Professional Documents

Culture Documents

InteliDrive Nano-1.3 - Reference Guide

Uploaded by

eng_moh04Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

InteliDrive Nano-1.3 - Reference Guide

Uploaded by

eng_moh04Copyright:

Available Formats

InteliDrive Nano

InteliDrive Nano

Engine Controller

Compact Controller for Industrial Engines

SW version 1.3, October 2012

Reference Guide

Copyright 2012 ComAp s.r.o.

ComAp, spol. s r.o.

Kundratka 17, 180 00 Praha 8, Czech Republic

Tel: +420 246 012 111, Fax: +420 266 316 647

E-mail: info@comap.cz, www.comap.cz

Table of contents

Table of contents ..................................................................................................................................... 2

General Guidelines.................................................................................................................................. 3

What describes this manual?............................................................................................................... 3

!! Warnings !!........................................................................................................................................ 3

Text ...................................................................................................................................................... 3

System Overview..................................................................................................................................... 4

General description.............................................................................................................................. 4

Configurability ...................................................................................................................................... 4

Application examples............................................................................................................................... 5

Engine Speed control in MAN mode.................................................................................................... 6

Control loop in AUT mode ................................................................................................................... 7

Installation and wiring .............................................................................................................................. 9

Terminals diagram ............................................................................................................................. 10

Wiring hints ........................................................................................................................................ 11

Operator interface.................................................................................................................................. 13

Setup mode........................................................................................................................................ 15

Inputs and Outputs ................................................................................................................................ 17

Logical Binary outputs........................................................................................................................ 18

Logical Binary and Analog inputs ...................................................................................................... 21

Setpoints................................................................................................................................................ 27

Setpoint overview............................................................................................................................... 28

B - Basic Settings............................................................................................................................... 29

E - Engine and Protection Parameters .............................................................................................. 30

R RPM Control................................................................................................................................ 34

Alarm and History Management............................................................................................................ 38

Events ................................................................................................................................................ 39

Warnings............................................................................................................................................ 40

Shutdowns ......................................................................................................................................... 41

ECU Messages .................................................................................................................................. 42

Technical data ....................................................................................................................................... 43

Power supply ..................................................................................................................................... 43

Operating conditions .......................................................................................................................... 43

Binary inputs and outputs .................................................................................................................. 43

Analog inputs ..................................................................................................................................... 43

Speed pick-up input ........................................................................................................................... 44

D+ function......................................................................................................................................... 44

InteliDrive Nano, SW version 1.3, ComAp October 2012 2

InteliDrive Nano-1.3 Reference Guide.pdf

General Guidelines

What describes this manual?

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTION - This manual contains important instructions for InteliDrive Nano

controller that shall be followed during installation and maintenance. The manual describes also

software, which is designed for single engine applications.

What is the purpose of the manual?

Provides general information how to install and operate InteliDrive Nano controller.

This manual is dedicated for

Engine operators

Engine control panel builders

For everybody who is concerned with installation, operation and maintenance of the industrial

engines with InteliDrive Nano.

!! Warnings !!

Remote control

InteliDrive Nano controller can be controlled remotely. In case of any work on the engine make sure

that nobody can start it remotely.

To be sure make the following steps:

Disconnect input REM START/STOP or Disconnect output STARTER

Because of large variety of InteliDrive Nano parameters setting, it is not possible to describe all

combinations. Some of InteliDrive Nano functions are subject of changes depending on SW version.

The data in this manual describes the product and are not warranty of performance or characteristic.

Text

PAGE Capital letters in the frame buttons on the front panel

Break Return Italic set points

Generator protections Bold Set point group

REMOTE START/STOP Capital letters binary inputs and outputs

Note:

ComAp believes that all information provided herein is correct and reliable ComAp however reserves

the right to update it at any time. ComAp does not assume any responsibility for its use unless

otherwise expressly undertaken.

Note:

SW and HW must be compatible otherwise some functions will be disabled.

InteliDrive Nano, SW version 1.3, ComAp October 2012 3

InteliDrive Nano-1.3 Reference Guide.pdf

System Overview

General description

InteliDrive Nano is a comprehensive controller for single industrial engines including the electronic EFI

engines.

InteliDrive Nano controller is equipped with a powerful graphic display showing icons and symbols

without texts for its intuitive operation, which sets, together with high functionality, new standards in

engine control.

InteliDrive Nano can operate an engine in MANual or AUTomatic modes.

The key feature of InteliDrive Nano is its easy-to-use operation and installation. Predefined

configurations of typical applications are available as well as user-defined configurations for special

applications.

Configurability

One of the key features of the controller is its high level of adaptability based on the needs of every

particular application. The way, how to achieve this, is the configuration.

NOTE:

Use DriveEdit PC software to the read configuration from the controller or disk, view it, modify it and

write the configuration to controller or disk.

The firmware contains a number of binary inputs and outputs needed for all necessary functions

available in the firmware. However not all functions are required at the same time. Configuration task

is mapping of "logical" firmware inputs and outputs to the "physical" hardware input and output

terminals and some setpoints modification.

Configuration parts:

1. Mapping of logical binary and analog inputs (functions) to physical binary input terminals

2. Mapping of logical binary outputs (functions) to physical binary output terminals

3. Assigning sensor characteristics

4. Selecting of ECU type if an ECU is connected

5. Setpoints modification

The controller is delivered with a default configuration, which should suit to most standard

applications. This default configuration can be changed either directly from controllers front panel or

by using PC with DriveEdit software.

NOTE:

For connection to PC please use the USB interface. Controller can be powered directly from USB

communication port. In this case LCD backlight is turned off and all outputs are open.

Configuration of InteliDrive Nano controller can be stored in an ain file for later use or for its

modification in DriveEdit PC software. Such file is called archive. The archive contains full image of

the controller at the moment of saving. Besides the configuration there is also recorded actual

adjustment of all setpoints as well as all measured values and history logs.

The archive can be simply used for preparing controllers with identical configuration and settings.

InteliDrive Nano, SW version 1.3, ComAp October 2012 4

InteliDrive Nano-1.3 Reference Guide.pdf

Application examples

Application example 1

Engine type Mechanical engine, constant speed

Functions Start to Nominal RPM

Protections Overspeed, Oil Pressure, Cooling Temperature, Fuel level

Application example 2

Engine type Mechanical engine, variable speed

Functions Start to Idle then Nominal RPM, manual speed adjusting

Protections Overspeed, Oil Pressure, Cooling Temperature, Fuel level

MAN mode Manual: manual speed adjustment ramping function

AUT mode Automatic start/stop, automatic speed adjustment

Application example 3

Engine type Electronic engine, constant or variable speed, simple wiring

Functions Start to Idle then Nominal RPM

Protections Overspeed, Oil Pressure, Cooling Temperature, Fuel level

MAN mode Manual: manual speed adjustment ramp function

AUT mode Automatic start/stop, automatic speed adjustment

Diesel Engine

CAN - J1939

BO ECU relay ECU

- +

Battery

InteliDrive Nano, SW version 1.3, ComAp October 2012 5

InteliDrive Nano-1.3 Reference Guide.pdf

Application example 4

Engine type Electronic engine, constant or variable speed, simple wiring

Functions Start to Idle then Nominal RPM

Protections Overspeed, Oil Pressure, Cooling Temperature, Fuel level

MAN mode Manual: manual speed adjustment ramp function

AUT mode Automatic start/stop, automatic control loop

Application example 5

Engine type Electronic engine, constant or variable speed, simple wiring

Functions Start to Idle then Nominal RPM

Protections Overspeed, Fuel level, ECU Alarms indication

MAN mode Manual: manual speed adjustment ramp function

AUT mode Automatic start/stop, automatic speed adjustment

Engine Speed control in MAN mode

p

am

R

ed

pe

-S

05

R

Engine starts to R02-Idle Speed, increases after Idle time to the R03-Operational Speed that can be

changed by panel Up/Down buttons, switched by Binary input I-28 Speed Switch to another R04-

Speed Switch value that can be again changed by panel Up/Down buttons and returns to previous

value of R03-Operational Speed.

InteliDrive Nano, SW version 1.3, ComAp October 2012 6

InteliDrive Nano-1.3 Reference Guide.pdf

All RPM changes are accepted within R15-Max and R16-Min Speed Limits. Operational and Speed

Switch change (by Up/Down buttons) is remembered in case of switching by Binary input Speed

Switch for all time engine is running. After Engine Start are R03-Operational Speed and R04-Speed

Switch actualized to default R03, R04 setpoint values.

Up/Down buttons function

Up/Down button Speed request step

1x pressed + / - 1 RPM

2x pressed + / - R05 / 2 + 1 - see Note below

Press and hold for 3s Follow the R05-Speed Ramp

Note: (R05-Speed Ramp / 2 + 1) = 100/2+1 = 51RPM . when R05 = 100 RPM/s.

RPM

MAN

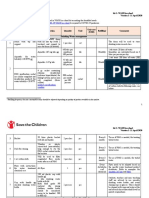

Control loop in AUT mode

Pressure sensor is connected to T22 AIN4, converted to Bars by T22-AI4 curve, compared with R11

Request, processed in PI block. Speed request is limited by R15, R16 and transferred to CAN J1939

and converted via R07, R08 to T29 Analog output 1.

Control Loop I/O

Function Terminal Mnemo Type Conversion

Control Loop In T22 AIN4 0/4-20mA T22 AI4 Obligatory

Loop Dislabled T25 BIN7 BIN HiSide n.a. Optional

Speed Request T29 AO1 0 5VDC R07, R08 Optional

Loop In Indication T30 AO2 0 5VDC R13, R14 Optional

CAN

InteliDrive Nano, SW version 1.3, ComAp October 2012 7

InteliDrive Nano-1.3 Reference Guide.pdf

CAN interface EFI engine

Engine Compressor

ECU Pressure

Sensor

J1939 T22 (-I50)

CAN AIN4

0/4-20mA

Control Loop In

Curve 4 Curve 4

Speed ID-Nano AUT mode 10,0

Request

Bar

PI block

R09-Control Loop Gain

R15-Min Speed Limit 0,0

R10-Control Loop Int

R16-Max Speed Limit

R12-Control Loop Bias 4mA 20mA

R13-Control Loop In 0%

R11-Control Loop Request R14-Control Loop In 100%

Control Loop In Indication

T25 (-I27) T30

BI7 AO2

+ VBatt LoopDisabled 0 - 5VDC

External

gauge

Analog interface Mechanical engine

Engine Compressor

Speed

Governor Pressure

Sensor

T22 (-I50)

T29 AIN4

AO1 0/4-20mA

0 - 5VDC Control Loop In

Speed Request

ID-Nano Curve 4 10,0

Curve 4

R07-Speed request 0%

AUT mode

Bar

R08-Speed Request 100%

PI block

R09-Control Loop Gain 0,0

R15-Min Speed Limit R10-Control Loop Int

R16-Max Speed Limit 4mA 20mA

R11-Control Loop Request

InteliDrive Nano, SW version 1.3, ComAp October 2012 8

InteliDrive Nano-1.3 Reference Guide.pdf

Installation and wiring

Mounting

The controller is to be mounted into the switchboard door. Requested cut-out size is 96x96mm. Use

the screw holders delivered with the controller to fix the controller into the door as described on

pictures below.

Package contents

Accessories Description Optional / Obligatory

InteliDrive Nano InteliDrive Nano controller unit Obligatory

Short Guide InteliDrive Nano brief overview Obligatory

Holders Two controller holders Obligatory

InteliDrive Nano, SW version 1.3, ComAp October 2012 9

InteliDrive Nano-1.3 Reference Guide.pdf

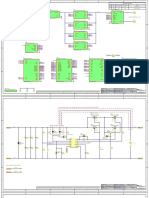

Terminals diagram

Default configuration

T15 AIN1-R / BIN1 Wrn/Cd - Coolant Wrn/Cd Protection 2 AIN8: 0 - 10V T16

User curve 8

T14 AIN2-R / BIN2 Wrn/Sd - Oil Press GND T17

T13 AIN3-R / BIN3 Wrn/Cd - Fuel level Speed Request AIN7: 0 - 2400 T18

User curve 7

T12 BIN4 Hi-side Emergency Stop GND T19

T11 BIN5 Hi-side Remote Start/Stop Wrn/Cd Protection 1 AIN6: 0/4 - 20mA T20

User curve 6

T10 IN-COM Level Start/Stop AIN5: 0/4 - 20mA T21

User curve 5

T09 BO3 / 0,5A Hi-side Close Load Ctrl Loop In AIN4: 0/4 - 20mA T22

User curve 4

T08 BO4 / 0,5A Hi-side Alarm GND T23

T07 FUEL / 10A Relay FUEL /ECU /STOP Speed Switch BIN6 Hi-side T24

T06 FUEL / 10A Relay FUEL /ECU /STOP Loop Disabled BIN7 Hi-side T25

T05 Starter / 10A Relay STARTER Pick-up RPM - GND T26

T04 Starter / 10A Relay STARTER RPM T27

T03 SUPPLY+ (+VBAtt) 8 to 36 VDC GND T28

T02 D+ Connect to T03 Speed Request AO1: 0 5V T29

when not used !!!

T01 SUPPLY - (0VBatt) AIN4 Ctrl Loop In AO2: 0 5V T30

User curves for Resistive measuring AIN7

Ohm Conversion curve 1000ohm / 800-2500RPM

1 0,0 800

2 1000,0 2500 1000,0 means 1000 ohms; 2500 means RPM

User curves for mA measuring AIN4 Ctrl Loop In, AIN5 Level Start Stop, AIN6 Wrn/Cd Protection1

Ohm Conversion curve 20mA / 20,0

1 0,0 0

2 200,0 200 200,0 means 20 mA

User curves for Voltage measuring AIN8

Ohm Conversion curve 10V / 10,00

1 0,0 0

2 10,0 100 10,0 means 10 V

InteliDrive Nano, SW version 1.3, ComAp October 2012 10

InteliDrive Nano-1.3 Reference Guide.pdf

Sensor fail is indicated below of low and over +12% of high limit of sensor characteristic.

Wiring hints

To ensure proper function:

Use min. power supply cable of 2.5mm2

Maximum continuous DC power supply voltage is 36 VDC. Maximum allowable power supply voltage

is 39VDC. The InteliDrive Nano power supply terminals are protected against large pulse power

disturbances. When there is a potential risk of the controller being subjected to conditions outside its

capabilities an outside protection devise should be used.

For the connections with 12VDC power supply, the InteliDrive Nano includes internal capacitors that

allow the controller to continue operation during cranking if the battery voltage dip occurs. If the

voltage before drop is 10V, after 100ms the voltage recovers to 5 V, the controller continues operating.

During this voltage drop the controller screen backlight can turn off and on but the controller keeps

operating.

Power supply fusing

Controller should never be connected directly to the starting battery. App 6 amp fuse should be

connected in-line with the battery positive terminal to the controller.

Fuse value and type depends on number of connected devices and wire length.

Recommended fuse (not fast) type - T1A. Not fast due to internal capacitors charging during

power up.

The capacitor size should be 5 000 F to

withstand 150ms voltage dip under following

conditions:

Voltage before the drop is 12V, after 150ms the

voltage recovers to min. allowed voltage, i.e. 8V.

+

C

D

Motor starter

Motor starter

D+

Charging alternator D+ output is on terminal T02.

Hint:

Do not leave it opened. If not used connect T02 D+ terminal to battery positive T03.

InteliDrive Nano, SW version 1.3, ComAp October 2012 11

InteliDrive Nano-1.3 Reference Guide.pdf

Binary outputs

Use minimally 1 mm2 cables for wiring of all binary outputs.

CAUTION!

Controller Binary outputs are high side type (connecting +VBatt on output terminal) !

Never connect any analog sensor to this output to avoid sensor damage.

All outputs are short circuit protected.

Use suppression diodes on all relays and other inductive loads!

CPU

+ -

Analog inputs

Analog inputs are designed for resistive automotive type sensors like VDO or DATCON. The sensors

are connected either by one wire (the second pole is sensor body) or by two wires.

In case of grounded sensors connect the terminal T10 to the engine body as near from the

sensors as possible.

In case of isolated sensors connect the terminal T10 to the negative power supply terminal of

the controller as well as the opposite poles of the sensors.

NOTE:

Symbol #### is displayed when measured value is out of range or sensors wire is broken.

Analog Sensors wiring

GROUNDED SENSORS ISOLATED SENSORS

ID Nano

InteliDrive Nano, SW version 1.3, ComAp October 2012 12

InteliDrive Nano-1.3 Reference Guide.pdf

Operator interface

Stop button

Stop button 0,5s delay, no auto repeat.

Dual Up/Down keys function

Menu enables to change the Up - and Down - keys function between Screen listing or Speed

Up/Down command (indicated by + - bar).

Screen listing mode RPM adjustment mode

Switch screen Up Speed Up

Switch screen Down Speed Down

Menu selection

Press Menu button to modify following functions below. Use Up/down to select item and press

Start button to change mode or Enter Runtime setpoints. Use Stop button to escape back to menu,

press Menu to return back to previous measuring screen.

Adjust PID setpoints

- Change Up/Down buttons function

- Switch between MAN AUT mode

Screen Icons START button function

Switch to Runtime Ctrl Loop - setpoints screen

Change of Up/Down buttons function between

Screen listing mode and RPM adjustment mode

Switching between MAN and AUTO mode

Press Menu button to return back to measuring screen. It is not possible to change screens when

Up/Down keys are in Speed Up/down mode i.e. enter Menu from screen what you want to see after.

Runtime setpoints

Only below setpoints are available to modify on running engine. Select requested item by Up/Down,

press Start to edit, Use Up/Down to modify, Enter to confirm, Stop to return to Menu.

R09 Ctrl Loop Gain

R10 Ctrl Loop Int

R11 Ctrl Loop Request

R12 Ctrl Loop Bias

R13 LoopReq 0%

R14 Loop Req 100%

InteliDrive Nano, SW version 1.3, ComAp October 2012 13

InteliDrive Nano-1.3 Reference Guide.pdf

Press Stop to return to Menu, press Menu to return back to Measuring screen.

Measuring screens

1-st measuring screen

Engine RPM

Engine state and Timers

Running hours

Status

2-nd measuring screen

Oil pressure T14 AIN2

Cooling temperature T15 AIN1

Fuel level T13 AIN3

Battery voltage

3-rd RPM control screen

1800 RPM Engine RPM Actual (T26-T27)

1800 RPM Engine RPM Requested

5,0 Bar Control loop Actual value T22 AIN4

5,0 Bar Control loop Requested value

The 3-rd screen disappears when B01 Basic settings: Application = SingleSpeed

4-th measuring screen

Level Start/Stop T21 AIN5

Wrn/Cd Protection 1 T20 AIN6

Wrn/Cd Protection 2 T16 AIN8

free line

Not configured value is displayed as ----------.

The 4-th screen disappears when all AIN5, AIN6, AIN8 values are not configured.

Alarm-History (10 items screen)

Alarm-History (10 items screen)

Status icons

Active LBI Remote Start/Stop (T11 BIN5)

Active LBI Access Lock

Active function Level Start/Stop

AUT mode, AIN5 configured,

Active Control Loop

AUT mode, AIN4 configured, No Loop block

Remote AUT

Active Speed Switch (T24 BI6)

InteliDrive Nano, SW version 1.3, ComAp October 2012 14

InteliDrive Nano-1.3 Reference Guide.pdf

Reserve

Active Alarm

State machines indication 1st Measuring screen - 2nd line

Ready

Starting

Running

Loaded

Cooling

Not Ready

Data from ECU

The analog measuring T14Oil Pressure and T15-Coolant Temperature has to be configured as Not

used (function code I00) to display those ECU values on the second screen when ECU is configured.

Engine RPM is switched to ECU source automatically.

The ECU Fault codes are reported in the Alarm-History Screen as well as the ECU communication

fail.

Setup mode

Setup mode is available when:

Engine is not running,

Controller is in MAN mode,

Panel Up/Dn keys are switched to Screen listing mode.

The Setup mode is blocked by the binary function Access lock as well as the Menu button.

To enter Setup mode press and hold then press shortly button and then and then .

Setup mode enables partial controller configuration (I/O function modification and setpoints setting)

using just panel buttons without PC tool.

NOTE:

The controller will automatically switch to Setup mode when there is some problem with checksum

(i.e. memory integrity) or when there is incompatibility between firmware and archive version. This

situation can occur when you upgrade a firmware. If this happen just check and set all setpoints

properly.

InteliDrive Nano, SW version 1.3, ComAp October 2012 15

InteliDrive Nano-1.3 Reference Guide.pdf

Setup mode icons

Outputs settings RPM control

Inputs settings ECU setting

Basic settings Info

Engine parameters

and protections

For move in menu use and buttons. Press Start button to select choice or Stop button for exit.

Supported ECU

InteliDrive Nano, SW version 1.3, ComAp October 2012 16

InteliDrive Nano-1.3 Reference Guide.pdf

Inputs and Outputs

In the table below you can see which logical function can be assigned to physical binary or analog

input or binary output. Each logical input or output function has unique code. Input codes firs letter is

I output codes letter is O. Summary of all logical input function is in chapter Logical binary and

analog inputs, summary of logical output function is in Logical binary outputs.

Each logical binary input and output can be configured as Normally Open (NO) or Normally Close

(NC).

Physical Inputs

Terminal Type Direction Input function assignment

T11 binary input I00, I02-NO, I30

T12 binary input I00, I01-NC, I10, I16, I29, I30

T13 binary/analog input I00, I20, I21-ch1

T14 binary/analog input I00, I22, I23-ch2

T15 binary/analog input I00, I24, I25-ch3

T16 Analog input I00, I54

T18 Analog input I00, I52

T20 Analog input I00, I53

T21 Analog input I00, I51

T22 Analog input I00, I50

T24 Binary input I00, I04, I10, I16, I28-NO, I30

T25 Binary input I00, I04, I10, I16, I27-NO, I30

Default configuration is in bold e.g. I02-NO = function 02 Normally Opened; I21-ch1 = I21 with

sensor characteristics 1.

Physical Outputs

Terminal Type Direction Input function assignment

T04-T05 binary output O00,O01-NO, O04, O07, O08, O09, O10, O 11

T06-T07 binary output O00, O02-NO, O03, O04, O07, O08, O09, O10, O11

T08 binary output O00, O04-NO, O07, O08, O09, O10, O11

T09 binary output O00, O04, O07, O08, O09, O10, O11-NO

T29 Analog Output Speed request - fix

T30 Analog Output AIN4 indication output fix

Normally Open contact

Normally Open contact no voltage on output terminal or no passing current from/to binary input

terminal. When the contact is opened controller read logical 0 (L) on binary input when is closed

controller read logical 1 (H).

In case of output logical 0 (L) means 0V on binary output and logical 1 (H) means battery positive

voltage on output.

Normally Open contact Normally Closed contact

output output

Normally Open contact Normally Closed contact

input button input button

InteliDrive Nano, SW version 1.3, ComAp October 2012 17

InteliDrive Nano-1.3 Reference Guide.pdf

Normally Closed contact

Normally Close contact (inverted) represents close contact positive voltage on output terminal or

passing current from/to binary input terminal. When the contact is opened controller read logical 1 (H)

on binary input when is closed controller read logical 0 (L).

In case of output logical 1 (H) means 0V on binary output and logical 0 (L) means battery positive

voltage on output.

Logical Binary outputs

Output code Output name Type Terminal assignment

O00 Not Used binary T04-5, T06-7, T08, T09

O01 Starter binary T04

O02 Fuel Solenoid binary T06

O03 Stop Solenoid binary T06

O04 Alarm binary T04-5, T06-7, T08, T09

O07 Ready To Load binary T04-5, T06-7, T08, T09

O08 Prestart binary T04-5, T06-7, T08, T09

O09 ECU Power Relay binary T04-5, T06-7, T08, T09

O10 Cooling Pump Binary T04-5, T06-7, T08, T09

O11 Close Load binary T04-5, T06-7, T08, T09

For outputs configuration use PC software DriveEdit or switch controller to Setup mode. On the picture

below is example how to configure binary output via front controllers screen. At first you have to select

output terminal. For move use and buttons for choice press Start button and Stop button for

return. Then pick out logical function (O00-O09) and select contact type (Normally Open contact or

Normally Closed contact) and confirm change.

InteliDrive Nano, SW version 1.3, ComAp October 2012 18

InteliDrive Nano-1.3 Reference Guide.pdf

InteliDrive Nano, SW version 1.3, ComAp October 2012 19

InteliDrive Nano-1.3 Reference Guide.pdf

O00 Not Used

Output has no function. Use this configuration when output is not connected.

O01 Starter

This output is dedicated for starter motor control.

Corresponding setpoints:

E01-Prestart Time, E02-MaxCrankTime.

O02 Fuel Solenoid

This output is dedicated to control the fuel solenoid (valve). The output is closed in the same time as

Starter output and remains closed all the time the engine runs.

O03 Stop Solenoid

This output is dedicated to control the stop solenoid (valve). The output is closed in the moment when

the engine shall stop and remains active until is stopped, but at least for 60s.

The engine is stopped if: RPM < 2 and Oil pressure < 4,5 Bar.

O04 Alarm

The output is designed to be used as external alarm indication like a red bulb in the control room etc.

The output is active when at least one unconfirmed alarm is present in the event log.

O07 Ready To Load

The output is activated when engine is running, idle is over and no shutdown or cool down alarms are

active. The output opens during cooling state or when emergency stop or any shutdown / cool down

alarm is active.

O08 Prestart

The output is activated prior to the engine start and deactivated when 25% of Nominal RPM speed is

reached. During crank attempts the output is activated too.

The output could be used for pre-glow, pre-heat or pre-lubrication.

O09 ECU Power Relay

This output is to be used for control of "keyswitch" input or power supply (over relay) of an ECU. If the

particular ECU does not have keyswitch or similar input, it can be used for control of DC power for the

ECU.

The output closes together with O08 Prestart and remains closed all the time the engine shall be

running. It is opened in the moment the engine shall stop (i.e. together with the O02 Fuel Solenoid ).

InteliDrive Nano, SW version 1.3, ComAp October 2012 20

InteliDrive Nano-1.3 Reference Guide.pdf

NOTE:

The controller does not evaluate the communication failure alarm during the period when this output

is not active +1 second after Prestart activation.

O10 Cooling Pump

The output is activated prior to the engine start and deactivated when Aftercool time is over.

The output could be used for engine cooling after stop.

O11 Close Load

The output is activated when the START button is closed in Running state. Output is disconnected

when panel STOP button is pressed or any shut-down or cool-down alarm occurs.

The output could be used for any kind of load (clutch) activation.

Logical Binary and Analog inputs

Input code Input name Type Terminal assignment

Binary T11,T12,T13,T14,T15,T16,T18,T20,

I00 Not Used Analog T21,T22,T24,T25

I01 Emergency Stop Binary T12

I02 Remote Start/Stop Binary T11

I04 Access Lock Binary T24, T25

I10 External Warning 1 Binary T12, T24, T25

I15 External Cooldown 1 Binary T12, T24, T25

I20 Low Fuel Level Binary T13

I21 Fuel Level Analog Analog T13

I22 Low Oil Pressure Binary T14

I23 Oil Pressure Analog Analog T14

I24 High Coolant Temperature Binary T15

I25 Coolant Temperature Analog Analog T15

I27 Loop Disabled Binary T25

I28 Speed Switch Binary T24

I29 SD Override Binary T12, T24, T25

I30 Remote AUT Binary T12, T24, T25

Analog inputs

Input code Input name Type Terminal assignment

I50 Control Loop AIN Analog T22

I51 Start/Stop Level Analog T21

I52 Speed Request Analog T18

I53 Wrn/Cd Protection 1 High Analog T20

I54 Wrn/Cd Protection 2 High Analog T16

For inputs configuration use PC software DriveEdit or switch controller to Setup mode. On the picture

below is example how to configure binary inputs via front controllers screen. At first you have to select

input terminal. For move use and buttons for choice press Start button and Stop button for

return. Then pick out logical function (I00-I20, I22 and I24) and select contact type (Normally Open

contact or Normally Closed contact) and confirm change.

InteliDrive Nano, SW version 1.3, ComAp October 2012 21

InteliDrive Nano-1.3 Reference Guide.pdf

3x 3x

InteliDrive Nano, SW version 1.3, ComAp October 2012 22

InteliDrive Nano-1.3 Reference Guide.pdf

I00 Not Used

Input has no function. Use this configuration when binary or analog input is not connected.

I01 Emergency Stop

This input will activate the built-in Emergency Stop alarm. It is recommended to use Normally

Closed button for this input because of safety reasons.

If this binary input is activated left red LED above Stop button starts blinking, general shutdown

symbol is displayed on LCDs upper right corner, Emergency Stop symbol is displayed on event log

with running hours stamp and shut down procedure will occur.

I02 Remote Start/Stop

External request for engine start active in Auto mode only.

NOTE:

The Remote Start/stop can be configured only on terminal T11 for reason awaking controller from

Zero Power mode.

I04 Access Lock

If the input is closed the controller Menu button, Setup mode and Engine Start and Stop buttons are

blocked. No setpoints no I/O function can be adjusted from controllers front panel and mode (Manual

- Auto) cannot be changed.

Access Lock does not protect setpoints and mode changing from DriveEdit. Also history is accessible.

Access Lock is also functionless in case that the controller is in Setup mode.

I10 External Warning 1

If this binary input is activated the Alarm red LED above Stop button will start blinking, general

warning symbol will be displayed on LCDs upper right corner and External Warning 1 symbol will be

displayed on event log with running hours stamp. This alarm is only warning.

I16 External Cooldown 1

If this binary input is activated the Alarm red LED above Stop button will start blinking, general

shutdown symbol will be displayed on LCD, External Shutdown 1 symbol will be displayed on event

log with running hours stamp and Cool down procedure will occur.

I20 Low Fuel Level

If this binary input is activated the Alarm red LED above Stop button will start blinking, general

warning symbol will be displayed on LCDs upper right corner and Low Fuel Level symbol will be

displayed on event log with running hours stamp. This alarm is only warning.

NOTE:

Input has 10s delay.

InteliDrive Nano, SW version 1.3, ComAp October 2012 23

InteliDrive Nano-1.3 Reference Guide.pdf

I21 Fuel Level Analog

Analog input for fuel level measurement. When measured value exceed preset threshold left red LED

above Stop button will start blinking, general warning symbol will be displayed on LCDs upper right

corner and fuel level symbol will be displayed on event log with running hours stamp . This alarm is

only warning.

You can choice one from two preset resistive sensors (VDO, Datcon) or you can create your own

sensor curve.

NOTE:

Input has 10s delay.

I22 Low Oil Pressure

If this binary input is activated the Alarm red LED above Stop button will start blinking, general

shutdown symbol will be displayed on LCDs upper right corner, oil pressure symbol will be displayed

on event log with running hours stamp and shut down procedure will occur.

I23 Oil Pressure Analog

Analog input for oil pressure measurement. When measured value exceed preset threshold the red

LED above Stop button will start blinking, general shutdown symbol will be displayed on LCDs upper

right corner and oil pressure symbol will be displayed on event log with running hours stamp and shut

down procedure will occur.

You can choice one from five default resistive sensors (VDO, Datcon) or you can create your own

sensor curve.

You can setup shutdown threshold (E04 Oil Pressure Shutdown) in Engine parameters and

protection group.

NOTE:

Input has 3s delay.

I24 High Coolant Temperature

If this external binary input is activated the red LED above Stop button will start blinking, general

shutdown symbol will be displayed on LCDs upper right corner, Coolant Temperature symbol will be

displayed on event log with running hours stamp and shut down procedure will occur.

I25 Coolant Temperature Analog

Analog input for coolant temperature measurement. When measured value exceed preset threshold

the red LED above Stop button will start blinking, general shutdown symbol will be displayed on

LCDs upper right corner and coolant temperature symbol will be displayed on event log with running

hours stamp and shut down procedure will occur.

Default threshold is 90C. You can choose one from four default resistive sensors (VDO, Datcon) or

you can create your own sensor curve.

You can setup shutdown threshold (E05 Coolant Temperature Shutdown) in Engine parameters

and protection group.

InteliDrive Nano, SW version 1.3, ComAp October 2012 24

InteliDrive Nano-1.3 Reference Guide.pdf

NOTE:

Input has 5s delay.

I27 Loop Disabled

Active input deactivates the Control loop and switch the Speed Request output to R12 Control Loop

Bias.

I28 Speed Switch

Active input switch the Speed request from R03-Operational Speed to R04-Speed Switch in MAN

mode.

I29 Shut-down Override

Active input blocks the engine Cool-down and stop except the Overspeed protection and Emergency

stop. All alarm indications and History records stays active.

I30 Remote AUT

Active input switch controller mode from MAN to AUT and returns back to MAN when is inactive. AUT

mode is indicated by panel LED AUTO and by symbol A on first screen dashboard - position 5-th.

Active input blocks Menu setting to MAN.

Remote AUT is available on T11-BIN5, T12-BIN4, T24-BIN6, T25-BIN7.

I50 Control Loop AIN

Input for value that can be controlled by engine RPM.

Available on AIN4 (4-20mA) on T22 terminal.

Corresponding RPM control setpoints:

Ctrl Loop Gain-R09, Ctrl Loop Int-R10, Ctrl Loop Request-R11, Ctrl Loop Bias-R12, Loop Request

0%-R13, Loop Request 100%-R14.

I51 Start/Stop Level

Analog input for Automatic Engine Start Stop function in AUT mode based on analog value e.g.

level signal.

Available on AIN5 (4-20mA) on T21 terminal. AIN5 sensor fail activates the engine stop.

Corresponding setpoints:

Level Start-E09, Level StopE10, Level Delay-E11.

I52 Speed Request

Analog Input for Engine speed request in MAN mode using external potentiometer.

Available on AIN7 (0-2400ohm) on terminal T18.

InteliDrive Nano, SW version 1.3, ComAp October 2012 25

InteliDrive Nano-1.3 Reference Guide.pdf

I53 Warning / Cool down Protection 1

General AIN6 (4-20mA) T20 Analog input protection - type of Running only.

Corresponding setpoints:

Warning Protection1-E12, Cool down Protection1-E13, Protection1 Delay-E14, Protection1 Run Del

E23.

The protection type Over/Under depends on Wrn/Cd limits setting it is:

"Over" when E12 (Wrn limit) is lower then E13 (Cd limit)

"Under" when E12 (Wrn limit) is higher then E13 (Cd limit)

I54 Warning / Cool down Protection 2

General AIN8 (10V) T16 Analog input protection type of All time.

Corresponding setpoints:

Warning Protection 2-E15, Cool down Protection 2-E16, Protection 2 Delay-E17

The protection type Over/Under depends on Wrn/Cd limits setting it is:

"Over" when E15 (Wrn limit) is lower then E16 (Cd limit)

"Under" when E15 (Wrn limit) is higher then E16 (Cd limit)

Hint:

The I53 and I54 protections type Over/Under depends on corresponding Warning and Cooldown

limits.

Limits Protection type

Wrn limit < Cd limit Over

Wrn limit > Cd limit Under

InteliDrive Nano, SW version 1.3, ComAp October 2012 26

InteliDrive Nano-1.3 Reference Guide.pdf

Setpoints

Setpoints are analog, binary or special data objects that are used for adjusting the controller to the

specific environment. Setpoints are collected to groups according to their meaning. Setpoints can be

adjusted from the controllers front panel or PC. On the picture below is example how to change

setpoint via controllers front panel.

InteliDrive Nano, SW version 1.3, ComAp October 2012 27

InteliDrive Nano-1.3 Reference Guide.pdf

Setpoint overview

Basic settings Range / default

B03 Gear Teeth 1-300 / 120

B04 Nominal RPM 100-4000 / 2200RPM

B05 Units Format 1 = Metric; 2 = US / 1

B07 Zero Power Mode 0 360 min / 10min

B08 Application 1 = SS; 2 = VS / 2

B09 RPMbyWterminal 0,05 2,00 / 1,00

Engine and Protection Range / default

Parameters

E01 Prestart Time 0 600 / 2s

E02 Maximum Cranking Time 0 - 60 / 5s

E03 Cooling Time 0 3600 / 30s

E04 Oil Pressure Shut Down 0 10,0 / 1,0bar

E05 Coolant Temperature Cool Down 0 150 / 90C

E06 Battery Under voltage Warning 8 36,0 / 22,0V

E07 Warning Maintenance 0-10000 / 9999h

E08 Running Timer 0 1000 / 0min

E09 Level Start 0 100 / 0%

E10 Level Stop 0 100 / 0%

E11 Level Delay 0 1800 / 5s

E12 Warning Protection 1 32000 / 0

E13 Cool Down Protection 1 32000 / 0

E14 Protection 1 Delay 0 60 / 5s

E15 Warning Protection 2 32000 / 0

E16 Cool down Protection 2 32000 / 0

E17 Protection 2 Delay 0 60 / 5s

E18 After Cooling Time 0 3600 / 30s

E19 Oil Pressure Warning 0 10,0 / 2,0bar (fix delay 3s)

E20 Coolant Temperature Warning 0 150 / 90C (fix delay 5s)

E21 Fuel Level Warning 0 100 / 10% (fix delay 20s)

E22 Fuel Level Cool Down 0 100 / 5% (fix delay 20s)

E23 Protection1 Run Delay 0 3600s / 10s

E24 Starting RPM 5 1500 / 350 RPM

RPM control

R01 Idle Time 1 180 / 5s

R02 Idle Speed 500 4000 / 800RPM

R03 Operational Speed 500 4000 / 2200RPM

R04 Speed Switch 500 4000 / 1500RPM

R05 Speed Ramp 100 1000 / 400RPM/s

R06 Speed Request in MAN mode 1 = BIN - 2 = AIN / 1

R07 Speed Request 0% 500 4000 / 800RPM

InteliDrive Nano, SW version 1.3, ComAp October 2012 28

InteliDrive Nano-1.3 Reference Guide.pdf

R08 Speed Request 100% 500 4000 / 2200RPM

R09 Control Loop Gain 100,00 / 10, 00%

R10 Control Loop Int 100,0 / 10, 0%

R11 Control Loop Request 32000 / 0

R12 Control Loop Bias 0 10000 / 0

R13 Control Loop In 0% 0 10000 / 0

R14 Ctrl Loop In 100% 0 10000 / 1000

R15 Max Speed Limit 500 4000 / 800RPM

R16 Min Speed Limit 500 4000 / 2200RPM

RunTime setpoints R09, R10, R11, R12 can be changed on running engine from Menu - .

B - Basic Settings

B03 Gear Teeth

Units:

Step: 1

Range: 1 300

Default value: 120

Number of teeth on the engine gear for the pick-up sensor. The setpoint is ignored when ECU is

configured.

B04 Nominal RPM

Units: RPM

Step: 1

Range: 100 4000

Default value: 2200

RPM base for Overspeed (fix 115%) protection. To increase Overspeed limit increase the B04-

Nominal voltage.

B05 Units Format

Units:

Step:

Range: Metric = 1, US = 2;

Default value: Metric

Converts dimension of values coming from ECU.

1. METRIC = C, bar, l/h

2. US = F, psi, gallon/h

B07 Zero Power Mode Delay

Units: min

Step: 1

Range: 0 to 360

Default value: 10

The controller is switched to Zero Power Mode when there is no user interaction with the controller for

the preset time. Zero Power Mode is disabled in AMF automatic mode. Value 0 also disables this

function. For the controller wake up press button Start or activate input T11. The controller will not

switch to Zero Power Mode if any alarm is active.

InteliDrive Nano, SW version 1.3, ComAp October 2012 29

InteliDrive Nano-1.3 Reference Guide.pdf

B08 Application

Units:

Step:

Range: SS = 1, VS = 2; SS= Single (constant) speed; VS = Variable speed engine.

Default value: VS=2

Selection to hide RPM ctrl setpoints group and 3-rd measuring screen when not needed.

B09 RPMbyWterminal

Units:

Step: 0,01

Range: 0,05 2,00

Default value: 1,00

Coefficient for RPM calculation when RPM input is connected to charging alternator - W terminal

instead to magnetic pick-up.

E - Engine and Protection Parameters

E01 Prestart Time

Units: seconds [s]

Step: 1s

Range: 0-600s

Default value: 2

Time of closing of the O08 Prestart output prior to the engine start.

Set to zero if you want to leave the output O08 Prestart open.

E02 Maximum Cranking Time

Alternative name: MaxCrank Time

Units: seconds [s]

Step: 1s

Range: 0-60s

Default value: 5

Maximum duration when the starter motor is energized.

E03 Cooling Time

Units: seconds [s]

Step: 1s

Range: 0-3600s

Default value: 30

Runtime of the unloaded to cool the engine before stop.

E04 Oil Pressure Shutdown

Units: Bar [Bar]

InteliDrive Nano, SW version 1.3, ComAp October 2012 30

InteliDrive Nano-1.3 Reference Guide.pdf

Step: 0,1

Range: 0-10

Default value: 1

Delay: 3s

Shutdown threshold level for I23 Oil Pressure Analog input.

E05 Coolant Temperature Cooldown

Units: degree Celsius [C]

Step: 1

Range: 0 -150

Default value: 90

Delay: 5s

Shutdown threshold level for I25 Coolant Temperature Analog input.

E06 Battery Undervoltage Warning

Units: Volts [V]

Step: 0,1

Range: 8 40

Default value: 22

Delay: 30 s

Warning threshold for Low Battery voltage.

E07 Warning Maintenance

Units: hours [h]

Step: 1h

Range: 0 10000 h

Default value: 9999 h

Counts down when engine running. If reaches zero, an alarm will appear. When the value 10000 is

set, than the Maintenance function is disabled and counter does not count. Counter value disappear

in controllers statistics. Maximum value for running countdown is 9999. Warning Maintenance will

appear when counter elapsed.

E08 Running timer

Units: minutes [min]

Step: 1

Range: 0 1000

Default value: 0

Engine will stop in MAN mode when Running timer is over.

E09 Level Start

Units: %[%]

Step: 1

Range: 0 100

InteliDrive Nano, SW version 1.3, ComAp October 2012 31

InteliDrive Nano-1.3 Reference Guide.pdf

Default value: 0

Engine start level in AUT mode for Analog input AIN5. Value over or below this level activates the

engine start. The function depends on relation between Start and Stop Level:

StartLevel > Stop Level: engine starts over Start and Stops below Stop.

StartLevel < Stop Level: engine starts over Stop and Stops below Start.

E10 Level Stop

Units: %[%]

Step: 1

Range: 0 100

Default value: 0

Stop level in AUT mode for Analog input AIN5.

E11 Level Delay

Units: s[s]

Step: 1

Range: 0 1800

Default value: 5

Delay for Level Start or Level Stop activation in AUT mode time to be level out of limit.

E12 Warning Protection 1

Units: [-]

Step: 1

Range: 32000

Default value: 0

Warning limit for protection 1.

E13 Cool down Protection 1

Units: [-]

Step: 1

Range: 32000

Default value: 0

Cooldown limit for protection 1.

E14 Protection 1 Delay

Units: s[s]

Step: 1

Range: 0 60

Default value: 5

Delay for protection 1.

InteliDrive Nano, SW version 1.3, ComAp October 2012 32

InteliDrive Nano-1.3 Reference Guide.pdf

E15 Warning Protection 2

Units: [-]

Step: 1

Range: 32000

Default value: 0

Warning limit for general protection 1.

E16 Cd Protection 2

Units: [-]

Step: 1

Range: 32000

Default value: 0

Cooldown limit for engine protection 1.

E17 Protection 2 Delay

Units: s[s]

Step: 1

Range: 0 60

Default value: 5

Delay for Engine protection 2.

E18 After Cooling Time

Units: seconds [s]

Step: 1s

Range: 0-3600s

Default value: 30

Runtime of the cooling pump to cool the engine after stop.

E19 Oil Pressure Warning

Units: Bar [Bar]

Step: 0,1

Range: 0-10

Default value: 2

Delay: 3s

Shutdown threshold level for I23 Oil Pressure Analog input.

E20 Coolant Temperature Warning

Units: degree Celsius [C]

Step: 1

Range: 0 -150

Default value: 90

InteliDrive Nano, SW version 1.3, ComAp October 2012 33

InteliDrive Nano-1.3 Reference Guide.pdf

Delay: 5s

Shutdown threshold level for I25 Coolant Temperature Analog input.

E21 Fuel Level Warning

Units: % [%]

Step: 1

Range: 0 -100

Default value: 10

Delay: 20 s

Shutdown threshold level for I21 Coolant Temperature Analog input.

E22 Fuel Level Cooldown

Units: % [%]

Step: 1

Range: 0 -100

Default value: 5

Delay: 20 s

Shutdown threshold level for I21 Coolant Temperature Analog input.

E23 Protection 1 Run Delay

Units: s [s]

Step: 1

Range: 0 -3600

Default value: 5

Running delay for I53-Wrn/Cd Protection 1 Runing only type delay.

R RPM Control

R01 Idle Time

Units: s[s]

Step: 1

Range: 1 180

Default value: 5

Time when engine Speed request = Idle Speed-R02 and Binary output Close load cant be activated.

R02 Idle Speed

Units: RPM [ RPM ]

Step: 1

Range: 500 - 4000

Default value: 800

InteliDrive Nano, SW version 1.3, ComAp October 2012 34

InteliDrive Nano-1.3 Reference Guide.pdf

Speed request after engine start for Idle Time-R01.

R03 Operational Speed

Units: RPM [ RPM ]

Step: 1

Range: 500 4000

Default value: 2200

Requested speed in Running state when Idle time-R01 is over and Binary input Speed Switch-I28 is

not active.

R04 Speed Switch

Units: RPM [ RPM ]

Step: 1

Range: 500 4000

Default value: 1500

Active input changes Speed request from setpoint OperationalSpeed-R03 to SpeedSwitch-R04.

The Speed request change is done by SpeedRamp-R05.

R05 Speed Ramp

Units: RPM/s [ R/s ]

Step: 1

Range: 100 1000

Default value: 400

Setpoint limits the engine Speed request changes when changed from Speed Up / Speed Down

buttons or from AIN7-T18 by potentiometer.

R06 Speed Request in MAN mode

Units:

Step:

Range: BIN = 1; AIN = 2

Default value: BIN = 1

Speed request source selection in MAN mode:

1. BIN: Speed Up / Speed Down panel buttons, Binary input Speed Switch-I28.

2. AIN: AIN7-T18 (potentiometer).

R07 Speed Request 0%

Units: RPM [ RPM ]

Step: 1

Range: 500 4000

Default value: 800

Setting of voltage output characteristics for Analog interface to Speed governor AOUT1 (5V) -T29.

Default setting means AOUT1 = 0V at 800RPM (and less).

R08 Speed Request 100%

Units: RPM [ RPM ]

InteliDrive Nano, SW version 1.3, ComAp October 2012 35

InteliDrive Nano-1.3 Reference Guide.pdf

Step: 1

Range: 500 4000

Default value: 2200

Setting of voltage output characteristics for Analog interface to Speed governor AOUT1 (5V) -T29.

Default setting means AOUT1 = 5V at 2200RPM (and more).

R09 Control Loop Gain

Units: %[%]

Step: 0,01

Range: 100,00

Default value: 10

Control loop gain factor. Loop is active in AUT mode; BI7-Loop Disable-T25 disables the loop and set

Speed Request = CtrlLoopBias-R12.

Loop input: AIN4 (4-20mA)-T22; Loop output: Speed request;

R10 Control Loop Int

Units: %[%]

Step: 1

Range: 0 - 100

Default value: 10

Control loop Integration factor. Loop input: AIN4 (4-20mA)-T22; Loop output: Speed request; Loop

active in AUT mode; BI7-T25 disables the loop and set the CtrlLoopBias-R12 on the output.

R11 Control Loop Request

Units:

Step: 1

Range: 32000

Default value: 10

Control loop Requested value. Loop input: AIN4 (4-20mA)-T22; Loop output: Speed request; Loop

active in AUT mode; BI7-T25 disables the loop and set the CtrlLoopBias-R12 on the output.

R12 Control Loop Bias

Units: %[%]

Step: 1

Range: 0 - 100

Default value: 10

Control loop Integration factor. Loop input: AIN4 (4-20mA)-T22; Loop output: Speed request; Loop

active in AUT mode; BI7-T25 disables the loop and set the CtrlLoopBias-R12 on the output.

R13 Control Loop In 0%

Units:

Step: 1

Range: 0 10000

Default value: 0

AOUT2-T30 setting of voltage output characteristics for actual value gauge conversion from T22

AIN4.

InteliDrive Nano, SW version 1.3, ComAp October 2012 36

InteliDrive Nano-1.3 Reference Guide.pdf

R14 Control Loop In 100%

Units:

Step: 1

Range: 0 10000

Default value: 0

AOUT2-T30 setting of voltage output characteristics for actual value gauge conversion from T22

AIN4.

R15 Max Speed Limit

Units: RPM [ RPM ]

Step: 1

Range: 500 4000

Default value: 800

The Speed request from any source ( in any mode) cant get over those limits.

R16 Min Speed Limit

Units: RPM [ RPM ]

Step: 1

Range: 500 4000

Default value: 2200

The Speed request from any source ( in any mode) cant get over those limits.

InteliDrive Nano, SW version 1.3, ComAp October 2012 37

InteliDrive Nano-1.3 Reference Guide.pdf

Alarm and History Management

On the screen can be displayed maximally four records. Total capacity is 10 records. Controller

will stop writing records to the history when the shutdown alarm will occur.

^ press

1800 RPM !

OK 9s

26,3 h

press ^ press

press ^ press

1800 RPM

1800 RPM

5,0 bar

5,0 bar

press ^ press

^

press press

and and

hold3s hold3s

press press ^ press

^

press

and

hold3s

Following alarms and records are available:

Event

Warnings

Shutdowns

ECU Messages

InteliDrive Nano, SW version 1.3, ComAp October 2012 38

InteliDrive Nano-1.3 Reference Guide.pdf

Events

Every event listed in table below is saved in history with running hours stamp see picture below.

Possible Events

Manual Start

Engine was manually started by pressing button Start in Manual mode.

Remote Start

Engine was remotely started via input terminals function I02 Remote Start/Stop.

Controller is in Auto mode.

Level Start

Engine was started in AUT mode crossing the Start level limit.

Manual Stop

Engine was manually stopped by pressing button Stop in Manual mode.

Remote Stop

Engine was remotely stopped via input terminals function I02 Remote Start/Stop.

Controller is in Auto mode.

Level Stop

Engine was stopped in AUT mode by crossing the Stop level limit.

Run Time Stop

Engine was stopped by Runtime function.

Auto On

AUTO mode turned on.

Man On

MAN mode turned on.

Power On

Controller is turned on.

InteliDrive Nano, SW version 1.3, ComAp October 2012 39

InteliDrive Nano-1.3 Reference Guide.pdf

Warnings

Active warning

When warning comes up, only O04 Alarm output is closed, red LED above Stop button will start

blinking. Warning symbol will start blinking on up-and-right LCD corner and proper warning symbol

is displayed in history with running hours stamp. Active warning cant be confirmed. See list of

possible warnings.

Non-active warning

When warning became non-active, O04 Alarm output is opened and red LED above Stop button stop

blinking and the warning symbol on main screen goes out.

Possible warnings

Warning Maintenance

The period for servicing is set by the WrnMaintenance setpoint. The protection comes

active if the running hours of the engine reach this value.

Watchdog

Software timer that triggers a system reset or other corrective action if the main

program, due to some fault condition, such as a hang, neglects to regularly service the

watchdog. The intention is to bring the system back from the unresponsive state into

normal operation.

Low Battery

This warning comes up if the battery voltage is lower than preset Battery Undervoltage

limit for longer than 30s.

Fuel Level

This warning occurs when analog input Fuel Level is below 20% or binary input Fuel

Level is closed longer than 10s.

External Warning 1

Indication of active Binary input I15 - External Cool Down 1. If the input is closed

external warning 1 is activated.

External Cool Down 1

Indication of active Binary input I15 - External Cool Down 1. If the input is closed

external warning 1 is activated.

InteliDrive Nano, SW version 1.3, ComAp October 2012 40

InteliDrive Nano-1.3 Reference Guide.pdf

ECU Communication Error

The warning is activated when ECU if configured is not communicating and all values

from ECU show #####.

Shutdowns

Shutdown procedure

InteliDrive Nano controller opens outputs O01 Starter, O08 Prestart and O02 Fuel Solenoid or close

O03 Stop Solenoid to stop the engine immediately. O04 Alarm output is closed. Active or not

confirmed protection disables start.

Active unconfirmed shutdown

When shutdown comes up, Shutdown procedure will start, red LED above Stop button starts blinking.

Shutdown symbol will start blinking on up-and-right LCD corner and proper shutdown symbol is

displayed in history with running hours stamp. The record in history is negative, see picture below.

See list of Possible shutdown alarms. For shutdown alarm confirmation press Stop button

Active confirmed shutdown

When active shutdown is confirmed the red LED above the Stop button stops blinking. The record in

history stays negative with confirmation symbol at the end. O04 Alarm output endures closed.

Inactive unconfirmed shutdown

O04 Alarm output is closed, red LED above Stop button is shining. Shutdown symbol is displayed

on right up LCD corner and proper warning symbol is displayed in history with running hours stamp,

see picture below. See list of possible shutdown alarms. For shutdown alarm confirmation press Stop

button

Inactive confirmed shutdown

O04 Alarm output is opened. It is possible to start engine when all shutdowns are inactive and

confirmed.

Possible shutdown alarms

Emergency Stop

The binary input Emergency Stop was activated.

Overspeed

The protection comes active if the speed is greater than 115% of nominal engine RPM

InteliDrive Nano, SW version 1.3, ComAp October 2012 41

InteliDrive Nano-1.3 Reference Guide.pdf

which are derived from frequency.

Underspeed

Low engine RPM. This alarm will be issued when the is running and then stops by

itself, i.e. the RPM drops under the nominal engine RPM.

The underspeed alarm starts to be evaluated 5 sec after successful start and is being

evaluated all the time the fuel solenoid is on.

Low Oil Pressure

Engine will stop when oil pressure declined to or less than 1 bar or binary input I22

Low Oil Pressure is active.

High Coolant temperature

Engine will stop when temperature of coolant exceed Coolant Temperature Shutdown

threshold.

External Shutdown 1

Start Fail

start failed.

Stop Fail

stop failed.

Battery Flat

If the controller switches off during starting sequence due to bad battery condition it

doesnt try to start again and activates this protection.

ECU Messages

ECU Message

Diagnostic messages are read and displayed in history behind ECU Warning symbol.

For Standard J1939 SPN (Suspect Parameter Number) and FMI (Failure Mode

Identifier) are shown.

Detail SPN/FMI code specification see in:

SAE Truck and Bus Control and Communications Network Standards Manual,

SAE HS-1939 Publication

Or refer to corresponding engine manufacturers ECU error codes list.

Complete list of text diagnostic messages for each ECU can be found in ComAp

Electronic Engines Support manual.

InteliDrive Nano, SW version 1.3, ComAp October 2012 42

InteliDrive Nano-1.3 Reference Guide.pdf

Technical data

Power supply

Voltage supply 8-36V DC

Operating conditions

Operating temperature -20..+70oC

Storage temperature -30..+80oC

Protection of front panel IP65

Humidity 95% without condensation

Standard conformity

Low Voltage Directive EN 61010-1:95 +A1:97

Electromagnetic Compatibility EN 50081-1:94, EN 50081-2:96

EN 50082-1:99, EN 50082-2:97

Vibration 5 - 25 Hz, 1,6mm

25 - 100 Hz, a = 4 g

Shocks a = 200 m/s2

Binary inputs and outputs

Binary inputs

Number of inputs 4

Input resistance 20 k

Input voltage range 0-36 VDC

Switching voltage level for close contact indication over 5VDC

Binary outputs BO1, BO2

Relay type free contacts

Number of outputs 2

Maximum current 10 A / 24V

Maximum switching voltage 36 VDC

Binary outputs BO3, BO4

Hi side switches

Number of outputs 2

Maximum current 0,5 A

Maximum switching voltage 36 VDC

Analog inputs

Not electrically separated

Number of resistive inputs 4 up to 2400 ( 2%)

Number of mA inputs 3 0/4-20 mA ( 1%)

Input impedance 180

Number of inputs 1 0 10V ( 1%)

InteliDrive Nano, SW version 1.3, ComAp October 2012 43

InteliDrive Nano-1.3 Reference Guide.pdf

Speed pick-up input

Type of sensor magnetic pick-up (connection by shielded cable is

recommended)

Minimum input voltage 3 Vpk-pk (from 4 Hz to 4 kHz)

Maximum input voltage 50 Veff

Minimum measured frequency 4 Hz

Maximum measured frequency 10 kHz (min. input voltage 6Vpk-pk)

Frequency measurement tolerance 0,2 %

D+ function

Max. T02 D+ output current 300 mA

Guaranteed level for signal Charging OK 80% of supply voltage

Hint:

Unused TO2-D+ terminal has to be connected to T03-SUPPLY+.

InteliDrive Nano, SW version 1.3, ComAp October 2012 44

InteliDrive Nano-1.3 Reference Guide.pdf

You might also like

- P1 CraneDocument1 pageP1 Craneeng_moh04No ratings yet

- 1091 CompleteDocument283 pages1091 Completeeng_moh04No ratings yet

- Mokveld-Brochure Axial On-Off enDocument16 pagesMokveld-Brochure Axial On-Off enteacgNo ratings yet

- MZ-14235 Applicatie Leaflet HIPPSDocument8 pagesMZ-14235 Applicatie Leaflet HIPPSTimothy LeonardNo ratings yet

- Mokveld Test Unit VTU-1Document1 pageMokveld Test Unit VTU-1eng_moh04No ratings yet

- Fan For General Purpose Vib. & Balancing PDFDocument48 pagesFan For General Purpose Vib. & Balancing PDFeng_moh04No ratings yet

- DKG 109 InstrDocument44 pagesDKG 109 Instreng_moh04No ratings yet

- Hy La Technik Shock DampersDocument4 pagesHy La Technik Shock Damperseng_moh04No ratings yet

- Installation Instructions - All DrivesDocument1 pageInstallation Instructions - All Driveseng_moh04No ratings yet

- DSE7110 MKII DSE7120 MKII Installation InstructionsDocument2 pagesDSE7110 MKII DSE7120 MKII Installation Instructionseng_moh04100% (1)

- DSE5120 Installation Instructions PDFDocument2 pagesDSE5120 Installation Instructions PDFeng_moh04No ratings yet

- Expands The Limits of Your Power Transmission Solutions: 8Mgt Pitch: 8 MMDocument2 pagesExpands The Limits of Your Power Transmission Solutions: 8Mgt Pitch: 8 MMeng_moh04No ratings yet

- 3008 Tag 4Document2 pages3008 Tag 4eng_moh04No ratings yet

- Dse720 ManualDocument25 pagesDse720 ManualSandeep Saikia100% (7)

- Installation NotesDocument2 pagesInstallation Noteseng_moh04No ratings yet

- Dkg-105 Automatic Mains Failure UnitDocument12 pagesDkg-105 Automatic Mains Failure Uniteng_moh04No ratings yet

- MS150119 00eDocument139 pagesMS150119 00eeng_moh04No ratings yet

- Sync Belt OverviewDocument4 pagesSync Belt OverviewRubens Rando SanchezNo ratings yet

- Expands The Limits of Your Power Transmission Solutions: 8Mgt Pitch: 8 MMDocument2 pagesExpands The Limits of Your Power Transmission Solutions: 8Mgt Pitch: 8 MMeng_moh04No ratings yet

- Omnipage User's GuideDocument94 pagesOmnipage User's GuideSetang BesarNo ratings yet

- Installation NotesDocument2 pagesInstallation Noteseng_moh04No ratings yet

- Sync Belt OverviewDocument4 pagesSync Belt OverviewRubens Rando SanchezNo ratings yet

- Seven Steps To Belt Maintenance - White PaperDocument27 pagesSeven Steps To Belt Maintenance - White PaperJameel KhanNo ratings yet

- DKG 109 InstrDocument44 pagesDKG 109 Instreng_moh04No ratings yet

- ETP Shaft BushingDocument2 pagesETP Shaft Bushingeng_moh04No ratings yet

- Bushing QD SpecDocument11 pagesBushing QD Speceng_moh04No ratings yet

- Automatic Fan Parts ListDocument1 pageAutomatic Fan Parts Listeng_moh04No ratings yet

- Seven Steps To Belt Maintenance - White Paper - PDFDocument27 pagesSeven Steps To Belt Maintenance - White Paper - PDFeng_moh04No ratings yet

- Automatic Fan Parts ListDocument1 pageAutomatic Fan Parts Listeng_moh04No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Payment Plan 3-C-3Document2 pagesPayment Plan 3-C-3Zeeshan RasoolNo ratings yet

- SKF LGMT-2 Data SheetDocument2 pagesSKF LGMT-2 Data SheetRahul SharmaNo ratings yet

- 8524Document8 pages8524Ghulam MurtazaNo ratings yet

- Https Code - Jquery.com Jquery-3.3.1.js PDFDocument160 pagesHttps Code - Jquery.com Jquery-3.3.1.js PDFMark Gabrielle Recoco CayNo ratings yet

- Rundown Rakernas & Seminar PABMI - Final-1Document6 pagesRundown Rakernas & Seminar PABMI - Final-1MarthinNo ratings yet

- POM 3.2 Marketing Management IIDocument37 pagesPOM 3.2 Marketing Management IIDhiraj SharmaNo ratings yet

- Well Stimulation TechniquesDocument165 pagesWell Stimulation TechniquesRafael MorenoNo ratings yet

- Management Interface For SFP+: Published SFF-8472 Rev 12.4Document43 pagesManagement Interface For SFP+: Published SFF-8472 Rev 12.4Антон ЛузгинNo ratings yet

- Faculty of Business and Law Assignment Brief Mode E and R RegulationsDocument4 pagesFaculty of Business and Law Assignment Brief Mode E and R RegulationsSyeda Sana Batool RizviNo ratings yet

- DC0002A Lhires III Assembling Procedure EnglishDocument17 pagesDC0002A Lhires III Assembling Procedure EnglishНикола ЉубичићNo ratings yet

- Scheme Bidirectional DC-DC ConverterDocument16 pagesScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaNo ratings yet

- DPC SEMESTER X B Project ListDocument2 pagesDPC SEMESTER X B Project ListVaibhav SharmaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Modal Case Data Form: GeneralDocument4 pagesModal Case Data Form: GeneralsovannchhoemNo ratings yet

- 1.2 The Main Components of Computer SystemsDocument11 pages1.2 The Main Components of Computer SystemsAdithya ShettyNo ratings yet

- Dreamfoil Creations & Nemeth DesignsDocument22 pagesDreamfoil Creations & Nemeth DesignsManoel ValentimNo ratings yet

- Permit To Work Audit Checklist OctoberDocument3 pagesPermit To Work Audit Checklist OctoberefeNo ratings yet

- Business Occupancy ChecklistDocument5 pagesBusiness Occupancy ChecklistRozel Laigo ReyesNo ratings yet

- Comparative Analysis of Mutual Fund SchemesDocument29 pagesComparative Analysis of Mutual Fund SchemesAvinash JamiNo ratings yet

- Double Inlet Airfoil Fans - AtzafDocument52 pagesDouble Inlet Airfoil Fans - AtzafDaniel AlonsoNo ratings yet

- Jainithesh - Docx CorrectedDocument54 pagesJainithesh - Docx CorrectedBala MuruganNo ratings yet

- Eclipsecon MQTT Dashboard SessionDocument82 pagesEclipsecon MQTT Dashboard Sessionoscar.diciomma8446No ratings yet

- Kit 2: Essential COVID-19 WASH in SchoolDocument8 pagesKit 2: Essential COVID-19 WASH in SchooltamanimoNo ratings yet

- LR Format 1.2Document1 pageLR Format 1.2Ch.Suresh SuryaNo ratings yet

- Cara Membuat Motivation LetterDocument5 pagesCara Membuat Motivation LetterBayu Ade Krisna0% (1)

- Charlemagne Command ListDocument69 pagesCharlemagne Command ListBoardkingZeroNo ratings yet

- Common OPCRF Contents For 2021 2022 FINALE 2Document21 pagesCommon OPCRF Contents For 2021 2022 FINALE 2JENNIFER FONTANILLA100% (30)

- A Study On Effective Training Programmes in Auto Mobile IndustryDocument7 pagesA Study On Effective Training Programmes in Auto Mobile IndustrySAURABH SINGHNo ratings yet

- Pie in The Sky 3Document5 pagesPie in The Sky 3arsi_yaarNo ratings yet

- Elb v2 ApiDocument180 pagesElb v2 ApikhalandharNo ratings yet