Professional Documents

Culture Documents

Honeywell Sensing I2c Communications Digital Airflow Sensors Technical Note 008210 5 en PDF

Uploaded by

moabdolyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Honeywell Sensing I2c Communications Digital Airflow Sensors Technical Note 008210 5 en PDF

Uploaded by

moabdolyCopyright:

Available Formats

Technical Note

I2C Communication with Honeywell Digital Airflow Sensors

1.0 Introduction (Other custom values are available. Please contact Honeywell

Customer Service if there are questions regarding custom slave

2

The I C bus is a simple, serial 8-bit oriented computer bus for addresses.)

2

efficient I C (Inter-IC) control. It provides good support for

communication between different ICs across short circuit-board 3.0 Digital Flow Reading

distances, such as interfacing microcontrollers with various low

2

speed peripheral devices. For detailed specifications of the I C Honeywell’s digital output airflow sensors are designed to work

2

protocol, see I C Bus Specification Version 2.1 January as slaves and will therefore only respond to requests from a

2000. Source: NXP Semiconductor at master device. The sensors operate as a slave-only and the

http://www.nxp.com/acrobat_download/literature/9398/393400 READ command structure is shown in Figure 2.

11.pdf. (Note: this link is controlled by NXP Semiconductor and

is subject to change by them.) The sensors report the “data not ready” status until after a

start-up time. The first two consecutive READ commands that

Each device connected to the bus is software addressable by a respond with non-zero valid data will provide the contents of

unique address and a simple master/slave relationship that two 16-bit registers with serial number information.

exists at all times. The output stages of devices connected to

2

the bus are designed around an open collector architecture. Figure 2. Standard I C READ Command and Word Structure

Because of this, pull-up resistors to +VDD must be provided on

READ (Slave Returning Data to the Master)

the bus.

S 6 5 4 3 2 1 0 1 A 7 6 5 4 3 2 1 0 A 7 6 5 4 3 2 1 0 N S

Both SCL and SDA are bidirectional lines, and it is important to

system performance to match the capacitive loads on both Address Byte Response Byte Response Byte

2

lines. In addition, in accordance with the I C specification, the

maximum allowable capacitance on either line is 400 pF to Wait for Slave ACK Master ACK Master NACK

ensure reliable edge transitions at 400 kHz clock speeds (see

S Start bit 0 Read/write (example: write)

Figure 1). When the bus is free, both lines are pulled up to

2

+VDD. Data on the I C-bus can be transferred at a rate up to S Stop bit 2 Slave address bit (example: bit 2)

100 kbit/s in the standard-mode, or up to 400 kbit/s in the fast-

mode. A Acknowledge 2 Response bit (example: bit 2)

2

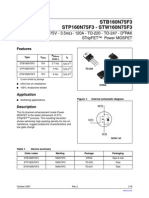

Figure 1. I C Bus Configuration

+VDD The sensor is asynchronous at start-up and will wait to supply the

Pull-Up RSCL RSDA sequential serial number values on the first two READ

SCL Resistors

(Serial Clock Line)

commands.

Master SDA

(Serial Data Line) After the serial number registers are read in succession, the

sensor will then begin repeating 14-bit calibrated flow sensor

2

Slave 1 Slave 3 output values updated every 1 ms (I C 16-bit word including

two leading zero bits = ’00’ specifying calibrated flow data

Slave 2 packet). Table 1 shows the initial start-up sequence and

subsequent data transfers of the sensor after power is applied.

2.0 Sensor Address

2

Each I C digital sensor is referenced on the bus by a 7-bit slave

2

address. The I C default address is 0x49; however, the address

is selectable according to the Nomenclature and Order Guide in

the Honeywell Zephyr™ Digital Airflow Sensors: HAF Series-

High Accuracy product data sheet.

Sensing and Control

I2C Communication with Honeywell Digital Airflow Sensors

Table 1. Start-up Sequence

2 2 2 2

Data I C Transfer 1 I C Transfer 2 I C Transfer 3 I C Transfer 4

Received by slave address with slave address with slave address with slave address with read

airflow sensor read bit read bit read bit bit

2 2 2 2

Command I C read op I C read op I C read op I C read op

Transmitted by 0x0000 Data [15:0] Data[15:0] {00, Data[13:0]}

airflow sensor

Response diagnostic low customer Reg0 customer Reg1 corrected flow

Comment data not ready data ready, send serial number start sending flow for

send serial number register 1 once successive reads

register 0 once

Note: The leading 2-bits of each word of the 14-bit sensor output data are ‘00’.

4.0 Parameter Specifications and Timing

2

Table 2 describes the minimum and maximum limits for parameters for I C operation with the Honeywell airflow sensors.

2

Table 2. Parameters for I C Bus Communication with Honeywell Digital Airflow Sensors

Characteristic Sym. Condition Min. Typ. Max. Unit Note

Input high level VIH 0.9 1 VDD 1

Input low level VIL 0 0.1 VDD 1

open drain, 1

Output low level VOL 0.1 VDD

IOL = -4 mA

Pull up current IOH pins SCL and SDA 5 20 μA

Load capacitance SDA CL_SDA 400 pF

SCL clock frequency fSCL 100 kHz

Bus free time between STOP and

tBUF 4.7 μs

START condition

Hold time (repeated) START condition tHD,STA to first clock pulse 4.0 μs

Low period of SCL tLOW 4.7 μs

High period of SCL tHIGH 4.0 μs

Setup time repeated start condition tSU,STA 4.7 μs

Data hold time tHD,DAT 0 ns

Data setup time tSU,DAT 250 ns

Rise time of both SDA and SCL tR 300 ns

Fall time of both SDA and SCL tF 300 ns

Set up time for stop condition tSU,STO 4 μs

spikes on SDA or

Input filter spike suppression tSP SCL of that length are 50 ns

suppressed

Note:

1. VDD is the supply voltage.

2 Honeywell Sensing and Control

I2C Communication with Honeywell Digital Airflow Sensors

WARNING

PERSONAL INJURY

DO NOT USE these products as safety or emergency stop

devices or in any other application where failure of the

product could result in personal injury.

Failure to comply with these instructions could result in

death or serious injury.

Honeywell warrants goods of its manufacture as being free of

defective materials and faulty workmanship. Honeywell’s

standard product warranty applies unless agreed to otherwise

by Honeywell in writing; please refer to your order

acknowledgement or consult your local sales office for specific

warranty details. If warranted goods are returned to Honeywell

during the period of coverage, Honeywell will repair or replace,

at its option, without charge those items it finds defective. The

foregoing is buyer’s sole remedy and is in lieu of all other

warranties, expressed or implied, including those of

merchantability and fitness for a particular purpose. In no

event shall Honeywell be liable for consequential, special,

or indirect damages.

While we provide application assistance personally, through

our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the

application.

Specifications may change without notice. The information we

supply is believed to be accurate and reliable as of this printing.

However, we assume no responsibility for its use.

Honeywell serves its customers through a worldwide network

of sales offices, representatives and distributors. For

application assistance, current specifications, pricing or name

of the nearest Authorized Distributor, contact your local sales

office or:

E-mail: info.sc@honeywell.com

Internet: sensing.honeywell.com

Phone and Fax:

USA/Canada +1-800-537-6945

International +1-815-235-6847; +1-815-235-6545 Fax

Sensing and Control

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422 008210-5-EN IL50

February 2015

honeywell.com Copyright © 2015 Honeywell International Inc. All rights reserved.

You might also like

- I2C Comms HumidIcon TN - 009061-2-EN - Final - 07jun12 PDFDocument4 pagesI2C Comms HumidIcon TN - 009061-2-EN - Final - 07jun12 PDFAdriana Waldorf100% (1)

- Digital Compass Solution HMC6352: Features BenefitsDocument13 pagesDigital Compass Solution HMC6352: Features BenefitsCarlos Alberto Espindola SilvaNo ratings yet

- ASSESSMENT 2: D/A and A/D convertersDocument7 pagesASSESSMENT 2: D/A and A/D convertersRamesh RaamNo ratings yet

- DS1624 Digital Thermometer and Memory: Features Pin AssignmentDocument16 pagesDS1624 Digital Thermometer and Memory: Features Pin AssignmentJhónatan JuárezNo ratings yet

- Sigma2 Modbus - Jan 2016Document19 pagesSigma2 Modbus - Jan 2016Dave PotterNo ratings yet

- LM8751-National Semiconductor (Inglês)Document32 pagesLM8751-National Semiconductor (Inglês)vanmarteNo ratings yet

- T-920 User Manual v1.2Document11 pagesT-920 User Manual v1.2Aung Kyaw OoNo ratings yet

- Integrated Circuit Bus Protocol GuideDocument53 pagesIntegrated Circuit Bus Protocol GuideFarman Rizvi100% (2)

- Chapter 1. OverviewDocument58 pagesChapter 1. OverviewmgitecetechNo ratings yet

- Line Following With PID AlgorithmDocument12 pagesLine Following With PID AlgorithmJason RichardsonNo ratings yet

- ASHIDA Numerical 3OC + 1EF Protection RelayDocument19 pagesASHIDA Numerical 3OC + 1EF Protection RelayNamrata ShettiNo ratings yet

- A Control System Using Parallel Interface.: Microprocessor ControllerDocument4 pagesA Control System Using Parallel Interface.: Microprocessor Controllernovo orderNo ratings yet

- XK3118 - D2008F (A、P、P1) technical manual bookDocument42 pagesXK3118 - D2008F (A、P、P1) technical manual bookvuong buiNo ratings yet

- DS1624Document17 pagesDS1624superpuma86No ratings yet

- Inter Integrated CircuitDocument14 pagesInter Integrated CircuitSurya ChandraNo ratings yet

- Us 1Document4 pagesUs 1serviciobsasNo ratings yet

- I2C Bus Specifications for CMS Tracker 2S & PS ModulesDocument13 pagesI2C Bus Specifications for CMS Tracker 2S & PS ModulesGasthim KiranNo ratings yet

- Datasheet SDP600series Differential Pressure SensorDocument9 pagesDatasheet SDP600series Differential Pressure SensorRahul Albuquerque100% (1)

- DS1200Document7 pagesDS1200naseerNo ratings yet

- ASHIDA Numerical 3OC Protection RelayDocument17 pagesASHIDA Numerical 3OC Protection RelayNamrata ShettiNo ratings yet

- Cardinal Nic SpecificationsDocument6 pagesCardinal Nic Specificationselectronics enthusiast pradeepNo ratings yet

- Chapter 5 Serial IO InterfaceDocument51 pagesChapter 5 Serial IO InterfacetesfayebbNo ratings yet

- DS1624Document15 pagesDS1624jnax101No ratings yet

- Arduino Project Burglar Zone Input TesterDocument4 pagesArduino Project Burglar Zone Input TesterCezary Jan JaronczykNo ratings yet

- Mini Project ReportDocument15 pagesMini Project ReportShirsendu AcharyyaNo ratings yet

- Programmable V/I/Hz Transducer Setup GuideDocument32 pagesProgrammable V/I/Hz Transducer Setup GuideRanjit Sahoo0% (1)

- ADC (Analog-To-Digital Converter)Document11 pagesADC (Analog-To-Digital Converter)Abdullah Muzammil0% (1)

- DPS5005 Communication Protocol - English Google Translate Version V1.2Document7 pagesDPS5005 Communication Protocol - English Google Translate Version V1.2Giordano De StefanisNo ratings yet

- 12-Bit Monitor and Control System With Multichannel Adc, Dacs, Temperature Sensor, and Current SenseDocument47 pages12-Bit Monitor and Control System With Multichannel Adc, Dacs, Temperature Sensor, and Current SenseMichael SaligaoNo ratings yet

- Experiment #8 Serial Communication Using The Asynchronous Communications Interface Adapter (Acia)Document29 pagesExperiment #8 Serial Communication Using The Asynchronous Communications Interface Adapter (Acia)Felipe DiasNo ratings yet

- SM43 J R20 Especificacao TecnicaDocument4 pagesSM43 J R20 Especificacao TecnicaMarcoNo ratings yet

- Transmitter Reciver: ChannelDocument5 pagesTransmitter Reciver: ChannelAmit Raj KamatNo ratings yet

- Design of a High Speed Multi-Channel Data Acquisition SystemDocument16 pagesDesign of a High Speed Multi-Channel Data Acquisition SystemVinod HandiNo ratings yet

- Ls 7166Document14 pagesLs 7166Tronix RepaireNo ratings yet

- EE6008 Unit 3Document8 pagesEE6008 Unit 3TakeItEasyDude TIEDNo ratings yet

- I2C-Master Core SpecificationDocument17 pagesI2C-Master Core Specificationvarunmr100% (1)

- Ad7714 15 Faqs Serial InterfaceDocument3 pagesAd7714 15 Faqs Serial Interfacethg_teixeiraNo ratings yet

- Load Cell Input Module: 1 Specifications of FBS-PLC Load Cell Measurement ModulesDocument8 pagesLoad Cell Input Module: 1 Specifications of FBS-PLC Load Cell Measurement ModulesNelson GilNo ratings yet

- AD7705 Serial Interface FAQsDocument3 pagesAD7705 Serial Interface FAQsAP SinghNo ratings yet

- Remote Controlled Digital Audio Processor - Full Project AvailableDocument3 pagesRemote Controlled Digital Audio Processor - Full Project AvailableK Raja SekarNo ratings yet

- CAN BUS Communication Manual For The DNC Series: ContentDocument9 pagesCAN BUS Communication Manual For The DNC Series: Contentstu807No ratings yet

- How To Connect Multiple I2C Devices To An Arduino MicrocontrollerDocument5 pagesHow To Connect Multiple I2C Devices To An Arduino MicrocontrollerEdwardNo ratings yet

- I2C PROTOCOL APPLICATIONDocument4 pagesI2C PROTOCOL APPLICATIONcarlos huamanNo ratings yet

- Lm40 Hardware Monitor With Dual Thermal Diodes and Sensorpath BusDocument27 pagesLm40 Hardware Monitor With Dual Thermal Diodes and Sensorpath BusStuxnetNo ratings yet

- LTC 2499Document34 pagesLTC 2499m3rishorNo ratings yet

- RS232 Communication StandardDocument25 pagesRS232 Communication StandardRahil HussainNo ratings yet

- Diff ADR233A - V2 - BESTDocument15 pagesDiff ADR233A - V2 - BESTtoogooodNo ratings yet

- Installation and Operating Instructions for POWER PHASE ANGLE POWER FACTOR TRANSDUCERDocument44 pagesInstallation and Operating Instructions for POWER PHASE ANGLE POWER FACTOR TRANSDUCERpadmawarNo ratings yet

- Chapter 3Document8 pagesChapter 3Jayanth ReddyNo ratings yet

- Communication Interface: SD20 Series Digital IndicatorDocument28 pagesCommunication Interface: SD20 Series Digital IndicatorChristianNo ratings yet

- Switchboard ManualDocument14 pagesSwitchboard ManualAbdo Rsv100% (1)

- Eeprom BL24C32 BL24C64Document13 pagesEeprom BL24C32 BL24C64Hugo PerezNo ratings yet

- PmodCMPS Manual HMC5883Document2 pagesPmodCMPS Manual HMC5883soros4No ratings yet

- Unit Iii I/O Interfacing Reference: Chapter 9 Microcomputer Systems, Cheng Liu, Glenn GibsonDocument337 pagesUnit Iii I/O Interfacing Reference: Chapter 9 Microcomputer Systems, Cheng Liu, Glenn GibsonGomathi PsNo ratings yet

- 14.4. Register Description: 14.4.1. I2C - M - 0 - CONTROL - REG 0x2140Document3 pages14.4. Register Description: 14.4.1. I2C - M - 0 - CONTROL - REG 0x2140asdasdasfli.elkinNo ratings yet

- Applicatoin Note - Phil Zanotti (AD Converter)Document4 pagesApplicatoin Note - Phil Zanotti (AD Converter)arturovinnNo ratings yet

- EDN Design Ideas 1998Document166 pagesEDN Design Ideas 1998chag1956100% (4)

- SolidWorks Premium 2013 x64 Edition - (BindingAnchor PDFDocument1 pageSolidWorks Premium 2013 x64 Edition - (BindingAnchor PDFmoabdolyNo ratings yet

- Molavi Dar Erfane IranDocument417 pagesMolavi Dar Erfane Iranhaseeb4evaNo ratings yet

- Advanced ExcelDocument72 pagesAdvanced ExcelSaiful Fx FxNo ratings yet

- Shams MaghalatDocument369 pagesShams MaghalatmoabdolyNo ratings yet

- Excel Dashboards Tutorial PDFDocument166 pagesExcel Dashboards Tutorial PDFmoabdoly93% (15)

- Honeywell Sensing Airflow Awm Series Introduction Catalog PagesDocument1 pageHoneywell Sensing Airflow Awm Series Introduction Catalog PagesmoabdolyNo ratings yet

- Excel Dax Tutorial PDFDocument23 pagesExcel Dax Tutorial PDFmoabdolyNo ratings yet

- Advanced ExcelDocument72 pagesAdvanced ExcelSaiful Fx FxNo ratings yet

- Honeywell Sensing Pressure Force Flow Rangeguide 008081 24 EN - Lowres PDFDocument12 pagesHoneywell Sensing Pressure Force Flow Rangeguide 008081 24 EN - Lowres PDFmoabdolyNo ratings yet

- DM 00039831Document12 pagesDM 00039831moabdolyNo ratings yet

- Honeywell Sensing Airflow Sensors Line Guide 008150 7 en PDFDocument6 pagesHoneywell Sensing Airflow Sensors Line Guide 008150 7 en PDFmoabdolyNo ratings yet

- Gate Drive TrafoDocument4 pagesGate Drive Trafobenygiurgiu100% (1)

- IGBT Reverse Conduction Characteristics Hard-Switching and Soft-SwitchingDocument7 pagesIGBT Reverse Conduction Characteristics Hard-Switching and Soft-SwitchingmoabdolyNo ratings yet

- Mosfet Gate Driving CircuitDocument37 pagesMosfet Gate Driving Circuitkannanrk1984No ratings yet

- Power Mos 7 Fredfet: APT55M50JFLLDocument5 pagesPower Mos 7 Fredfet: APT55M50JFLLmoabdolyNo ratings yet

- General Questions About Gate DriversDocument5 pagesGeneral Questions About Gate DriversmoabdolyNo ratings yet

- Steval Isv001v1 BomDocument2 pagesSteval Isv001v1 BommoabdolyNo ratings yet

- AV02-2483EN DS ACNV4506 31aug2011Document14 pagesAV02-2483EN DS ACNV4506 31aug2011moabdolyNo ratings yet

- CD 00218772Document6 pagesCD 00218772moabdolyNo ratings yet

- DS FT232HDocument65 pagesDS FT232HmoabdolyNo ratings yet

- DS Um232h-BDocument14 pagesDS Um232h-BmoabdolyNo ratings yet

- Stb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetDocument16 pagesStb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetmoabdolyNo ratings yet

- Hy1z 12VDocument4 pagesHy1z 12VmoabdolyNo ratings yet

- Modern Homework2Document1 pageModern Homework2moabdolyNo ratings yet

- ControlDocument30 pagesControlmoabdolyNo ratings yet

- AB-8-Selection of MOSFETs in Switch ModeDocument4 pagesAB-8-Selection of MOSFETs in Switch ModebmmostefaNo ratings yet

- Linear Switching Regulator FundamentalsDocument29 pagesLinear Switching Regulator FundamentalsbudituxNo ratings yet

- ARM Based Development Course by Mouli SankaranDocument1,027 pagesARM Based Development Course by Mouli SankaranChandramouleeswaran Sankaran100% (7)

- How To Get Information About Users Connected To The TTY by Using SNMPDocument5 pagesHow To Get Information About Users Connected To The TTY by Using SNMPparikhdineshNo ratings yet

- Organizations and IT Support Systems ExplainedDocument35 pagesOrganizations and IT Support Systems ExplainedvenkeekuNo ratings yet

- Corrige 2Document3 pagesCorrige 2Sergio FernandesNo ratings yet

- Issue With Native USB Tethering in Windows 7 - Post #18 - XDA ForumsDocument2 pagesIssue With Native USB Tethering in Windows 7 - Post #18 - XDA Forumse0nealiffNo ratings yet

- A1800 Meter - Modbus MapDocument48 pagesA1800 Meter - Modbus MaphazimeNo ratings yet

- LEAKED_RECEIVERSDocument5 pagesLEAKED_RECEIVERSMg Soe KyannNo ratings yet

- STM 32Document8 pagesSTM 32Simone FontanaNo ratings yet

- Maintenance Planning PDFDocument5 pagesMaintenance Planning PDFarpit_saraswat89No ratings yet

- Windows 8 Product Key 100% Working Serial Keys - Latest Free Software DownloadDocument8 pagesWindows 8 Product Key 100% Working Serial Keys - Latest Free Software DownloadMahesh DeodharNo ratings yet

- Network OrchestrationDocument2 pagesNetwork OrchestrationMo ElNo ratings yet

- 4-bit Ripple Carry Adder DesignDocument32 pages4-bit Ripple Carry Adder DesignSubhajit DasNo ratings yet

- GameKit GuideDocument84 pagesGameKit GuideСаша ЈанковићNo ratings yet

- Ps Virtual Web Application Firewall Admin GuideDocument622 pagesPs Virtual Web Application Firewall Admin GuideWalter BlokNo ratings yet

- Fuses Del PicDocument7 pagesFuses Del PicCarlos RodríguezNo ratings yet

- Evolution of Routing TechniquesDocument69 pagesEvolution of Routing Techniquestusarkar85No ratings yet

- Download PDF A Closed and Common Orbit (Wayfarers) | Read OnlineDocument1 pageDownload PDF A Closed and Common Orbit (Wayfarers) | Read OnlineEdo Shima0% (2)

- STBDocument7 pagesSTBRavi ReddyNo ratings yet

- Wifi Weather Station Esp 8266Document7 pagesWifi Weather Station Esp 8266MoogNo ratings yet

- Database Administrators GuideDocument123 pagesDatabase Administrators GuideCarlotta Jones-Ford100% (2)

- IT Requirements Paper For Library Management System TemplateDocument23 pagesIT Requirements Paper For Library Management System TemplateSaadi FaidNo ratings yet

- PDF Steve Jobs Commencement Address 005Document4 pagesPDF Steve Jobs Commencement Address 005Lucas MachadoNo ratings yet

- GIS in DMDocument84 pagesGIS in DMrajasekaranvgNo ratings yet

- Pd4x e Map 5 Wiring (Map)Document6 pagesPd4x e Map 5 Wiring (Map)ALBERTONo ratings yet

- Psa Modules Wiring Diagrams: Obd2 DB9Document9 pagesPsa Modules Wiring Diagrams: Obd2 DB9Ĵames-Ĕddìne BaîaNo ratings yet

- (HUAWEI) Poster-GPON TechnologyDocument1 page(HUAWEI) Poster-GPON Technologyjorgecif100% (1)

- Acer Aspire 4535 (Compal LA-4921P) PDFDocument57 pagesAcer Aspire 4535 (Compal LA-4921P) PDFMustafa AkanNo ratings yet

- A Simple SDR Receiver: AbstractDocument8 pagesA Simple SDR Receiver: AbstractbilalNo ratings yet

- Student Study Guide: Windows Development FundamentalsDocument63 pagesStudent Study Guide: Windows Development FundamentalsIvan KalinichenkoNo ratings yet

- TCP Data FlowDocument39 pagesTCP Data FlowAkshayasrinivasanNo ratings yet