Professional Documents

Culture Documents

Lean Production in Precast Concrete

Uploaded by

Prateek ModyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lean Production in Precast Concrete

Uploaded by

Prateek ModyCopyright:

Available Formats

557

Lean Production in the Precast

Concrete Components’ Industry

Jean Deffense1, Nuno Cachadinha2

Abstract

This article is a case study applying Lean Thinking and Lean Production principles in

a factory that produces prefabricated reinforced concrete components. The objective is

to reduce waste production and increase productivity. Nine factories were analyzed, of

which one was chosen for developing an implementation model. A number of changes

were proposed based on Lean concepts and the study of several similar factories to

improve productivity. A Black Belt Team was created to improve the execution and

continuance of the lean concepts. Value Stream Mapping was also used as an aid in

the identification of existing waste and improvement opportunities, to which various

Lean tools were applied in order to solve the identified problems.

The main conclusions of this study are that it is possible to achieve a significant

improvement in the production system of prefabricated reinforced concrete components

using Lean philosophy. Improvements in the reduction of lead-time, reduction of

waste and increase in productivity are achieved with simple and low cost techniques.

KEY WORDS

Lean Production, Value Stream Mapping, Black Belt Team, Implementation Model,

Prefabrication

Introduction

Conventional construction with on site solutions have been criticized for a long time,

with their low productivity, poor safety records and large waste production (Chen et al.

2010, Albarran 2008). Prefabrication can offer significant advantages, such as reducing

overall costs, reduction in construction time, improved quality, enhanced safety on

site and reduction of waste production. The advantages depend on standardization and

good organization of work.

Lean Production was born just after World War II, with the development of

Toyota’s automotive production by Taiichi Ohno. The essence was to no longer focus

on individual parts of production but to analyse the production line as a whole. This

was to ensure flow throughout the process and eliminate waste, with the ability to

deliver variety of consumer products.

The term Lean was proposed by James P. Womack’s research team and described in

the book “The Machine That Changed The World” (Womack et al., 1990). Lean is a

dynamic way of thinking; its goals are to produce more using less.

1

MS.c in Civil Engineering. Faculdade de Ciências e Tecnologia, Universidade Nova de Lisboa. Phone

+351 214673485 ; jeandeffense@gmail.com

2

Assistant Professor, UNIDEMI, Departamento de Engenharia Civil, , Universidade Nova de Lisboa, Mon-

te da Caparica, 2829-516 Caparica, Portugal. Phone +351 212948557, n.cachadinha@fct.unl.pt

Production System Design

558 Jean Deffense, Nuno Cachadinha

This article sets out to study the benefits of Lean principles and tools in the precast

concrete industry. For this purpose, 9 factories that agreed to participate in this study

were analysed and a set of production processes identified that could be improved

through the implementation of Lean solutions. One case study was then selected

among the factories analysed. Its current state was analysed changes were proposed,

their impact accessed and the gains quantified. The Lean solutions were chosen based

on their potential to increase efficiency, eliminate waste, increase flow and reduce

lead-time. The work was developed at a precast reinforced concrete components

factory of a Portuguese company. The scope of this work is to study and verify the

status of a “Non Lean” production and apply Lean principles and tools, this provides

useful evidence to demonstrate and support the benefits of Lean.

Literature review

According to Warnecke and Hüser (1995), Lean management is an intellectual approach

consisting of a set of measures and methods, which have the potential to bring about

a lean and therefore more competitive state in a company. A Lean organization means

Lean principles are used in all its actions. The basic idea is to do all activities as lean

as possible (Kosonen and Buhanist, 1995).

The concept of eliminating waste is an important aspect to Lean Production.

Ohno (1988) stated that waste is any activity that does not add value to the product,

establishing seven main waste factors calling them “Muda”: overproduction,

transportation, inventory, motion, defects, over-processing and waiting

Lean Tools and Mythologies

Value Stream Mapping (VSM): This is a commonly used tool in Lean applications.

VSM is a paper and pen tool where a map of the complete process is drawn out with a

set of standardized icons, introduced by Rother and Shook (1998). With a map of the

complete process, it is easier to analyze and identify any weaknesses or waste sources.

Once these are identified, changes are proposed and implemented and the new process

is evaluated.

Black Belt Team (BBT): One of the main problems to the application of Lean concepts

is the lack of time (Melton, 2005). For an effective Lean implementation, teams should

be formed to coordinate the transition and keep continuous improvement. This team

is the BBT, and its functions are to have a deep understanding of Lean concepts,

analyze and understand the process, and find improvement opportunities, providing

the changes and verifying that they are implemented correctly.

Cellular Manufacturing: Is a model for workplace design. It is based on the

principles of Group Technology, which seeks to take advantage of similarity between

parts. Cellular Manufacturing consists in bringing equipment and work areas together

joined by their similarities, in order to maintain a steady product flow throughout the

process (Abdullah, 2003)

Proceedings IGLC-19, July 2011, Lima, Perú

Lean Production in the Precast Concrete Components’ Industry 559

5S Methodology: The 5S’s are of Japanese origin and are distributed in five actions

aimed at organization and standardization of work. The 5S’s of this methodology

are:

• Seiri (Sorting): Go through all tools and materials, keeping only essential items

and eliminating all others throughout the work area.

• Seiton (Stabilize): All items should have a specific place for them, clearly labeled

and marked. Items must also be arranged in such a way that it promotes efficient

workflow, being accessible at all times.

• Seiso (Systematic Cleaning): Maintaining cleanliness should be part of the daily

job. Keeping the workplace tidy and organized makes it easier to know what goes

where and ensures better workflow.

• Seiketsu (Standardizing): The work practices should be consistent and

standardized, following the previous rules established.

• Shitsuke (Sustaining): Once the previous rules have been established, they

become the new way to operate. The focus now is to maintain these new rules and

continuously seek improvement, repeating the steps all over again.

Just-In-Time (JIT): This is a production method based on “Pull”, where each step

demands from its previous step. This is in opposition to “Push” production, where

each step pushes its finished product on to the next step. JIT strives to deliver the right

product at the right time in the right quantity. It is used by high-tech manufacturing to

minimize inventory and stock (Chan, 2001).

Kanban: This is a subsystem of JIT, which is a cue card that controls production flow.

The Kanban controls the time and amount required for delivery (Junior and Filho,

2010). It is often used for ordering raw materials with a cue card that signals the need

to place the order. This signaling system can be varied, such as; empty boxes, light

signal or a marked item.

First In – First Out: Used in chain production the first item to go into a process

should be the first one to leave. All processes must be scheduled and processed by

order of flow entry.

Research Method

This article spans a theoretical analysis of the Lean philosophy to a practical

application. It was therefore necessary to perform an extensive study on the subject,

in order to obtain a good theoretical framework. At the same time it was necessary to

search for companies in the precast reinforced concrete industry that would authorize

the study of their production facilities and allow for a practical application of changes

according to Lean Production. A total of 9 factories where achieved that allowed to

study their production, as long as their identity was kept confidential. Those factories

set a sample for identifying a number of production processes that could be improved

through Lean principles and tools, as well as to assess the generalization of these

solutions to the Industry. One of the factories was then selected as a case study for

the implementation of the selected Lean solutions and an in-depth analysis of their

Production System Design

560 Jean Deffense, Nuno Cachadinha

benefits. This selection was based on the combination of three criteria: the possibility

to implement the highest number of selected solutions and the willingness of its

management to implement those solutions.

The evaluation of the current state of operation was developed through numerous

visits to the factories, with desk research and many interviews.

Factory Visits: In order to achieve a good analysis of the production process, it

is necessary to experience the situation firsthand. One must go see for oneself to

thoroughly understand the situation.

Interviews: The aim of the interviews is to collect data from the stakeholders’ view

on the production process. This is one of the most important sources of understanding

the activities in the production. These interviews follow a standard protocol with two

main parts:

• Identification: Collection of information concerning the respondent, such as name,

age, occupation, training and years of experience.

• Main Section: Sequence of questions to evaluate and characterize the present state

of production and check on how Lean the manufacturing process is. This part

follows the criteria stipulated by Womack (2008) for a Lean process, where every

process must be: Valuable, Capable, Available, Adequate and Flexible.

A total of 57 internal stakeholders were interviewed, namely 4 Board members, 7

Factory Directors, 3 Staff from the Technical Department, 4 Staff from Health and

Safety Management and 39 Workers involved in Production.

The interviews conducted with the workers included a set of questions to evaluate their

job satisfaction. A Likert scale was used, as follows:1 – Unsatisfied, 2 – Moderately

Unsatisfied, 3 – Satisfied, 4 – Very Satisfied and 5 – Totally Satisfied

The level of job satisfaction at the case study factory was calculated based on the

average of the responses deemed valid. These interviews were carried out before and

after the implementation of the selected changes, and the results compared.

Desk Research: To complete the research on the factories a desk research was

conducted. Most of the information collected was taken from the following

documents: plants of the factories, company and factory flow chart, raw materials

sheet, production equipment specifications, health and safety plan, balance sheet,

workers detail information and performance records.

Value Stream Mapping: VSM was used in the case study factory, to assist in the

identification of possible improvement areas. A future state VSM was then drawn,

based on the Lean solutions selected. A Black Belt Team was created to help in change

decisions and to monitor these changes. The improvements were quantified and

evaluated, as well as the limitations and conditions for a successful implementation.

This was carried out in two stages: first, each single change carried out and analysed

individually, then they were implemented simultaneously and studied as a whole.

Change Proposals

Proceedings IGLC-19, July 2011, Lima, Perú

Lean Production in the Precast Concrete Components’ Industry 561

Based on the observation and analysis of the production processes in the 9 factories

that built the research sample, a set of common problems were identified and Lean

solutions selected for their mitigation or elimination. These problems occurred in

5 specific areas: steel inventory, aggregates’ inventory, molding process, vibration

process, stocks of finished products and work area. They will now be portrayed, the

respective change proposals and their limitations described and discussed.

Steel Inventory Management: Excess raw material requires large storage areas. This

excess inventory, along with its poor management, overuses financial resources and

does not favor product flow. In this case it also undermines product quality because

the stock is not well organized. When a new order of steel is delivered it is unloaded

onto the previous stock of steel, trapping the older steel. This means that the workers

then use the new steel, leading to the oxidation of the older steel, thus affecting the

quality of the final product.

For this situation the level of inventory will be reduced and, for better inventory

management, Just-In-Time will be used along with Kanban, to signal the need to

place a new order of steel. Each kind of steel will be given two basket systems, where

the steel is consumed from one basket until it is empty. When this happens the steel

is taken from the other basket and signals the need to place an order of steel. After

placing an order, the steel takes between three to five working days to be delivered.

Thus, each of the baskets is designed to store enough steel to keep production running

for five days.

Steel Inventory Location: Unnecessary moving and transportation are a big waste in

production. This increases lead-time, consumes manpower and increases damage and

safety risks. The steel inventory is located far and in a perpendicular way from the next

stage in the process. This makes it necessary to use a vehicle for the transportation of

the steel and includes labor consumption.

Following Cellular Manufacturing and 5S methodology, the steel inventory is aligned

and moved close to the next stage in the process, promoting product flow.

Aggregates Inventory Location: The transportation of the aggregates from their

inventory to the concrete mixer is a waste of time and energy. The aggregates are

pushed into a recipient that dosages it into a bucket, which then elevates it into the

mixer. Production layout should not only be analyzed horizontally but also vertically.

Focusing on “Sorting” from the 5S methodology, the aggregates inventory should

be located at a higher point than the mixer. This way the filter basket can drain the

aggregates directly into the concrete mixer.

Molding: All equipment, tools and processes should be adequate. These should also

work at a similar pace, in order to create product flow. The molds used presently are

fixed and may only be used once each day. This system strangles production and limits

the number of components produced daily to the number of existing molds. Also,

because the molds are fixed, another problem arises, which is the transportation of the

Production System Design

562 Jean Deffense, Nuno Cachadinha

steel frame and the concrete. The transportation of the concrete requires a vehicle and

consumes labor.

For this problem the molding equipment will be changed for a molding system

that can almost instantly de-mold the component onto a platform. This means that

only one mold is necessary and may be placed directly below the mixer, eliminating

the need to transport the concrete to the various molds. This also allows reducing used

space because the platforms may be stored neatly and staked occupying less space.

Vibration: Once the concrete is placed in the mold it has to be vibrated to fill all

corners and areas of the mold with concrete, thus eliminating all the air pockets. This

process adds a great amount of time to the manufacturing process, also damaging

the molds on a long term basis. This also produces a high level of noise, affecting

particularly the workers in this step. An easy way of eliminating this problem is to use

additives in the concrete that render vibration unnecessary.

Stock: In the factory there is an excess stock of products. This occupies a great amount

of the factory area. Based on “Pull” production, which seeks to produce after order,

the stock of products will be reduced. This will reduce the space necessary and will

increase product flow.

Work Area: Over-processing, waiting and unnecessary movement, be it of work,

material, tools or products, contribute to an increase in lead time and production costs.

The work area is usually unorganized and overloaded with tools and materials. The

workers spend too much time looking for tools and materials to perform their tasks. In

the work area there should only be the tools, materials and workers needed for the job.

In addition, these tools and materials should be stored in strategic locations so they are

easily accessible at all times.

To solve this issue all workers will receive a brief training on Lean concepts, focusing

on 5S methodology and Cellular Manufacturing. This way they may organize their

work areas and promote a good working environment.

Results and Discussion

The changes proposed needed to be followed closely and were analyzed in two ways.

First the changes were evaluated independently, revealing their results without being

influenced by the others. Next, all changes were be taken into consideration and

analyzed as a whole, and the final conclusions were reached.

Independent Analysis

Steel Inventory Management: The changes in this sector reveal a reduction of the

necessary area by 42%, the area occupied is now 340m2 comparing to the initial 586m2.

This is due to the fact that the inventory levels were reduced and that the steel is now

organized and limited within the basket. Another benefit lies in the capital invested

in inventory, which was reduced by 50%. Regarding quality, the problem of steel

oxidation is completely eliminated, since the oxidized steel went from representing

Proceedings IGLC-19, July 2011, Lima, Perú

Lean Production in the Precast Concrete Components’ Industry 563

29% to 0% of the steels inventory. The improvement in quality results from the steel

being separated in two basket systems. This way the new order of steel is never

unloaded on top of existing steel. A precaution that must be taken into consideration

is the fact that the steel should never be in direct contact with the ground. It should

always be placed on top of wooden pallets. This precaution was already taken into

consideration in the factory prior to this work.

Steel Inventory Location: The relocation of the steel inventory eliminates the need to

transport the steel with the use of a vehicle and reduces the time in the preparation of the

steel by 38 seconds from its original time of 4 minutes and 33 seconds, representing a

reduction of 14%. There is a substantial increase in product flow with the elimination

of the unnecessary transportation of the steel. This change not only promotes an

increase in work safety, but also reduces production costs. Without the need of a

vehicle for the task, factory insurance becomes cheaper, fuel consumption goes down,

and vehicle maintenance or even purchase is eliminated. Regarding the area occupied

for this purpose, it was hoped to achieve its reduction. This did not happen, since the

trucks that deliver the steel still need the space to maneuver around.

Aggregates Inventory Location: This proposed change could not be tested because

the factory director did not accept it. The justification was that it would take a large

investment in new equipment and the implementation would compromise production

far beyond the benefits that this change would bring.

Molding: With the change in equipment and layout of the molding process, production

rose from 55 to 76 components produced per day, representing a 38% increase. The

benefits do not arise solely in this field, the area required was reduced by 230m2 from

720m2, giving a 32% reduction in the occupied area. Also the transportation of the

concrete was eliminated, no longer needing a vehicle for this task and the respective

waste in manpower. This new system uses only one mold for the entire production,

where the components are de-molded onto a platform. This is very beneficial, since

the cost of molds is very high, comparing to the platforms, which are small, light

and easy to maneuver. However, a problem arises with this new process, regarding

the First In - First Out principles. As the platforms are stacked after de-molding ,the

first one to enter the next step in production is the last to leave. Also this system has

limitations on the kind of product that can be produced. According to the equipment

manufacturer, its use is not advisable for items with lengths over 11m. This is due to

the vertical settlement being too great after de-molding, as well as the longitudinal

deformations that arise from product manipulation while the concrete is still fresh.

There is also another limitation regarding the cross section of the components produced.

They must have a cross section that allows to proceed with instant de-molding without

it losing its original shape. Some examples are shown in Figure 1 below:

Production System Design

564 Jean Deffense, Nuno Cachadinha

Figure 1: Cross section comparison

Vibration: The introduction of an additive in the concrete eliminates the vibration

process, reducing the number of workers by one in a team of 4 while simultaneously

increasing production by 3 components per day. Also this increases product flow and

contributes to the prolonging of the molds life span. But the cost of this additive

must be taken into consideration. Although this may seem to increase cost, in reality

it is more beneficial, since the additives cost represents only 45% of the cost of one

worker. There is also the benefit of not having to invest in the vibration equipment and

the frequent maintenance or purchase of new molds caused by the damage from the

vibration process. This also reduces energy consumption and eliminates the high level

of noise produced by the vibration of the molds. However, this additive may only be

used for the fixed molds. This additive may not be used simultaneously with the new

molding equipment, since it makes the concrete too fluid for the instant de-molding

process.

Stock: The reduction of stock was not implemented. The company did not allow it,

stating that orders are not constant, varying with the season. Also when these orders

are placed they are of great quantities, therefore forcing the need for a large stock to

balance the difference in orders. Supporting this idea, Dawood and Marasini (2002)

state that seasonality is inevitable for the precast concrete industry, obliging the

creation of a stock able to address this imbalance.

Work Area: With a clean and organized work area followed by 5S principles and

Cellular Manufacturing, work efficiency was increased and required work space was

reduced. For this section, three different areas were studied with efficiency percentages

relating to the number of units produced daily. The results are as followed:

• Preparation of Steel: Efficiency Increase 8%; Space Reduction 17%.

• Steel Frame Production: Efficiency Increase 11%; Space Reduction 8%.

• Molding: Efficiency Increase 2%; Space Reduction 0%.

In the overall production, efficiency suffered an increase of only 2%, since this value

is limited by the lowest of the three. This is due to the molding process which is

extremely limited by the transportation of the concrete from the mixer to the molds.

It consumes a fair amount of time and requires lots of space between the molds so the

vehicle may pass to unload the concrete into the molds.

Looking upon the steel frame production, the increase in efficiency is due to the

development of a new working bench, which was built and designed with the help

of the Black Belt Team, following 5S principles. This increases standardization,

Proceedings IGLC-19, July 2011, Lima, Perú

Lean Production in the Precast Concrete Components’ Industry 565

increasing production speed. For the preparation of steel the simple fact of eliminating

all unnecessary materials and tools, cleaning and organizing the work area, increased

job efficiency.

The workers influenced by these changes were again interviewed briefly to analyze

their job satisfaction. Out of the 57 interviews, only 18 were used to calculate the level

of job satisfaction.

The results on job satisfaction before the changes came to an average of 2.8. After

the changes it came to 3.4. This means that job satisfaction, on average, went from

“Satisfied” (tending towards “Moderately Satisfied”) to “Satisfied” (but on the verge

of “Very Satisfied”).

These changes lead to an increase in efficiency, reduction of occupied space and

increase in the workers job satisfaction. The satisfaction and productivity are affected

by a number of variables, but they are related. High satisfaction of the workers leads

to higher productivity, and higher productivity leads to greater satisfaction (Shikdar

and Das, 2003).

Overall Analysis

Once these changes were individually analyzed, they were studied as a whole. In this

step the changes taken into consideration were: steel inventory management, steel

inventory location, molding and work area.

The changes in the Aggregates Inventory Location and Stock were not tested due to

lack of authorization. Regarding the changes in the vibration, because it is incompatible

with the equipment changes, it was not implemented in the overall analysis.

In this analysis some of the values did not change from the results obtained in

the individual analyzes, such as the areas occupied, equipment reduction and capital

invested in inventory. However, production did increase by 58%, comparing to the

original value. This means production has gone from an initial 55 to 87 components

produced daily. According to the information provided by the Board of the company,

this increase in production represents an increase in profit of 155.358,72 € a year for

the first 5 years, since the equipment was purchased with a loan. Once the credit is

paid off, the annual profit increases by 410.55,68 €, assuming that there is no market

inflation.

The same 18 workers were again briefly interviewed to obtain results regarding

job satisfaction. This came to an average of 4.1 taking job satisfaction to an average

of “Very Satisfied”. Although these results may be a reflection of the novelty in the

changes done around the production line, it was astonishing to notice the enthusiasm

that these changes have made among the workers and stakeholders of this process. But

this high level of satisfaction may not be totally beneficial. One of the Lean principles

is continuous improvement and if the workers are very satisfied with the present state

of production, an interest in pursuing improvement may not arise.

Although independently all changes proved to be slightly beneficial in various

ways, when all aspects are taken into consideration production efficiency increases

dramatically.

Production System Design

566 Jean Deffense, Nuno Cachadinha

Conclusions

The objectives outlined in this work were successful at both development and

achievement level. The intense study of the Lean concepts resulted in a good

knowledge of its principles and features. The initial analysis of the sample set of

factories allowed to draw an overall picture of production process in the precast

reinforced concrete components’ industry and to determine a series of changes based

on Lean principles. The case study selected for in-depth analysis and implementation

allowed the assessment and quantification of the benefits obtained.

For a successful application of Lean concepts, the creation of a Black Belt Team,

consisting of various stakeholders in the production and the use of Value Stream

Mapping are very important. These proved to be extremely important tools in the

application of lean concepts. But these are not the solution to the problems. They

highlight the problems in the process and help improve and monitor the changes

performed. The key to successful results lies on the knowledge of Lean concepts and

the industry to which it is being applied.

The main tools used to solve the issues in production were Just-In-Time, Kanban,

5S and Cellular Manufacturing.

Just-In-Time and Kanban resulted in a reduction of required space and capital

invested in inventory. Also they contributed with an increase in product quality,

eliminating oxidation of the steel.

5S and Cellular Manufacturing proved to be great tools for this industry. They

successfully reduced lead time in production, product flow was increased and health

and safety risk levels were improved. Also the necessary equipment was reduced and

productivity increased.

The results obtained in this work confirm previous studies on the benefits that

Lean concepts may have, by increasing productivity using less resources. The results

achieved were: reduction in occupation area of the steel inventory by 42%., financial

investment in steel inventory was reduced by 50%, oxidized steel was eliminated

increasing product quality, increase in product flow, reduction in production costs,

increase in job satisfaction from 2.9 to 4.1 in a scale from 1 to 5, health and safety risk

improvement and increase in available factory space.

These improvements in the precast production also directly benefit construction

projects by reducing expenses and increasing delivery.

References

Abdullah, F. (2003). “Lean Manufacturing Tools and Techniques in the Process

Industry with a Focus on Steel”. Ph.D. Diss, University of Pittsburgh.

Albarran, E. G. (2008). “Construção com Elementos Pré-Fabricados em Betão Armado

– Adaptação de uma Slução Estrutural “in situ” a uma Solução Pré-fabricada”.

MSc. Diss, Instituto Superior Técnico, Portugal.

Chan, F. T. S. (2001). “Effect of kanban size on just-in-time manufacturing systems”.

Journal of Materials Processing Technology , 116 (2-3), 146-160.

Proceedings IGLC-19, July 2011, Lima, Perú

Lean Production in the Precast Concrete Components’ Industry 567

Chen, Y., Okudan, G. E., & Riley, D. R. (2010). “Decision support for construction

method selection in concrete buildings: Prefabrication adoption and

optimization”. Automation in Construction , 19 (6), 665-675.

Dawood, N., & Marasini, R. (2002). “Visualisation of a stockyard layout simulator

“SimStock”: a case study in precast concrete products industry”. Automation

in Construction , 12 (2), 113-122.

Junior, M. L., & Filho, M. G. (2010). “Variations of the kanban system: Literature

review and classification”. International Journal of Production Economics ,

125 (1), 13-21.

Kosonen, K., & Buhanist, P. (1995). “Customer focused lean production development”.

International Journal of Production Economics , 41 (1-3), 211-216.

Melton, T. (2005). “The Benefits of Lean Manufacturing: What Lean Thinking has to

Offer the Process Industries”. Chemical Engineering Research and Design , 83

(6), 662-673.

Ohno, Taiichi. (1988). “Toyota Production System: Beyond Large-Scale Production”.

Productivity Press.

Rother, M., & Shook, J. (1998). “Learning to See – Value-Stream Mapping to Create

Value and Eliminate Muda”. Massachusetts, EUA. The Lean Enterprise

Institute.

Shikdar, A. A., & Das, B. (2003). “The relationship between worker satisfation and

productivity in a repetitive industrial task”. Applied Ergonomics, 34 (6), 603-

610.

Warnecke, H., & Hüser, M. (1995). “Lean production”. International Journal of

Production Economics , 41 (1-3), 37-43.

Womack, J. P., Jones, D. T., & Roos, D. (1990). “The Machine that Changed the

World: The Story of Lean Production”. New York: Rawson Associates.

Womack, J. (2008). Lean Production to Lean Solutions. Available at http://www.lean.

org/WhatsLean/. (opened on 16/11/2009).

Production System Design

You might also like

- Achieving Lean Goals Through Elimination of WasteDocument4 pagesAchieving Lean Goals Through Elimination of WasteNikka VelascoNo ratings yet

- Implementing Lean Principles in the Textile IndustryDocument10 pagesImplementing Lean Principles in the Textile IndustryIshmam AhmedNo ratings yet

- The Role and Importance of Lean Tools in Warehouse ManagementDocument8 pagesThe Role and Importance of Lean Tools in Warehouse ManagementIbrahim SkakriNo ratings yet

- Applying Lean Management in Textile IndustryDocument12 pagesApplying Lean Management in Textile IndustryZakria ArshadNo ratings yet

- Topic 3 BPR in Manufaturing IndustryDocument9 pagesTopic 3 BPR in Manufaturing Industryneyom bitvooNo ratings yet

- Implementing Lean ManufacturingDocument46 pagesImplementing Lean ManufacturingAg0% (2)

- Lean Production Literature ReviewDocument8 pagesLean Production Literature Reviewafdtwtdsa100% (1)

- Lean Management Application at IntelDocument9 pagesLean Management Application at IntelBrandy M. TwilleyNo ratings yet

- A Study of Lean Manufacturing Practice With Reference To Indian ManufacturingDocument11 pagesA Study of Lean Manufacturing Practice With Reference To Indian ManufacturingRahul Ramesh PareraoNo ratings yet

- 2nd Int'l Conf on Manufacturing EngineeringDocument9 pages2nd Int'l Conf on Manufacturing EngineeringLiju AlexNo ratings yet

- Lean Technology in ConstructionDocument11 pagesLean Technology in ConstructionIJRASETPublicationsNo ratings yet

- Must ReadDocument10 pagesMust ReadJuby JoyNo ratings yet

- Manea 2013 - Lean ProductionDocument8 pagesManea 2013 - Lean ProductionwoainiNo ratings yet

- 2.0 Lean ProductionDocument54 pages2.0 Lean ProductionSheryll PascobilloNo ratings yet

- Lean manufacturing maximizes value with fewer resourcesDocument8 pagesLean manufacturing maximizes value with fewer resourcesVijay KumarNo ratings yet

- Lean Production Research PapersDocument5 pagesLean Production Research Papersc9s9h7r7100% (1)

- Lean principles in shipbuildingDocument5 pagesLean principles in shipbuildingdavid kariukiNo ratings yet

- Criteria For A Lean Organisation: Development of A Lean Assessment ToolDocument23 pagesCriteria For A Lean Organisation: Development of A Lean Assessment ToolSandaruwan TharinduNo ratings yet

- Implementation of Lean Manufacturing Principles in FoundriesDocument5 pagesImplementation of Lean Manufacturing Principles in FoundriesIJMERNo ratings yet

- Lean Manufacturing Implementation DMAICDocument25 pagesLean Manufacturing Implementation DMAICSamir MejiaNo ratings yet

- Implications: Applying Lean Production in Healthcare FacilitiesDocument5 pagesImplications: Applying Lean Production in Healthcare FacilitiesVibhor MahajanNo ratings yet

- 3B202BDocument10 pages3B202BAhmed Dahi100% (1)

- Optimizing Lean ImplementationDocument3 pagesOptimizing Lean ImplementationAgNo ratings yet

- Lean Manufacturing, or Lean Production DefinitionDocument8 pagesLean Manufacturing, or Lean Production DefinitionAnjan KumarNo ratings yet

- Practical Improvement Planning For FactoriesDocument158 pagesPractical Improvement Planning For FactoriesIrani MohsenNo ratings yet

- Lean Manufacturing Literature Review and Research IssuesDocument5 pagesLean Manufacturing Literature Review and Research IssueseyewhyvkgNo ratings yet

- Amm PDFDocument13 pagesAmm PDFShruti AirenNo ratings yet

- More Value With Less WorkDocument1 pageMore Value With Less WorkAllan JuarezNo ratings yet

- Implementation of Standardized Work in A LCV Production Line To Improve Its ProductivityDocument12 pagesImplementation of Standardized Work in A LCV Production Line To Improve Its Productivityirfan iruNo ratings yet

- Lean principles improve software project performanceDocument9 pagesLean principles improve software project performanceAnirban ChakrabortyNo ratings yet

- IJASS Sample Single Column Standard PDFDocument11 pagesIJASS Sample Single Column Standard PDFshidqi_2008No ratings yet

- 00 Lean ManufacturingDocument12 pages00 Lean ManufacturingErnesto Rascon Basaldua0% (1)

- Case StudyDocument15 pagesCase StudychitranshhNo ratings yet

- Facility Layout and Design: A Case Study of A Soap Manufacturing Company in NigeriaDocument10 pagesFacility Layout and Design: A Case Study of A Soap Manufacturing Company in Nigeriabiniam meazanehNo ratings yet

- IETEBanglore509Document10 pagesIETEBanglore509Muthu KumarNo ratings yet

- Applying Lean Thinking To New Product IntroductionDocument32 pagesApplying Lean Thinking To New Product IntroductionAhmed YousryNo ratings yet

- Production Mnagement Short ReportDocument5 pagesProduction Mnagement Short Reportayon100% (1)

- Research Paper On Lean ManufacturingDocument5 pagesResearch Paper On Lean ManufacturingkwbfbzundNo ratings yet

- Thesis Paper On Lean ManufacturingDocument5 pagesThesis Paper On Lean Manufacturinggbxfr1p1100% (2)

- Lean Manufacturing, Lean Enterprise, or Lean Production, Often Simply, "Lean," Is A Production PracticeDocument4 pagesLean Manufacturing, Lean Enterprise, or Lean Production, Often Simply, "Lean," Is A Production PracticeDip PatelNo ratings yet

- 1 Lean Manufacturing 1.1: Lean, Is A Production Practice That ConsidersDocument37 pages1 Lean Manufacturing 1.1: Lean, Is A Production Practice That ConsidersJuanRodríguezNo ratings yet

- JIT and Lean Operations Techniques for Eliminating WasteDocument8 pagesJIT and Lean Operations Techniques for Eliminating WasteGerline MaeNo ratings yet

- 3P Lean Production Preparation PDFDocument12 pages3P Lean Production Preparation PDFshan4600100% (2)

- Simulation of Lean Assembly Line for High Volume ManufacturingDocument6 pagesSimulation of Lean Assembly Line for High Volume Manufacturingkarthik_avadiNo ratings yet

- Lean Manufacturing Implementation Using Value Stream Mapping: A Case Study of Pumps Manufacturing CompanyDocument7 pagesLean Manufacturing Implementation Using Value Stream Mapping: A Case Study of Pumps Manufacturing Companyirfan iruNo ratings yet

- JIT Philosophy and Continuous ImprovementDocument5 pagesJIT Philosophy and Continuous Improvementvikrant gulhaneNo ratings yet

- 16bme0920 VL2019201001233 DaDocument9 pages16bme0920 VL2019201001233 Dashiv wadhwaNo ratings yet

- Process Improvement by Application of Lean Six Sigma and TRIZ Methodology Case Study in Coffee CompanyDocument12 pagesProcess Improvement by Application of Lean Six Sigma and TRIZ Methodology Case Study in Coffee CompanyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Developing a Performance Measurement System for Lean ManufacturingDocument5 pagesDeveloping a Performance Measurement System for Lean ManufacturingJuan JacksonNo ratings yet

- Thesis On Lean ManufacturingpdfDocument4 pagesThesis On Lean ManufacturingpdfWhoCanWriteMyPaperForMeUK100% (2)

- 3044 13094 2 PBDocument6 pages3044 13094 2 PBOlaleye S.ANo ratings yet

- Henderson - Lean ManufacturingDocument79 pagesHenderson - Lean ManufacturingSharif M Mizanur RahmanNo ratings yet

- Lean Principles PDFDocument5 pagesLean Principles PDFILma NafiaNo ratings yet

- How to Create Continuous Production Flow?: Toyota Production System ConceptsFrom EverandHow to Create Continuous Production Flow?: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- New Appoaches in the Process Industries: The Manufacturing Plant of the FutureFrom EverandNew Appoaches in the Process Industries: The Manufacturing Plant of the FutureNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Taguchi on Robust Technology Development: Bringing Quality Engineering UpstreamFrom EverandTaguchi on Robust Technology Development: Bringing Quality Engineering UpstreamRating: 1 out of 5 stars1/5 (1)

- Steel FiberDocument1 pageSteel FiberMustafaMahdiNo ratings yet

- 12.11.2018 BASF MasterGlenium Ace 30JP v2Document3 pages12.11.2018 BASF MasterGlenium Ace 30JP v2Prateek ModyNo ratings yet

- A Mix Design Methodology For Concrete Block UnitsDocument11 pagesA Mix Design Methodology For Concrete Block UnitsRameshNayakaNo ratings yet

- PC 01 12 PC 01 12Document1 pagePC 01 12 PC 01 12Prateek ModyNo ratings yet

- ENG MasterGlenium ACE 30 TdsDocument4 pagesENG MasterGlenium ACE 30 TdsPrateek ModyNo ratings yet

- SIKA Product Information ChartDocument32 pagesSIKA Product Information ChartPrateek ModyNo ratings yet

- Class ScheduleDocument1 pageClass SchedulePrateek ModyNo ratings yet

- First Col DSN Fina RCC-Biaxial-BendingDocument7 pagesFirst Col DSN Fina RCC-Biaxial-BendingmukhleshNo ratings yet

- Staff Visit ReportDocument1 pageStaff Visit ReportPrateek ModyNo ratings yet

- ResourcesDocument1 pageResourcesPrateek ModyNo ratings yet

- Kharagpur - Staircase Design PDFDocument38 pagesKharagpur - Staircase Design PDFjmusopole50% (2)

- StaircaseDocument1 pageStaircasePrateek ModyNo ratings yet

- Double Wall Mould - 11.2016Document1 pageDouble Wall Mould - 11.2016Prateek ModyNo ratings yet

- Aerocon Panels Product Literature FOLDER A4Document2 pagesAerocon Panels Product Literature FOLDER A4Varsha DasNo ratings yet

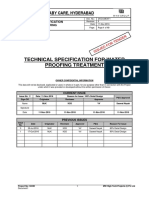

- Technical Specification For Water Proofing Treatment: Baby Care, HyderabadDocument10 pagesTechnical Specification For Water Proofing Treatment: Baby Care, HyderabadPrateek ModyNo ratings yet

- ECONOMICAL PRECAST SOLUTIONSDocument2 pagesECONOMICAL PRECAST SOLUTIONSPrateek Mody100% (1)

- Charminar Fibre Cement SheetsDocument1 pageCharminar Fibre Cement SheetsPrateek ModyNo ratings yet

- Site plan for proposed office building and shed at 30m wide roadDocument1 pageSite plan for proposed office building and shed at 30m wide roadPrateek ModyNo ratings yet

- 1 s2.0 S1877705812010788 Main PDFDocument7 pages1 s2.0 S1877705812010788 Main PDFAkhlaq HussainNo ratings yet

- Precast Concrete Residential Project Manufacturing ProcessDocument9 pagesPrecast Concrete Residential Project Manufacturing ProcessPrateek ModyNo ratings yet

- RCC - Properties of Steel and ConcreteDocument17 pagesRCC - Properties of Steel and Concretenitishpathak79No ratings yet

- Beam Column Base Plate DesignDocument10 pagesBeam Column Base Plate DesignSPUD1100% (3)

- Steel Table Box-Circular Sections PDFDocument24 pagesSteel Table Box-Circular Sections PDFPrateek ModyNo ratings yet

- INDIA PRECAST - Boundary-WallDocument2 pagesINDIA PRECAST - Boundary-WallPrateek ModyNo ratings yet

- Evaluation of Structural Efficiency of Steel Diagrid Systems For Multi-Storey BuildingsDocument4 pagesEvaluation of Structural Efficiency of Steel Diagrid Systems For Multi-Storey BuildingsPrateek ModyNo ratings yet

- PPFormDocument1 pagePPFormParyushan BujurgeNo ratings yet

- Guide to Precast Concrete SpecificationsDocument9 pagesGuide to Precast Concrete SpecificationsPrateek Mody100% (1)

- Precast Concrete Construction by Madan Mohanjana2012 141005112145 Conversion Gate01Document18 pagesPrecast Concrete Construction by Madan Mohanjana2012 141005112145 Conversion Gate01Huzaifa J AhmedabadwalaNo ratings yet

- Pakistan Academy School Al-Ahmadi Kuwait Monthly Test Schedule Class: 9 FBISEDocument16 pagesPakistan Academy School Al-Ahmadi Kuwait Monthly Test Schedule Class: 9 FBISEapi-126472277No ratings yet

- Animate Ggplots With Gganimate::: Cheat SheetDocument2 pagesAnimate Ggplots With Gganimate::: Cheat SheetJosé AnguloNo ratings yet

- Cover Page ( (DLW 5013) ) 11 April 2020 - .222 PDFDocument4 pagesCover Page ( (DLW 5013) ) 11 April 2020 - .222 PDFElamaaran AlaggarNo ratings yet

- Handout TMA GuidanceDocument3 pagesHandout TMA GuidanceElizabeth FernandezNo ratings yet

- Ausubel's Theory of Meaningful LearningDocument21 pagesAusubel's Theory of Meaningful LearningasyiqqinNo ratings yet

- An Integrative Approach To Enhancing Small-Scale Poultry Slaughterhouses by Addressing Regulations and Food Safety in Northern - ThailandDocument9 pagesAn Integrative Approach To Enhancing Small-Scale Poultry Slaughterhouses by Addressing Regulations and Food Safety in Northern - ThailandgustiNo ratings yet

- M&E Plan for Project NameDocument5 pagesM&E Plan for Project NameFarhan FudowNo ratings yet

- Sophia A. McClennen, Remy M. Maisel (Auth.) - Is Satire Saving Our Nation - Mockery and American Politics-Palgrave Macmillan US (2014)Document254 pagesSophia A. McClennen, Remy M. Maisel (Auth.) - Is Satire Saving Our Nation - Mockery and American Politics-Palgrave Macmillan US (2014)Nicoleta Aldea100% (1)

- Purpose Meaning MeaninginlifeDocument2 pagesPurpose Meaning MeaninginlifeTaufik GeodetikNo ratings yet

- 1 ECI 2015 Final ProgramDocument122 pages1 ECI 2015 Final ProgramDenada Florencia LeonaNo ratings yet

- Geometric and Algebraic Foundations of Computational OrigamiDocument25 pagesGeometric and Algebraic Foundations of Computational Origamisqrt_2_Complex100% (1)

- Human Resource ManagementDocument18 pagesHuman Resource Managementsamruddhi_khale67% (3)

- Tilak Highschool Exam Activity Sheet for English SubjectDocument8 pagesTilak Highschool Exam Activity Sheet for English SubjectJay Bhatia0% (1)

- Key Sentence Patterns - Ielts WritingDocument5 pagesKey Sentence Patterns - Ielts Writingranga priyasadNo ratings yet

- UT71 Computer Interface SoftwareDocument3 pagesUT71 Computer Interface SoftwareOrlando FernandezNo ratings yet

- HydroVision Brochure Q Eye PSC 2014Document4 pagesHydroVision Brochure Q Eye PSC 2014sreeyukthaNo ratings yet

- Camote Tops Acid-BaseDocument3 pagesCamote Tops Acid-BaseAldren BeliberNo ratings yet

- The Historic 7Th March Speech of Bangabandhu Sheikh Mujibur RahmanDocument31 pagesThe Historic 7Th March Speech of Bangabandhu Sheikh Mujibur RahmanSanzid Ahmed ShaqqibNo ratings yet

- Soft Uni SolutionsDocument8 pagesSoft Uni Solutionsnrobastos1451No ratings yet

- Tradition and Transformation: Democracy and The Politics of Popular Power in Ghana by Maxwell OwusuDocument38 pagesTradition and Transformation: Democracy and The Politics of Popular Power in Ghana by Maxwell OwusuKwame Zulu Shabazz ☥☥☥No ratings yet

- MANT Maintenance Check List For Simplex FL-16, Issue 6Document9 pagesMANT Maintenance Check List For Simplex FL-16, Issue 6hassan SardarNo ratings yet

- Bethesda Softworks LLC v. Behaviour Interactive, Inc. and Warner Bros. Entertainment Inc.Document34 pagesBethesda Softworks LLC v. Behaviour Interactive, Inc. and Warner Bros. Entertainment Inc.Polygondotcom100% (1)

- Journal Final For WEBDocument84 pagesJournal Final For WEBnormanwillowNo ratings yet

- Prospectus 2023-24Document11 pagesProspectus 2023-24Niranjan SahooNo ratings yet

- Jurnal Terapi Marital IndonesiaDocument10 pagesJurnal Terapi Marital IndonesiaErickson Arthur SiahaanNo ratings yet

- Sokolowski Robert Logic Parts Wholes in Husserls InvestigationsDocument18 pagesSokolowski Robert Logic Parts Wholes in Husserls InvestigationsveronicavronskyNo ratings yet

- SHIFADocument4 pagesSHIFAAbira Bilal Hanif0% (1)

- Adolescent Sleep Patterns and Insomnia Rates in a Large Population StudyDocument8 pagesAdolescent Sleep Patterns and Insomnia Rates in a Large Population StudyPradipta ShivaNo ratings yet

- Affinity Monitor 2017 StudyDocument16 pagesAffinity Monitor 2017 StudyagarwalharshalNo ratings yet

- Rapport HP t930Document8 pagesRapport HP t930Mohamed EL Guennouni RichNo ratings yet