Professional Documents

Culture Documents

Minimum Test Requirement Miscellaneous

Uploaded by

rheymar diwaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minimum Test Requirement Miscellaneous

Uploaded by

rheymar diwaCopyright:

Available Formats

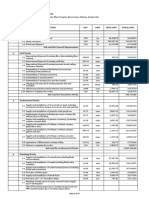

MATERIALS FOR EACH

SAMPLE SUBMITTED

1. Cement 1 sample per 2000 bags 10 kg

1 sample per 40T or 200

2. Asphaltic material 5L

drums

3. Aspahlt mix 1 sample per 130T 20 kg

4. Aggregates 1 sample per 1,500 m3

a. coarse aggregate 70 kg

b. fine aggregate 50 kg

5. Soil aggregates 1 sample per 1,500 m3

a. Classification 20 kg

b. Routinary tests 50 kg

c. MDR test and CBR 50 kg

6. Non – Reinforced Concrete 2 pipes min./0.5% of no.

2 pipes

Pipes of pipes

1 sample per 50 pipes or 1 pipe (1 m length)

7. Reinforced Concrete Pipes

2% of # of pipes

1 sample per 500 lengths 2 pcs Of 100 mm long taken

8.Steel pipe (galvanized)

from both ends w/ thread

9. Concrete hollow blocks (CHB) 1 sample per 10,000 units

a. strength 3 units

b. moisture content 3 units

10. Steel bar 1 sample per 10T 1m

11. Steel sheet (galvanized) 1 sample per 100 sheets 3 pcs 60mm x 60mm

12. Wire strand 1 sample per 20T 2m

13. Gabion 1m x 2m

14. Paints 1 sample per 100 cans 1 - 4L can

15. Joint – filler (pre – molded) 1 – 400mm x 400mm

16. Curing compound 1L

17. Concrete cylinder 1 sample per 75 m3 1 set (3 cylinders)

18. Concrete beam 1 sample per 75 m3 or 1

1 set (3 cylinders)

day pouring

19. Concrete core 5 holes for every km/lane

20. Asphalt core 1 core for every 100m

21. Water

500 ml

a. Chemical analysis

500 ml

b. Sediment load analysis

22. Structural steel/sheet 1 sample per 50T Reduced section as prescribed

23. Hydrated lime 1 sample per 100T

COMPOSITION AND STRENGTH OF CONCRETE FOR USE IN STRUCTURE

falb_02@yahoo.com 27

To GOD be the glory!!!

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 2.2. IBM (Real World Lens)Document1 page2.2. IBM (Real World Lens)rheymar diwaNo ratings yet

- 2014 - 001 Introduction To House PlumbingDocument16 pages2014 - 001 Introduction To House PlumbingRon Julienne RebugioNo ratings yet

- Ranbaxy's Shift to Branded Drugs & US MarketDocument1 pageRanbaxy's Shift to Branded Drugs & US Marketrheymar diwaNo ratings yet

- Lessons Learned in General ElectricDocument1 pageLessons Learned in General Electricrheymar diwaNo ratings yet

- Fire Code of The Philppines 2008 PDFDocument16 pagesFire Code of The Philppines 2008 PDFjpkhepNo ratings yet

- Mem608 - Diwa - Chapter 2Document3 pagesMem608 - Diwa - Chapter 2rheymar diwaNo ratings yet

- Mem608 - Diwa - Chapter 5Document3 pagesMem608 - Diwa - Chapter 5rheymar diwaNo ratings yet

- 4.1. Interpharm Holdings (Real World Lens)Document1 page4.1. Interpharm Holdings (Real World Lens)rheymar diwaNo ratings yet

- 1.2. X-Rite (Real World Lens)Document1 page1.2. X-Rite (Real World Lens)rheymar diwaNo ratings yet

- Upload For Scribd 1Document1 pageUpload For Scribd 1rheymar diwaNo ratings yet

- Mem608 - Diwa - Chapter 3Document3 pagesMem608 - Diwa - Chapter 3rheymar diwaNo ratings yet

- 001a Refresher Arithmetic ElementsDocument701 pages001a Refresher Arithmetic ElementsFritz NatividadNo ratings yet

- Mem608 - Diwa - Chapter 1Document2 pagesMem608 - Diwa - Chapter 1rheymar diwaNo ratings yet

- Mem608 - Diwa - Chapter 4Document4 pagesMem608 - Diwa - Chapter 4rheymar diwaNo ratings yet

- Upload For Scribd 2Document1 pageUpload For Scribd 2rheymar diwaNo ratings yet

- Upload For Scribd 3Document1 pageUpload For Scribd 3rheymar diwaNo ratings yet

- Wilmont's Drone Delivery WBSDocument3 pagesWilmont's Drone Delivery WBSrheymar diwaNo ratings yet

- Upload For ScribdDocument1 pageUpload For Scribdrheymar diwaNo ratings yet

- FinalNHAQualityManual 12 11 15 PDFDocument79 pagesFinalNHAQualityManual 12 11 15 PDFLouise MendozaNo ratings yet

- Illustrator For Beginners Tastytuts PDFDocument25 pagesIllustrator For Beginners Tastytuts PDFBejenaru GeorgeNo ratings yet

- Boq ToiletsDocument15 pagesBoq Toiletsrheymar diwaNo ratings yet

- 1.finishing ScheduleDocument1 page1.finishing Schedulerheymar diwaNo ratings yet

- Wilmont Pharmacy Drone Project Scope StatementDocument2 pagesWilmont Pharmacy Drone Project Scope StatementLotanna Obika100% (1)

- Various Repair Works of SSD Toilets at Building CDocument1 pageVarious Repair Works of SSD Toilets at Building Crheymar diwaNo ratings yet

- General Methodology For The Renovation of BSP ToiletsDocument1 pageGeneral Methodology For The Renovation of BSP Toiletsrheymar diwaNo ratings yet

- PERT, CPM Toilets 90 DaysDocument1 pagePERT, CPM Toilets 90 Daysrheymar diwaNo ratings yet

- RENOVATION OF BSP-QC TOILETS GANTT CHART AND S-CURVEDocument1 pageRENOVATION OF BSP-QC TOILETS GANTT CHART AND S-CURVErheymar diwaNo ratings yet

- Project Scope Statement Rheymar Diwa PDFDocument2 pagesProject Scope Statement Rheymar Diwa PDFrheymar diwaNo ratings yet

- RENOVATION OF BSP-QC TOILETS GANTT CHART AND S-CURVEDocument1 pageRENOVATION OF BSP-QC TOILETS GANTT CHART AND S-CURVErheymar diwaNo ratings yet

- Project Scope Statement Rheymar Diwa PDFDocument2 pagesProject Scope Statement Rheymar Diwa PDFrheymar diwaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- How Does A Refrigerator WorkDocument5 pagesHow Does A Refrigerator WorkAlfis0% (1)

- Test For Cations, Anions and Gases (QA) NotesDocument10 pagesTest For Cations, Anions and Gases (QA) Noteschong56100% (2)

- AL REScheck CertificateDocument6 pagesAL REScheck Certificatebcap-oceanNo ratings yet

- Water WastewaterDocument20 pagesWater WastewaterterryjoseeNo ratings yet

- Synthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid DerivativesDocument4 pagesSynthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid Derivativesmik100% (1)

- Bio HGHDocument19 pagesBio HGHapi-240332064No ratings yet

- Is 2986Document9 pagesIs 2986sreenathaNo ratings yet

- Alpha ProfileDocument2 pagesAlpha ProfileGovind SinghNo ratings yet

- 1 s2.0 S2352179118302382 MainDocument5 pages1 s2.0 S2352179118302382 MainIrfan IsdhiantoNo ratings yet

- Top 305 Companies in Pune RegionDocument39 pagesTop 305 Companies in Pune RegionNiraj Thakkar0% (1)

- Successful Intraoral RadiographyDocument19 pagesSuccessful Intraoral RadiographyMonica Agustine HartonoNo ratings yet

- AlbendazoleDocument13 pagesAlbendazoleShankar SoniNo ratings yet

- Application of Industrial and Agricultural Waste For Sustainable Construction PDFDocument9 pagesApplication of Industrial and Agricultural Waste For Sustainable Construction PDFJayesh MagarNo ratings yet

- ASTM D3013 Epoxy Molding CompoundsDocument3 pagesASTM D3013 Epoxy Molding CompoundsNelson RomeroNo ratings yet

- Astm D 2863Document13 pagesAstm D 2863Ma PonyNo ratings yet

- Instruction Manual Instruction Manual: HDI 2D949-80Document30 pagesInstruction Manual Instruction Manual: HDI 2D949-80GeorgianaNo ratings yet

- დ მიქელაძის-ბიოქიმიაDocument201 pagesდ მიქელაძის-ბიოქიმიაJuli JulianaNo ratings yet

- ME6008 WELDING TECHNOLOGY Part B IQDocument1 pageME6008 WELDING TECHNOLOGY Part B IQVikram mNo ratings yet

- HP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced MaterialsDocument4 pagesHP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced Materialssirjole7584No ratings yet

- New Australian Curriculum Senior Secondary ChemistryDocument44 pagesNew Australian Curriculum Senior Secondary Chemistryapi-252350138No ratings yet

- Gas TransportDocument19 pagesGas TransportJesus GutierrezNo ratings yet

- Deal-Grove Model for Thermal Oxide GrowthDocument13 pagesDeal-Grove Model for Thermal Oxide GrowthChithraParameswaranNo ratings yet

- Farmacologia en ArdillasDocument3 pagesFarmacologia en ArdillasIvan Gonzalez BernalNo ratings yet

- ASPHALT METHOD STATEMENTDocument7 pagesASPHALT METHOD STATEMENTBasem Donia100% (1)

- Sunward SWE08B Operator's ManualDocument96 pagesSunward SWE08B Operator's ManualIisakki50% (2)

- Rigaku Nex QCDocument12 pagesRigaku Nex QCLuis ReyesNo ratings yet

- Steps in Balancing Redox ReactionsDocument28 pagesSteps in Balancing Redox ReactionsRUZCHEMISTRYNo ratings yet

- Gnaser H., Huber B., Ziegler C. - Nanocrystalline TiO2 For Photocatalysis (2004) PDFDocument32 pagesGnaser H., Huber B., Ziegler C. - Nanocrystalline TiO2 For Photocatalysis (2004) PDFoscuraNo ratings yet

- Preslia 68 - MSDSDocument12 pagesPreslia 68 - MSDSFraNo ratings yet

- Hele 6Document16 pagesHele 6Ella Mae Berro0% (1)