Professional Documents

Culture Documents

Heat Sealing Roll Stock

Uploaded by

Đăng Hải0 ratings0% found this document useful (0 votes)

28 views13 pagesHeat Sealing Roll Stock

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHeat Sealing Roll Stock

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views13 pagesHeat Sealing Roll Stock

Uploaded by

Đăng HảiHeat Sealing Roll Stock

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

Heat Seal Pouches

How to seal a Heat Seal &

Roll Type Pouch

Heat Sealing the Pouch

• Follow general Guidelines for all pouches

• Ensure that the proper sealer conditions are

used. (temperature each peel pouch has a

temperature range to provide maximum

sealing, if a heat seal type pouch)

• To prevent injury keep fingers away from

sealer bars/ rollers

Heat Sealing the Pouch continued

• Hold the pouch taut in the sealer, to prevent

wrinkles or air bubbles from forming in the seal.

If using a rolling type sealer let the peel pouch

move along the guide on it’s own.

• When heat sealing “ tubing/ roll” type

pouches, always leave enough material beyond

the seal for the opener to easily grasp (usually

1-1/2 to 2 inches)

General Information

• Pouches and roll stock are

commonly used for small

instruments, light weight

devices and porous items

• Roll stock is cut to fit

• Scallop cut opening end.

• Make Sure scallop cut

recognizes the correct opening

direction.

• Must be pinhole free and non-

toxic

• Must be resistant to tears and

punctures

Sealing the Pouch Continued

• Hold the pouch taut in the

sealer, to prevent wrinkles or

air bubbles from forming in

the seal. If using a rolling type

sealer let the peel pouch

move along the guide on it’s

own.

• Always leave enough

material beyond the

seal for the opener to

easily grasp (usually 1-

1/2 to 2 inches) critical

to allow for aseptic

presentation

Opening Roll Stock

• Open at scalloped end

• (Verify your opening in the correct direction)

Peel Down Top-Side Seams (Thumb

Tabs)

Grab & Roll Down Top Seam (4th side user

created) - pulling film away from paper

Once Top Seam is released open the package using proper aseptic technique

Peeling the film from the paper side of package for Sterile Presentation

Verifying the seal

• In 2006 ISO 11607 was updated. This is a two part

document concerning packaging. To complement the

release of this new standard, the AAMI guidance

document, Technical Information Report – TIR

22:2007 was updated.

• Under the new ISO Standard 11607-2: 2006 a process

validation program is required to validate the efficacy

and reproducibility of all sterilization and packaging

processes, and this validation must be documented.

Verifying the seal

• Commercial products available

• The Steriking® Seal Control Sheet

SC250 is made of ESPP film and

medical grade paper. It simulates

the sealing process very

effectively and is suitable for the

rotosealers and impulse units in

widespread use.

Heat Sealing the Pouch

• Ensure that the proper sealer

conditions are used.

• Use a sealer designed for

medical packaging

• Each brand may have a slightly

different melt point.

• Be sure to test your brand.

• Green tinted 320 – 356 F (160-

180 degrees C)

You might also like

- Creating Sterile FieldDocument18 pagesCreating Sterile FieldROSAMMA JOSEPH100% (1)

- LM Glassware - Safety Fin PDFDocument1 pageLM Glassware - Safety Fin PDFEstanislao Amadeo AvogadroNo ratings yet

- Seminar, 30 Mins, Sterilization PackagingDocument32 pagesSeminar, 30 Mins, Sterilization PackagingArdyNo ratings yet

- Packaging of Sets and Other Sterile Consumables FinalDocument14 pagesPackaging of Sets and Other Sterile Consumables FinalKevo YoungNo ratings yet

- ct014 ManualDocument12 pagesct014 Manual19donmateoscribdNo ratings yet

- Instructions: Tub, Sink & TileDocument4 pagesInstructions: Tub, Sink & TileMaxwell SmartNo ratings yet

- Guide to Decontamination and Sterilization ProcessesDocument38 pagesGuide to Decontamination and Sterilization ProcessesShafqat UllahNo ratings yet

- 0220 - Sop AutoclaveDocument6 pages0220 - Sop Autoclaveankit7588No ratings yet

- Machine Shop Theory: Classification, Applications and Operations of MachinesDocument5 pagesMachine Shop Theory: Classification, Applications and Operations of MachinesIsmaeli KielNo ratings yet

- Process DO's & DON'TsDocument4 pagesProcess DO's & DON'TsAnand JNo ratings yet

- Safety Precautions and Sanitation ProceduresDocument5 pagesSafety Precautions and Sanitation Proceduresma cleah ramos67% (3)

- 9 Foreign MaterialDocument3 pages9 Foreign MaterialSarthak GuptaNo ratings yet

- Tissue Sectioning ProtocolDocument2 pagesTissue Sectioning Protocolvasu_mahalingam5688No ratings yet

- Cylindrical Bend Test 100mm Incl Mandrel Set Sp1820 m44 1Document2 pagesCylindrical Bend Test 100mm Incl Mandrel Set Sp1820 m44 1oktaviani fajar handiniNo ratings yet

- Pipe Sealing Bags ManualDocument2 pagesPipe Sealing Bags ManualKea PratamaNo ratings yet

- First Aid KitDocument18 pagesFirst Aid KitGianni100% (1)

- InoculationDocument26 pagesInoculationGulab KhanNo ratings yet

- General Solder Paste Handling Guidelines - Asia: Reference BulletinDocument2 pagesGeneral Solder Paste Handling Guidelines - Asia: Reference BulletinMohan BaskaranNo ratings yet

- Sterile FieldDocument8 pagesSterile FieldAsiah IsmailNo ratings yet

- Pack and SterilizeDocument31 pagesPack and SterilizeboazNo ratings yet

- FM-Gr-11-Homework-booklet-Term-1-4-Teacher-Guide-expecetd-answersDocument34 pagesFM-Gr-11-Homework-booklet-Term-1-4-Teacher-Guide-expecetd-answersNonhlanhla NhlapoNo ratings yet

- SOP Operating A Pressure Cooker and AutoclaveDocument5 pagesSOP Operating A Pressure Cooker and AutoclavejuliaNo ratings yet

- Steriking® LT Blueline Pouches and Rolls - IFU - MDR - 062021Document2 pagesSteriking® LT Blueline Pouches and Rolls - IFU - MDR - 062021batefNo ratings yet

- Automotive Servicing Nc1: Sealants and AdhesivesDocument20 pagesAutomotive Servicing Nc1: Sealants and Adhesiveslaylayden kaNo ratings yet

- Washer Dryer: (1 8Vhu0DqxdoDocument36 pagesWasher Dryer: (1 8Vhu0DqxdojojondNo ratings yet

- 4D Pouches User GuideDocument2 pages4D Pouches User GuideSamuel GleisnerNo ratings yet

- Washer Dryer: EN User ManualDocument36 pagesWasher Dryer: EN User Manualbenski21295No ratings yet

- Infant Incubators: Penlon B e Llo W S UnitDocument3 pagesInfant Incubators: Penlon B e Llo W S Unitjose_mario1128No ratings yet

- Principles OF Sterile Technique: Prepared By: Mrs. R. M. Dimalibot RM, RN ManDocument36 pagesPrinciples OF Sterile Technique: Prepared By: Mrs. R. M. Dimalibot RM, RN ManCerisse RemoNo ratings yet

- Periop-Principles N PracDocument16 pagesPeriop-Principles N PracgladyaresNo ratings yet

- BAG TECHNIQUE FOR EFFECTIVE PUBLIC HEALTH NURSING CAREDocument40 pagesBAG TECHNIQUE FOR EFFECTIVE PUBLIC HEALTH NURSING CAREhapices100% (1)

- Standard UnitsDocument10 pagesStandard UnitsysilangitNo ratings yet

- Parenteral S RonaDocument14 pagesParenteral S RonalanDraynNo ratings yet

- Pizza Cutter Kit InstDocument4 pagesPizza Cutter Kit InstwchoyleNo ratings yet

- New! UV Resistant Under Pressure: Syntho-GlassDocument2 pagesNew! UV Resistant Under Pressure: Syntho-GlassNshuti Rene FabriceNo ratings yet

- Tracheostomy Care GuideDocument2 pagesTracheostomy Care Guideirish felixNo ratings yet

- Avoid cross contamination in sterile proceduresDocument31 pagesAvoid cross contamination in sterile proceduresShamsa Afdal100% (1)

- Safety handling sharps broken glassDocument10 pagesSafety handling sharps broken glassDebanjan LahiriNo ratings yet

- Tips On Extrusion DDS8Document4 pagesTips On Extrusion DDS8Hector AmarfilNo ratings yet

- Managing Adhesive Ooze PDFDocument3 pagesManaging Adhesive Ooze PDFkapasariNo ratings yet

- SEB Autoclave TrainingDocument19 pagesSEB Autoclave TrainingFahim FahimNo ratings yet

- Air Fry Toaster Oven Horno Tostador Con Freidora de Aire: Use and Care Manual Manual de Uso y CuidadoDocument24 pagesAir Fry Toaster Oven Horno Tostador Con Freidora de Aire: Use and Care Manual Manual de Uso y CuidadoJosadac LunaNo ratings yet

- Abrasive Blasting Safety EssentialsDocument2 pagesAbrasive Blasting Safety Essentialssarge18100% (2)

- Bissell Lift-Off MultiCyclonic Pet HEPA Upright Vacuum 89Q9Document20 pagesBissell Lift-Off MultiCyclonic Pet HEPA Upright Vacuum 89Q9Jer EmyNo ratings yet

- 1_Tourniquet Cuff Brochure(2)Document12 pages1_Tourniquet Cuff Brochure(2)bashar mohammedNo ratings yet

- Tracheostomy Care ChecklistDocument6 pagesTracheostomy Care ChecklistZero TwoNo ratings yet

- Yara's Guide To The Safe Use of Fertilizers On Farm: Knowledge GrowsDocument24 pagesYara's Guide To The Safe Use of Fertilizers On Farm: Knowledge GrowsKent AlpayNo ratings yet

- Boratory Sfety PracticesDocument20 pagesBoratory Sfety PracticesBabbooNo ratings yet

- Good Laboratory Practices & Basic Laboratory ProceduresDocument8 pagesGood Laboratory Practices & Basic Laboratory ProceduresCHARMAINE FEARL FABROSNo ratings yet

- PDF DocumentDocument31 pagesPDF Documentirish felixNo ratings yet

- HandDocument4 pagesHandCharl BaranganNo ratings yet

- Introduction To Mech MH SafetyDocument29 pagesIntroduction To Mech MH Safetybalamurugan sNo ratings yet

- Pack 'N Play Care Suite Playard Corralito Pack 'N Play Care Suite™Document32 pagesPack 'N Play Care Suite Playard Corralito Pack 'N Play Care Suite™yttgjjm579No ratings yet

- Caps and ClosuresDocument26 pagesCaps and ClosuresSubhadip RoyNo ratings yet

- Bosch Dishwasher Quick Start GuideDocument7 pagesBosch Dishwasher Quick Start GuideSamuel Ramos-ArchundiaNo ratings yet

- Sop - Ac Standard Operating Procedures For Safe Operation of AutoclavesDocument3 pagesSop - Ac Standard Operating Procedures For Safe Operation of Autoclavesimmanuel izaniNo ratings yet

- 12 Steps of Aseptic TechniqueDocument7 pages12 Steps of Aseptic TechniqueRobbie MejiaNo ratings yet

- Glass Policy SummaryDocument3 pagesGlass Policy SummaryMATTHEW MUNGAI100% (3)

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersFrom EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersNo ratings yet

- NADH Consulting Job Description Lead TSD Specialist PSPDocument2 pagesNADH Consulting Job Description Lead TSD Specialist PSPĐăng HảiNo ratings yet

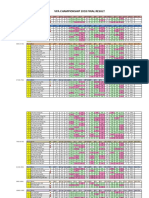

- VPA Chapionship 2018Document3 pagesVPA Chapionship 2018Đăng HảiNo ratings yet

- 200Document1 page200Đăng HảiNo ratings yet

- Merge 1401507949Document5 pagesMerge 1401507949Đăng HảiNo ratings yet

- InDocument16 pagesInĐăng HảiNo ratings yet

- SHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsDocument8 pagesSHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsMahmoud ElsherifNo ratings yet

- EC2151 Electric Circuit Important QuestionsDocument47 pagesEC2151 Electric Circuit Important QuestionschitragowsNo ratings yet

- Autocad 2010 Tutorial Series Autocad Mechanical 2010 Tutorial SeriesDocument4 pagesAutocad 2010 Tutorial Series Autocad Mechanical 2010 Tutorial Seriesbdi_roNo ratings yet

- Ejercicio para CompararDocument4 pagesEjercicio para CompararCamila SarabiaNo ratings yet

- Degaussing N Magnetic MinesDocument3 pagesDegaussing N Magnetic MinesGus MellonNo ratings yet

- CS5001 CourseworkDocument9 pagesCS5001 CourseworkpeteligijusNo ratings yet

- History of JS: From Netscape to Modern WebDocument2 pagesHistory of JS: From Netscape to Modern WebJerraldNo ratings yet

- Pfaff 360 Sewing Machine Instruction ManualDocument55 pagesPfaff 360 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- CV Software Engineer Sarika DhingraDocument2 pagesCV Software Engineer Sarika DhingravirenderbishnoiNo ratings yet

- Psan en Tcd210185ab 20220523 Inst WDocument2 pagesPsan en Tcd210185ab 20220523 Inst Wsinar automationNo ratings yet

- Military Standard for Circular Connector Insert ArrangementsDocument59 pagesMilitary Standard for Circular Connector Insert ArrangementsVadim RiabovNo ratings yet

- Multisite ErpDocument5 pagesMultisite ErparavindhsekarNo ratings yet

- Basic Silicone Chemistry P 1Document21 pagesBasic Silicone Chemistry P 1Rahul Yadav100% (1)

- Lime Metering Tomal GB PDFDocument6 pagesLime Metering Tomal GB PDFJose Antonio Caballero BeldaNo ratings yet

- Fsls 11.10 Adminguide EngDocument67 pagesFsls 11.10 Adminguide Engsurender78No ratings yet

- Inductance Measurements For Synchronous MachinesDocument2 pagesInductance Measurements For Synchronous MachinesYusuf YaşaNo ratings yet

- Coverage of Quiz 1Document24 pagesCoverage of Quiz 1Ben RileyNo ratings yet

- Hitachi Sumitomo Scx1500 2 Hydraulic Crawler Crane SpecificationsDocument2 pagesHitachi Sumitomo Scx1500 2 Hydraulic Crawler Crane Specificationsmargeret100% (50)

- MWD Log Quality & StandardsDocument168 pagesMWD Log Quality & StandardsHamed Sadeghi100% (1)

- 2011 Equipment Packing InstructionsDocument3 pages2011 Equipment Packing InstructionsNidhi MurthyNo ratings yet

- 21 - Al Ghubaiba Bus Station To Al Quoz, Clinical Pathology Dubai Bus Service TimetableDocument26 pages21 - Al Ghubaiba Bus Station To Al Quoz, Clinical Pathology Dubai Bus Service TimetableDubai Q&A100% (3)

- Dunlop Cement Based Adhesives - SDS10024Document4 pagesDunlop Cement Based Adhesives - SDS10024Dominic LeeNo ratings yet

- Slides - OOP With SmalltalkDocument51 pagesSlides - OOP With Smalltalkapi-3728136No ratings yet

- Room Air Conditioner Owner's Manual GuideDocument19 pagesRoom Air Conditioner Owner's Manual GuideMunteanu LucianNo ratings yet

- Cable Memebres ProfiledirectoryDocument5 pagesCable Memebres ProfiledirectoryMigration Solution100% (1)

- WM 5.4 CLI Reference Guide PDFDocument1,239 pagesWM 5.4 CLI Reference Guide PDFHermes GuerreroNo ratings yet

- 747ERDocument8 pages747ERelmobareck elghadhiNo ratings yet

- Genetic AlgorithmDocument46 pagesGenetic AlgorithmJerryNo ratings yet

- Categoria ApiDocument61 pagesCategoria ApiHector MARTINEZ DEL ANGELNo ratings yet