procedure eninternetNo ratings yet

- Inspection Form: Frame-Loaded Rope ClampDocument1 pageInspection Form: Frame-Loaded Rope ClampDimasDianaFerreiraNo ratings yet

- Sce - Life Saving Equipment, Life Jackets: Tick The Appropriate Box To Indicate Which Areas Require To Be Complied WithDocument4 pagesSce - Life Saving Equipment, Life Jackets: Tick The Appropriate Box To Indicate Which Areas Require To Be Complied Withsafar matakNo ratings yet

- 801 I.1.3 Man Rider Winch Product Maintenance InformationDocument14 pages801 I.1.3 Man Rider Winch Product Maintenance InformationPedro SanchezNo ratings yet

- Ac Spindle DL-SCZDocument96 pagesAc Spindle DL-SCZBa DuyNo ratings yet

- MHD56305 Ed3Document16 pagesMHD56305 Ed3mukhtarahmadaNo ratings yet

- Checklist - Backup Device - Petzl ASAP-LOCKDocument1 pageChecklist - Backup Device - Petzl ASAP-LOCKMax BeeksNo ratings yet

- Warning: Synthetic Tie Down Safety BulletinDocument3 pagesWarning: Synthetic Tie Down Safety BulletinAlejandro CampomarNo ratings yet

- Ecoline User Guide 25-300Document8 pagesEcoline User Guide 25-300eduardo roqueNo ratings yet

- Edgetech SuperSpacer Systems Insulating Glass Manufacturing ManualDocument51 pagesEdgetech SuperSpacer Systems Insulating Glass Manufacturing ManualJelena ĆukNo ratings yet

- Verif EPI Longes Procedure enDocument5 pagesVerif EPI Longes Procedure enDarwin AndyNo ratings yet

- Power Shovel Operation: Surface Metal and Nonmetal MinesDocument16 pagesPower Shovel Operation: Surface Metal and Nonmetal MinesHowk RiosNo ratings yet

- Verif EPI Sangleamarrage Procedure FRDocument2 pagesVerif EPI Sangleamarrage Procedure FRinternetNo ratings yet

- Table 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019Document1 pageTable 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019MehoNo ratings yet

- PRO12 2P621CT - Rev 7 - 09 19Document24 pagesPRO12 2P621CT - Rev 7 - 09 19Edwin Montenegro MurilloNo ratings yet

- Section 3: Maintenance Instructure: Cleaning Fastening Aligment Lubrication InspectionDocument25 pagesSection 3: Maintenance Instructure: Cleaning Fastening Aligment Lubrication Inspectionabdelhadi houssinNo ratings yet

- Checklist - Ascenders - Petzl Hand & Chest - 050717Document1 pageChecklist - Ascenders - Petzl Hand & Chest - 050717Max BeeksNo ratings yet

- Chapter 5: Checking and Maintaining Ultrasound EquipmentDocument8 pagesChapter 5: Checking and Maintaining Ultrasound EquipmentUmar DhaniNo ratings yet

- T48. Annexure - 11 RFT Check SheetDocument11 pagesT48. Annexure - 11 RFT Check SheetarissaNo ratings yet

- Verif EPI IDS IDL RIG Procedure enDocument5 pagesVerif EPI IDS IDL RIG Procedure enAldisley OliveiraNo ratings yet

- LY38 Ops Manual PDFDocument36 pagesLY38 Ops Manual PDForlando chullo llave100% (1)

- Travelling Block AdaptorDocument1 pageTravelling Block AdaptormhmdtrainingNo ratings yet

- PV System Operations & Maintenance FundamentalsDocument9 pagesPV System Operations & Maintenance FundamentalsSolar - Marketing/CELNo ratings yet

- Koss KS4102 Progressive-Scan DVD Home Theater ManualDocument40 pagesKoss KS4102 Progressive-Scan DVD Home Theater ManualASHLEY011266No ratings yet

- Job Safety Analysis: Date/ Jsa No: Jsa Team Members Job: Location: Project/ Client: SupervisorDocument1 pageJob Safety Analysis: Date/ Jsa No: Jsa Team Members Job: Location: Project/ Client: SupervisorMuhammad Akbar Al BardawiNo ratings yet

- X-Seal Jointcord: Technical Data SheetDocument2 pagesX-Seal Jointcord: Technical Data Sheetnader enanyNo ratings yet

- Technical Notice AVAO BOD BOD FAST ANSI 2Document28 pagesTechnical Notice AVAO BOD BOD FAST ANSI 2Jhon NcNo ratings yet

- Technical Notice NANO TRAXION 1Document14 pagesTechnical Notice NANO TRAXION 1Enaitz OtazuaNo ratings yet

- Stiffness Tester A 45 Grados PDFDocument7 pagesStiffness Tester A 45 Grados PDFramonNo ratings yet

- Airjet Loom Toyotaa Jat710 Trouble ShootingDocument18 pagesAirjet Loom Toyotaa Jat710 Trouble Shootingselvapdm100% (25)

- V30ZMUDocument26 pagesV30ZMUmanuelsaenzNo ratings yet

- CDI Manual Computorq IIDocument12 pagesCDI Manual Computorq IIDavid DercyNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- SOP Mobile Crane-Rev.1Document7 pagesSOP Mobile Crane-Rev.1RonniNo ratings yet

- FrogLink Riveted Anchor Maintenance Check ListDocument3 pagesFrogLink Riveted Anchor Maintenance Check ListNirooban VigneswaranNo ratings yet

- User's Manual - Synthetic Μooring RopesDocument32 pagesUser's Manual - Synthetic Μooring RopesNikos StratisNo ratings yet

- Maintenance DCM SLITTING MACHINEDocument4 pagesMaintenance DCM SLITTING MACHINEDeniMestiWidianto100% (1)

- 750X User Manual HighlightedDocument17 pages750X User Manual HighlightedThomas BetressNo ratings yet

- Bruc 1 081 001Document6 pagesBruc 1 081 001Adel AhmedNo ratings yet

- How To Inspect Your Wire Ropes: Focus On Your Rope'S Critical PointsDocument2 pagesHow To Inspect Your Wire Ropes: Focus On Your Rope'S Critical PointskaloordenisNo ratings yet

- FFD - 4 - Maintenance Manual PDFDocument15 pagesFFD - 4 - Maintenance Manual PDFKaleb Z king webNo ratings yet

- Masterpact Maintenance ProcedureDocument94 pagesMasterpact Maintenance ProcedureYassin Alkady100% (1)

- System and Work Methodology For Casting Final 2Document6 pagesSystem and Work Methodology For Casting Final 2Dan GoNo ratings yet

- Verif EPI Casques PRO Procedure EN PDFDocument6 pagesVerif EPI Casques PRO Procedure EN PDFDimasDianaFerreiraNo ratings yet

- Sop Template 2018 v1 Makerspace VinylcutterDocument4 pagesSop Template 2018 v1 Makerspace VinylcutterAkhil GeorgeNo ratings yet

- Equipment Inspection ChecklistDocument4 pagesEquipment Inspection ChecklistBharathi SilambarasanNo ratings yet

- NDT ProcessingFilms TechDataDocument17 pagesNDT ProcessingFilms TechDataAli Ben AmorNo ratings yet

- Safe Made: Marine Product CoDocument1 pageSafe Made: Marine Product CoAli Ben AmorNo ratings yet

- Focus: Features and BenefitsDocument2 pagesFocus: Features and BenefitsAli Ben AmorNo ratings yet

- Bachelor of Computer Application (BCA) (Indian & Angolan Embassy Attested)Document3 pagesBachelor of Computer Application (BCA) (Indian & Angolan Embassy Attested)Ali Ben AmorNo ratings yet

- Tsunamis: A Tsunami in The Pacific OceanDocument1 pageTsunamis: A Tsunami in The Pacific OceanAli Ben AmorNo ratings yet

- 23145879Document5 pages23145879Ali Ben AmorNo ratings yet

- Asme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediDocument7 pagesAsme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediAli Ben AmorNo ratings yet

- Mostafa Hassan Salah: Career ObjectivesDocument3 pagesMostafa Hassan Salah: Career ObjectivesAli Ben Amor100% (1)

- Safe Made: Marine Product CoDocument1 pageSafe Made: Marine Product CoAli Ben AmorNo ratings yet

- News Release: 3D Systems Completes The Acquisition of Z Corp and VidarDocument4 pagesNews Release: 3D Systems Completes The Acquisition of Z Corp and VidarAli Ben AmorNo ratings yet

- Capabilities and Limitations of Radiography and Phased Array Ultrasonic Test in The Detection of Subtle Welding DefectsDocument8 pagesCapabilities and Limitations of Radiography and Phased Array Ultrasonic Test in The Detection of Subtle Welding DefectsAli Ben AmorNo ratings yet

- CODES & STANDARDS: NQA-1 2015 Key ChangesDocument1 pageCODES & STANDARDS: NQA-1 2015 Key ChangesAli Ben AmorNo ratings yet

- HSBC PDFDocument9 pagesHSBC PDFAli Ben AmorNo ratings yet

- IOTA Company ProfileDocument11 pagesIOTA Company ProfileAli Ben AmorNo ratings yet

- Manual of Petroleum Measurement StandardsDocument23 pagesManual of Petroleum Measurement StandardsAli Ben AmorNo ratings yet

- Project Management Plan PDFDocument15 pagesProject Management Plan PDFAli Ben AmorNo ratings yet

- Structural Integrity Management of Ageing Offshore InstallationsDocument36 pagesStructural Integrity Management of Ageing Offshore InstallationsAli Ben AmorNo ratings yet

- Strer PDFDocument36 pagesStrer PDFAli Ben AmorNo ratings yet

- Cexhib PDFDocument5 pagesCexhib PDFAli Ben AmorNo ratings yet

- Ctakitki Kitoko PDFDocument308 pagesCtakitki Kitoko PDFAli Ben AmorNo ratings yet

- Takitki KitokoDocument308 pagesTakitki KitokoAli Ben AmorNo ratings yet

- Surveying Lesson 6 To 10 PDFDocument68 pagesSurveying Lesson 6 To 10 PDFNadane AldoverNo ratings yet

- X Ray DiffractionDocument12 pagesX Ray DiffractionSiddraKhalidNo ratings yet

- UA&P-JD Application FormDocument4 pagesUA&P-JD Application FormuapslgNo ratings yet

- Iron Ore Value-In-Use: Benchmarking and Application: Peter Hannah AnalystDocument19 pagesIron Ore Value-In-Use: Benchmarking and Application: Peter Hannah AnalystAnkit BansalNo ratings yet

- TestingDocument116 pagesTestingAkarsh LNo ratings yet

- Sayre Materia Medica-1Document108 pagesSayre Materia Medica-1ven_bams584075% (4)

- General Lecture - Paper Deep RiversDocument13 pagesGeneral Lecture - Paper Deep RiversAJ TabuenaNo ratings yet

- Qaisra Shahraz - A Pair of JeansDocument3 pagesQaisra Shahraz - A Pair of Jeansmonkey3333389% (19)

- Indra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043Document28 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- Unit 2 Computer Hardware and SoftwareDocument24 pagesUnit 2 Computer Hardware and SoftwareNgHanSeongNo ratings yet

- Thermodynamics QsDocument3 pagesThermodynamics QsT Hari PrasadNo ratings yet

- Gas Rating Summary 2010Document2 pagesGas Rating Summary 2010ahmadhadraniNo ratings yet

- Rudolf DreikursDocument17 pagesRudolf DreikursKatrina Cassandra0% (1)

- First ContingencyDocument2 pagesFirst Contingencymanju bhargavNo ratings yet

- Outsourcing-Insourcing CriteriaDocument8 pagesOutsourcing-Insourcing CriteriaGuadagustinNo ratings yet

- Human Behavior TestDocument22 pagesHuman Behavior TestEsmani BraineNo ratings yet

- Understanding Culture, Society and Politics: Prepared By: Ms. Shiela Mae B. CombalicerDocument31 pagesUnderstanding Culture, Society and Politics: Prepared By: Ms. Shiela Mae B. CombalicerAzeLuceroNo ratings yet

- Discuss The Nature and Extent of Slavery As An Institution in Greco-Roman SocietyDocument4 pagesDiscuss The Nature and Extent of Slavery As An Institution in Greco-Roman SocietySouravNo ratings yet

- Micro Hydro BrochureDocument4 pagesMicro Hydro BrochureErlangga SatyawanNo ratings yet

- Architechture of 8086 or Functional Block Diagram of 8086 PDFDocument3 pagesArchitechture of 8086 or Functional Block Diagram of 8086 PDFAdaikkal U Kumar100% (2)

- 10.1007@s10157 020 01867 yDocument6 pages10.1007@s10157 020 01867 yGin RummyNo ratings yet

- 04 IMS Technical Differences (Nokia)Document4 pages04 IMS Technical Differences (Nokia)stern_uNo ratings yet

- IC Hotel Revenue Projection Template 10708Document3 pagesIC Hotel Revenue Projection Template 10708carolisdwi permanaNo ratings yet

- Macroeconomics AssignmentDocument3 pagesMacroeconomics AssignmentAyush MittalNo ratings yet

- ISC HydroCom ComparisonDocument22 pagesISC HydroCom Comparisonrahilshah100No ratings yet

- Tutorial Week 10 Topic 9Document14 pagesTutorial Week 10 Topic 9patricia93limNo ratings yet

- January 15, 1986Document6 pagesJanuary 15, 1986Accompaniment WorldNo ratings yet

- Evaporator Pressure Regulating Valve SporlanDocument16 pagesEvaporator Pressure Regulating Valve SporlanSubramanian gokul100% (1)

- The Atom: Cornell Doodle NotesDocument22 pagesThe Atom: Cornell Doodle NotesSalina SalujaNo ratings yet

- Find The Best Location For Your Business or For Your Rice Retailing BusinessDocument2 pagesFind The Best Location For Your Business or For Your Rice Retailing BusinessAAAAANo ratings yet