Professional Documents

Culture Documents

Clutch NISSAN B16

Uploaded by

Alex HernandezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clutch NISSAN B16

Uploaded by

Alex HernandezCopyright:

Available Formats

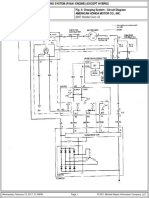

TRANSMISSION/TRANSAXLE

CL

A

B

SECTION

CLUTCH CL

E

CONTENTS

SERVICE INFORMATION ............................ 2 Inspection ................................................................. 9 F

Air Bleeding Procedure ............................................. 9

PRECAUTIONS ................................................... 2

Precaution for Supplemental Restraint System CLUTCH MASTER CYLINDER ........................ 11

G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- Removal and Installation .........................................11

SIONER" ................................................................... 2

Precaution Necessary for Steering Wheel Rota-

CSC (CONCENTRIC SLAVE CYLINDER) ....... 13

Removal and Installation .........................................13 H

tion After Battery Disconnect ..................................... 2

Service Notice or Precaution ..................................... 3 CLUTCH PIPING ............................................... 14

PREPARATION ................................................... 4 Removal and Installation .........................................14

I

Special Service Tools ................................................ 4 CLUTCH DISC, CLUTCH COVER AND FLY-

Commercial Service Tools ........................................ 4 WHEEL .............................................................. 15

NOISE, VIBRATION AND HARSHNESS Exploded View .........................................................15 J

(NVH) TROUBLESHOOTING ............................. 5 Removal and Installation .........................................15

NVH Troubleshooting Chart ...................................... 5 SERVICE DATA AND SPECIFICATIONS

K

CLUTCH PEDAL ................................................. 6 (SDS) ................................................................. 17

On-vehicle Inspection and Adjustment ...................... 6 Clutch Control System .............................................17

Removal and Installation ........................................... 7 Clutch Pedal ............................................................17

Clutch Disc ..............................................................17 L

CLUTCH FLUID ................................................... 9 Clutch Cover ............................................................17

Revision: January 2010 CL-1 2010 Sentra

PRECAUTIONS

< SERVICE INFORMATION >

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000005612373

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005612374

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 2010 CL-2 2010 Sentra

PRECAUTIONS

< SERVICE INFORMATION >

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.) A

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precaution INFOID:0000000005284060

B

• Use recommended brake fluid when adding fluid to the clutch reservoir tank. Refer to MA-15,

"MR20DE" or MA-15, "QR25DE".

• Never reuse fluid drained from clutch system. CL

• Be careful not to splash brake fluid on painted areas.

• Use new brake fluid to clean or wash all parts of master cylinder and CSC (Concentric slave cylin-

der).

D

• Never use mineral oils such as gasoline or kerosene. It will ruin the rubber parts of the hydraulic sys-

tem.

• If transaxle assembly is removed from the vehicle, always replace CSC. Return CSC to original posi-

tion to remove transaxle assembly. Dust on clutch disc sliding parts may damage CSC seal and may E

cause clutch fluid leakage.

• Do not disassemble clutch master cylinder and CSC.

WARNING: F

After cleaning clutch disc, clean it with a dust collector. Do not use compressed air.

Revision: January 2010 CL-3 2010 Sentra

PREPARATION

< SERVICE INFORMATION >

PREPARATION

Special Service Tools INFOID:0000000005284061

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number Description

(Kent-Moore No.)

Tool name

ST20050240 Adjusting unevenness of diaphragm spring of

( — ) clutch cover

Diaphragm spring adjusting wrench

ZZA0508D

Commercial Service Tools INFOID:0000000005284062

Tool name Description

Clutch aligner Installing clutch disc

MCIB0404E

Power tool Loosening bolts and nuts

PBIC0190E

Revision: January 2010 CL-4 2010 Sentra

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

A

NVH Troubleshooting Chart INFOID:0000000005284063

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec- B

tion. If necessary, repair or replace these parts.

EM-184 (QR25DE)

EM-75 (MR20DE),

EM-97 (MR20DE),

EM-202(QR25DE)

CL

CL-13

CL-15

CL-6

CL-9

Reference page

D

CSC (Concentric slave cylinder) (Worn, dirty or damaged)

E

F

CLUTCH PEDAL (Inspection and adjustment)

DIAPHRAGM SPRING (Out of tip alignment)

CLUTCH DISC (Lack of spline grease)

CLUTCH DISC (Runout is excessive)

G

DIAPHRAGM SPRING (Damaged)

CLUTCH DISC (Dirty or burned)

PRESSURE PLATE (Distortion)

CLUTCH DISC (Lining broken)

SUSPECTED PARTS (Possible cause)

ENGINE MOUNTING (Loose)

CLUTCH DISC (Out of true)

CLUTCH DISC (Hardened)

CLUTCH DISC (Worn out)

CLUTCH LINE (Air in line)

FLYWHEEL (Distortion)

CLUTCH DISC (Oily)

I

Clutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 K

Symptom Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1 2 5 5 5 5 5 5 6 6 7 L

Revision: January 2010 CL-5 2010 Sentra

CLUTCH PEDAL

< SERVICE INFORMATION >

CLUTCH PEDAL

On-vehicle Inspection and Adjustment INFOID:0000000005284064

1. Check to see if the master cylinder rod end moves freely. It

should not be bound by the clutch pedal.

• If the rod end does not move freely, remove the rod end and

check for deformation or damage on the rod end. Leave the

rod end removed for step 2.

PCIB1491E

2. Check the clutch pedal stroke for free range of movement.

a. With the master cylinder rod end removed, manually move the pedal up and down to determine if it moves

freely.

b. If any sticking is noted, replace the clutch pedal assembly. Re-verify that the master cylinder rod end

moves freely.

3. Inspect the ASCD switch position (if equipped).

a. If the rod end does not move freely, check that the ASCD switch is not applying pressure to the clutch

pedal causing the rod end to bind. To adjust, disconnect the ASCD switch electrical connector and turn

the ASCD switch.

b. Connect the ASCD switch electrical connector.

4. Adjust clutch interlock switch (1) position so that clearance

between clutch pedal (2) and thread end of clutch interlock

switch (1), with clutch pedal fully depressed, is within specifica-

tion (C).

Clearance C Refer to CL-17, "Clutch Pedal"

WCIA0668E

Revision: January 2010 CL-6 2010 Sentra

CLUTCH PEDAL

< SERVICE INFORMATION >

5. Adjust the ASCD clutch switch (1) (if equipped). Adjust ASCD

clutch switch position with the clutch pedal fully released, so that A

clearance between clutch pedal (2) and thread end of ASCD

clutch switch (1) is within specification (A).

B

Clearance A Refer to CL-17, "Clutch Pedal"

CL

G

WCIA0669E

6. Check the clutch hydraulic system components (clutch master cylinder, CSC (Concentric slave cylinder),

clutch damper) for sticking or binding. H

a. If any sticking or binding is noted, repair or replace the related parts as necessary.

b. If any hydraulic system repair was necessary, bleed the clutch hydraulic system. Refer to CL-9, "Air

Bleeding Procedure". I

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all of the air from the system. J

Removal and Installation INFOID:0000000005284065

COMPONENTS K

Revision: January 2010 CL-7 2010 Sentra

CLUTCH PEDAL

< SERVICE INFORMATION >

WCIA0666E

1. Clutch pedal assembly 2. Lock nut 3. Clutch interlock switch

4. ASCD clutch switch (if equipped) 5. Lock nut

REMOVAL

1. Remove instrument panel lower finisher. Refer to IP-12, "Removal and Installation".

2. Remove front upper floor duct. Refer to MTC-77, "Removal and Installation".

3. Disconnect ASCD clutch switch harness connector (if equipped).

4. Disconnect master cylinder rod end from clutch pedal lever.

5. Remove clutch pedal assembly nuts, and then remove clutch

pedal assembly.

6. Disconnect clutch interlock switch harness connector.

PCIB1491E

INSPECTION AFTER REMOVAL

Check clutch pedal for bend, damage or a cracked weld. If bend, damage or a cracked weld is found, replace

clutch pedal assembly.

INSTALLATION

Installation is in the reverse order of removal.

• After installing the clutch switches, adjust the switch positions. Refer to CL-6, "On-vehicle Inspection and

Adjustment".

Revision: January 2010 CL-8 2010 Sentra

CLUTCH FLUID

< SERVICE INFORMATION >

CLUTCH FLUID

A

Inspection INFOID:0000000005613066

FLUID LEVEL B

• Check that the fluid level in the reservoir tank is within the specified

range (MAX – MIN lines).

• Visually check for any clutch fluid leakage around the reservoir CL

tank.

• Check the clutch system for any leakage if the fluid level is

extremely low (lower than MIN).

D

E

JPFIA0007ZZ

FLUID LEAKAGE

• Check clutch line for cracks, deterioration or other damage. Replace any damaged parts. F

• Check for fluid leakage by fully depressing clutch pedal while engine is running.

CAUTION:

If leakage occurs around joints, reinstall the joints or, if necessary, replace damaged parts. G

Air Bleeding Procedure INFOID:0000000005284066

CAUTION: H

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the affected

area with water.

NOTE: I

• Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all the air from the system.

• Carefully monitor fluid level in reservoir tank during bleeding operation.

• Bleed the air of bleeding connector (1). J

1. Fill reservoir tank with new clutch fluid.

CAUTION:

Never reuse drained clutch fluid. K

2. Connect a transparent vinyl hose to air bleeder of bleeding con-

nector.

3. “Depress” and “release” the clutch pedal slowly and fully 15 L

times at an interval of 2 to 3 seconds and release the clutch

pedal.

JPDIB0166ZZ

M

4. Press the lock pin (1) into the bleeding connector (2), and main-

tain the position. N

CAUTION:

Since the inside of clutch tube is under hydraulic pressure,

hold the tube to prevent it from getting disconnected.

O

JPDIB0041ZZ

Revision: January 2010 CL-9 2010 Sentra

CLUTCH FLUID

< SERVICE INFORMATION >

5. Slide bleeding connector (1) in the direction of the arrow as

shown.

2 : Clutch housing

Dimension “A” : 10 mm (0.39 in)

6. Depress the clutch pedal soon and hold it, and then bleed the air

from the piping.

CAUTION:

Since the inside of clutch tube is under hydraulic pressure, JPDIB0042ZZ

hold the tube to prevent it from getting disconnected.

7. Return clutch tube and lock pin in their original positions.

8. Release clutch pedal and wait for 5 seconds.

9. Repeat steps 3 to 8 until no bubbles are observed in the clutch fluid.

10. Check that the fluid level in the reservoir tank is within the specified range after air bleeding. Refer to CL-

9, "Inspection".

Revision: January 2010 CL-10 2010 Sentra

CLUTCH MASTER CYLINDER

< SERVICE INFORMATION >

CLUTCH MASTER CYLINDER

A

Removal and Installation INFOID:0000000005284067

REMOVAL B

1. Remove the battery and battery tray. Refer to SC-7, "Removal and Installation (MR20DE Battery)" or SC-

9, "Removal and Installation (QR25DE Battery Tray)".

2. Remove the engine room cover. CL

3. Remove the air cleaner and air duct. Refer to EM-16, "Removal and Installation" (MR20DE) or EM-133,

"Removal and Installation" (QR25DE).

4. Remove engine under cover. Refer to EI-14, "Removal and Installation". D

5. Use one of the following methods to remove hose from master cylinder.

• Drain clutch fluid from reservoir tank and remove hose.

• Remove hose from master cylinder. Immediately plug hose and reservoir tank to prevent clutch fluid E

from dripping.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the F

affected area with water.

6. Remove master cylinder rod end from clutch pedal assembly.

G

PCIB1491E

J

7. Remove lock pin (1) from connector of master cylinder (2) and

separate clutch tube (3).

M

PCIB1497E

8. Rotate master cylinder clockwise by 45° and remove from the vehicle.

N

INSTALLATION

1. Tilt master cylinder clockwise by 45° and insert it in the mounting

hole. Rotate counterclockwise to secure it. At this time, nipple is

O

in the up position.

2. Install master cylinder rod end to clutch pedal.

P

SCIA1286E

Revision: January 2010 CL-11 2010 Sentra

CLUTCH MASTER CYLINDER

< SERVICE INFORMATION >

3. Install clutch tube (1) fully into connector of master cylinder (2).

4. Install lock pin (3) fully into connector of master cylinder (2).

5. Fill with new clutch fluid and bleed air from the system. Refer to

CL-9, "Air Bleeding Procedure".

6. After completing this procedure, inspect clutch pedal operation.

Refer to CL-6, "On-vehicle Inspection and Adjustment".

7. Install the air cleaner and air duct. Refer to EM-16, "Removal

and Installation" (MR20DE) or EM-133, "Removal and Installa-

tion" (QR25DE).

8. Install the battery and battery tray. Refer to SC-7, "Removal and PCIB1500E

Installation (MR20DE Battery)" or SC-9, "Exploded View

(QR25DE Battery Tray)".

9. Install the engine room cover.

10. Install the engine under cover. Refer to EI-14, "Removal and Installation".

Revision: January 2010 CL-12 2010 Sentra

CSC (CONCENTRIC SLAVE CYLINDER)

< SERVICE INFORMATION >

CSC (CONCENTRIC SLAVE CYLINDER)

A

Removal and Installation INFOID:0000000005284068

COMPONENTS B

CL

JPDIB0040GB

H

1. Transaxle assembly 2. CSC (Concentric Slave Cylinder)

CAUTION:

• If transaxle assembly is removed from the vehicle, always replace CSC (Concentric slave cylinder). I

Return CSC insert to original position to remove transaxle assembly. Dust on clutch disc sliding

parts may damage CSC seal and may cause clutch fluid leakage.

• Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the affected

area with water. J

REMOVAL

1. Remove transaxle assembly. Refer to MT-18, "Removal and Installation" (RS6F94R), MT-68, "Removal K

and Installation" (RS6F52A) or MT-145, "Removal and Installation" (RS6F52H).

2. Remove CSC bolts and the CSC from clutch housing.

L

PCIB1498E

INSTALLATION O

1. Install CSC to clutch housing and then tighten bolts to specification.

CAUTION:

• Do not reuse CSC. P

• Do not insert and operate CSC because piston and stopper of CSC components may fall off.

2. Install transaxle assembly. Refer to MT-18, "Removal and Installation" (RS6F94R), MT-68, "Removal and

Installation" (RS6F52A) or MT-145, "Removal and Installation" (RS6F52H).

3. Bleed the air from the clutch hydraulic system. Refer to CL-9, "Air Bleeding Procedure".

Revision: January 2010 CL-13 2010 Sentra

CLUTCH PIPING

< SERVICE INFORMATION >

CLUTCH PIPING

Removal and Installation INFOID:0000000005284069

PCIB1499E

1. Clutch tube 2. Clutch tube lock pin 3. CSC

4. Clutch damper 5. Clutch master cylinder 6. Clutch pedal

Carefully observe the following steps during clutch tube removal and installation.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the affected

area with water.

REMOVAL

1. Remove the battery. Refer to SC-7, "Removal and Installation (MR20DE Battery)" or SC-8, "Removal and

Installation (QR25DE Battery)".

2. Remove the air cleaner and air duct. Refer to EM-16, "Removal and Installation" (MR20DE) or EM-133,

"Removal and Installation" (QR25DE).

3. Remove clutch tube lock pin from clutch master cylinder, if necessary.

4. Remove clutch tube lock pin at clutch housing, if necessary.

5. Remove clutch tube lock pins (2) from clutch damper (3).

6. Remove clutch tubes (1) from clutch damper (3).

7. Remove clutch damper (3) from bracket (4).

BCIA0043E

INSTALLATION

Installation is in the reverse order of removal.

• Make sure that all tubes are fully installed into connectors.

• Make sure that all connector lock pins are fully installed.

• After installation, bleed the air from the clutch hydraulic system. Refer to CL-9, "Air Bleeding Procedure".

Revision: January 2010 CL-14 2010 Sentra

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

< SERVICE INFORMATION >

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

A

Exploded View INFOID:0000000005284070

CL

G

PCIB1394E

1. Flywheel 2. Clutch disc 3. Clutch cover

H

Removal and Installation INFOID:0000000005284071

CAUTION: I

• If transaxle assembly is removed from the vehicle, always replace CSC (Concentric slave cylinder).

Return CSC insert to original position to remove transaxle assembly. Dust on clutch disc sliding

parts may damage CSC seal and may cause clutch fluid leakage.

• Be careful not to apply any grease to the clutch disc facing, pressure plate surface and flywheel sur- J

face.

REMOVAL

K

1. Remove transaxle assembly from the vehicle. Refer to MT-18, "Removal and Installation" (RS6F94R) or

MT-68, "Removal and Installation" (RS6F52A), MT-145, "Removal and Installation" (RS6F52H).

2. Loosen clutch cover bolts evenly. Then remove clutch cover and clutch disc.

L

INSPECTION AFTER REMOVAL

Clutch Disc

• Measure circumferential runout relative to clutch disc center spline. M

If it is outside the specification, replace clutch disc.

Runout limit/diameter of the area : Refer to CL-17, N

to be measured "Clutch Disc".

• Measure backlash to clutch disc spline and main drive gear spline

at the circumference of clutch disc. If it is outside the specification, O

replace clutch disc.

Maximum allowable spline back- : Refer to CL-17, P

SCL221

lash (at outer edge of disc) "Clutch Disc".

Revision: January 2010 CL-15 2010 Sentra

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

< SERVICE INFORMATION >

• Measure the depth “A” to clutch disc facing rivet heads, using a

calipers. If it exceeds the allowable wear limit, replace clutch disc.

Facing wear limit (depth to the : Refer to CL-17,

rivet head) “A” "Clutch Disc".

JPDIB0026ZZ

Clutch Cover

• Check clutch cover thrust ring for wear or breakage. If wear or breakage is found, replace clutch cover.

NOTE:

• Worn thrust ring will generate a beating noise when tapped at the rivet with a hammer.

• Broken thrust ring will make a clinking sound when cover is shaken up and down.

• If a trace of burn or discoloration is found on the clutch cover pressure plate to clutch disc contact surface,

repair the surface with sandpaper. If surface is damaged or distorted, replace clutch cover.

INSTALLATION

1. Clean clutch disc and input shaft splines to remove grease and dust caused by abrasion.

2. Apply recommended grease to clutch disc and input shaft splines.

CAUTION:

Be sure to apply grease to the points specified. Otherwise, noise, poor disengagement, or damage

to the clutch may result. Excessive grease may cause slip or shudder. If it adheres to CSC seal, it

will cause clutch fluid leakage. Wipe off excess grease.

3. Install clutch disc, using a clutch aligner (A) [Commercial service

tool].

4. Install clutch cover and then temporarily tighten clutch cover

mounting bolts.

5. Tighten clutch cover mounting bolts to the specified torque

evenly in two steps in the numerical order as shown.

6. Install transaxle assembly. Refer to MT-18, "Removal and Instal-

lation" (RS6F94R), MT-68, "Removal and Installation"

(RS6F52A) or MT-145, "Removal and Installation" (RS6F52H).

JPDIB0141ZZ

INSPECTION AFTER INSTALLATION

Clutch Cover

Check diaphragm spring lever claws for unevenness with the lever

still on the vehicle. If they exceed the tolerance, adjust lever height,

using the diaphragm adjusting wrench (A) [SST: ST20050240 ( - )].

Tolerance for diaphragm spring : Refer to CL-17,

lever unevenness "Clutch Cover".

JPDIB0160ZZ

Revision: January 2010 CL-16 2010 Sentra

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

A

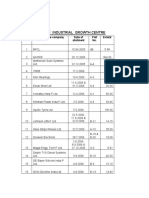

Clutch Control System INFOID:0000000005284072

B

Type of clutch control Hydraulic

Clutch Pedal INFOID:0000000005284073

CL

Clearance ″A″ between clutch pedal and ASCD switch threaded

0.74 - 1.96 mm (0.0291 - 0.0772 in)

end while clutch pedal is fully released (if equipped). D

Clearance ″C″ between clutch pedal and clutch interlock switch

0.74 - 1.96 mm (0.0291 - 0.0772 in)

threaded end while clutch pedal is fully depressed.

Clutch Disc INFOID:0000000005284074

E

Engine MR20DE QR25DE F

Model 225 240

225 mm × 160 mm × 3.2 mm (8.86 in 240 mm x 160 mm x 3.2 mm (9.45 in

Facing size (outer dia. × inner dia. × thickness)

× 6.30 in × 0.126 in) x 6.30 in x 0.126 in) G

1.0 mm (0.039 in) / 215 mm (8.46 in) 0.7 mm (0.028 in) / 230 mm (9.06 in)

Runout limit/diameter of the area to be measured

dia. dia.

Maximum allowable spline backlash (at outer edge of H

1.0 mm (0.039 in)

disc)

Facing wear limit (depth to the rivet head) (A) 0.3 mm (0.012 in)

I

Clutch Cover INFOID:0000000005284075

Engine MR20DE QR25DE

J

Tolerance for diaphragm spring lever unevenness 0.7 mm (0.028 in) or less

Revision: January 2010 CL-17 2010 Sentra

You might also like

- CYLINDER HEAD COMPONENTS AND REMOVAL GUIDEDocument35 pagesCYLINDER HEAD COMPONENTS AND REMOVAL GUIDEAlex Hernandez100% (2)

- Nissan Rogue 2014 Service Repair ManualDocument4,971 pagesNissan Rogue 2014 Service Repair ManualAlex Hernandez100% (1)

- Fusileras Fuso 2012Document4 pagesFusileras Fuso 2012Alex HernandezNo ratings yet

- Diesel Injection Pump Service ManualDocument48 pagesDiesel Injection Pump Service ManualЙОРДАН ГЕОРГИЕВ90% (21)

- Engine mechanical guideDocument204 pagesEngine mechanical guidehectorgonzalezm100% (6)

- NPR MANUAL Y DIAGRAMA MOTOR ISUZU 729 - 4HK1 - Training PDFDocument121 pagesNPR MANUAL Y DIAGRAMA MOTOR ISUZU 729 - 4HK1 - Training PDFRoyert Salas96% (81)

- Service Manual Common Rail System Isuzu 4HK1 6HK1Document48 pagesService Manual Common Rail System Isuzu 4HK1 6HK1vagpoul95% (148)

- Index for DTCsDocument14 pagesIndex for DTCsAlex Hernandez100% (1)

- ISUZU N-Series 4HK1-manual-de-confianza-2Document34 pagesISUZU N-Series 4HK1-manual-de-confianza-2Alex Hernandez100% (6)

- 4HK1 & 6HK1 ManualDocument352 pages4HK1 & 6HK1 Manuallionkinghd94% (104)

- Service Manual: Group 14A CoolingDocument27 pagesService Manual: Group 14A CoolingAlex HernandezNo ratings yet

- 54 - Fuller FSO 6109A Transmission Service Manual PDFDocument134 pages54 - Fuller FSO 6109A Transmission Service Manual PDFJulio OrtegaNo ratings yet

- Isuzu 6HK 1 Engine Fuel System CE Applications Rep Package 1 PDFDocument50 pagesIsuzu 6HK 1 Engine Fuel System CE Applications Rep Package 1 PDFVirgo100% (5)

- 4Hk1 6HK1 Engine Diagnostic and Drivability Student PDFDocument199 pages4Hk1 6HK1 Engine Diagnostic and Drivability Student PDFโจ้ สแปร์แร็ค92% (74)

- ISUZU Truck Service Manual PDFDocument439 pagesISUZU Truck Service Manual PDFkaled ben abdallah100% (2)

- YD25 CR Fault Diagnosis PDFDocument101 pagesYD25 CR Fault Diagnosis PDFMaurihuaanaa Navarro Santana100% (6)

- Nissan Patrol ZD30 Y61 Reference Document - ColourDocument129 pagesNissan Patrol ZD30 Y61 Reference Document - ColourIurie Maxim92% (12)

- 6M60 High Idle Test - EPA '07Document2 pages6M60 High Idle Test - EPA '07Alex HernandezNo ratings yet

- Honda Civic LX 2007Document1 pageHonda Civic LX 2007Alex HernandezNo ratings yet

- Transfer Control UnitDocument6 pagesTransfer Control UnitAlex HernandezNo ratings yet

- Technical specifications of a 2002-2009 Nissan Terrano II 3.0 TD Di 4WDDocument2 pagesTechnical specifications of a 2002-2009 Nissan Terrano II 3.0 TD Di 4WDJefferson Humberto HerreraNo ratings yet

- Denso CR - HP3 NissanDocument14 pagesDenso CR - HP3 NissanHerbert Sanchez75% (4)

- Steering Control SystemDocument22 pagesSteering Control SystemAlex HernandezNo ratings yet

- ZD30 CRD 2008 1Document74 pagesZD30 CRD 2008 1powermanager96% (28)

- Body LOCK SECURITY SYSTEMDocument231 pagesBody LOCK SECURITY SYSTEMAlex HernandezNo ratings yet

- Cooling System NISSAN B16Document56 pagesCooling System NISSAN B16Alex HernandezNo ratings yet

- Wiper and Washer Nissan b16Document29 pagesWiper and Washer Nissan b16Alex HernandezNo ratings yet

- Srs NISSAN SENTRA B16Document52 pagesSrs NISSAN SENTRA B16Alex HernandezNo ratings yet

- Brake System NISSAN B16Document51 pagesBrake System NISSAN B16Alex HernandezNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hero Honda's Mission, Vision, Environmental & Indusrtial AnalysisDocument40 pagesHero Honda's Mission, Vision, Environmental & Indusrtial Analysisashish67% (6)

- Training Basic HydraulicsDocument50 pagesTraining Basic Hydraulicssalicurri88% (8)

- BMW-F30 General Vehicle ElectronicsDocument84 pagesBMW-F30 General Vehicle Electronicskukumarcic100% (1)

- Technical Specification Scooptram ST7 BatteryDocument10 pagesTechnical Specification Scooptram ST7 BatteryMISBAHUL MUAFFANNo ratings yet

- Competitive Markets and Market EquilibriumDocument33 pagesCompetitive Markets and Market EquilibriumRajeev SinghNo ratings yet

- Roto Rainer 2011Document8 pagesRoto Rainer 2011sunilbholNo ratings yet

- UnicornDocument14 pagesUnicornVenu ChintapalliNo ratings yet

- Job Satisfaction AdarshaDocument70 pagesJob Satisfaction AdarshabhagathnagarNo ratings yet

- Battery Electric Vehicles vs. Internal Combustion Engine VehiclesDocument48 pagesBattery Electric Vehicles vs. Internal Combustion Engine VehiclesKapil SharmaNo ratings yet

- Sponsorship Proposal: Jaipur Street Karting CupDocument5 pagesSponsorship Proposal: Jaipur Street Karting CupGaurav sharmaNo ratings yet

- 2006 S60 S60R S80 Wiring DiagramDocument242 pages2006 S60 S60R S80 Wiring DiagramjohnfranksNo ratings yet

- CUSTOMER SATISFACTION STUDY OF HYUNDAI CARSDocument85 pagesCUSTOMER SATISFACTION STUDY OF HYUNDAI CARSMano Raja100% (1)

- Dealership Presentation NewDocument27 pagesDealership Presentation NewJayesh Patel100% (1)

- King Engine Bearings Catalog 2015Document552 pagesKing Engine Bearings Catalog 2015Walid Benazi50% (2)

- Process Capability and CPKDocument58 pagesProcess Capability and CPKYen NguyenNo ratings yet

- Six Stroke EngineDocument24 pagesSix Stroke EngineSeema NadigNo ratings yet

- Axle and Steering Boots 2012 2013Document367 pagesAxle and Steering Boots 2012 2013Borcan CristiNo ratings yet

- ToyataDocument2 pagesToyataDilip PanditNo ratings yet

- Working Paper No.: Sectoral Policies DepartmentDocument62 pagesWorking Paper No.: Sectoral Policies DepartmentAarón LinaresNo ratings yet

- DRRP of PMGSY-II - 132073258585745580Document4,746 pagesDRRP of PMGSY-II - 132073258585745580prabhatkumar25011992No ratings yet

- MR-03 A-Arm Front Suspension InstructionsDocument5 pagesMR-03 A-Arm Front Suspension InstructionsAlex Torregrosa OrtizNo ratings yet

- 6-Speed Automatic PSADocument34 pages6-Speed Automatic PSAPapuciev Ivan100% (11)

- ARB 3438100 FittingDocument7 pagesARB 3438100 FittingthailanNo ratings yet

- MINDADocument22 pagesMINDASamay MeenaNo ratings yet

- History of FordDocument9 pagesHistory of FordRF EstradaNo ratings yet

- Competition Brief - Auto-Rickshaw Stand DesignDocument14 pagesCompetition Brief - Auto-Rickshaw Stand DesignShreyash ChapleNo ratings yet

- McQuai Applied General Catalogue 2012Document69 pagesMcQuai Applied General Catalogue 2012Dana LoreNo ratings yet

- Conquest IIDocument6 pagesConquest IILyster67% (3)

- Sipcot Oragadam PDFDocument3 pagesSipcot Oragadam PDFSK Business group100% (1)

- FORDISM IntroductionDocument8 pagesFORDISM IntroductionSù Lï100% (1)