Professional Documents

Culture Documents

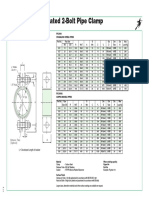

Specification Chart Guide

Uploaded by

Michael DoyleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification Chart Guide

Uploaded by

Michael DoyleCopyright:

Available Formats

Specification Chart

Anodizing Type II Anodizing is an electrolytic oxidation process in which the Anodizing Type III A type of coating that penetrates the base material while

surface of the metal is converted to a coating having desirable protective, decorative, and building up the surface of the material. Hard anodized coatings are typically applied to

functional properties. Available in a wide range of colors such as clear, black, red, blue, heavy wear industrial parts intended for use in aggressive or highly corrosive

and gold. Provides corrosion resistance while aesthetically appealing. Electrical insulator. applications. Excellent wear, abrasion resistance, and electrical insulator.

MIL‐A‐8625/AMS‐A‐8625 AMS 2471 AMS 2472 AMS 2482 MIL‐A‐8625 ASTM B580‐79

Class 1: Non‐dyed Clear Anodize only Black, gold, red, or blue 0015‐.0025” Thickness Class 1: Non‐dyed, customer Grade A: Engineering

must ask for seal Hardcoat

Class 2: Dyed Type I: Teflon impregnated

ASTM B580‐79 aluminum oxide Class 2: Dyed

Type II: Sulfuric acid anodize Type B: Architectural Class Type E: Interior, moderate Type II: Co-deposited Teflon and Type III: Hard anodic coatings

I /.0007” min. abrasion resistance/.0002” aluminum oxide

Type IIB: Thin sulfuric min.

anodizing for use as Type C: Architectural Class

nonchromate II /.0004” min. Type F: Interior, limited

abrasion resistance

Type D: Automotive/.0003”

min. Type G: Chromic

Black Oxide A conversion coating for ferrous materials applied most commonly on Bright Tin Used to protect ferrous and non-ferrous metals. High ductility, heat

steel. When applied, an attractive black finish is obtained. The high-temperature black conductive, non-toxic, and high solder-ability.

oxide process is essentially a chemical conversion of the steel surface with no dimensional

MIL‐DTL‐13924 AMS 2485 MIL‐T‐10727 ASTM B545‐13 Types: Matte, bright

Class 1: Alkaline oxidizing Black Oxide on steel Type I: Electrodeposited Class A: .0001” min. Class D: .0006‐.0008” min.

process

For moving parts which cannot tolerate the dimensional change of Class B: .0002” min. Class E: .0012” min.

Alkaline oxidizing. For wrought a more corrosion‐resistant finish. For decorative applications and

iron, cast and malleable irons, can be used to decrease light reflection. Class C: .00032‐.0004” min. Class F: .0006” min.

plain carbon, and low‐alloy steel

Cadmium Corrosive-resistant cyanide finish as it functions as a sacrificial coating that Chromate Conversion A thin gel-like film coating applied on aluminum

enhances corrosion protection and can be applied to cast iron, powdered metal, components that offers excellent corrosion resistance and is a great primer for painting

aluminum, and steel.

QQ‐P‐416 MIL‐DTL‐5541 AMS 2473

Class 1: .0005” min. Type I: As plated Type I: Contains hexavalent Class 1A: Yellow

chrome

Class 2: .0003” min. Type II: Supplementary Chromate Treatment

Type II: Does not contain ASTM B921‐08 (2013) RoHS Compliant

Class 3: .0002” min. Type III: Supplementary phosphate treatment hexavalent chrome‐RoHS

Compliant Class 1: Maximum corrosion resistance

Class 1A: Maximum protection Class 2: Moderate corrosion resistance used as a paint base

against corrosion

Class 3: Decorative, slight corrosion resistance, low electrical

Class 3: Corrosion protection resistance

with lower electrical resistance

Class 4: No corrosion resistance, used as paint base

Copper The process in which a layer of copper is deposited on steel or aluminum . Dry Film Lubricant Materials which, despite being in the solid phase, are able

through rack or barrel plating and is plated by using an electrical current. It creates and to reduce friction between two surfaces sliding against each other without the need for

excellent undercoat for subsequent deposits.

MIL‐C‐14450 AMS‐2418 MIL‐PRF‐4601

Class 0 .001”‐.005” Class 3 .0002” min. Type I Color 1: Natural product color

Engineering/.0005”‐.0007”

Class 1 .001” min. Class 4 .0001” min. min. Color 2: Black

Electroless Nickel An auto-catalytic chemical process used to deposit a layer of Electropolish An electro-chemical process that removes material. It is used to

nickel phosphorus on a substrate controlled by a chemical reaction that does not require polish, passivate, and deburr stainless steel.

any source of current. Uniform and consistent finish.

AMS 2404, AMS‐C‐26074, ASTM‐B733‐04 (2014) ASTM B‐912-02 (2013)

MIL‐C‐26074

SC 0: .000004” Type I: No phosphorus Yields maximum tarnish and corrosions resistance in stainless steel. Simultaneously deburrs as it

Grade A .001" min. requirement polishes.

SC 1: .0002”

Grade B .0005" min. Type II: 1‐3% Phosphorus

SC 3: .001” requirement

Grade C .0015" min.

SC 4: .003” Type III: 2‐4% requirement

Class 1: As plated Type IV: 5‐9% requirement

Class 2: Bake at 500+ to harden Type V: 10% or Higher

nickel

651-645-0787 or quotes@coopplating.com TURN OVER FOR MORE FINISHES!

Gold A method of depositing a thin layer of gold on a surface of another metal, most Hard Chrome Delivers high corrosion, wear, and friction resistance. Fights friction

often on copper. without changing component dimensions. Excellent hardness (68-74 RC).

MIL‐DTL‐45204/ASTM AMS 2422 QQ‐C‐320

B488‐11

Grade A: Knopp 90 max. .00005” min., unless otherwise Class 1: Decorative plating Type I: Bright

Type I: 99.7% Gold min. specified

Grade B: Knopp 91‐129 Class 2: Engineering plating Type I: Satin

Type II: 99.0% Gold min.

Grade C: Knopp 201 and

Nickel Protects metallic objects from corrosion and promotes a high cosmetic Nickel Chrome The process of electroplating a thin deposit of chromium onto

appearance, its good for solderability. nickel for a decorative finish, great corrosion resistance.

QQ‐C‐320 ASTM B689‐97 (2013) Type I: No hardeners, brighteners, QQ‐C‐320 ASTM B689‐97 (2013)

or stress control additives

Class 1: Corrosion protective Class 5: .0002” min. Class 1: Corrosion protective Type I: Solutions that do not Class 5: .0002” min.

plating Type II: Deposit used at moderate plating contain hardeners, brighteners, or

Class 25: .001” min. temp., contains sulfur or other stress control additives Class 25: .001” min.

Class 2: Engineering plating compound to increase hardness, Class 2: Engineering plating

Class 50: .002” min. Type II: Moderate temp, deposit Class 50: .002” min.

refine the grain structure, and/or

Type I: Bright Finish contains sulfur or other

Class 100: .004” min. control internal stress Class 100: .004” min.

compounds to increase hardness,

Type II: Satin Finish Type I: Bright Finish

Class 200 : .008” min. Type III: Contains dispersed refine the grain structure, and/or Class 200: .008” min.

submicron particles such as silicon Type II: Satin Finish control inner stress

carbide to increase hardness and

wear resistance Type III: Contains dispersed

submicron particles such as

silicon carbide to increase

hardness and wear resistance

Nickel Sulfamate An electronically deposited process in which a sulfamate bath is Passivate The removal of free irons or iron compounds from the surface of stainless

used to plate the substrate. A pure deposit of nickel allows soldering and brazing. steel by means of chemical dissolution. Most typically by a treatment with an acid

AMS 2424 MIL‐P‐27418 QQ‐P‐35 AMS‐QQ‐P‐35 ASTM 967

Dull gray or silver Type II: Medium temp nitric with Type II: Medium temp nitric with Nitric 1

sodium dichromate sodium dichromate

.002‐.0003” Thickness Nitric 2

AMS-2700 Type VI: Low temp nitric acid

Soft Nickel, Electrodeposited Bath ASTM-A380

Phosphate A conversion coding that increases corrosion resistance and increases the Silver An electro-deposited coating for electrical, decorative, or solderable surfaces.

overall surface area while promoting adhesion. It provides durability for paint and metal

products.

TT‐C‐490 QQ‐S‐365 ASTM B700‐08 (2014)

Grade A Zinc Phosphate coating with no additional sealer Grade A: With supplementary Type I: Matte Grade A: Matte

tarnish‐resistant treatment

Grade B Zinc Phosphate coating with a dry organic sealer Type II: Semi‐bright Grade B: Bright

Grade B: Without supplementary

Grade C Zinc Phosphate with a supplemental protective oil type compound tarnish‐resistant treatment Type III: Bright Grade C: Bright

Grade D Zinc Phosphate with a supplemental protective oil type compound Grade D: Semi‐bright

Tin Lead Excellent solder-ability. In critical electrical applications, eliminates the Zinc Provides the most effective and economical way to protect steel against

potential for tin whisker formation. Matte appearance. 50-70% Tin, remainder lead. corrosion. Zinc plating protects steel by providing a physical barrier as well as cathodic

MIL‐P‐81728 B ASTM B579-73 (2015) ASTM B 633‐13 QQ‐Z‐325 AMS 2402

SC4 Very Severe (Steel .0003”/Copper 0003”) SC 1: .0002”/SC 2: .0003” mins. Class 1: .001” min. Class 1: .001” min.

SC3 Severe (Steel 0002”/Copper .00015”) SC 3: .0005”/SC 4: .001” mins. Class 2: .0005” min. Class 2: .0005” min.

SC2 Moderate (Steel .0001”/Copper .0008”) Type I: As plated Class 3: .0002” min. Class 3: .002” min.

SC1 Mild (Steel .005”/Copper .005” ) Type II: With colored chromate Type I: No dip (chromate) Clear Chromate unless

otherwise indicated by

Type III: With colorless coatings Type II: Yellow chromate customer

Type IV: With phosphate Type III: Phosphate treatment

conversion coatings

Type V: With colorless passivate

RoHS

Type VI: With colored passivate

Zinc-Nickel It provides 10 times the corrosion resistance of zinc plating. Gives

Office

exceptional sacrificial corrosion resistance and can be readily passivated. Available in

217 Snelling Avenue N. yellow, clear, and black chromate that provides enhanced paint adhesion, solder-able

Co-operative Plating Co.

St. Paul, MN 55104 properties, and conductive properties.

651-645-0787 AMS 2417 ASTM B841-99 (2010) Class q: 5‐12% Nickel

Grade A: Yellow Chromate Type A: Clear Chromate

Plant www.coopplating.com

Grade B: Clear Chromate Type B: Yellow Chromate

1605 Iglehart Avenue quotes@coopplating.com Type I: No dip Type C: Dark Yellow Chromate

St. Paul, MN 55104

Type II: With chromate treatment Type D: Black Chromate

You might also like

- Black Oxide MIL DTL 13924DDocument11 pagesBlack Oxide MIL DTL 13924DadamhomeNo ratings yet

- Surface Finishing OperationsDocument88 pagesSurface Finishing OperationsKodeboyina Chandramohan100% (1)

- Black PassivationDocument12 pagesBlack PassivationZineb100% (1)

- Plating and MetPLATING & METAL FINISHING SPECIFICATIONS ISO 9001:2008, Nadcap, ITAR, Federal Fire Arms Licenseal Finishing SPECDocument1 pagePlating and MetPLATING & METAL FINISHING SPECIFICATIONS ISO 9001:2008, Nadcap, ITAR, Federal Fire Arms Licenseal Finishing SPECStas Zabarsky0% (1)

- The T6 Heat Treatment of Semi-Solid Metal Processed Alloy A356Document5 pagesThe T6 Heat Treatment of Semi-Solid Metal Processed Alloy A356tumoyeNo ratings yet

- Galvanizing QA/QC Department Protects MetalsDocument43 pagesGalvanizing QA/QC Department Protects MetalsShakirNo ratings yet

- TALAT Lecture 3704: Deep DrawingDocument15 pagesTALAT Lecture 3704: Deep DrawingCORE MaterialsNo ratings yet

- Electroplating Anodizing Metal PDFDocument53 pagesElectroplating Anodizing Metal PDFCrystian Kobee EmpeynadoNo ratings yet

- ANODIZING (Autosaved)Document17 pagesANODIZING (Autosaved)Sonu JajamNo ratings yet

- Black OxideDocument2 pagesBlack OxideGerman ToledoNo ratings yet

- Surface TreatmentDocument34 pagesSurface TreatmentnagarajNo ratings yet

- ANKURDocument20 pagesANKURDevashish JoshiNo ratings yet

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Coating and Deposition Processes - Chapter 29Document41 pagesCoating and Deposition Processes - Chapter 29xharpreetxNo ratings yet

- TALAT Lecture 5105: Surface Treatment of AluminiumDocument15 pagesTALAT Lecture 5105: Surface Treatment of AluminiumCORE MaterialsNo ratings yet

- GEOMETDocument4 pagesGEOMETtoyota952No ratings yet

- Resistance WeldingDocument21 pagesResistance WeldingAyush KumarNo ratings yet

- Surface Preparation Of: Aluminum, Copper, BrassDocument14 pagesSurface Preparation Of: Aluminum, Copper, BrassGaneshNo ratings yet

- Tests on Bitumen MaterialsDocument34 pagesTests on Bitumen MaterialsLaxmikantNo ratings yet

- Hard Chrome 105 Plating ProcesDocument3 pagesHard Chrome 105 Plating ProcesKishora BhatNo ratings yet

- Surface FinishesDocument8 pagesSurface FinishesasritaipNo ratings yet

- Chemical Processing Scope Determination MatrixDocument20 pagesChemical Processing Scope Determination MatrixnorlieNo ratings yet

- SURFACE ENGINEERING TECHNIQUESDocument21 pagesSURFACE ENGINEERING TECHNIQUESPalak Naik100% (1)

- TALAT Lecture 3402: Forging ProcessDocument17 pagesTALAT Lecture 3402: Forging ProcessCORE MaterialsNo ratings yet

- Electroplating Cost Calculation - RefDocument12 pagesElectroplating Cost Calculation - RefJitendra PatilNo ratings yet

- Jayco Safety Products Pvt. Ltd. OverviewDocument10 pagesJayco Safety Products Pvt. Ltd. OverviewGanda PrajaNo ratings yet

- Reducing Aluminium Anodizing Costs with Solar HeatingDocument14 pagesReducing Aluminium Anodizing Costs with Solar Heatingaditya_welekarNo ratings yet

- Testing Methods For Plating BathsDocument3 pagesTesting Methods For Plating BathsR.Subramanian100% (1)

- Surface Pretreatment by Phosphate Conversion CoatiDocument49 pagesSurface Pretreatment by Phosphate Conversion CoatiJhon QsacNo ratings yet

- Guide to Specifying Powder Coated AluminiumDocument2 pagesGuide to Specifying Powder Coated AluminiumAnwar100% (1)

- Guide Totinplate PDFDocument124 pagesGuide Totinplate PDFPrakhar MishraNo ratings yet

- Electroplating Processes and CoatingsDocument5 pagesElectroplating Processes and CoatingsSinar Cemaramas AbadiNo ratings yet

- Safecoat Hard AnodizingDocument47 pagesSafecoat Hard AnodizingyahsooyNo ratings yet

- Brochure - Rev 15 PDFDocument9 pagesBrochure - Rev 15 PDFCicero Gomes de SouzaNo ratings yet

- Benefits of Anodizing AluminumDocument31 pagesBenefits of Anodizing AluminumSenthil Kumar100% (2)

- Anodize ProcessDocument42 pagesAnodize ProcessJigar GalaNo ratings yet

- DS16 Road Moisture ControlDocument9 pagesDS16 Road Moisture ControlChaminda KumaraNo ratings yet

- Metal Finishing Processes Best PracticesDocument44 pagesMetal Finishing Processes Best PracticesHoang TanNo ratings yet

- Military Plating Spec-1Document11 pagesMilitary Plating Spec-1Durbha RaviNo ratings yet

- Difference Between Forging and CastingDocument2 pagesDifference Between Forging and CastingMOHAMMAD ALINo ratings yet

- Advances in Surface Treatments: Technology — Applications — EffectsFrom EverandAdvances in Surface Treatments: Technology — Applications — EffectsNo ratings yet

- ATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeDocument4 pagesATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeWK Sinn100% (1)

- DacrometDocument6 pagesDacrometdavideNo ratings yet

- Shaftwall7.0 001Document9 pagesShaftwall7.0 001Wissam AlameddineNo ratings yet

- Zinc Flake Technology-Technical PDFDocument1 pageZinc Flake Technology-Technical PDFKalyan DhakaneNo ratings yet

- Poly Phenylene Oxide (PPO) : Corporate Training and PlanningDocument27 pagesPoly Phenylene Oxide (PPO) : Corporate Training and PlanningAkash YadavNo ratings yet

- Instructions Tifoo Anodization Starterkit enDocument23 pagesInstructions Tifoo Anodization Starterkit enHoang TanNo ratings yet

- TALAT Lecture 5204: Organic Coating of AluminiumDocument17 pagesTALAT Lecture 5204: Organic Coating of AluminiumCORE MaterialsNo ratings yet

- Blackening Processes For ZincDocument13 pagesBlackening Processes For Zincvasudev_nNo ratings yet

- Aluminium and Aluminium AlloysDocument3 pagesAluminium and Aluminium AlloysCherie DiazNo ratings yet

- Rheocasting of Aluminum 201Document56 pagesRheocasting of Aluminum 201Nahid LatonaNo ratings yet

- GMW14668Document20 pagesGMW14668Carlos LanzillottoNo ratings yet

- Chrome Plating and Anodizing Operations GuideDocument6 pagesChrome Plating and Anodizing Operations GuidePuguh Cahpordjo BaeNo ratings yet

- CED Coating Defect That Affect Your CarsDocument1 pageCED Coating Defect That Affect Your CarsOliver Reazon Ruelo100% (1)

- Qualanod SpecDocument62 pagesQualanod SpecwilliamNo ratings yet

- Electro CoatingDocument2 pagesElectro CoatingViswanathan SrkNo ratings yet

- ImportedfromGoogleNotebook MaterialScienceDocument97 pagesImportedfromGoogleNotebook MaterialScienceHarish PothepalliNo ratings yet

- Acid ZincDocument27 pagesAcid ZincHacı OsmanNo ratings yet

- Sur Tec 650Document17 pagesSur Tec 650donhan91No ratings yet

- Anodizing Basics: Mechanical & Chemical Surface TreatmentsDocument4 pagesAnodizing Basics: Mechanical & Chemical Surface TreatmentsSporkx100% (1)

- ASE 02 FundamentalDocument62 pagesASE 02 FundamentalsriNo ratings yet

- Corrosion Management Issue140 LowResDocument32 pagesCorrosion Management Issue140 LowResReno100% (1)

- Anodizing Standards and and Quality Control Tests Quality Control Tests of America's AutomakersDocument25 pagesAnodizing Standards and and Quality Control Tests Quality Control Tests of America's AutomakersshrikantbagalNo ratings yet

- Chrome Plating On ABSDocument52 pagesChrome Plating On ABSmarkNo ratings yet

- Data Sheet: AEDR-850xDocument10 pagesData Sheet: AEDR-850xMichael DoyleNo ratings yet

- Echnical ATA Heet: CastinDocument2 pagesEchnical ATA Heet: CastinMichael DoyleNo ratings yet

- Admin Image Option Editor GoEngineerDocument23 pagesAdmin Image Option Editor GoEngineerMichael DoyleNo ratings yet

- Clean SolidWorks UninstallDocument8 pagesClean SolidWorks UninstallBlueNo ratings yet

- MN Rules Chapter 5208 DLIDocument24 pagesMN Rules Chapter 5208 DLIMichael DoyleNo ratings yet

- Calculation of Tolerance Stacks Using Direct Position Approach in Geometric Dimensioning and TolerancingDocument10 pagesCalculation of Tolerance Stacks Using Direct Position Approach in Geometric Dimensioning and TolerancingMichael DoyleNo ratings yet

- MN Statutes 182.653Document5 pagesMN Statutes 182.653Michael DoyleNo ratings yet

- An Employer's Guide To Developing A Workplace Accident and Injury Redictopm (AWAIR) ProgramDocument25 pagesAn Employer's Guide To Developing A Workplace Accident and Injury Redictopm (AWAIR) ProgramMichael DoyleNo ratings yet

- RIGOL DM3058 Technical Characteristics GuideDocument9 pagesRIGOL DM3058 Technical Characteristics GuideMichael DoyleNo ratings yet

- Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Document1 pageHussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Michael DoyleNo ratings yet

- Ingun Ada Catalogue enDocument80 pagesIngun Ada Catalogue enMichael DoyleNo ratings yet

- Spisak Svih EUROCODE-ovaDocument4 pagesSpisak Svih EUROCODE-ovapedjaNo ratings yet

- Building Materials Price ListDocument109 pagesBuilding Materials Price ListGels GenovaNo ratings yet

- Toggle SwitchDocument119 pagesToggle SwitchLuis MendozaNo ratings yet

- Detecting Air Pollution in CitiesDocument7 pagesDetecting Air Pollution in CitiesWild RiftNo ratings yet

- Sikalite Powdered Waterproofing AdmixtureDocument2 pagesSikalite Powdered Waterproofing AdmixtureNathàn Ocày100% (1)

- Properties of Concrete Incorporating Nano-SilicaDocument7 pagesProperties of Concrete Incorporating Nano-SilicaChan NovNo ratings yet

- Pattern Making Assignment-2 Specification Sheet: Bachelor'S of Fashion TechnologyDocument11 pagesPattern Making Assignment-2 Specification Sheet: Bachelor'S of Fashion TechnologyIshikaNo ratings yet

- C&P WITCHLINER Insulated 2-Bolt Pipe ClampDocument1 pageC&P WITCHLINER Insulated 2-Bolt Pipe ClampAchraf BoudayaNo ratings yet

- New Microsoft Excel WorksheetDocument4 pagesNew Microsoft Excel WorksheetRaheel Neo AhmadNo ratings yet

- Buffer Solution 1Document23 pagesBuffer Solution 1Arvit CtkhuNo ratings yet

- Designation Codes for Harmonized CablesDocument7 pagesDesignation Codes for Harmonized Cablesvinayak.khorate2707No ratings yet

- VSM Metalworking SolutionsDocument12 pagesVSM Metalworking Solutionsforough sardarzadehNo ratings yet

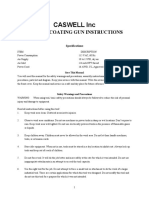

- Caswell, Inc - Plating Manual - Powder Coating Gun InstructionsDocument8 pagesCaswell, Inc - Plating Manual - Powder Coating Gun InstructionsClaudio SiqueiraNo ratings yet

- 20140331WFIProduct-BRANCH FITTINGS PDFDocument20 pages20140331WFIProduct-BRANCH FITTINGS PDFmoorthymech1979No ratings yet

- SI1285F Non-Destructive TestingDocument3 pagesSI1285F Non-Destructive TestingAngelina MatutinaNo ratings yet

- RW Ti Pds Prorox WM 960 Astm IndiaDocument1 pageRW Ti Pds Prorox WM 960 Astm IndiaLee Kok RoyNo ratings yet

- Course Syllabus - Chemistry For EngineersDocument10 pagesCourse Syllabus - Chemistry For EngineersNEALE OLIVER BONBONNo ratings yet

- Materials and Processes For The Third-Generation Advanced High-Strength SteelsDocument10 pagesMaterials and Processes For The Third-Generation Advanced High-Strength SteelsMathews LimaNo ratings yet

- Method OgyDocument7 pagesMethod OgyClairole Marie QuilantangNo ratings yet

- CINTEC Design Guide European VersionBDocument29 pagesCINTEC Design Guide European VersionBDavid MiguelNo ratings yet

- Honing Your Style Kitchen Worksheet: by Erinn ValencichDocument2 pagesHoning Your Style Kitchen Worksheet: by Erinn ValencichHafsa SellaiNo ratings yet

- Delta MS500 Product Data SheetDocument9 pagesDelta MS500 Product Data SheetAmit KumarNo ratings yet

- Chemical Bonding PropertiesDocument20 pagesChemical Bonding PropertiesHema LataNo ratings yet

- United States Patent Office: Patented June 23, 1970Document2 pagesUnited States Patent Office: Patented June 23, 1970MãdãlinaStanciuNo ratings yet

- CORPUZ Contempo ReportingDocument16 pagesCORPUZ Contempo ReportingTalaNo ratings yet