Professional Documents

Culture Documents

Bakery

Uploaded by

elaineurbCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bakery

Uploaded by

elaineurbCopyright:

Available Formats

Bakery

Premix

Market

Bakery Premix

Dry Bakery Products

Prepared in APS Equipment

Cake Pre-Mixes

Cake Donut Pre-Mixes

Yeast Raised Donut Pre‑Mixes

Milled Flour Bread Pre-Mixes

Whole Grain Bread Pre-Mixes

Pizza Crust Pre‑Mixes

Biscuit Pre-Mixes

Cookie Dough Pre‑Mixes

Danish Pre-Mixes

Croissant Pre-Mixes

Brownie Pre-Mixes

Pancake Mixes

Muffin Pre-Mixes

Bread-Machine Mixes

Mixing Technology for Bakery Premix

Ribbon Blender: APS agitator shafts are

constructed of solid stainless steel and designed

to be free of any nuts, bolts or flanges. The unique

“spoke” design provides

much greater strength than

pipes or tubes.

OptimaBlend™ eliminates roll apart

segregation caused by gravity when mixing

ingredients of greatly varying density, shape

and size by fluidizing.

Fluidization is achieved by

a combination of a defined

geometry lifting action via

a triple paddle, multi-zoned

rotor turning about 80%

faster than a traditional

ribbon blender.

OptimaIIBlend™ consists of twin shaft,

overlapping paddle assemblies which are

counter rotating at comparatively low rotor

speeds drawing material

from each rotor drum and

lifting the ingredients up

and between the rotors.

This creates a fluidized

zone where particles can

freely transpose, thereby

eliminating segregation.

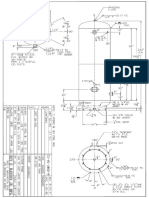

Mix Systems: Typical Stack-up’s

Horizontal: Increased Capacity Under a Low Ceiling

Traditionally the mixer discharges directly into the packaging line. The graphic below shows a horizontal design combining a DRB-

155 (5,000 lb. capacity) double ribbon blender with a DRB-180 (6,000 lb.) half-speed, half horsepower Agitated Surge/Re-Mixer

to increase plant capacity. While the DRB-180 agitated surge feeds lower usage packaging, another batch is being prepared in the

5,000 lb. DRB-155. A high speed finisher disperses lumps of solid shortening or butter, assuring uniform product to your packages.

SCALE HOPPER

DRB-180 MIXER (RE-MIXER)

VERTICAL PLANT

DRB-155

MIXER HIGH SPEED FINISHER

SCALE HOPPER

SURGE HOPPER

PACKAGING MACHINE DRB-155

MIXER

5,000 lb.

Vertical: Achieve Four Batches per Hour

Maximum system efficiency is realized with a multi-story equipment stackup in DRB-180 DRB-180

SURGE SURGE

a vertical plant layout design. Putting gravity to work eliminates the cost of con- 6,000 lb. 6,000 lb.

veyors and the associated capital expenditures, maintenance, clean-up and any

product segregation. CONICAL

FINISHERS

SURGE HOPPERS

Mixers BULK BAG

LOADERS

Because we manufacture one of the most comprehensive lines of mixers on the

market, we can be completely impartial when recommending equipment to meet

your specific product requirements. You don’t buy what we have, you buy what

you need.

Bag Dump Stations

Don’t Lose Your Ingredients in a

Cloud of Dust!

Opening bags of dusty ingredients need not produce a cloud

of dust—dust that settles on equipment, pipes, walls or any

other surface, making housekeeping a nuisance and the working

environment uncomfortable or even hazardous.

The APS bag dump work station has a self-contained filter

system which captures dust before it can enter the workplace.

It also reclaims this dust, pulsing minors and majors back into

the process.

Model FBD-200 Filtered Bag Dump Work Station

With Integrated Pneumatic Bag Compactor

Over 30 Years of Building Process Equipment for Bakery Pre-Mixes

Bakery Pre-Mixes offer their own set of challenges. American Process Systems has met those challenges for over 30 years

with innovative products and solutions oriented process engineering.

Turning Mixing Art Into Mixing Science!

Our test lab is fully equipped with double-ribbon blenders, paddle and paddle/ribbon combination

blenders, PlowBlendTM and OptimaIIBlendTM mixers, as well as high-speed finishers, and bag dump

work stations. All of this equipment is also available fo in-plant testing. Customer participation in test-

ing is much encouraged.

Eirich Machines, Inc.

4033 Ryan Rd • Gurnee, IL 60031

(847) 406-1300 • (847) 336-0914

Email: eirich@eirichusa.com

Website: www.eirichusa.com

Ask about other equipment by American Process Systems & Eirich Machines:

PlowBlend™ Ribbon Blenders OptimaIIBlend™ Bag Dump Stations OptimaBlend™

You might also like

- Illustrated Catalogue of Cotton MachineryFrom EverandIllustrated Catalogue of Cotton MachineryNo ratings yet

- LSB Series: Large Square BalersDocument24 pagesLSB Series: Large Square BalersSedat KahramanNo ratings yet

- Bucket Elev - Low X Ser TubeDocument8 pagesBucket Elev - Low X Ser TubeMauri AlvarezNo ratings yet

- MiniDrill_2022_enDocument2 pagesMiniDrill_2022_enPaXoNNo ratings yet

- Astec Voyager 140 enDocument8 pagesAstec Voyager 140 enumerNo ratings yet

- Buhler Rice Processing Catalogue SOA MEA 2015 V6Document28 pagesBuhler Rice Processing Catalogue SOA MEA 2015 V6Jibin Rajan VargheseNo ratings yet

- Complete Offerings: Thermal Processing Agglomeration Material HandlingDocument8 pagesComplete Offerings: Thermal Processing Agglomeration Material HandlingjuanalbertohaNo ratings yet

- FEECO Complete OfferingsDocument8 pagesFEECO Complete OfferingsawfahNo ratings yet

- Bag Opener System: Features BenefitsDocument2 pagesBag Opener System: Features BenefitsRicardo UsecheNo ratings yet

- Servolift Blending SystemsDocument4 pagesServolift Blending SystemsIcee SinlapasertNo ratings yet

- KUHN - Large Square BailersDocument20 pagesKUHN - Large Square BailersAndrew ReidNo ratings yet

- 2019 Bale Processor LiteratureDocument7 pages2019 Bale Processor LiteratureNícoli GaloNo ratings yet

- SYMTEC ADMIX AllProdBrochureDocument20 pagesSYMTEC ADMIX AllProdBrochureRodolfo RuaroNo ratings yet

- Versatility and precision with handtmann VF 600 vacuum fillerDocument12 pagesVersatility and precision with handtmann VF 600 vacuum fillermiloNo ratings yet

- Vemag 500 Bakery BrochureDocument4 pagesVemag 500 Bakery BrochureMilanVukicNo ratings yet

- Admix All Product Brochure PDFDocument20 pagesAdmix All Product Brochure PDFVishal SalveNo ratings yet

- Ross General BrochureDocument16 pagesRoss General BrochurefresitoNo ratings yet

- Mobile Mixing PlantDocument7 pagesMobile Mixing PlantEneng RismawatiNo ratings yet

- CPM Feed BrochureDocument16 pagesCPM Feed Brochureferry brandone njitacke tiamNo ratings yet

- CV YUWANA BAKTI Company ProfileDocument16 pagesCV YUWANA BAKTI Company Profileaditya pamungkasNo ratings yet

- GB7150 - en 1 22Document5 pagesGB7150 - en 1 22ErwinNo ratings yet

- Hobart Hood Type DishwasherDocument24 pagesHobart Hood Type DishwasherneelkamalNo ratings yet

- Mobile Concrete Plant Features & AdvantagesDocument15 pagesMobile Concrete Plant Features & Advantagesnew2trackNo ratings yet

- Rotary dryers and coolersDocument2 pagesRotary dryers and coolersvahidNo ratings yet

- Kin Randa DatDocument41 pagesKin Randa DatimukonNo ratings yet

- Detergent CatalogDocument37 pagesDetergent CatalogHaithamNo ratings yet

- Wet Mix Plant Capacities and FeaturesDocument9 pagesWet Mix Plant Capacities and FeaturesBrajnandan AryaNo ratings yet

- Wet Mix Plant: Atlasindustries - inDocument9 pagesWet Mix Plant: Atlasindustries - inWangdid KhatiNo ratings yet

- Transavon Plodders Provide a New Approach to Toilet Soap FinishingDocument35 pagesTransavon Plodders Provide a New Approach to Toilet Soap FinishingSarwat Naim SiddiquiNo ratings yet

- Sunsai Pharma Equipments Pvt. ltd-1Document2 pagesSunsai Pharma Equipments Pvt. ltd-1Sunsai VasaiNo ratings yet

- Guide To Turf Sod Equipment at 999 TPI Summer Field Day: HarvestersDocument19 pagesGuide To Turf Sod Equipment at 999 TPI Summer Field Day: Harvestersirawan syadzali gunawanNo ratings yet

- Hobart Dish Washer - Product-Brochure - AUP-AMX-series - en - UK - 0614 - 0120Document32 pagesHobart Dish Washer - Product-Brochure - AUP-AMX-series - en - UK - 0614 - 0120sk lukoNo ratings yet

- Flygt Biogas Production Brochure A4 Final Lo RezDocument12 pagesFlygt Biogas Production Brochure A4 Final Lo RezFabricio TrosarelloNo ratings yet

- Brochure Presses UKDocument8 pagesBrochure Presses UKEng.ibrahim FathyNo ratings yet

- Darley ApparatusDocument12 pagesDarley ApparatusAdvenser GroupNo ratings yet

- Inline Powder Wetting-YstralDocument3 pagesInline Powder Wetting-Ystralpsvel123No ratings yet

- Se Andritz KMPT Peeler Centrifuge HZ enDocument16 pagesSe Andritz KMPT Peeler Centrifuge HZ enlimim56582No ratings yet

- EN3190v1 Information Sheet SLIM Globe (EN)Document4 pagesEN3190v1 Information Sheet SLIM Globe (EN)EmmanuelNo ratings yet

- Latest Technology in Cereals ProductionDocument5 pagesLatest Technology in Cereals ProductionNadherah MohamadNo ratings yet

- Transavon Plodders: A New Approach to Toilet Soap FinishingDocument35 pagesTransavon Plodders: A New Approach to Toilet Soap FinishingAbdurahman YassinNo ratings yet

- Fortuna Automat Semi Automat 2010Document8 pagesFortuna Automat Semi Automat 2010faraonce2007No ratings yet

- Leading Mixing Technology ManufacturerDocument8 pagesLeading Mixing Technology ManufacturerRandallharwellNo ratings yet

- Ribbon BlenderDocument4 pagesRibbon BlenderRoberston Albornoz RomeroNo ratings yet

- FEECO Agglomeration SolutionsDocument8 pagesFEECO Agglomeration SolutionsRafael RiosNo ratings yet

- LB Bohle Blending ENDocument5 pagesLB Bohle Blending ENWalas ribeiro da silvaNo ratings yet

- Forage Compactor 7700: Part of The FC7000 Series of Hay PressesDocument4 pagesForage Compactor 7700: Part of The FC7000 Series of Hay PressesAbimelec TaipeNo ratings yet

- RS 1500 Sulphur GranulatorDocument4 pagesRS 1500 Sulphur GranulatorvzgscribdNo ratings yet

- 60cumhr H Series Bro2018 PDFDocument16 pages60cumhr H Series Bro2018 PDFRUSTAM ANSARINo ratings yet

- 02EN3v1 Brochure Working With Bread (EN)Document16 pages02EN3v1 Brochure Working With Bread (EN)EmmanuelNo ratings yet

- Flour Mill Machinery: Become DealerDocument12 pagesFlour Mill Machinery: Become Dealerdeepuchauhan848No ratings yet

- CHP BrochureDocument8 pagesCHP BrochureHoward BellabyNo ratings yet

- Fowler Westrup-BrochureDocument20 pagesFowler Westrup-BrochureDevelopment [Agrosaw]No ratings yet

- SB Imagebrochure en LQ CompressedDocument13 pagesSB Imagebrochure en LQ Compressedred patriotNo ratings yet

- FB Hammermill en DataDocument8 pagesFB Hammermill en DataAditya Whisnu Heryudhanto100% (1)

- Oxbo Berry-22Document8 pagesOxbo Berry-22masonluNo ratings yet

- Ultra-High Shear Mixing Strategies: A White Paper Prepared by Charles Ross & Son CompanyDocument9 pagesUltra-High Shear Mixing Strategies: A White Paper Prepared by Charles Ross & Son Companydevang asherNo ratings yet

- Filtration Technology For The Grain IndustryDocument8 pagesFiltration Technology For The Grain IndustryShubham SahuNo ratings yet

- BAUER-catalogue 6.0 GB 72dpiDocument152 pagesBAUER-catalogue 6.0 GB 72dpiMoviechanelNo ratings yet

- Round-SeparatorDocument10 pagesRound-SeparatorDenis BernierNo ratings yet

- Cristal BallDocument21 pagesCristal BallelaineurbNo ratings yet

- Tecnologias EmergentesDocument15 pagesTecnologias EmergenteselaineurbNo ratings yet

- Reotemp Sani TempDocument2 pagesReotemp Sani TempelaineurbNo ratings yet

- Wireless Gateway: Quick Start GuideDocument2 pagesWireless Gateway: Quick Start GuideelaineurbNo ratings yet

- Reotemp Sani TempDocument2 pagesReotemp Sani TempelaineurbNo ratings yet

- FD 7 120 Modelos de Secadores Atlas Copco PDFDocument20 pagesFD 7 120 Modelos de Secadores Atlas Copco PDFelaineurbNo ratings yet

- Hansen Valves PDFDocument21 pagesHansen Valves PDFelaineurbNo ratings yet

- Tune-Up Cooling System & Belts: Item Part Number Remarks Item Part Number RemarksDocument6 pagesTune-Up Cooling System & Belts: Item Part Number Remarks Item Part Number RemarkselaineurbNo ratings yet

- M1b - Warning Letter - AMKSDocument5 pagesM1b - Warning Letter - AMKSelaineurbNo ratings yet

- Datasheet Vessel VerticalDocument1 pageDatasheet Vessel VerticalelaineurbNo ratings yet

- Biflow SB (Con)Document7 pagesBiflow SB (Con)elaineurbNo ratings yet

- Passive Intake ScreensDocument4 pagesPassive Intake Screensfininho555No ratings yet

- Goulds 3700 - OhungDocument9 pagesGoulds 3700 - OhungelaineurbNo ratings yet

- Operating Instructions for Plate Heat ExchangersDocument32 pagesOperating Instructions for Plate Heat Exchangerselaineurb100% (1)

- Passive Intake ScreensDocument4 pagesPassive Intake Screensfininho555No ratings yet

- PSS User GuideDocument16 pagesPSS User GuideelaineurbNo ratings yet

- Optimum Work Methods in The Nursery Potting ProcessDocument107 pagesOptimum Work Methods in The Nursery Potting ProcessFöldi Béla100% (1)

- UntitledDocument4 pagesUntitledMOHD JEFRI BIN TAJARINo ratings yet

- UK Commutator Maintenance CatalogueDocument9 pagesUK Commutator Maintenance CatalogueCarlosNo ratings yet

- Complex Numbers GuideDocument17 pagesComplex Numbers GuideGus EdiNo ratings yet

- (V) 2020-Using Extensive Reading in Improving Reading Speed and Level of Reading Comprehension of StudentsDocument7 pages(V) 2020-Using Extensive Reading in Improving Reading Speed and Level of Reading Comprehension of StudentsMEYTA RAHMATUL AZKIYANo ratings yet

- Lesson Plan 12 Climate ChangeDocument5 pagesLesson Plan 12 Climate ChangeRey Bello MalicayNo ratings yet

- Edexcel A2 Biology 6BI06Document7 pagesEdexcel A2 Biology 6BI06abhayNo ratings yet

- Conceptual Framework For Group Processing of Lyric Analysis Interventions in Music Therapy Mental Health PracticeDocument9 pagesConceptual Framework For Group Processing of Lyric Analysis Interventions in Music Therapy Mental Health Practiceantonella nastasiaNo ratings yet

- Hollywood Game Plan 20 Page Sample PDFDocument20 pagesHollywood Game Plan 20 Page Sample PDFMichael Wiese Productions0% (1)

- OV2640DSDocument43 pagesOV2640DSLuis Alberto MNo ratings yet

- Differentiation: Vehicle Network SolutionsDocument1 pageDifferentiation: Vehicle Network SolutionsДрагиша Небитни ТрифуновићNo ratings yet

- 7 Equity Futures and Delta OneDocument65 pages7 Equity Futures and Delta OneBarry HeNo ratings yet

- Robin Engine EH722 DS 7010Document29 pagesRobin Engine EH722 DS 7010yewlimNo ratings yet

- Minimum Fees To Be Taken by CADocument8 pagesMinimum Fees To Be Taken by CACA Sanjay BhatiaNo ratings yet

- Product Data: T T 13 SEER Single - Packaged Heat Pump R (R - 410A) RefrigerantDocument36 pagesProduct Data: T T 13 SEER Single - Packaged Heat Pump R (R - 410A) RefrigerantJesus CantuNo ratings yet

- Yamaha RX-A3000 - V3067Document197 pagesYamaha RX-A3000 - V3067jaysonNo ratings yet

- Assessment of Benefits and Risk of Genetically ModDocument29 pagesAssessment of Benefits and Risk of Genetically ModSkittlessmannNo ratings yet

- Alpha Phi Omega National Service Fraternity Strategic PlanDocument1 pageAlpha Phi Omega National Service Fraternity Strategic Planlafay3tteNo ratings yet

- Module-1 STSDocument35 pagesModule-1 STSMARYLIZA SAEZNo ratings yet

- Primary Homework Help Food ChainsDocument7 pagesPrimary Homework Help Food Chainsafnaxdxtloexll100% (1)

- Required Reading For Piano Technicians PDFDocument28 pagesRequired Reading For Piano Technicians PDFNinaNo ratings yet

- TSGE - TLGE - TTGE - Reduce Moment High Performance CouplingDocument6 pagesTSGE - TLGE - TTGE - Reduce Moment High Performance CouplingazayfathirNo ratings yet

- Women Safety AppDocument18 pagesWomen Safety AppVinod BawaneNo ratings yet

- Pharma Pathway SopDocument350 pagesPharma Pathway SopDinesh Senathipathi100% (1)

- Type of PoemDocument10 pagesType of PoemYovita SpookieNo ratings yet

- Performance of a Pelton WheelDocument17 pagesPerformance of a Pelton Wheellimakupang_matNo ratings yet

- Case 1 1 Starbucks Going Global FastDocument2 pagesCase 1 1 Starbucks Going Global FastBoycie TarcaNo ratings yet

- Windows Keyboard Shortcuts OverviewDocument3 pagesWindows Keyboard Shortcuts OverviewShaik Arif100% (1)

- Teacher Commitment and Dedication to Student LearningDocument8 pagesTeacher Commitment and Dedication to Student LearningElma Grace Sales-DalidaNo ratings yet

- Roll Covering Letter LathiaDocument6 pagesRoll Covering Letter LathiaPankaj PandeyNo ratings yet