Professional Documents

Culture Documents

Asa Rubric

Uploaded by

api-313716520Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asa Rubric

Uploaded by

api-313716520Copyright:

Available Formats

AUTOMOTIVE SERVICE TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE ASA3400: BASIC TOOLS & MATERIALS

Level: First Period Apprenticeship, Section One

Prerequisite: ASA3900: Apprenticeship Safety

Description: Students develop knowledge, skills and attitudes to use workshop specialty hand tools, measuring tools and fasteners.

Parameters: Access to a materials work centre, complete with basic measuring tools, specialty hand tools and fastening devices, and to

instruction from an individual with specialized training and/or an automotive service technician.

ILM Resources: Measuring Tools 090101e; Specialty Hand Tools 090101f; Fastening Devices 090101g

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3400 / 1

Alberta Education, Alberta, Canada 2015

COURSE ASA3400: BASIC TOOLS & MATERIALS

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. demonstrate the correct use

of measuring tools common

to the trade

2. demonstrate the correct use

of hand tools common to the

trade

3. assemble components, using

a variety of fasteners,

adhesives and sealers

common to the trade

Teacher Signature Date

2 / CTS, TMT: ASA3400 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE ASA3400: BASIC TOOLS & MATERIALS

Rubric

Student Name: Date:

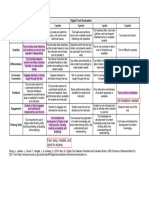

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. demonstrate the correct use of measuring tools common to the trade

1.1 perform calculations I can consistently I can usually perform I sometimes need I often need assistance I have not yet

related to measurement perform calculations calculations related to assistance to perform to perform calculations provided evidence of

using imperial and metric related to measurement measurement using calculations related to related to measurement this performance task.

units using imperial and imperial and metric measurement using using imperial and

metric units. units. imperial and metric metric units.

units.

1.2 perform linear I can consistently I can usually perform I sometimes need I often need assistance I have not yet

measurements using basic perform linear linear measurements assistance to perform to perform linear provided evidence of

non-precision measuring measurements using using basic linear measurements measurements using this performance task.

tools basic non-precision non-precision using basic basic non-precision

measuring tools. measuring tools. non-precision measuring tools.

measuring tools.

1.3 perform linear I can consistently I can usually perform I sometimes need I often need assistance I have not yet

measurements using perform linear linear measurements assistance to perform to perform linear provided evidence of

precision measuring tools measurements using using precision linear measurements measurements using this performance task.

precision measuring measuring tools. using precision precision measuring

tools. measuring tools. tools.

1.4 perform accurate torque I can consistently I can usually perform I sometimes need I often need assistance I have not yet

measurements perform accurate torque accurate torque assistance to perform to perform accurate provided evidence of

measurements. measurements. accurate torque torque measurements. this performance task.

measurements.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3400 / 3

Alberta Education, Alberta, Canada 2015

2. demonstrate the correct use of hand tools common to this trade

2.1 perform double lap and SI I can consistently I can usually perform I sometimes need I often need assistance I have not yet

tube flaring perform double lap and double lap and SI tube assistance to perform to perform double lap provided evidence of

SI tube flaring. flaring. double lap and SI tube and SI tube flaring. this performance task.

flaring.

2.2 demonstrate knowledge I can consistently I can usually I sometimes need I often need assistance I have not yet

and use of drills and demonstrate knowledge demonstrate assistance to to demonstrate provided evidence of

reamers and use of drills and knowledge and use of demonstrate knowledge knowledge and use of this performance task.

reamers. drills and reamers. and use of drills and drills and reamers.

reamers.

2.3 demonstrate knowledge I can consistently I can usually I sometimes need I often need assistance I have not yet

and correct use of taps and demonstrate knowledge demonstrate assistance to to demonstrate provided evidence of

dies and use of taps and knowledge and use of demonstrate knowledge knowledge and use of this performance task.

dies. taps and dies. and use of taps and dies. taps and dies.

2.4 demonstrate thread repair I can consistently I can usually I sometimes need I often need assistance I have not yet

and broken fastener demonstrate thread demonstrate thread assistance to to demonstrate thread provided evidence of

removal repair and broken repair and broken demonstrate thread repair and broken this performance task.

fastener removal. fastener removal. repair and broken fastener removal.

fastener removal.

2.5 describe types, uses and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

care of hammers describe types, uses and types, uses and care of assistance to describe to describe types, uses provided evidence of

care of hammers. hammers. types, uses and care of and care of hammers. this performance task.

hammers.

2.6 describe the types, uses I can consistently I can usually describe I sometimes need I often need assistance I have not yet

and care of screwdrivers describe the types, uses the types, uses and assistance to describe to describe the types, provided evidence of

and care of care of screwdrivers. the types, uses and care uses and care of this performance task.

screwdrivers. of screwdrivers screwdrivers.

2.7 identify the various types I can consistently I can usually identify I sometimes need I often need assistance I have not yet

of punches and their uses identify the various the various types of assistance to identify to identify the various provided evidence of

types of punches and punches and their the various types of types of punches and this performance task.

their uses. uses. punches and their uses. their uses.

4 / CTS, TMT: ASA3400 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

2.8 identify the various types I can consistently I can usually identify I sometimes need I often need assistance I have not yet

of chisels and their uses identify the various the various types of assistance to identify to identify the various provided evidence of

types of chisels and chisels and their uses. the various types of types of chisels and this performance task.

their uses. chisels and their uses. their uses.

2.9 describe the various I can consistently I can usually describe I sometimes need I often need assistance I have not yet

types of wrenches and describe the various the various types of assistance to describe to describe the various provided evidence of

their uses types of wrenches and wrenches and their the various types of types of wrenches and this performance task.

their uses. uses. wrenches and their their uses.

uses.

2.10 identify the various types I can consistently I can usually identify I sometimes need I often need assistance I have not yet

of pliers and their uses identify the various the various types of assistance to identify to identify the various provided evidence of

types of pliers and their pliers and their uses. the various types of types of pliers and their this performance task.

uses. pliers and their uses. uses.

2.11 identify various types of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

holding devices identify various types various types of assistance to identify to identify various types provided evidence of

of holding devices. holding devices. various types of holding of holding devices. this performance task.

devices.

2.12 identify the various tools I can consistently I can usually identify I sometimes need I often need assistance I have not yet

for removing broken identify the various the various tools for assistance to identify to identify the various provided evidence of

fasteners and explain tools for removing removing broken the various tools for tools for removing this performance task.

how to use them broken fasteners and fasteners and explain removing broken broken fasteners and

explain how to use how to use them. fasteners and explain explain how to use

them. how to use them. them.

2.13 describe the procedures I can consistently I can usually describe I sometimes need I often need assistance I have not yet

required to safely operate describe the procedures the procedures assistance to describe to describe the provided evidence of

various types and required to safely required to safely the procedures required procedures required to this performance task.

capacities of shop puller operate various types operate various types to safely operate safely operate various

and capacities of shop and capacities of shop various types and types and capacities of

and pressing equipment

puller and pressing puller and pressing capacities of shop puller shop puller and pressing

equipment. equipment. and pressing equipment. equipment.

2.14 describe and use cutting I can consistently I can usually describe I sometimes need I often need assistance I have not yet

hand tools common to describe and use cutting and use cutting hand assistance to describe to describe and use provided evidence of

the trade hand tools common to tools common to the and use cutting hand cutting hand tools this performance task.

the trade. trade. tools common to the common to the trade.

trade.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3400 / 5

Alberta Education, Alberta, Canada 2015

2.15 demonstrate how to I can consistently I can usually I sometimes need I often need assistance I have not yet

sharpen a twist drill demonstrate how to demonstrate how to assistance to to demonstrate how to provided evidence of

sharpen a twist drill. sharpen a twist drill. demonstrate how to sharpen a twist drill. this performance task.

sharpen a twist drill.

2.16 identify tools and I can consistently I can usually identify I sometimes need I often need assistance I have not yet

demonstrate proper identify tools and tools and demonstrate assistance to identify to identify tools and provided evidence of

thread repair techniques demonstrate proper proper thread repair tools and demonstrate demonstrate proper this performance task.

thread repair techniques. proper thread repair thread repair

techniques. techniques. techniques.

2.17 demonstrate the use of I can consistently I can usually I sometimes need I often need assistance I have not yet

tubing flaring tools; sheet demonstrate the use of demonstrate the use of assistance to to demonstrate the use provided evidence of

abrasives and grinding tubing flaring tools; tubing flaring tools; demonstrate the use of of tubing flaring tools; this performance task.

compounds; and lapping sheet abrasives and sheet abrasives and tubing flaring tools; sheet abrasives and

grinding compounds; grinding compounds; sheet abrasives and grinding compounds;

blocks and honing stones

and lapping blocks and and lapping blocks grinding compounds; and lapping blocks and

honing stones. and honing stones. and lapping blocks and honing stones.

honing stones.

2.18 demonstrate the care and I can consistently I can usually I sometimes need I often need assistance I have not yet

safe use of common demonstrate the care demonstrate the care assistance to to demonstrate the care provided evidence of

hand tools and safe use of common and safe use of demonstrate the care and safe use of common this performance task.

power hand tools. common power hand and safe use of common power hand tools.

tools. power hand tools.

2.19 demonstrate knowledge I can consistently I can usually I sometimes need I often need assistance I have not yet

of personal safety demonstrate knowledge demonstrate assistance to to demonstrate provided evidence of

equipment (PPE) and of personal safety knowledge of personal demonstrate knowledge knowledge of personal this performance task.

tool safety equipment (PPE) and safety equipment of personal safety safety equipment (PPE)

tool safety. (PPE) and tool safety. equipment (PPE) and and tool safety.

tool safety.

6 / CTS, TMT: ASA3400 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

3. assemble components, using a variety of fasteners, adhesives and sealers common to the trade

3.1 demonstrate fastening and I can consistently I can usually I sometimes need I often need assistance I have not yet

torquing procedures using demonstrate fastening demonstrate fastening assistance to to demonstrate provided evidence of

threaded fasteners and torquing procedures and torquing demonstrate fastening fastening and torquing this performance task.

using threaded procedures using and torquing procedures procedures using

fasteners. threaded fasteners. using threaded threaded fasteners.

fasteners.

3.2 demonstrate the use of I can consistently I can usually I sometimes need I often need assistance I have not yet

other retaining devices demonstrate the use of demonstrate the use of assistance to to demonstrate the use provided evidence of

other retaining devices. other retaining demonstrate the use of of other retaining this performance task.

devices. other retaining devices. devices.

3.3 demonstrate the use of I can consistently I can usually I sometimes need I often need assistance I have not yet

sealers and adhesives demonstrate the use of demonstrate the use of assistance to to demonstrate the use provided evidence of

common to the trade sealers and adhesives sealers and adhesives demonstrate the use of of sealers and adhesives this performance task.

common to the trade. common to the trade. sealers and adhesives common to the trade.

common to the trade.

3.4 describe tools and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

procedures used for describe tools and tools and procedures assistance to describe to describe tools and provided evidence of

plastic trim fasteners procedures used for used for plastic trim tools and procedures procedures used for this performance task.

plastic trim fasteners. fasteners. used for plastic trim plastic trim fasteners.

fasteners.

Teacher feedback and

assessment.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3400 / 7

Alberta Education, Alberta, Canada 2015

AUTOMOTIVE SERVICE TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE ASA3402: VEHICLE SERVICE INFORMATION

Level: First Period Apprenticeship, Section One

Prerequisites: ASA3900: Apprenticeship Safety

ASA3400: Basic Tools & Materials

Description: Students develop the necessary knowledge, skills and attitudes to use electronic service information and scan tools in

the servicing and repair of vehicles, and perform metal heating and cutting operations safely by using oxyacetylene

equipment.

Parameters: Access to a materials work centre, complete with related service information tools and technologies, scan and test

equipment and oxyacetylene equipment, and to instruction from an individual with journeyperson certification as an

automotive service technician.

ILM Resources: Electronic Service Information 090101h; Oxyacetylene Heating and Cutting 090101i; Scan Tools 090104f

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

8 / CTS, TMT: ASA3402 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3402 / 9

Alberta Education, Alberta, Canada 2015

COURSE ASA3402: VEHICLE SERVICE INFORMATION

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. use electronic service

information from various

sources when diagnosing,

servicing or repairing

vehicles

2. use generic, manufacturer-

specific or laptop-based scan

tools and software

3. perform metal heating and

cutting operations safely

using oxyacetylene

equipment

Teacher Signature Date

10 / CTS, TMT: ASA3402 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE ASA3402: VEHICLE SERVICE INFORMATION

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. use electronic service information from various sources when diagnosing, servicing or repairing vehicles

1.1 use electronic service I can consistently use I can usually use I sometimes need I often need assistance I have not yet

information to diagnose, electronic service electronic service assistance to use to use electronic service provided evidence of

service or repair vehicles information to information to electronic service information to diagnose this performance task.

diagnose, service or diagnose service or information to diagnose service or repair

repair vehicles. repair vehicles. service or repair vehicles.

vehicles.

1.2 access vehicle repair or I can consistently I can usually access I sometimes need I often need assistance I have not yet

service forums and online access vehicle repair or vehicle repair or assistance to access to access vehicle repair provided evidence of

discussion groups for service forums and service forums and vehicle repair or service or service forums and this performance task.

diagnostic purposes online discussion online discussion forums and online online discussion

groups for diagnostic groups for diagnostic discussion groups for groups for diagnostic

purposes. purposes. diagnostic purposes. purposes.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3402 / 11

Alberta Education, Alberta, Canada 2015

2. use generic, manufacturer-specific or laptop-based scan tools and software

2.1 use scan tools to retrieve I can consistently use I can usually use scan I sometimes need I often need assistance I have not yet

diagnostic trouble codes scan tools to retrieve tools to retrieve assistance to use scan to use scan tools to provided evidence of

and data, clear codes, reset diagnostic trouble codes diagnostic trouble tools to retrieve retrieve diagnostic this performance task.

warning systems and and data, clear codes, codes and data, clear diagnostic trouble codes trouble codes and data,

reset warning systems codes, reset warning and data, clear codes, clear codes, reset

perform function tests

and perform function systems and perform reset warning systems warning systems and

tests. function tests. and perform function perform function tests.

tests.

2.2 analyze and interpret scan I can consistently I can usually analyze I sometimes need I often need assistance I have not yet

data related to first period analyze and interpret and interpret scan data assistance to analyze to analyze and interpret provided evidence of

automotive systems scan data related to first related to first period and interpret scan data scan data related to first this performance task.

period automotive automotive systems. related to first period period automotive

systems. automotive systems. systems.

3. perform metal heating and cutting operations safely using oxyacetylene equipment

3.1 describe the characteristics I can consistently I can usually I sometimes need I often need assistance I have not yet

and handling procedures describe the describe the assistance to describe to describe the provided evidence of

for oxygen and acetylene characteristics and characteristics and the characteristics and characteristics and this performance task.

handling procedures for handling procedures handling procedures for handling procedures for

oxygen and acetylene. for oxygen and oxygen and acetylene. oxygen and acetylene.

acetylene.

3.2 demonstrate handling I can consistently I can usually I sometimes need I often need assistance I have not yet

procedures for regulators demonstrate handling demonstrate handling assistance to to demonstrate handling provided evidence of

(single- and two-stage), procedures for procedures for demonstrate handling procedures for this performance task.

hoses and check valves regulators (single- and regulators (single- and procedures for regulators (single- and

two-stage), hoses and two-stage), hoses and regulators (single- and two-stage), hoses and

check valves. check valves. two-stage), hoses and check valves.

check valves.

3.3 demonstrate the use, care I can consistently I can usually I sometimes need I often need assistance I have not yet

and maintenance of demonstrate the use, demonstrate the use, assistance to to demonstrate the use, provided evidence of

torches and tips care and maintenance care and maintenance demonstrate the use, care and maintenance of this performance task.

of torches and tips. of torches and tips. care and maintenance of torches and tips.

torches and tips.

12 / CTS, TMT: ASA3402 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

3.4 perform basic cutting I can consistently I can usually perform I sometimes need I often need assistance I have not yet

operations perform basic cutting basic cutting assistance to perform to perform basic cutting provided evidence of

operations. operations. basic cutting operations. operations. this performance task.

3.5 use personal protective I can consistently use I can usually use I sometimes need I often need assistance I have not yet

equipment (PPE) when personal protective personal protective assistance to use to use personal provided evidence of

heating or cutting equipment (PPE) when equipment (PPE) personal protective protective equipment this performance task.

heating or cutting. when heating or equipment (PPE) when (PPE) when heating or

cutting. heating or cutting. cutting.

Teacher feedback and

assessment.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3402 / 13

Alberta Education, Alberta, Canada 2015

AUTOMOTIVE SERVICE TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE ASA3405: ELECTRICAL PRINCIPLES

Level: First Period Apprenticeship, Section Four

Prerequisites: ASA3900: Apprenticeship Safety

ASA3400: Basic Tools & Materials

ASA3402: Vehicle Service Information

Description: Students develop the knowledge, skills and attitudes necessary to understand how electricity is created, stored and used

to support the requirements of the automobile.

Parameters: Access to a materials work centre, complete with hand tools, specialized tools and related resources, and to instruction

from an individual with journeyperson certification as an automotive service technician

ILM Resources: Electrical Fundamentals 1 090104a; Fundamentals of Magnetism 090104c; Batteries 090104d

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

14 / CTS, TMT: ASA3405 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE ASA3405: ELECTRICAL PRINCIPLES

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. explain basic electrical

principles

2. apply scientific principles to

explain the theory of

magnetism

3. diagnose and service

batteries

Teacher Signature Date

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3405 / 15

Alberta Education, Alberta, Canada 2015

COURSE ASA3405: ELECTRICAL PRINCIPLES

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. explain basic electrical principles

1.1 explain the physical I can consistently I can usually explain I sometimes need I often need assistance I have not yet

properties of insulators, explain the physical the physical properties assistance to explain the to explain the physical provided evidence

conductors and properties of insulators, of insulators, physical properties of properties of insulators, of this performance

semi-conductors conductors and conductors and insulators, conductors conductors and task.

semi-conductors. semi-conductors. and semi-conductors. semi-conductors.

1.2 explain electricity in terms I can consistently I can usually explain I sometimes need I often need assistance I have not yet

of voltage, current and explain electricity in electricity in terms of assistance to explain to explain electricity in provided evidence

resistance terms of voltage, voltage, current and electricity in terms of terms of voltage, of this performance

current and resistance. resistance. voltage, current and current and resistance. task.

resistance.

2. apply scientific principles to explain the theory of magnetism

2.1 explain the fundamental I can consistently I can usually explain I sometimes need I often need assistance I have not yet

laws of magnetism explain the fundamental the fundamental laws of assistance to explain the to explain the provided evidence

laws of magnetism. magnetism. fundamental laws of fundamental laws of of this performance

magnetism. magnetism. task.

2.2 explain the construction and I can consistently I can usually explain I sometimes need I often need assistance I have not yet

operation of explain the construction the construction and assistance to explain the to explain the provided evidence

electromagnetic coils and operation of operation of construction and construction and of this performance

electromagnetic coils. electromagnetic coils. operation of operation of task.

electromagnetic coils. electromagnetic coils.

16 / CTS, TMT: ASA3405 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

2.3 describe how magnetism or I can consistently I can usually describe I sometimes need I often need assistance I have not yet

electromagnetism can describe how how magnetism or assistance describe how to describe how provided evidence

change electrical energy magnetism or electromagnetism can magnetism or magnetism or of this performance

into mechanical energy electromagnetism can change electrical energy electromagnetism can electromagnetism can task.

change electrical energy into mechanical energy. change electrical energy change electrical energy

into mechanical energy. into mechanical energy. into mechanical energy.

2.4 describe how magnetism or I can consistently I can usually describe I sometimes need I often need assistance I have not yet

electromagnetism can describe how how magnetism or assistance to describe to describe how provided evidence

change mechanical energy magnetism or electromagnetism can how magnetism or magnetism or of this performance

into electrical energy electromagnetism can change mechanical electromagnetism can electromagnetism can task

change mechanical energy into electrical change mechanical change mechanical

through the form of

energy into electrical energy through the form energy into electrical energy into electrical

generators energy through the form of generators. energy through the form energy through the form

of generators. of generators. of generators.

3. diagnose and service batteries

3.1 describe the purpose, I can consistently I can usually describe I sometimes need I often need assistance I have not yet

construction, operation describe the purpose, the purpose, assistance to describe to describe the purpose, provided evidence of

and ratings of batteries construction, operation construction, the purpose, construction, operation this performance task.

and ratings of batteries. operation and ratings construction, operation and ratings of batteries.

of batteries. and ratings of batteries.

3.2 test and service batteries I can consistently test I can usually test and I sometimes need I often need assistance I have not yet

and service batteries. service batteries. assistance to test and to test and service provided evidence of

service batteries. batteries. this performance task.

3.3 diagnose problems related I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

to batteries diagnose problems problems related to assistance to diagnose to diagnose problems provided evidence of

related to batteries. batteries. problems related to related to batteries. this performance task.

batteries.

3.4 perform battery charging I can consistently I can usually perform I sometimes need I often need assistance I have not yet

and boosting repairs perform battery battery charging and assistance to perform to perform battery provided evidence of

charging and boosting boosting repairs. battery charging and charging and boosting this performance task

repairs. boosting repairs. repairs.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3405 / 17

Alberta Education, Alberta, Canada 2015

Teacher feedback and

assessment.

18 / CTS, TMT: ASA3405 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

AUTOMOTIVE SERVICE TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE ASA3410: ELECTRICAL CIRCUITS

Level: First Period Apprenticeship, Section Four

Prerequisites: ASA3900: Apprenticeship Safety

ASA3400: Basic Tools & Materials

ASA3402: Vehicle Service Information

ASA3405: Electrical Principles

Description: Students develop the knowledge, skills and attitudes necessary to service and repair electrical circuits.

Parameters: Access to a materials work centre, complete with hand tools, specialized tools and related resources, and to instruction

from an individual with journeyperson certification as an automotive service technician.

ILM Resources: Electrical Circuits 1 090104b

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3410 / 19

Alberta Education, Alberta, Canada 2015

COURSE ASA3410: ELECTRICAL CIRCUITS

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. perform electrical circuit

measurements

Teacher Signature Date

20 / CTS, TMT: ASA3410 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE ASA3410: ELECTRICAL CIRCUITS

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. perform electrical circuit measurements

1.1 recognize common I can consistently I can usually I sometimes need I often need assistance I have not yet

electrical symbols in order recognize common recognize common assistance to recognize to recognize common provided evidence of

to read and understand electrical symbols in electrical symbols in common electrical electrical symbols in this performance task.

basic electrical schematics order to read and order to read and symbols in order to read order to read and

understand basic understand basic and understand basic understand basic

electrical schematics. electrical schematics. electrical schematics. electrical schematics.

1.2 identify the three basic I can consistently I can usually identify I sometimes need I often need assistance I have not yet

circuit types and their identify the three basic the three basic circuit assistance to identify to identify the three provided evidence of

basic electrical properties circuit types and their types and their basic the three basic circuit basic circuit types and this performance task.

basic electrical electrical properties. types and their basic their basic electrical

properties. electrical properties. properties.

1.3 identify and explain I can consistently I can usually identify I sometimes need I often need assistance I have not yet

possible circuit issues and identify and explain and explain possible assistance to identify to identify and explain provided evidence of

problems possible circuit issues circuit issues and and explain possible possible circuit issues this performance task.

and problems. problems. circuit issues and and problems.

problems.

1.4 using Ohms law (voltage Using Ohms law Using Ohms law Using Ohms law Using Ohms law I have not yet

= current x resistance), (voltage = current x (voltage = current x (voltage = current x (voltage = current x provided evidence of

calculate for any of its resistance), I can resistance), I can resistance), I sometimes resistance), I often need this performance task.

variable when two are consistently calculate usually calculate for need assistance to assistance to calculate

for any of its variable any of its variable calculate for any of its for any of its variable

known

when two are known. when two are known. variable when two are when two are known.

known.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3410 / 21

Alberta Education, Alberta, Canada 2015

1.5 apply Ohms law to a I can consistently apply I can usually apply I sometimes need I often need assistance I have not yet

circuit to calculate Ohms law to a circuit Ohms law to a circuit assistance to apply to apply Ohms law to a provided evidence of

voltage, current and to calculate voltage, to calculate voltage, Ohms law to a circuit circuit to calculate this performance task.

resistance current and resistance. current and resistance. to calculate voltage, voltage, current and

current and resistance. resistance.

1.6 identify and explain I can consistently I can usually identify I sometimes need I often need assistance I have not yet

circuit failures and their identify and explain and explain circuit assistance to identify to identify and explain provided evidence of

effects circuit failures and their failures and their and explain circuit circuit failures and their this performance task.

effects. effects. failures and their effects.

effects.

1.7 calculate power and I can consistently I can usually calculate I sometimes need I often need assistance I have not yet

explain the implications calculate power and power and explain the assistance to calculate to calculate power and provided evidence of

of power requirements in explain the implications implications of power power and explain the explain the implications this performance task.

a circuit design of power requirements requirements in a implications of power of power requirements

in a circuit design. circuit design. requirements in a circuit in a circuit design.

design.

1.8 perform voltage drop I can consistently I can usually perform I sometimes need I often need assistance I have not yet

measurements using a perform voltage drop voltage drop assistance to perform to perform voltage drop provided evidence of

voltmeter measurements using a measurements using a voltage drop measurements using a this performance task.

voltmeter. voltmeter. measurements using a voltmeter.

voltmeter.

1.9 perform parasitic drain I can consistently I can usually perform I sometimes need I often need assistance I have not yet

and current draw tests perform parasitic drain parasitic drain and assistance to perform to perform parasitic provided evidence of

using an ammeter and current draw tests current draw tests parasitic drain and drain and current draw this performance task.

using an ammeter. using an ammeter. current draw tests using tests using an ammeter.

an ammeter.

1.10 measure electrical I can consistently I can usually measure I sometimes need I often need assistance I have not yet

resistance using both measure electrical electrical resistance assistance to measure to measure electrical provided evidence of

digital and analog resistance using both using both digital and electrical resistance resistance using both this performance task.

ohmmeters digital and analog analog ohmmeters. using both digital and digital and analog

ohmmeters. analog ohmmeters. ohmmeters.

22 / CTS, TMT: ASA3410 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

1.11 service electrical circuit I can consistently I can usually service I sometimes need I often need assistance I have not yet

protection devices service electrical circuit electrical circuit assistance to service to service electrical provided evidence of

protection devices. protection devices. electrical circuit circuit protection this performance task.

protection devices. devices.

Teacher feedback and

assessment.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3410 / 23

Alberta Education, Alberta, Canada 2015

AUTOMOTIVE SERVICE TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE ASA3412: ELECTRICAL SERVICE

Level: First Period Apprenticeship, Section Four

Prerequisites: ASA3900: Apprenticeship Safety

ASA3400: Basic Tools & Materials

ASA3402: Vehicle Service Information

ASA3405: Electrical Principles

ASA3410: Electrical Circuits

Description: Students develop the knowledge, skills and attitudes necessary to diagnose service and repair electrical systems, and

develop an understanding of active and passive restraint systems.

Parameters: Access to a materials work centre, complete with hand tools, specialized tools and related resources, and to instruction

from an individual with journeyperson certification as an automotive service technician

ILM Resources: Electrical System Diagnosis I 090104e; Active Passenger Restraint Systems 090305k

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

24 / CTS, TMT: ASA3412 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3412 / 25

Alberta Education, Alberta, Canada 2015

COURSE ASA3412: ELECTRICAL SERVICE

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. diagnose and repair simple

electrical circuits

2. describe the purpose,

function and operation of

occupant restraint systems

Teacher Signature Date

26 / CTS, TMT: ASA3412 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE ASA3412: ELECTRICAL SERVICE

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. diagnose and repair simple electrical circuits

1.1 use a variety of test I can consistently use a I can usually use a I sometimes need I often need assistance I have not yet

equipment to test simple variety of test variety of test assistance to use a to use a variety of test provided evidence of

circuits and interpret equipment to test equipment to test variety of test equipment to test this performance task.

results simple circuits and simple circuits and equipment to test simple circuits and

interpret results. interpret results. simple circuits and interpret results.

interpret results.

1.2 perform simple wire and I can consistently I can usually perform I sometimes need I often need assistance I have not yet

connector repairs perform simple wire simple wire and assistance to perform to perform simple wire provided evidence of

and connector repairs. connector repairs. simple wire and and connector repairs. this performance task.

connector repairs.

1.3 understand the hazards I can consistently I can usually I sometimes need I often need assistance I have not yet

associated with understand the hazards understand the hazards assistance to understand to understand the provided evidence of

electrostatic discharge associated with associated with the hazards associated hazards associated with this performance task.

(ESD) when working on electrostatic discharge electrostatic discharge with electrostatic electrostatic discharge

(ESD) when working (ESD) when working discharge (ESD) when (ESD)when working on

vehicle electronic systems

on vehicle electronic on vehicle electronic working on vehicle vehicle electronic

systems. systems. electronic systems. systems.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3412 / 27

Alberta Education, Alberta, Canada 2015

2. describe the purpose, function and operation of occupant restraint systems

2.1 describe the operation of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

active restraint systems describe the operation the operation of active assistance to describe to describe the provided evidence of

of active restraint restraint systems. the operation of active operation of active this performance task.

systems. restraint systems. restraint systems.

2.2 identify the components of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

an active restraint system identify the components the components of an assistance to identify to identify the provided evidence of

of an active restraint active restraint the components of an components of an active this performance task.

system. system. active restraint system. restraint system.

2.3 describe the operation of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

passive restraint systems describe the operation the operation of assistance to describe to describe the provided evidence of

of passive restraint passive restraint the operation of passive operation of passive this performance task.

systems. systems. restraint systems. restraint systems.

2.4 identify the components of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

a passive restraint system identify the components the components of a assistance to identify to identify the provided evidence of

of a passive restraint passive restraint the components of a components of a this performance task.

system. system. passive restraint system. passive restraint system.

Teacher feedback and

assessment.

28 / CTS, TMT: ASA3412 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

AUTOMOTIVE SERVICE TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE ASA3415: FRAMES & UNDERCARRIAGE

Level: First Period Apprenticeship, Section Two

Prerequisites: ASA3900: Apprenticeship Safety

ASA3400: Basic Tools & Materials

ASA3402: Vehicle Service Information

Description: Students develop the knowledge, skills and attitudes necessary to service and maintain vehicle frames and suspension

and steering linkage systems.

Parameters: Access to a materials work centre, complete with hand tools, specialized tools and related resources, and to instruction

from an individual with journeyperson certification as an automotive service technician

ILM Resources: Frames 090102a; Suspension and Steering Linkage Systems 090102b

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3415 / 29

Alberta Education, Alberta, Canada 2015

COURSE ASA3415: FRAMES & UNDERCARRIAGE

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. identify automotive frame

damage

2. describe the components

and operation of suspension

and steering systems

Teacher Signature Date

30 / CTS, TMT: ASA3415 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE ASA3415: FRAMES & UNDERCARRIAGE

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. identify automotive frame damage

1.1 identify various types of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

frame damage identify various types various types of frame assistance to identify to identify various types provided evidence of

of frame damage. damage. various types of frame of frame damage. this performance task.

damage.

1.2 identify the design features I can consistently I can usually identify I sometimes need I often need assistance I have not yet

and frame types identify the design the design features assistance to identify to identify the design provided evidence of

features and frame and frame types. the design features and features and frame this performance task.

types. frame types. types.

1.3 perform frame-checking I can consistently I can usually perform I sometimes need I often need assistance I have not yet

procedures using a variety perform frame- frame-checking assistance to perform to perform provided evidence of

of techniques checking procedures procedures using a frame-checking frame-checking this performance task.

using a variety of variety of techniques. procedures using a procedures using a

techniques. variety of techniques. variety of techniques.

2. describe the components and operation of suspension and steering systems

2.1 describe the construction I can consistently I can usually describe I sometimes need I often need assistance I have not yet

and design features of describe the the construction and assistance to describe to describe the provided evidence of

common suspension construction and design design features of the construction and construction and design this performance task.

systems features of common common suspension design features of features of common

suspension systems. systems. common suspension suspension systems.

systems.

2.2 explain the principles of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3415 / 31

Alberta Education, Alberta, Canada 2015

operation of suspension explain the principles of the principles of assistance to explain the to explain the principles provided evidence of

systems operation of suspension operation of principles of operation of operation of this performance task.

systems. suspension systems. of suspension systems. suspension systems.

2.3 diagnose and service I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

suspension system diagnose and service and service suspension assistance to diagnose to diagnose and service provided evidence of

components suspension system system components. and service suspension suspension system this performance task.

components. system components. components.

2.4 identify steering linkage I can consistently I can usually identify I sometimes need I often need assistance I have not yet

types and explain their identify steering linkage steering linkage types assistance to identify to identify steering provided evidence of

operation types and explain their and explain their steering linkage types linkage types and this performance task.

operation. operation. and explain their explain their operation.

operation.

2.5 diagnose and service I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

steering linkage diagnose and service and service steering assistance to diagnose to diagnose and service provided evidence of

components steering linkage linkage components. and service steering steering linkage this performance task.

components. linkage components. components.

Teacher feedback and

assessment.

32 / CTS, TMT: ASA3415 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

AUTOMOTIVE SERVICE TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE ASA3420: STEERING SYSTEMS

Level: First Period Apprenticeship, Section Two

Prerequisites: ASA3900: Apprenticeship Safety

ASA3400: Basic Tools & Materials

ASA3402: Vehicle Service Information

Description: Students develop the knowledge, skills and attitudes necessary to service and repair electric assist and hydraulic assist

steering systems.

Parameters: Access to a materials work centre, complete with hand tools, specialized tools and related resources, and to instruction

from an individual with journeyperson certification as an automotive service technician

ILM Resources: Electric Assist Steering 090102d; Hydraulic Assist Steering 090102e

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3420 / 33

Alberta Education, Alberta, Canada 2015

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

34 / CTS, TMT: ASA3420 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE ASA3420: STEERING SYSTEMS

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. diagnose and repair

electrically assisted steering

gear

2. diagnose and repair

hydraulic assist steering

systems

Teacher Signature Date

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3420 / 35

Alberta Education, Alberta, Canada 2015

COURSE ASA3420: STEERING SYSTEMS

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. diagnose and repair electrically assisted steering gear

1.1 explain the construction I can consistently I can usually explain I sometimes need I often need assistance I have not yet

and operation of a manual explain the construction the construction and assistance to explain the to explain the provided evidence of

steering rack and pinion and operation of a operation of a manual construction and construction and this performance task.

assembly manual steering rack steering rack and operation of a manual operation of a manual

and pinion assembly. pinion assembly. steering rack and pinion steering rack and pinion

assembly. assembly.

1.2 explain the operation of an I can consistently I can usually explain I sometimes need I often need assistance I have not yet

electrically assisted rack explain the operation of the operation of an assistance to explain the to explain the operation provided evidence of

and pinion steering system an electrically assisted electrically assisted operation of an of an electrically this performance task.

rack and pinion steering rack and pinion electrically assisted assisted rack and pinion

system. steering system. rack and pinion steering steering system.

system.

1.3 identify and explain the I can consistently I can usually identify I sometimes need I often need assistance I have not yet

operation of the five identify and explain the and explain the assistance to identify to identify and explain provided evidence of

primary components operation of the five operation of the five and explain the the operation of the five this performance task.

common to all electric primary components primary components operation of the five primary components

common to all electric common to all electric primary components common to all electric

assist systems

assist systems. assist systems. common to all electric assist systems.

assist systems.

1.4 identify and explain the I can consistently I can usually identify I sometimes need I often need assistance I have not yet

active steering modes identify and explain the and explain the active assistance to identify to identify and explain provided evidence of

active steering modes. steering modes. and explain the active the active steering this performance task.

steering modes. modes.

36 / CTS, TMT: ASA3420 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

1.5 explain the advantages of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

electrically assisted explain the advantages the advantages of assistance to explain the to explain the provided evidence of

steering systems of electrically assisted electrically assisted advantages of advantages of this performance task.

steering systems. steering systems. electrically assisted electrically assisted

steering systems. steering systems.

1.6 diagnose and repair I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

mechanical problems diagnose and repair and repair mechanical assistance to diagnose to diagnose and repair provided evidence of

related to electrically mechanical problems problems related to and repair mechanical mechanical problems this performance task.

assisted steering gears related to electrically electrically assisted problems related to related to electrically

assisted steering gears. steering gears. electrically assisted assisted steering gears.

steering gears.

2. diagnose and repair hydraulic assist steering systems

2.1 describe the construction I can consistently I can usually describe I sometimes need I often need assistance I have not yet

and design of hydraulic describe the the construction and assistance to describe to describe the provided evidence of

assist steering gears construction and design design of hydraulic the construction and construction and design this performance task.

of hydraulic assist assist steering gears. design of hydraulic of hydraulic assist

steering gears. assist steering gears. steering gears.

2.2 identify hydraulic assist I can consistently I can usually identify I sometimes need I often need assistance I have not yet

pump types and explain identify hydraulic assist hydraulic assist pump assistance to identify to identify hydraulic provided evidence of

their operation pump types and explain types and explain their hydraulic assist pump assist pump types and this performance task.

their operation. operation. types and explain their explain their operation.

operation.

2.3 describe the operation of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

hydraulic assist steering describe the operation the operation of assistance to describe to describe the provided evidence of

systems of hydraulic assist hydraulic assist the operation of operation of hydraulic this performance task.

steering systems. steering systems. hydraulic assist steering assist steering systems.

systems.

2.4 diagnose, repair and adjust I can consistently I can usually I sometimes need I often need assistance I have not yet

hydraulic assist non-rack diagnose, repair and diagnose, repair and assistance to diagnose, to diagnose, repair and provided evidence of

and pinion steering gears adjust hydraulic assist adjust hydraulic assist repair and adjust adjust hydraulic assist this performance task.

non-rack and pinion non-rack and pinion hydraulic assist non- non-rack and pinion

steering gears. steering gears. rack and pinion steering steering gears.

gears.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3420 / 37

Alberta Education, Alberta, Canada 2015

2.5 diagnose and repair I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

hydraulic assist rack and diagnose and repair and repair hydraulic assistance to diagnose to diagnose and repair provided evidence of

pinion steering gears hydraulic assist rack assist rack and pinion and repair hydraulic hydraulic assist rack this performance task.

and pinion steering steering gears. assist rack and pinion and pinion steering

gears. steering gears. gears.

2.6 diagnose hydraulic I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

steering problems diagnose hydraulic hydraulic steering assistance to diagnose to diagnose hydraulic provided evidence of

steering problems. problems. hydraulic steering steering problems. this performance task.

problems.

Teacher feedback and

assessment.

38 / CTS, TMT: ASA3420 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

AUTOMOTIVE SERVICE TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE ASA3425: SUSPENSION SYSTEMS

Level: First Period Apprenticeship, Section Two

Prerequisites: ASA3900: Apprenticeship Safety

ASA3400: Basic Tools & Materials

ASA3402: Vehicle Service Information

ASA3420: Steering Systems

Description: Students develop the knowledge, skills and attitudes necessary to service and repair suspension and steering systems.

Parameters: Access to a materials work centre, complete with hand tools, specialized tools and related resources, and to instruction

from an individual with journeyperson certification as an automotive service technician

ILM Resources: Steering Angles 090102f; Suspension and Steering Diagnosis 090102i

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3425 / 39

Alberta Education, Alberta, Canada 2015

COURSE ASA3425: SUSPENSION SYSTEMS

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. describe steering angles and

how each affects vehicle

handling

2. diagnose and repair

suspension systems and

steering linkages

Teacher Signature Date

40 / CTS, TMT: ASA3425 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE ASA3425: SUSPENSION SYSTEMS

Rubric

Student Name: Date:

Level Excellent Proficient Adequate Limited Not Yet

Criteria Demonstrated

1. describe steering angles and how each affects vehicle handling

1.1 describe the function and I can consistently I can usually I sometimes need I often need assistance I have not yet

effect of caster on vehicle describe the function describe the function assistance to describe to describe the function provided evidence of

operation and effect of caster on and effect of caster on the function and effect and effect of caster on this performance task.

vehicle operation. vehicle operation. of caster on vehicle vehicle operation.

operation.

1.2 describe the function and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

effect of camber on describe the function the function and effect assistance to describe to describe the function provided evidence of

vehicle operation and effect of camber on of camber on vehicle the function and effect and effect of camber on this performance task.

vehicle operation. operation. of camber on vehicle vehicle operation.

operation.

1.3 describe the function and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

effect of steering axis describe the function the function and effect assistance to describe to describe the function provided evidence of

inclination (SAI) on and effect of steering of steering axis the function and effect and effect of steering this performance task.

vehicle operation axis inclination (SAI) inclination (SAI) on of steering axis axis inclination (SAI)

on vehicle operation. vehicle operation. inclination (SAI) on on vehicle operation.

vehicle operation.

1.4 describe the function and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

effect of toe on vehicle describe the function the function and effect assistance to describe to describe the function provided evidence of

operation and effect of toe on of toe on vehicle the function and effect and effect of toe on this performance task.

vehicle operation. operation. of toe on vehicle vehicle operation.

operation.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3425 / 41

Alberta Education, Alberta, Canada 2015

1.5 describe the effect of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

thrust angle on vehicle describe the effect of the effect of thrust assistance to describe to describe the effect of provided evidence of

operation thrust angle on vehicle angle on vehicle the effect of thrust angle thrust angle on vehicle this performance task.

operation. operation. on vehicle operation. operation.

1.6 describe the measurement I can consistently I can usually describe I sometimes need I often need assistance I have not yet

procedures for each describe the the measurement assistance to describe to describe the provided evidence of

steering angle measurement procedures for each the measurement measurement this performance task.

procedures for each steering angle. procedures for each procedures for each

steering angle. steering angle. steering angle.

1.7 describe the adjustment I can consistently I can usually describe I sometime need I often need assistance I have not yet

procedures for each describe the adjustment the adjustment assistance to describe to describe the provided evidence of

steering angle procedures for each procedures for each the adjustment adjustment procedures this performance task.

steering angle. steering angle. procedures for each for each steering angle.

steering angle.

2. diagnose and repair suspension systems and steering linkages

2.1 describe the diagnosis of I can consistently I can usually describe I sometimes need I often need assistance I have not yet

suspension and steering describe the diagnosis the diagnosis of assistance to describe to describe the provided evidence of

problems of suspension and suspension and the diagnosis of diagnosis of suspension this performance task.

steering problems. steering problems. suspension and steering and steering problems.

problems.

2.2 diagnose problem(s) I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

related to suspension diagnose problem(s) problem(s) related to assistance to diagnose to diagnose problem(s) provided evidence of

systems related to suspension suspension systems. problem(s) related to related to suspension this performance task.

systems. suspension systems. systems.

2.3 diagnose problem(s) I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

related to steering systems diagnose problem(s) problem(s) related to assistance to diagnose to diagnose problem(s) provided evidence of

related to steering steering systems. problem(s) related to related to steering this performance task.

systems. steering systems. systems.

42 / CTS, TMT: ASA3425 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

2.4 choose an appropriate I can consistently I can usually choose I sometimes need I often need assistance I have not yet

repair method to correct choose an appropriate an appropriate repair assistance to choose an to choose an provided evidence of

suspension or steering repair method to correct method to correct appropriate repair appropriate repair this performance task.

problem(s) suspension or steering suspension or steering method to correct method to correct

problem(s). problem(s). suspension or steering suspension or steering

problem(s). problem(s).

2.5 service suspension and I can consistently service I can usually service I sometimes need I often need assistance to I have not yet provided

steering systems to correct suspension and steering suspension and steering assistance to service service suspension and evidence of this

systems to correct systems to correct suspension and steering steering systems to correct performance task.

problem(s) problems. problems. systems to correct problems.

problems.

Teacher feedback and

assessment.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3425 / 43

Alberta Education, Alberta, Canada 2015

AUTOMOTIVE SERVICE TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE ASA3430: ALIGNMENT PROCEDURES

Level: First Period Apprenticeship, Section Two

Prerequisites: ASA3900: Apprenticeship Safety

ASA3400: Basic Tools & Materials

ASA3402: Vehicle Service Information

ASA3420: Steering Systems

ASA3425: Suspension Systems

Description: Students develop the knowledge, skills and attitudes necessary to service and repair electric assist and hydraulic assist

steering systems.

Parameters: Access to a materials work centre, complete with hand tools, specialized tools and related resources, and to instruction

from an individual with journeyperson certification as an automotive service technician

ILM Resources: Alignment Procedures 090102g; Steering Columns 090102h

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

44 / CTS, TMT: ASA3430 Automotive Service Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

Automotive Service Technician Apprenticeship Assessment CTS, TMT: ASA3430 / 45

Alberta Education, Alberta, Canada 2015

COURSE ASA3430: ALIGNMENT PROCEDURES

Checklist