Professional Documents

Culture Documents

Install Sink Mixer Instructions Dorf

Uploaded by

testnationCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Install Sink Mixer Instructions Dorf

Uploaded by

testnationCopyright:

Available Formats

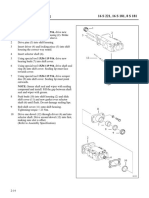

FLICKMIXER PLUS - SINK MIXER 1 2 3 4

WATER EFFICIENT TAPWARE

(NOMINAL FLOW RATE = 7 L/min)

PLUMBERS INSTALLATION INSTRUCTIONS

CARTRIDGE - Adjustable Features

Important Information See details on side 2 of this sheet 5

* Not suitable for gravity feed systems. Anti-Scald & Volume Limit Screw

* Mixer is fitted with a 7 L/min flow regulated aerator insert.

* Isolating stop taps must be fitted to the hot & cold water 6

supply connections. (Part No. 842018C - Mini cistern 1/4T)

* All pipework must be thoroughly flushed prior to

installation, as foreign materials may block the flow 9

regulating device and reduce the flow of water.

Note: Aerator insert housing must be retightened 10

to prevent removal by hand. Replacing Cartridge

Installation 1) Turn off hot and cold water supplies.

1) From fixing pack fit 'O'ring (12) into groove in base of mixer 2) Carefully remove plug (4) before using a 2.5mm allen

body (11). Screw stud (13) into underside of mixer body (11). key (3) to loosen grub screw (2) and remove handle (1).

Remove cap (5) taking care not to damage the decorative

2) Flexible Tail Mixer Connections: Apply suitable lubricant to finish. Unscrew nut (6) then lift out old cartridge (9).

'O'rings (20). Fit flexible tail (19) (with red indication) into

hole marked 'H' in underside of mixer body (11). 3) Ensure inside face of mixer body (11) is clean. Check that

Hand tighten the tail, ensuring the 'O'ring (20) has fully seals (10) are in position in base of new cartridge (9). Fit new 11

entered the sealing bore to provide a watertight joint. Fit cartridge (9) into mixer body (11), taking care that two lugs

other flexible tail (with blue indication) into remaining hole on base of cartridge (9) fit into mating holes in mixer body (11).

Deck

in a similar manner. 4) Screw on nut (6). Important: Nut (6) should be tightened 12

3)Insert the inlet connection end (18) of each flexible tail (19) to a torque of 10 Nm.

through the hole in the deck. Place mixer over deck hole, fit 5) Replace cap (5), tightening by hand. Fit handle (1) taking

gasket (14) and fixing plate (15) over stud (13) then screw care that it is pushed fully down, then tighten grub Mixer Connection End

on fixing nut (16). Position mixer as required then tighten screw (2). Replace plug (4) taking care not to damage

13

fixing nut (16) using spanner (17) provided. the decorative finish.

20

4)Flexible Tail Inlet Connections: Connect the flexible tails (19) 6) Turn on water supplies and check operation.

to the hot and cold isolating stop taps, hand tighten the

connecting nut (18) until rubber cone contacts the sealing 19 14

face of the connection end, then tighten a further one turn

IMPORTANT

to provide a watertight joint. Inlet Connection End

Important: Flexible tails must not be kinked, twisted or in Pressure & Temperature Requirements.

15

tension when installed. (Minimum Bend Radius:- 50mm) Hot and cold water inlet pressures should be equal. 18

Do not install flexible tails where subject to ultra violet light.

Static Inlet pressure range : 150-1000 kPa

New Regulation:- 500 kPa maximum static pressure 16

at any outlet within a building. 17

(Ref. AS/NZS 3500.1-2003, Clause 3.3.4)

Maximum hot water temperature : 80 C.

Deck Requirements Fig. 1

Distributed by:

Deck thickness : 45mm maximum (SIDE 1 OF 2)

Dorf Clark Industries Limited

Tap body hole (in deck) : 34-36mm

ABN 23 004 394 923 IS1115A(05/11)

FLICKMIXER PLUS - SINK MIXER

WATER EFFICIENT TAPWARE

(NOMINAL FLOW RATE = 7 L/min)

PLUMBERS ADJUSTMENT INSTRUCTIONS 7

Adjusting the HOT LIMIT RING (ANTI-SCALD STOP RING)

The cartridge fitted in this mixer has been factory pre-set to deliver

the maximum available hot water temperature. To use the ANTI-SCALD

feature adjust the cartridge as follows:-

Carefully remove plug (4). Using 2.5mm allen key (3) loosen screw (2)

and remove handle (1). Unscrew cap (5) taking care not to damage the

decorative finish. (See details on side 1 of this sheet.)

To remove the Hot Limit Ring (7) from the cartridge (9), use a small thin

flat bladed screwdriver and carefully lever in an upwards direction.

Rotate the Ring (7) in a clockwise direction then refit the Ring (7) onto

the cartridge (9).

Note:- Start by rotating the Ring (7) in small increments, then check the

hot water temperature with the mixer handle in the fully open maximum

hot water position. The Ring (7) can be removed & repositioned until the

desired maximum hot water temperature is achieved.

Ensure the Ring (7) is pushed fully down onto the cartridge (9), then replace

cap (5), tightening by hand. Fit handle (1), taking care that it is pushed

fully down, tighten screw (2) and replace plug (4). 9

Fig. 2

Adjusting the WATER VOLUME LIMIT SCREW

The cartridge fitted in this mixer has been factory pre-set to deliver

the maximum flow of water when the mixer handle is in the fully open

position. However the flow of water may be reduced by adjusting 8

the cartridge as follows:-

Carefully remove plug (4). Using 2.5mm allen key (3) loosen screw (2)

and remove handle (1). Unscrew cap (5) taking care not to damage the

decorative finish. (See details on side 1 of this sheet.)

Using a small thin flat bladed screwdriver, adjust screw (8) in an anti-clockwise

9

direction.

Note:- Start by rotating the Screw (8) in small amounts then check the

flow of water with the mixer handle in the fully open position. Readjust

the screw until the desired water flow is achieved.

Replace cap (5), tightening by hand. Fit handle (1), taking care that it is

pushed fully down, tighten screw (2) and replace plug (4).

Fig. 3

Distributed by:

Dorf Clark Industries Limited (SIDE 2 OF 2)

ABN 23 004 394 923 IS1115A(05/11)

You might also like

- Elasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyFrom EverandElasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyNo ratings yet

- 019061-InstallationGuideDocument1 page019061-InstallationGuidehadrian luciferNo ratings yet

- 134649-InstallationGuide PDFDocument1 page134649-InstallationGuide PDFthadNo ratings yet

- Posh Solus Mkii Basin Mixer 9502635 Tech WarrantyDocument3 pagesPosh Solus Mkii Basin Mixer 9502635 Tech WarrantymainpersonNo ratings yet

- 6567 905A BK File InstallationGuidelines 151313 Ori 2016sep20132637Document1 page6567 905A BK File InstallationGuidelines 151313 Ori 2016sep20132637Suresh ChajjedNo ratings yet

- Operation and Maintenance: Model 873-400 RegulatorDocument2 pagesOperation and Maintenance: Model 873-400 Regulatorilham rusdyNo ratings yet

- 873 400 Regulator Operation and Maintenance ManualDocument2 pages873 400 Regulator Operation and Maintenance ManualHassan KhattabNo ratings yet

- Fpg18Fb Manual Oil Return Kit (826-1517) Installation InstructionsDocument1 pageFpg18Fb Manual Oil Return Kit (826-1517) Installation InstructionsServicios y Repuestos Jeremy Azhael 2320 C.ANo ratings yet

- Manual - Filtru AQUAPHOR - CrystallDocument28 pagesManual - Filtru AQUAPHOR - Crystallgeta_danilaNo ratings yet

- 480 QuadrigageInstructionsDocument2 pages480 QuadrigageInstructionsjohn deereNo ratings yet

- Assembling Shift Housing ComponentsDocument2 pagesAssembling Shift Housing ComponentsThylaneNo ratings yet

- Aquaphor Crystall Product ManualDocument28 pagesAquaphor Crystall Product ManualChrisNo ratings yet

- Ultramat Plus Pneumo UFM PDocument6 pagesUltramat Plus Pneumo UFM PIsraelNo ratings yet

- Piper Seneca II Magneto Service ManualDocument9 pagesPiper Seneca II Magneto Service ManualTríade MusicNo ratings yet

- Inspeção de MagnetoDocument9 pagesInspeção de MagnetoTríade MusicNo ratings yet

- Amt Owner's ManualDocument8 pagesAmt Owner's ManuallrolindoNo ratings yet

- Manual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066Document2 pagesManual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066marklaforestNo ratings yet

- EPIC BLOC PROGRESSIVE BATH/SHOWER MIXER INSTALL GUIDEDocument1 pageEPIC BLOC PROGRESSIVE BATH/SHOWER MIXER INSTALL GUIDESuresh ChajjedNo ratings yet

- GR - WRDSP - Tech LiteratureDocument7 pagesGR - WRDSP - Tech LiteratureDigger Downhole ToolsNo ratings yet

- 4-06 Tandem Side Loading Stripper PackerDocument14 pages4-06 Tandem Side Loading Stripper PackerDEATH ASSASSIN GAMERNo ratings yet

- 3-06 Tandem Side Loading Stripper PackerDocument14 pages3-06 Tandem Side Loading Stripper PackerDEATH ASSASSIN GAMERNo ratings yet

- Compressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveDocument3 pagesCompressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveThylaneNo ratings yet

- Compressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveDocument3 pagesCompressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveThylaneNo ratings yet

- Fluid FaucetDocument2 pagesFluid Faucetmember1000No ratings yet

- Hutchride 2000: Completion Kit Parts & InstallationDocument4 pagesHutchride 2000: Completion Kit Parts & InstallationMario RodríguezNo ratings yet

- LZWSM8 (D) (P)Document7 pagesLZWSM8 (D) (P)marinanagy211No ratings yet

- XTV Trip ValvesDocument4 pagesXTV Trip ValvesBharath Nadimpalli50% (4)

- Series 42 Self-Operated Regulators ANSI Version: T 3010 EN Type 42-10 RS Check Valve (Backflow Protection)Document8 pagesSeries 42 Self-Operated Regulators ANSI Version: T 3010 EN Type 42-10 RS Check Valve (Backflow Protection)Yesid RodríguezNo ratings yet

- 43.88UK Mechanical Seal Replacement Instructions TCDocument4 pages43.88UK Mechanical Seal Replacement Instructions TCMohammed Mostafa El HaddadNo ratings yet

- Hvac Equipment Hanging Detail 1: SD SDDocument1 pageHvac Equipment Hanging Detail 1: SD SDSami KhouryNo ratings yet

- 43 88 - Mechanical - Seal - Replacement - Instructions - TCDocument4 pages43 88 - Mechanical - Seal - Replacement - Instructions - TCAlan MercesNo ratings yet

- Group 4 Disassembly and Assembly: 1. Main PumpDocument23 pagesGroup 4 Disassembly and Assembly: 1. Main PumpPriscila RodriguesNo ratings yet

- Compass R Volute Replacement InstructionsDocument6 pagesCompass R Volute Replacement InstructionsGOWTHAMNo ratings yet

- KIKAWA Manual kp8 enDocument4 pagesKIKAWA Manual kp8 enRamesh KrishmedaNo ratings yet

- Fitting InstructionDocument6 pagesFitting InstructionAan Sarkasi AmdNo ratings yet

- Airvac Portable Vacuum Recovery SystemDocument8 pagesAirvac Portable Vacuum Recovery SystemEngTamerNo ratings yet

- Group 7 RCV Lever Removal and InstallationDocument15 pagesGroup 7 RCV Lever Removal and InstallationRafał DworakNo ratings yet

- KIKAWA Manual KQ enDocument6 pagesKIKAWA Manual KQ enkanokNo ratings yet

- Hydraulic Stuffing Box Technical ManualDocument8 pagesHydraulic Stuffing Box Technical ManualsambhajiNo ratings yet

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 pagesOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNo ratings yet

- T 8546-2 EN SAMSTATION Type 7029 Supply Pressure Regulator: ApplicationDocument8 pagesT 8546-2 EN SAMSTATION Type 7029 Supply Pressure Regulator: ApplicationagrovadoNo ratings yet

- Pacific Water - Utah - Series 960 Manual WMDocument24 pagesPacific Water - Utah - Series 960 Manual WMGreg ReynekeNo ratings yet

- Racor Fuel Filtration - Turbine-Rebuild-Instructions - 7734Document2 pagesRacor Fuel Filtration - Turbine-Rebuild-Instructions - 7734Alfonso Alberto ArguelloNo ratings yet

- 3-06 Side Loading StripperDocument28 pages3-06 Side Loading StripperDEATH ASSASSIN GAMERNo ratings yet

- Lm-827 Maintenance ManualDocument25 pagesLm-827 Maintenance ManualElmer VillegasNo ratings yet

- Oceanic Delta 4Document14 pagesOceanic Delta 4afs121196No ratings yet

- Rci 400 Series Installation & Maintenance InstructionsDocument2 pagesRci 400 Series Installation & Maintenance InstructionsSandro MartinezNo ratings yet

- Roatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5ADocument7 pagesRoatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5AtungNo ratings yet

- Im 306Document10 pagesIm 306Iwan SetiawanNo ratings yet

- AEROMATIC LTD. Fluid Bed Dryer PDFDocument13 pagesAEROMATIC LTD. Fluid Bed Dryer PDFManuel Molina KorsNo ratings yet

- Sanroc Mini P/H/E: Operating and Maintenance Instructions and Spare Parts ListDocument36 pagesSanroc Mini P/H/E: Operating and Maintenance Instructions and Spare Parts ListAlexanderNo ratings yet

- Ls400 (Deutzengine) : Cold Start Relay KitDocument10 pagesLs400 (Deutzengine) : Cold Start Relay KitALEJONo ratings yet

- Manual Sillon Olsen PDFDocument14 pagesManual Sillon Olsen PDFbrisaNo ratings yet

- Montacarga Eléctrico 25bt HyundaiDocument24 pagesMontacarga Eléctrico 25bt HyundaimichaelshelterNo ratings yet

- Adjusting Shift Fork 16 S 221, 16 S 181, 8 S 181Document3 pagesAdjusting Shift Fork 16 S 221, 16 S 181, 8 S 181ThylaneNo ratings yet

- Ficha Manual Ingles Pluviometro LambrechtDocument8 pagesFicha Manual Ingles Pluviometro LambrechtMarcelo Alberto AiresNo ratings yet

- Manual Arranque NeumaticoDocument52 pagesManual Arranque NeumaticoSabry Socarrás AarónNo ratings yet

- Installation instructions for master solenoid kitDocument1 pageInstallation instructions for master solenoid kitGuilherme ZoboliNo ratings yet

- A 1020Document16 pagesA 1020Pong KrubNo ratings yet

- Fixed Nozzle DesuperheatersDocument16 pagesFixed Nozzle DesuperheatersChan PhingNo ratings yet

- How To Flip The Magnet On Spooky Remote v1.1Document4 pagesHow To Flip The Magnet On Spooky Remote v1.1testnationNo ratings yet

- Book 5 Music AlphabeticalDocument1 pageBook 5 Music AlphabeticaltestnationNo ratings yet

- Nokia - Web Based Provision Configuration Guide For Symbian ClientsDocument9 pagesNokia - Web Based Provision Configuration Guide For Symbian ClientstestnationNo ratings yet

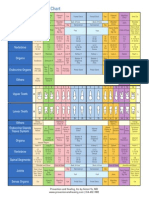

- Tooth-Organ Meridian Chart: Sense Organs Joints Spinal Segments Vertebrae OrgansDocument1 pageTooth-Organ Meridian Chart: Sense Organs Joints Spinal Segments Vertebrae Organsmoumona100% (1)

- Book 7 Music Alphabetical PianoDocument1 pageBook 7 Music Alphabetical PianotestnationNo ratings yet

- Book 6 Music AlphabeticalDocument2 pagesBook 6 Music AlphabeticaltestnationNo ratings yet

- Book 2 Music AlphabeticalDocument1 pageBook 2 Music AlphabeticaltestnationNo ratings yet

- Due Diligence QuestionnaireDocument5 pagesDue Diligence QuestionnairetestnationNo ratings yet

- Book Music Master List Alphabetical v2Document1 pageBook Music Master List Alphabetical v2testnationNo ratings yet

- Book 6: Faithfully (Journey) For The First Time v3 Right Here Waiting That's What Friends Are ForDocument2 pagesBook 6: Faithfully (Journey) For The First Time v3 Right Here Waiting That's What Friends Are FortestnationNo ratings yet

- 40+ Songs for Relaxation and ReflectionDocument1 page40+ Songs for Relaxation and ReflectiontestnationNo ratings yet

- Book 7 Music PianoDocument1 pageBook 7 Music PianotestnationNo ratings yet

- Book 4 Music AlphabeticalDocument1 pageBook 4 Music AlphabeticaltestnationNo ratings yet

- 40+ Songs for Relaxation and ReflectionDocument1 page40+ Songs for Relaxation and ReflectiontestnationNo ratings yet

- Book 8 Collection of Popular SongsDocument2 pagesBook 8 Collection of Popular SongstestnationNo ratings yet

- Book 3 Music AlphabeticalDocument1 pageBook 3 Music AlphabeticaltestnationNo ratings yet

- The Energy Grid - Harmonic 695 PDFDocument1 pageThe Energy Grid - Harmonic 695 PDFtestnationNo ratings yet

- Book 3 Music Piano ListDocument1 pageBook 3 Music Piano ListtestnationNo ratings yet

- Funding Your Retirement Max Newnham P 266-267Document1 pageFunding Your Retirement Max Newnham P 266-267testnationNo ratings yet

- Funding Your Retirement Max Newnham P 266-267 PDFDocument1 pageFunding Your Retirement Max Newnham P 266-267 PDFtestnationNo ratings yet

- FileDocument5 pagesFiletestnationNo ratings yet

- FilelistingDocument5 pagesFilelistingtestnationNo ratings yet

- Move BGL Software To A New Stand-Alone PC or LaptopDocument13 pagesMove BGL Software To A New Stand-Alone PC or LaptoptestnationNo ratings yet

- Homeopathic Potencies For Remedy MakerDocument1 pageHomeopathic Potencies For Remedy MakertestnationNo ratings yet

- NONLINEAR (NLS) DIAGNOSTIC SYSTEMS (Basic Physics and Principles of Equipment)Document13 pagesNONLINEAR (NLS) DIAGNOSTIC SYSTEMS (Basic Physics and Principles of Equipment)testnation100% (1)

- Using 4 Generators For Effective Cancer TreatmentDocument9 pagesUsing 4 Generators For Effective Cancer TreatmenttestnationNo ratings yet

- Healing Codes WorkbookDocument77 pagesHealing Codes Workbookdeepflm100% (1)

- 2011 Giant Cypress 3 SpecificationsDocument2 pages2011 Giant Cypress 3 SpecificationstestnationNo ratings yet

- Australian Trailer Plug Wiring InfoDocument1 pageAustralian Trailer Plug Wiring InfotestnationNo ratings yet

- 2011 Giant Suede SpecificationsDocument1 page2011 Giant Suede SpecificationstestnationNo ratings yet

- Etabloc Technical DataDocument108 pagesEtabloc Technical Dataedward ksbNo ratings yet

- Pricelist Mobil Area Jabodetabek Semester 2 2022 TerbaruDocument108 pagesPricelist Mobil Area Jabodetabek Semester 2 2022 TerbarutonymuzioNo ratings yet

- Sepuran® N Module 4": in NM /H at 7 Barg 25°CDocument2 pagesSepuran® N Module 4": in NM /H at 7 Barg 25°CsanjaigNo ratings yet

- Specification IC DK112Document10 pagesSpecification IC DK112ROlando EskadabaichoNo ratings yet

- 2tak Vs 4takDocument3 pages2tak Vs 4takTaufiq AlhakimNo ratings yet

- Prometheus BoundDocument10 pagesPrometheus BoundPhillip HosfeldtNo ratings yet

- Verbal ReasoningDocument8 pagesVerbal ReasoningyasirNo ratings yet

- Misamis Occidental Plans to Protect Aquamarine ResourceDocument8 pagesMisamis Occidental Plans to Protect Aquamarine ResourcejelosalisaliNo ratings yet

- Business Plan of Easy Meal ServiceDocument41 pagesBusiness Plan of Easy Meal ServiceCeddie UnggayNo ratings yet

- داينمك الملزمة كاملةDocument79 pagesداينمك الملزمة كاملةarno assassin33% (3)

- Aac Block Adhesive: Product DescriptionDocument2 pagesAac Block Adhesive: Product DescriptionmaznahNo ratings yet

- Ammonia Tech Manual 2002Document28 pagesAmmonia Tech Manual 2002Talha Bin Zubair0% (1)

- General Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsDocument108 pagesGeneral Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsharleyNo ratings yet

- CSSBI Tablas de Carga Perfiles PDFDocument60 pagesCSSBI Tablas de Carga Perfiles PDFRamón RocaNo ratings yet

- ECC Report: Mobile Coverage ObligationsDocument77 pagesECC Report: Mobile Coverage ObligationsRedamichael JemberuNo ratings yet

- Starter Unit Basic Vocabulary: Smart Planet 3Document21 pagesStarter Unit Basic Vocabulary: Smart Planet 3Rober SanzNo ratings yet

- CHM Analysis and Comparisons of CRUS MULTHULLS2013Document60 pagesCHM Analysis and Comparisons of CRUS MULTHULLS2013kkd108No ratings yet

- HTTP Verbs GET POST PUT PATCH DELETE (39Document12 pagesHTTP Verbs GET POST PUT PATCH DELETE (39Jefferson EducacionNo ratings yet

- Dr. Carlos S. Lanting College: College of Maritime EducationDocument14 pagesDr. Carlos S. Lanting College: College of Maritime EducationJeynard Moler J. TanNo ratings yet

- Filtros MaquinasDocument34 pagesFiltros MaquinasAndres AlfonzoNo ratings yet

- Spectrophotometric Determination of Triclosan Based On Diazotization Reaction: Response Surface Optimization Using Box - Behnken DesignDocument1 pageSpectrophotometric Determination of Triclosan Based On Diazotization Reaction: Response Surface Optimization Using Box - Behnken DesignFitra NugrahaNo ratings yet

- Brosur Sy135cDocument9 pagesBrosur Sy135cDenny KurniawanNo ratings yet

- ChecklistsDocument1 pageChecklistsnotme2120No ratings yet

- Study Plan NCEPU PDFDocument2 pagesStudy Plan NCEPU PDFAhsan100% (1)

- AkzoNobel-Trigonox 239Document6 pagesAkzoNobel-Trigonox 239Wafa AjiliNo ratings yet

- Error Correction - Test 1Document4 pagesError Correction - Test 1phucnguyen0429No ratings yet

- 43-101 Technical Report Quimsacocha, February 2009Document187 pages43-101 Technical Report Quimsacocha, February 2009Marco Vinicio SotoNo ratings yet

- Exogenous Driver Analysis Driver Relative GDP GrowthDocument107 pagesExogenous Driver Analysis Driver Relative GDP GrowthBhagya FoodsNo ratings yet

- 4TWX4036 Service FactsDocument4 pages4TWX4036 Service FactsAlejandro OrdoñezNo ratings yet

- Blower Selection For Wastewater Aeration PDFDocument10 pagesBlower Selection For Wastewater Aeration PDFRobert MontoyaNo ratings yet