Professional Documents

Culture Documents

En 16MnCr5

Uploaded by

gowrisankar320 ratings0% found this document useful (0 votes)

20 views1 pageH

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentH

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views1 pageEn 16MnCr5

Uploaded by

gowrisankar32H

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

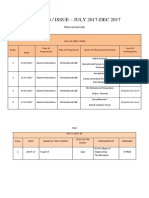

16MnCr5 (W. NR. 1.

7131)

Special alloy case-hardening steel

CHEMICAL COMPOSITION: (heat analysis according to the EN 10084 standard)

C% Si % Mn % P% S% Cr %

FROM 0,14 - 1,00 - - 0,80

TO 0,19 0,40 1,30 0,035 0,035 1,10

*MECHANICAL FEATURES: (according to the EN 10277-4 standard)

Soft annealed* + peeled rolled Soft annealed* + cold drawn

Thickness (+A +SH ) ( +A+C )

mm Hardness maximum values Hardness maximum values

HB HB

≥5≤10 - 250

>10≤16 - 250

>16≤40 207 245

>40≤63 207 240

>63≤100 207 240

* Delivery condition: subjected to a softening treatment according to the maximum hardness

prescription.

PROPERTIES :

Weldability:

It is a MnCr alloy steel, easily hot machinable and weldable.

Hardenability:

It has a low hardenability and therefore it can show good core features till thicknesses of about 20

mm.

Notes :

CORRESPONDENCE WITH OTHER STANDARDS ( purely as an indication ) :

UNI 7846 DIN 17210 ISO 683-11 AFNOR 35-551

16MnCr5 16MnCr5 16MnCr5 16MC5

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Mech Department RequirementsDocument2 pagesMech Department Requirementsgowrisankar32No ratings yet

- State Bank of India: A. Details of Post (Contractual) /vacancy/ Age/Selection ProcessDocument4 pagesState Bank of India: A. Details of Post (Contractual) /vacancy/ Age/Selection ProcessManirajNo ratings yet

- Apt-2 Answer KeyDocument21 pagesApt-2 Answer Keygowrisankar32No ratings yet

- Ppce Iat-3Document4 pagesPpce Iat-3gowrisankar32No ratings yet

- Engineering Subjects Gap Analysis ReportDocument9 pagesEngineering Subjects Gap Analysis Reportgowrisankar32No ratings yet

- PPCE Model 2018-19 B2Document2 pagesPPCE Model 2018-19 B2gowrisankar32No ratings yet

- I - Assessment QP - 03.07.2018Document3 pagesI - Assessment QP - 03.07.2018gowrisankar32No ratings yet

- VOL - NO.4 / ISSUE - JULY 2017-DEC 2017: Motivational TalkDocument2 pagesVOL - NO.4 / ISSUE - JULY 2017-DEC 2017: Motivational Talkgowrisankar32No ratings yet

- Revised Fee Structure: Fellow (FIE)Document1 pageRevised Fee Structure: Fellow (FIE)gowrisankar32No ratings yet

- Kinematics of MachineryDocument9 pagesKinematics of Machinerygowrisankar32No ratings yet

- Ppce FDocument2 pagesPpce Fgowrisankar32No ratings yet

- MT II Lab QuesDocument7 pagesMT II Lab Quesgowrisankar32No ratings yet

- Wa0023Document1 pageWa0023gowrisankar32100% (1)

- Design and Fabrication Automatic Paper Cutter Using Geneva MechanismDocument10 pagesDesign and Fabrication Automatic Paper Cutter Using Geneva Mechanismgowrisankar32No ratings yet

- Forward Kinematics: The Denavit-Hartenberg Convention: 3.1 Kinematic ChainsDocument19 pagesForward Kinematics: The Denavit-Hartenberg Convention: 3.1 Kinematic ChainsKispandu GuptaNo ratings yet

- Central Institute of Plastics Engineering & Technology (Department of Chemical & PetrochemicalsDocument1 pageCentral Institute of Plastics Engineering & Technology (Department of Chemical & Petrochemicalsgowrisankar32No ratings yet

- Wa0032Document22 pagesWa0032gowrisankar32No ratings yet

- Assignment No. 9 With Answer KeyDocument2 pagesAssignment No. 9 With Answer Keygowrisankar32No ratings yet

- AICTE Model Curriculum Ist YearDocument44 pagesAICTE Model Curriculum Ist YearPushpendra ShuklaNo ratings yet

- DhparamsDocument7 pagesDhparamsTolution OdujinrinNo ratings yet

- 2010 Girls PDFDocument47 pages2010 Girls PDFZachary BeckerNo ratings yet

- Material Science Conventional Question and AnswerDocument14 pagesMaterial Science Conventional Question and AnswerChitransh Agarwal100% (3)

- Iat-I Parents IntimationDocument1 pageIat-I Parents Intimationgowrisankar32No ratings yet

- அம்மா இரு சக்கர வாகன திட்ட அரசாணை.Document13 pagesஅம்மா இரு சக்கர வாகன திட்ட அரசாணை.gowrisankar32No ratings yet

- Design of Transmission SystemsDocument3 pagesDesign of Transmission Systemsgowrisankar32No ratings yet

- Environmental & Safety Information: Acute Oral Toxicity/Rates Skin Irritation - HumansDocument1 pageEnvironmental & Safety Information: Acute Oral Toxicity/Rates Skin Irritation - Humansgowrisankar32No ratings yet

- 100 - Laptop For StudentsDocument1 page100 - Laptop For Studentsgowrisankar32No ratings yet

- Discontinue ListDocument2 pagesDiscontinue Listgowrisankar32No ratings yet

- S.Iniyan's Profile and Research ContributionsDocument21 pagesS.Iniyan's Profile and Research Contributionsgowrisankar32No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)