Professional Documents

Culture Documents

Introduction To CNC Machining - 1feb16

Uploaded by

Bita MohajerniaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction To CNC Machining - 1feb16

Uploaded by

Bita MohajerniaCopyright:

Available Formats

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

CNC Machining

History of CNC machines

Introduction to CNC

G codes

Basic Programming

Startup block when programming

Absolute / Incremental

Rapid, Linear Interpolation, Circular Interpolation

Introduction to Spindle and Feed functions

Offsets – work offsets and tool offsets

Other commands

Dwell

Fixed cycles

Coordinate Rotation

Miscellaneous Functions

Program Structure

Dr. R. Jill Urbanic 1

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Introduction to CNC Machining

A little history of NC/ CNC machining

1725 – systematized punched cards were used to control the cloth pattern

1808 – punched holes in sheet metal cards to automatically control patterns made

by weaving machines

1863 – automatic player piano controlled by the Programmed sequence

1947 – First 3-axis curvature data employed to control M/C Tool.

1951 – First numerical control (NC) machine tool

1960s – Direct numerical control (DNC) was introduced

1970s – CNC machine introduced

1980s – Distributive numerical control

Numerical Control can defined as on operation of machine tools by the means of

specifically coded instructions to the machine control system. Instructions are

combinations of letters of the alphabet, digits and selected symbols. The explicit

instructions describe the type and order of the individual steps required to perform a

given task. We use an instruction language called G-code to deliver these instructions to

the machine.

NC CNC

NC Numerical Control uses fixed logical functions that are hardwired in the

controller. The system can interpret a part program, but does not allow any changes to the

program. All changes must be done away from the controller The NC system requires the

use of punched tapes for input of the program information.

CNC Computer Numerical Control uses an internal microprocessor; hence, the

program can be changed on the controller itself.

Simulations

Conversational controllers

G code:

- alphanumeric code delivering instructions to the machine

- uses the standard Cartesian coordinate system

- interpreted language evaluated one line segment at a time on the machine

controller

Dr. R. Jill Urbanic 2

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Describing A Machine Tool

Examination of various machine tools reveals that they all consist of a machine base

(usually a large casting) with an assortment of machine components (axes, tables, turrets,

spindles, etc) fastened to it in various configurations.

A machine tool consists of a multiple kinematic links. Each link ends with a tool or a

fixture. There are various machine topologies or machine structures. It is not sufficient to

state that the machine has X, Y, and Z axes. How these axes are fastened together has a

tremendous impact on the machine description. Topology basically distinguishes various

machine configurations from one another. (Gantry vs. column, table/table vs. head/table,

etc.)

Each axis has a stroke length, the table has dimensions, there are a certain number of

tools that may be stored on the machine, there is an RPM range for the spindle along with

the power output rating, a feedrate range, a rapid traverse rate, a maximum tool length,

diameter and weight. The specifications are machine dependent. The main specifications

have been listed; however, there are more.

Dr. R. Jill Urbanic 3

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Vertical Milling Machine Representation and Actual Machine Classic Machine

3 Axis Gantry Mill and Conceptual Representation

5 Axis Horizontal Milling Machine

Dr. R. Jill Urbanic 4

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Machine Geometry

Right hand coordinate system

Axes, planes, point of origin X0, Y0, Z0

o Z axis axis along which a simple hole can be machined with a single

point tool

o X axis longitudinal direction

o Y axis cross direction (vertical) column direction (horizontal)

o Z axis spindle direction

o machine origin part origin relationship work offset

Additional Axes:

o secondary axes (mounted on the spindle) U, V, W parallel to X, Y, Z

respectively

o rotary axes (fixture) A, B, C rotated about the X, Y, Z axes

respectively)

o Positive direction for the rotary axes follow the right hand rule

Standard Orientation of Planes and CNC machine tool axes

Dr. R. Jill Urbanic 5

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Relationship of Primary and Secondary Axes

From a programming perspective programming always takes place from the viewpoint

of the spindle, NOT the operator. The positive and negative motion of the machine axes

may be OPPOSITE to the positive and negative programming directions.

Remember the REFERENCE FRAME IS ALWAYS THE SPINDLE

Dr. R. Jill Urbanic 6

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Introduction to Process Planning

Processing Planning determines the appropriate procedures for transforming raw

materials into a final product given an engineering design

fabrication, heat treat, assembly, inspection, testing, finishing, packaging, …

drilling, milling, turning, grinding

Process selection depends on the following items:

- Material requirements

- Volumes

- Tolerances

- Part complexity Study the part print

- Setup costs

- Expertise

Generic Machining Operations

- Study the part print

- Select the most suitable machining method

o tool selection

o order of operations

o tool paths

- Decide on the method of holding the workpiece

- Select the cutting tools

- Establish the feeds and speeds

- Machine the part

Program Planning suggested order of operations [There will be iterations in this process]

Study of initial information (drawing, volumes, machine capabilities, and any

other relevant information)

Material stock evaluation (bar stock, forging, casting, etc.)

Machine tool specifications (work envelope, speeds, feeds, etc.)

Control system features

Sequence of machining operations

Tooling selection and arrangement of the cutting tools

Setup of the part

Technological data (speeds, feedrates)

Determination of the tool path

Working sketches and mathematical calculations (what if studies)

Program writing, verification

Transfer the program to the CNC machine(s)

Program testing and debugging

Program documentation

Dr. R. Jill Urbanic 7

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Basic Programming

A program for a numerically controlled machine tool is comprised of a series of program

blocks, each block being terminated by an “end of block” code. [The EOB button on the

keypad generates a semicolon (;) as the end of block code.] A block is comprised of one

or more words. A word is comprised of an address followed by numbers. Those

numbers that require decimal point programming are signed values. A positive value is

the default and thus the plus sign (+) need not be programmed. The address is a letter

which indicates the meaning of the numerical value following the address. Some

addresses may differ in meaning depending on the preparatory functions specified in the

program.

Character Word Block Program

Character: smallest unit of the CNC program, and can be a digit, letter or symbol

*Use capital letters*

Word: combination of alphanumeric characters, creating a single instruction to the

control system

Block: consists of one or more words Each block must be separated form all others

EOB or “end of block” code

The word address format notation for the metric system

X ±5.3

Number of digits after the decimal point

Decimal point

Number of digits before the decimal point

Possible value

Address

If there is no decimal point for a notation, the decimal point is not used. The following

address codes require decimal programming:

X, Y, Z, I, J, K, R, Q, F

If the decimal point is omitted, the value programmed represents the number of minimum

dimension units and in the metric mode would result in the value being multiplied by

0.001 mm. For example, X5 would result in a value of 0.005 mm in the x direction,

whereas X5. yields a value of 5.0 mm.

Dr. R. Jill Urbanic 8

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

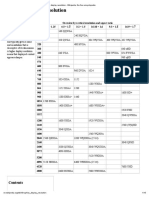

The functions, the address codes along with their numeric value ranges, and the meanings

of the functions are listed in the following table:

Note [ ] METRIC values

Description Codes Values Word Format Comment

Notation

Program O 0001 - 9999 O4

Number

Sequence N 001-99999 N5 Block number

Number

Preparatory G 00-99 G2 Motion mode

Function

Dimension A, B, C A+5.3 B+5.3 C+5.3 Rotary or indexing axes

Word X, Y, Z X4.4 Y+4.4 Z+4.4 Translational axes

[X5.3 Y+5.3 Z+5.3]

R R+4.4 [R+5.3] Arc radius, corner R

I, J, K I+4.4 [I+5.3] Coordinate value of arc

centre

U, V, W U+4.4 [U+5.3] Incremental values

Feed F Machine F5.3 Feed rate – the notation

Function dependent may vary depending on

0.0001 – the machine

3600.0000

mm/min

Spindle S Machine S5 Spindle speed in

Function dependent rev/min (integer value)

35-3500

rpm

Tool T 01-99 T4 Tool number, tool

Function offset number

Misc. M 00 - 99 M2 ON/OFF Special

Function controls that are

machine dependent

Offset H, D 00 - 99 D2, H3 Tool offsets

Number

Dwell P, X 0-99999.99 P5.3, X5.3 Dwell time

sec

Subprogram P 0001-9999 P4

Number

Repetitive L 0-9999 L4 Repetitive count in

Count canned cycles or

subprogram

Parameter P, Q, R See notes Parameters in canned

cycles

Symbols in Programming

Dr. R. Jill Urbanic 9

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Symbol Description Comment

. Decimal point

+ Plus sign Positive value or addition

- Minus sign Negative value or substraction

* Multiplication sign Multiplication

/ Slash Block skip function or

Division

() Parenthesis Program comments and messages

% Percent sign Stop code (end of program file)

: Colon Program number designation

, Comma Used only within comments

[] Brackets Arguments for Fanuc controls

; Semi-colon Non-programmable end of block symbol

(screen display only)

# Sharp sign Variable definition or call in Fanuc macros

= Equal sign Equality in Fanuc macros

Modality: Once a Modal command is turned on and executed, it remains active until it is

overridden by another modal command. If a command is not a modal command, it must

be repeated on every line of the CNC program that it is used.

Conflicting commands: The purpose of the preparatory codes is to select a mode of

operation. Consider G01 G00 X.3.5 Y6.125 F20.0

G00 is the rapid mode and is a code for a particular type of tool motion.

G01 is the linear interpolation command, and has an associated feed rate.

Both commands cannot be active at the same time. If a conflict situation occurs, then the

latter code will be active. In the above example, a rapid motion will occur. The feed rate

is ignored.

Word order in a block: G codes are normally programmed at the beginning of a block,

after the block number, before the other significant data. This is good programming

practice, and will avoid surprises, such as if you were switching between rapid and

interpolation modes, absolute and incremental modes, etc.

Group Codes (Grouping of commands): Fanuc has grouped “like commands” into

arbitrarily numbered group codes. If two or more commands are used in the same

program block, they are in conflict with each other. The group codes vary from 00 to 25.

G codes of group 00 are not modal.

A number of G codes can be specified in a single block if they are of different

groups from one another.

Dr. R. Jill Urbanic 10

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Startup Block or Safe Block

A startup block is a special sequence block. It contains one or more modal words that

preset the control system into a desired initial or default state. This block is placed at the

beginning of every program or at the beginning of every new tool this is a safe

programming approach, and should be followed consistently. If a program is transported

from one machine to another, the programmer does not have to rely on the default

settings of the machine. The startup block proceeds any motion commands, including tool

changes. The startup block will be different for milling and turning machines due to their

unique requirements.

The most common entries are:

G00 select the rapid mode

G17 select the XY plane

G20 / G21 select English or Metric mode. DO NOT mix modes within any program

G40 cancel cutter compensation

G54 select a default work coordinate system

G64 continuous cutting mode (normal cutting mode)

G80 cancels any active canned cycles

G90 (G91) select absolute or incremental programming modes

G98 retract to an initial level default

English / Metric

All controls are based on the metric system. Any switching does not ensure a full

conversion will take place. Some tool offset screens may still be in the metric mode.

Units must be consistent for dimensional words (X, Y, Z, I, J, K, …) Feedrate function

(F), tool offset values (H, D), and for constant surface speed mode (CSS – lathes).

G20: select English mode.

G21: select Metric mode.

Absolute / Incremental

There are two ways to command axis travel; the absolute command mode and the

incremental command mode. In the absolute command mode, the absolute coordinate

values (X,Y,Z) of the end points are programmed. The (X,Y,Z) values are measured with

respect to the program origin. In the incremental mode, the actual distance the tool is to

be moved is from one point to another is programmed. If the required motion for any axis

is zero, that axis in general need not be programmed. In the absolute mode if any of the

axis are not programmed, the existing absolute values in the buffers remain the same and

no motion is produced along those axes; in the incremental mode, if any of the axes are

not programmed, the incremental distance to be moved is assumed to be zero and thus no

incremental motion is produced along those axes.

G90: absolute

G91: incremental

Dr. R. Jill Urbanic 11

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

G90 X0 Y0 Z0 returns to the home position

G91 X0 Y0 Z0 no movement

Active Plane

The G codes to set the active planes are summarized in the following table. For three

dimensional helical interpolation, the arc vectors are I, J and K.

Active Linear Arc Vectors

G code Plane Motion

G17 XY Plane Z I, J

G18 ZX Plane Y I, K

G19 YZ Plane X J, K

Interpolation

Linear Interpolation

If we have two points, A and B, which lie in the XY plane and if we wish to move the

cutter from point A to point B, the path that is generated between A and B will depend on

the feedrates that are applied to the X and Y axes. For any machine tool there will be a

maximum federate that can be applied to each of its axes. In some machine tools the

maximum federate allowed will be the same for all axes; however, this is not always the

case.

If the reason for the move is merely to reposition the tool and cutting takes places during

the move, the actual path taken between A and B may not be important as long as the tool

is guaranteed to be at point B at the end of the move. This type of motion is referred to as

“point to point” because only the end point criterion must be satisfied and the path that

the tool takes to get there. Under these conditions, it would be desirable to perform the

positioning as quickly as possible and therefore point-to-point motion is usually

performed in a rapid feedrate mode.

On the other hand, if the pupose of moving the tool from A to B is to perform a straight

line cut along the line AB, then the path that the tool takes in moving from A to B is

critical and must be linearly interpolated. Linear interpolation is accomplished by

setting the relative feedrates of each axis such as to ensure that a straight line motion

between A and B is generated at the required feedrate.

Dr. R. Jill Urbanic 12

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Y

Point to Point C B 50,30

Path

Interpolated

A Path

10,10

Consider the above example illustrated above. The tool is to be moved 40 units in X and

20 units in Y. To rapid position the tool, the maximum feedrate, which is assumed to be

the same for both axes, is applied simultaneously to both axes. The resulting motion is

ACB since the required distances are not the same. The Y axis motion is completed

before the X axis motion.

If the tool is to perform a straight line motion, the feedrates must be calculated as

follows:

x y

Fx F . , F y F . , L x 2 y 2

L L

x and y are the distances required along the x and y axes

Here in the above example, Fx is twice Fy.

The above discussion on interpolation has been limited to a two dimensional example.

However, the concepts are identical when working with all three dimensions.

It is the programmer’s responsibility to assure that any tool motion

occurs without interfering with any obstacles along its way (e.g. clamps,

vices, fixtures, the part itself!)

Circular Interpolation

The circular interpolation mode permits the tool to be moved in a circular arc, if, and only

if, the arc line in a plane which is parallel to one of the three Cartesian planes (XY, ZX,

ZY). To specify circular interpolation, four pieces of data must be provided:

(1) plane selection (G17, G18, G19),

(2) direction of rotation CW or CCW (G02, G03 respectively)

(3) the end point position on the arc, and

(4) the distance from the starting point on the arc to the centre of the arc or the arc

radius

Format for an arc parallel to XY plane:

G17 G02 X____ Y____ Z____ I____ J____ K____ F____;

G03 R____

Dr. R. Jill Urbanic 13

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Circular Interpolation: Case 1 - XY plane and incremental center (X, Y, I, and J)

This section covers the use of G2 to make arcs in the X-Y plane on controllers that use

incremental center coordinates.

Center location method: Incremental using I and J

Controller modes: G90 (Absolute coordinates) G17 (XY plane circles)

Example:

G1 X1.375 Y0.25 (GO TO START OF ARC)

G2 X1.75 Y-0.125 I0 J-0.375 (CLOCKWISE CIRCULAR MOVE)

The G1 positions the tool at the start of the arc.

The G2 drives the arc to the coordinate position specified by X and Y.

The center point is specified by I and J coordinates.

I is measured along the X axis and J along the Y axis.

These are incremental values from the start point - in other words, they are the

distance from the start point to the center along X and Y.

I is zero because the start and center points have the same X value.

J is negative because the center point is in a negative direction on theY axis.

Note that Z values have been ignored. We are assuming that Z was set prior to the G1

linear move and we are creating a 2D arc so the Z value, whatever it is, remains the same

throughout.

Case 2 - XY plane and a radius R (X, Y, and R)

Dr. R. Jill Urbanic 14

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

This section covers the use of G2 to make arcs in the X-Y plane on controllers that let

you specify the arc radius with an R-word.

Center location method: R word

Controller modes: G90 (Absolute coordinates) G17 (XY plane circles)

Example:

G1 X1.375 Y0.25 (GO TO START OF ARC)

G2 X1.75 Y-0.125 R0.375 (CLOCKWISE CIRCULAR MOVE)

The G1 positions the tool at the start of the arc.

The G2 drives the arc to the coordinate position specified by X and Y.

The center point is calculated based on the radius which is specified in the R0.375.

It looks almost too easy - what's the catch?

There are a several things to consider.

If you need to program a 360° circle, you probably can't use an R-word - you'll need to

use I and J.

You are defining an arc using two points and a radius so there are two possible arcs that

will fit your values - you need to tell the control which one you mean. This is done by

using a positive R value if the arc is less than 180 degrees and a negative R value is

greater than 180 degrees.

Center location method: R word

Controller modes: G90 (Absolute coordinates) G17 (XY plane circles)

The figure shows

the path generated

with

G2 X1.75 Y-0.125 R0.375 (UNDER 180 DEG) and

G2 X1.75 Y-0.125 R-0.375 (OVER 180 DEG)

Dr. R. Jill Urbanic 15

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

If the arc is exactly 180 degrees, you have a choice to make. You can try a positive value

and see what happens (best to "cut air" for this and a bit of prayer won't hurt) or you can,

and should, break the arc into two segments and program it in two moves.

Special cases - Quadrants and complete circles

Some controllers will not handle arcs that pass through an "axis crossover point" (a

quadrant boundary - 0, 90, 180, 270 degrees.) If this is the case, you need to break the arc

at these points. Many people recommend doing this for all arcs, regardless of controller

capabilities, and many postprocessors offer the option to do it automatically. Also, see if

your controller uses a G-code for this, usually a G75 for "multi-quadrant" mode which is

cancelled by a G74. A bit of needless info - the "axis crossover" restriction usually relates

to motors having to change direction at this point.

Example:

G1 X1.1053 Y0.1355

G2 X1.375 Y0.25 I0.2697 J-0.2605

G2 X1.75 Y-0.125 I0 J-0.375

G2 X1.6887 Y-0.3305 I-0.375 J0

The G1 positions the tool at the start of the arc.

The G2's drive the arc to the quadrant boundaries and the end positions specified

by X and Y.

The center point is specified by I and J coordinates. I is measured along the X axis

and J along the Y axis.

These are incremental values from the start point of each arc segment.

Don't forget that the controller sees this as three separate arcs, not just one.

Most controllers would not require that the "G2" be repeated in each block above.

Regarding complete circles - some controllers handle them and some don't. A controller

that can process multi-quadrant arcs may accept an arc end point that is identical to the

current tool position and machine a complete circle. Others may do nothing, and others

may throw an error condition. If you have any doubt about the capabilities, break the

circle into pieces and cut each arc separately.

Dr. R. Jill Urbanic 16

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Planes other than XY

On many machines, G2 and G3 commands can be used to drive arcs in the ZX and YZ

planes. G18 is usually used to switch to the ZX plane and G19 selects the YZ plane.

Don't forget, though, that to make a circular feature on a part in these planes using a 3

axis machine the tool path itself won't be circular unless an angled head is used.

A G2 causes clockwise motion as viewed from the positive direction of the perpendicular

axis and the figure reflects this.

Y X Z

G03 G03 G03

G02 G02 G02

X Z Y

To determine the direction of rotation, the plane is viewed from the positive direction of

the Z axis (X / Y) onto the XY plane (ZX or YZ) in the right hand Cartesian coordinate

system. Note the axis labels and the G02 / G03 directions. Do not get this confused or

you will have unexpected results.

Lathes

Use of G2 and G3 on a lathe is similar to their use on a machining center, although tool

shape is more of a consideration. A 2 axis lathe operates in the ZX plane, and uses the I

and K words for center location.

Dr. R. Jill Urbanic 17

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

The figure shows a simple case using an imaginary tool tip as a reference point. The nose

radius is 0.0625. The program fragment below follows the part profile, accounting for

insert geometry.

G1 Z1.6875

G2 X0.9375 Z1.6875 I1.6875 K0

G1 X1.5 (GO PAST)

Note that the G2 direction is "backwards" based on normal G18 conventions. This just

illustrates how important it is to read the programming manual applicable to the machine

being programmed. If we programmed this move using the center point of the nose

radius, the instructions would be more like previous examples although the setup would

be different.

Cutter Compensation

Cutter (radius) compensation can generally be used for G2 and G3 moves just as for

linear moves. Most considerations are the same - you need to be careful where you turn it

on and off and so on. Also, be sure that you don't inadvertently enter a tool radius that is

larger than, or even equal to, the smallest arc radius used in an inside corner.

3D Circular Interpolation

Some machines provide helical interpolation via G2 and G3 commands. Programming it

is pretty straightforward - just include a Z value in the G2/G3 that differs from the

starting position. The motion will end with the tool in the specified Z position. The Z

increments will be determined by the number of actual XY moves to complete the arc. In

other words, when the arc is 40 percent done, so is the Z motion. This can be used for

ramping into a pocket or other approach moves.

Also, some controllers allow a more advanced form of 3D arcs using a sphere to control

depth. An explanation is outside the scope of this course.

Dr. R. Jill Urbanic 18

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Spindle Function

The program command relative to spindle speed is controlled in the CNC system by the

address S. The actual spindle speed range of values must be determined by the machine

specifications.

There are two main methods of programming the spindle speed. They are:

Direct spindle speed r/min [typical for milling machines]

Peripheral spindle speed ft/min or m/min [typical for turning machines]

G96 Constant surface speed control

G97 Constant surface speed control cancel

Most machine spindles can be rotated both clockwise and counter clockwise. There are

two miscellaneous functions that control the direction of the spindle.

M03: CW

M04: CCW

Feedrate Function

The address for a feedrate word is F, followed by the number of digits. There are two

types of feedrates:

Feedrate per minute in/min or mm/min

Feedrate per revolution in/rev or mm/rev

G94 Per minute feed

G95 Per revolution feed

To select the best spindle speed and feedrate, some general knowledge of machining is

required. There are several parameters that must be considered, such as:

Cutting tool material

Workpiece material

Tool diameter [machining centre] or tool radius [turning]

Tool geometry (number of flutes or cutting edges)

Tool overhang

Amount of material to be removed (depth and width of cut)

Surface finish requirements for the part

Dr. R. Jill Urbanic 19

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Acceleration and Deceleration

During a contouring operation, the cutting direction is constantly being changed. The

control may have to stop the X axis motion, then start the Y axis motion. To stop, the X

axis must decelerate, and the Y axis must accelerate. A possible cutting error may occur

at sharp corners because of undesirable overshoot, especially when using high feedrates.

Exaggerated

overshoot

Exact Stop

G09/G61 used

If the error needs correction, Fanuc controls provides two Gcodes to alleviate this

problem (note: this increases cycle time):

G09 Exact stop check (one block only)

G61 Exact stop check mode (modal)

For completeness, there are 3 other feedrate modes, G62 (automatic corner override),

G64 (normal) and G63 (tapping mode ignores any feedrate override settings on the

control panel). G62 and G64 are illustrated below.

G62 G64

Check out these links:

Simulations: http://www.cncsimulator.com/

G codes / CNC training:

Dr. R. Jill Urbanic 20

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Cutter Compensation

In the homework assignment, the tool coordinates had to be hand calculated. These points

would then need to be incorporated into the program to generate the correct tool path.

You spent some time to create the coordinate values. For complex geometry or a non-

standard cutter, errors could be easily made. The results will be potentially a scrapped

part, tool, fixture, and machine damage. If a different tool is used, the program needs to

be completely rewritten – obviously there has to be a better way. There is no guarantee

that the person developing the program will know the actual cutter diameter at the time of

programming. We will now examine cutter compensation – or 2D cutter offset

compensation IN THE COMPENSATION PLANE (remember G17, G18, G19).

G40 Cutter compensation Cancel

G41 Cutter compensation Left

G42 Cutter compensation Right

G41 G42

Left Right

G42 G41 M03

M03

Right Left

G40 G40 Climb milling – G41 Conventional milling – G42

None None

Figure 2.1: G40, G41, G42 Compensation

The concept of compensation is simple, but there are three steps that must be taken:

Select the tool plane

Select the compensation mode for the tool path under consideration

o Must know the direction of the cutter motion and which side of the feature

is being cut (i.e. clockwise / counter clockwise direction, internal or

external tool path)

CANCEL the compensation immediately after it is utilized to prevent catastrophic

problems

Dr. R. Jill Urbanic 21

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Figure 2.2: G40, G41, G42 Compensation and Arc Mode

Class Exercise

Essentially, the controller must know three things:

Tool diameter / radius

Coordinates of the part

Which side the part that the tool path is to be generated

When you are using cutter compensation, the outline of the part is programmed.

The controller must determine the 2D offset vector based on the effective radius of the

cutter in order to generate the tool coordinates for the required cutter path. The vector is

calculated base on the offset amount that has been set in the tool offset memory and is

specified in the program by the D code. The compensation methods are controller

specific. Some generic issues (based on Fanuc controllers) are presented here.

The D code is a two digit integer code (address notation from lecture 1). This code

represents the location in the tool offset file memory where the actual tool offset value is

stored. It is good programming practice to relate the D code to the designated tool

number for which the code is used.

The appropriate side of the part to be cut is determined by viewing the geometry in the

direction the cutter is to travel – you compensate the cutter either to the left or to the

right.

G40, G41 and G42 are used simultaneously with G00, G01, G02 and G03 to define a

mode that determines the amount and direction of the offset vectors and the direction of

tool motion. A G41 or G42 command causes the controller to enter the offset mode with

the offset specified by the D code, and a G40 command cause the controller to cancel the

offset mode. Thus for sections of programming that employ cutter compensation there are

Dr. R. Jill Urbanic 22

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

three modes or sequences of blocks that must be programmed: they are the start up block,

subsequent machining blocks, and the cancel block.

ALWAYS CANCEL THE CUTTER COMPENSATION WHEN FINISHED.

Following are some illustrations (using G42) how the tool paths are generated when

employing cutter compensation. The controller may generate “intermediate” tool path

motions internally. You must be aware of the potential tool path variations to ensure that

the tool motion programmed will yield the desired results. The tool paths for G41 AND

G40 are similar in nature.

180

r

3

2

1 G42

Figure 2.3: Linear Moves, 180 for G42 Compensation

Solid Line Programmed Moves, Dashed Line Tool Motion

Figure 2.4: Linear Moves, 90 < 180 for G42 Compensation

Solid Line Programmed Moves, Dashed Line Tool Motion

Dr. R. Jill Urbanic 23

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Figure 2.5: Linear Moves, < 90 for G42 Compensation

Solid Line Programmed Moves, Dashed Line Tool Motion

Always select the start position of the cutter away from the contour,

in a clear area.

Always apply the cutter radius offset together with a tool motion.

Notes: In order for the controller to determine the offset vectors, it may employ a look

ahead operation reading two blocks ahead of the current block being executed (which is

how you can get screwed up if you are mixing metric and inch systems!). If this is the

case (older controllers do not have two block look ahead) as a result, the controller

imposes the restriction that when cutter compensation is in effect two consecutive

program blocks in which no motion is programmed (in the compensated plane) is NOT

ALLOWED. If you do not follow this practice, unexpected results may occur.

…

Consider the tool motion for the following block: N21 G01 G41 X0 D01 F17.0

N22 M08 (coolant on)

N6 G41 X0 D01 F15.0 N23 G04 P1000 (dwell 1 sec.)

N24 Y 2.5

What happens? Example of 2 no motion codes will

create problems

It depends.

If the controller cannot compute a

On what? compensation mode, compensation

will not be turned on.

The NEXT move

If the next move is a Y +ve move, the cutter moves to the left of the X axis.

If the next move is a Y –ve move, the cutter moves to the right of the X axis.

Dr. R. Jill Urbanic 24

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

The controller must look ahead to properly apply the compensation mode.

G41 G41

D01 D01

X0 X0

Figure 2.6: Compensation and Look Ahead

Arc commands (G02 & G03) are not allowed in the cutter compensation start up

and cancel blocks.

The start up and cancel blocks are often used to position the cutter and in such a case no

actual machining takes place in these blocks (i.e. move the cutter to a safety zone).

Make certain that the plane selection G code is active and that the required D code is

programmed.

Preventing Scrap:

(1) Ensure the cutter radius is smaller than smallest inside radius of the part

contour.

(2) Ideal conditions are rare. You can use tool wear offsets to change the effective

radius of the cutting tool. The goal is to create some temporary settings that

will leave residual stock, and allow you to make adjustments before

performing the final cut.

External cut make the part intentionally larger positive offset value to

increase radius

Internal cut make the part intentionally smaller negative offset value to

decrease radius

Measure the part to determine the effective diameter size, adjust the offsets

again, and then recut to the right size.

Dr. R. Jill Urbanic 25

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Reference Points

Machine Reference Point – machine zero or the home position for each axis

Program Reference Point – program zero point

Part Reference Point – part datum

Tool Reference Point – tool tip

All of these reference points interact. The Machine Reference Point is the origin of the

machine coordinate system. This point will vary between machine manufacturers, and the

various machine configurations. The part is located in a work fixture. The location of this

device is critical you must check for angular alignment in all 3 planes. [Note: the

spindle must be square as well]. The program zero should take into consideration

practical restrictions:

o part datum points and feature relationships

o convenience of setup and operation

o safety of the working conditions

There may be multiple datum points on a part – i.e. casting datum points, machining

datum points, feature datum points, and so forth. A datum is selected on the basis of its

geometric relationship to other features and the functional requirements of the design. A

part datum may NOT be the best point for a program zero. The part drawing must be

carefully analysed to determine the best program zero.

Figure 2.7: Datum Points, Planes

The relationship between the machine zero point and the workpiece zero is established

using a work offset. The relationship between tool, part and the machine is established

using a tool offset.

Dr. R. Jill Urbanic 26

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Figure 2. 8: Multiple Program / Part Zero Reference Points

Work Offsets

The coordinate system used for machining is called the work coordinate system. Up to 6

different work coordinate systems can be specified in a Fanuc controller. With the newer

Fanuc controllers, even more coordinate systems can be specified. A work coordinate

system is established by measuring the program zero datum points relative to the machine

zero point, and storing the values in the appropriate workpiece offset table. The G codes

representing the work offsets are modal.

G54 Workpiece Coordinate System 1

G55 Workpiece Coordinate System 2 Establish the part datum

G56 Workpiece Coordinate System 3 points using an edge

G57 Workpiece Coordinate System 4 finder or similar device.

G58 Workpiece Coordinate System 5

G59 Workpiece Coordinate System 6

Dr. R. Jill Urbanic 27

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

G54 G55 G56 G57

Offset Offset

P02 P03

Offset Offset

P01 P04

Machine Zero

Figure 2.9: Work Offsets

The Z offset interacts with the tool length offset, which is discussed in the next section. A

Z offset is used when there are several parts with variable height, within the same setup.

If there is only one part to be considered, set the Z offset to Z=0, and utilize the tool

length offset.

z

Use this surface to

establish tool offsets Z25

Z0 x

-Z10

G56

G54 G55

Table

G54 X-100. Y30.0 Z0

G55 X-10. Y30.0 –Z10

G56 X100. Y30.0 Z25

Figure 2.10: Work Offsets and Z

There are 6 work offset tables in the Fanuc controller. If this is not sufficient, the work

offset vector can be programmed directly in the main program using the following

notation:

G10 Program parameter input

G10 L2P## X__ Y__ Z__

P varies from 1 to 6, which corresponds to the individual G5x offsets

X, Y, Z are the offset values for the respective axes

Tool Offsets

Realistically, all tools are of different lengths and we would like to simplify our

programming by ignoring this fact. Most CNC machine tools provide a mechanism by

Dr. R. Jill Urbanic 28

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

which the tools can be measured and their relative lengths or OFFSETS stored so that

when a particular tool is called up, the controller will automatically compensate for these

differences in length. There are length offsets (H code address notation – lecture 1) and

radius offsets (D code). Typically there are two parameters associated with a tool offset

one for geometry, and one for wear. The amount of tool length offset that is to be

compensated for each tool is stored in the tool length offset table. For example, if tool 1

were being used, H01 would be the required H code. Correlate the tool numbers, H

and D codes.

Various points can be selected on a tool you must understand the repercussions of the

reference point selection. For example, if you have the offset the extreme tip of the drill,

the depth of the hole must take the drill tip geometry (depth) into consideration. Note:

CAM software will take care of these issues automatically.

Flat End Drill Ball Nosed

mill End mill

Care must be

taken with the

tool position

or final part

program

geometry

Figure 2.11: Tool Reference Points

Tool Length Compensation

The value stored in the tool length compensation offset table added to (G43) or subtracted

from (G44) the absolute value of the programmed Z coordinate (work offset value in Z).

G43 Tool Length Compensation (Plus)

G44 Tool Length Compensation (Minus) Not commonly used

G49 Tool Length Compensation Cancel

N## G43 Z__ H__

The logic is simple: the stored tool length value is added (G43) or subtracted (G44) from

the absolute value of the programmed Z coordinate (work offset).

There are two methods of establishing the tool offsets:

(1) On Machine Tool Setting: The tool is advanced to the part. Positioning a piece

of paper on the part under which the tool will touch, you slowly advance the tool

Dr. R. Jill Urbanic 29

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

until the paper cannot move under the tool. Then you push the offset button on the

controller to establish the offset length. The offset value is the travel distance

between the machine zero PLUS the tip of the tool and the touch off surface

(program zero). This value will be a negative number. You use a G43 to add this

value to the absolute Z coordinate, which is Z0 in this case. (This method induces

non – productive time on the machine).

Gauge

Line

H01 H02

part

Figure 2.12: On-Machine Tool Offsets

(2) Off Machine Tool Setting: Some users prefer to preset the tools away from the

machine, which eliminates non-productive setup time. The actual value for the

tool length is stored in the offset table, and is a positive number. Z does not equal

0 for the work offset value. Presetting equipment and trained personnel is

expensive.

Gauge

Line

H01

H02

G54

part

Figure 2.13: Off-Machine Tool Offsets

At the end of the program, cancel the tool length offset using a G49.

Lathe Tool Nose Radius Offset

Milling cutters are always round in the top view; hence, the work offset strategy is

simple. All of the above discussion applies to lathe programming, but because the turning

Dr. R. Jill Urbanic 30

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

tools have a different design, there are some unique programming considerations for a

lathe. There are centreline tools such as drills, reamers and taps, but boring, facing, and

other turning operations have offset tool positions. As well, inserts are commonly used,

which have different configurations, and the cutting edge has a small corner radius.

Therefore, a complementary method for tool setting is used for a lathe. Both the work and

tool offsets are tied in together.

Centreline tools are always measured from the centre of the tool to the centreline of the

spindle along the X axis, and from the tool tip to the program zero along the Z axis.

Turret

@ home

T01

(X)

(Z)

Figure 2.14: Lathe Centreline Tool / Work Offsets

Once the X and Z values are established, the tool / work offsets are set.

For turning / boring tools, the situation is different. The tool nose reference point is a

virtual or imaginary point.

T01

(X)

(Z)

Figure 2.15: Lathe turning Tool / Work Offsets

There are many insert styles used in turning / boring, as shown in Figure 2.17. The

X+Z+ orientation is used for OD turning, the X-Z+ orientation is used for ID boring. It is

Dr. R. Jill Urbanic 31

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

difficult to determine the actual radius periphery. When establishing the work offset, you

touch off on the furthest points on the insert in X and Z, and create an imaginary

intersection point in space.

to Z0 to Z0

X+ Z+

to X0 X- Z+ to X0

Reference

Pt

How do we find the centre of the

insert radius? (green)

We cannot easily – but we can

find the reference point (red).

Figure 2.16: Lathe Imaginary Reference Points

The theoretical sharp point created from the work offset is established. However, this is

not correct. Compensation is applied to create an offset to generate the correct tool path.

An offset is used which is based on the nose radius, and the X Z distances from the centre

of the tool to the reference point.

Figure 2.17: Theoretical Sharp Corner Programming

Dr. R. Jill Urbanic 32

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Dwell

The time for a dwell, or a pause in the machining program is in milliseconds. The P or X

code is used with a G04 command. The structure is G04 P1000 for a 1 second pause.

G04 Dwell

This command is not modal. The dwell function is used to break up chips when drilling,

grooving, parting off, and so forth. It may also be used when tapping, between feeding in

and out of the hole. It is also used for non-cutting applications after certain miscellaneous

functions such as moving the tailstock, a bar feeder, etc.

NEVER use a dwell function to perform manual operations on a machine.

Canned Cycles

Canned cycles or fixed cycles are pre-programmed cycles within the controller that

reduces repetitive programming for common features. The G codes are listed below. The

general format for these fixed cycles is a series of parameter values specified by a unique

address. The general format is

N## G## G@@ X.. Y.. R.. Z.. P.. Q.. I.. J.. F.. L.. K..

N – line number

G## - G98 or G99

G98 Set Initial Plane default

G99 Return to Retract (Rapid) Plane

G@@ - canned cycle number (from next table)

G73 High-Speed Peck Drilling Cycle

G74 Counter tapping cycle

G75 User canned cycle

G76 Fine boring cycle

G77 User canned cycle

G78 User canned cycle

G79 User canned cycle

G80 Cancel Canned Cycles

G81 Drilling Cycle

G82 Counter Boring Cycle

G83 Deep Hole Drilling Cycle

G84 Tapping cycle

G85 Boring Cycle

Dr. R. Jill Urbanic 33

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

G86 Boring Cycle

G87 Back Boring Cycle

G88 Boring Cycle

G89 Boring Cycle

X – hole position X

Y – hole position Y

R – z axis start position (R level)

Z – z axis end position (Z depth)

P – dwell time

Q – G73 or G83

Depth of each peck cycle

Q – G76 or G87

Amount of shift for boring

I – Amount of X axis shift for boring G76 or G87

J – Amount of Y axis shift for boring G76 or G87

F – feedrate specification

L or K – number of cycle repetitions

_______________________________________________________________________

Initial level

1

point

rapid

2 6 feed

Rapid

plane Z0

3 5

4

Bottom of hole

Figure 2.18: Generic Canned Cycle Showing Initial and R Levels

G98 Set Initial Plane default

G99 Return to Retract (Rapid) Plane

Dr. R. Jill Urbanic 34

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

The tool can retract to either a programmed initial level or rapid level. Absolute or

incremental programming can be used with canned cycles. Common cycles are

summarized below:

G81 – drilling cycle mainly used for drilling and centre drilling

G98 (G99) G81 X.. Y.. R.. Z.. F..

G82 – spot drilling / counter boring / spot facing cycle uses a dwell at the bottom of

the hole to create a smooth finish

G98 (G99) G82 X.. Y.. R.. Z.. P .. F..

G83 – peck (deep hole) drilling cycle used to break up and clear the chips when

drilling deep holes (note: the depth of rapid motion between pecks is set using a system

parameter)

G98 (G99) G83 X.. Y.. R.. Z.. Q .. F..

Initial level rapid

point feed

Rapid

plane Z0

Q

Bottom of hole

Figure 2.19: Pecking Cycle

G73 – High speed peck (deep hole) drilling cycle same as above, but the tool never

clears the hole between pecks (note: the depth of rapid motion between pecks is set using

a system parameter)

G98 (G99) G73 X.. Y.. R.. Z.. Q .. F..

The best peck depth is based on the design of the cutting tool, the machinability of the

material, the depth of the hole, and the fixturing.

Dr. R. Jill Urbanic 35

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

G84 – normal tapping cycle using M03 the spindle turns CW when the tool is

feeding in, and then turns CCW when feeding out

G98 (G99) G84 X.. Y.. R.. Z.. F..

G74 – reverse tapping cycle using M04 the spindle turns CCW when the tool is

feeding in, and then turns CW when feeding out

G98 (G99) G84 X.. Y.. R.. Z.. F..

_______________________________________________________________________

Fixed Cycle Repetition

When a selected fixed cycle is programmed for many holes, it is processed only once

unless the L or K address is used. This can be used in absolute or incremental modes to

repeat the canned cycle at other XY locations. The following examples provide the

equivalent results

N33 G90 G99

N34 G81 X17.0 Y20.0 R0.15 Z-2.4 F12.0 L1 (K1)

N35 X22.0 L1 (K1)

N36 X27.0 L1 (K1)

N37 X32.0 L1 (K1)

N38 G80

N33 G90 G99

N34 G81 X17.0 Y20.0 R0.15 Z-2.4 F12.0 L1 (K1)

N35 G91 X5.0 L3 (K1)

N36 G80

Y20.0

X17.0 X22.0 X27.0 X32.0

Figure 2.20: Repetition

Dr. R. Jill Urbanic 36

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Coordinate Rotation

The two rectangles below are identical except that the bottom rectangle has been rotated

30 °. It is much easier to program the top rectangle than the bottom. Instead of

determining what the end coordinates are for the rectangle with the angular rotation, the

controller can do so if the coordinate rotation feature is used.

Figure 2.21: Coordinate Rotation

G68 Coordinate system rotation ON

G69 Coordinate system rotation OFF

Three items are required to define a rotated part:

o Centre of rotation

o Angle of rotation

o The tool path to rotate

G68 X…. Y …. R….

X – absolute x coordinate of the centre of rotation

Y – absolute x coordinate of the centre of rotation

R – angle of rotation

The XY coordinates are the pivot point (XZ for G18, YZ for G19). The plane selection

command must be entered before the coordinate rotation command. R can be positive

(CW) or negative (CCW).

When is this feature used?

(1) If the work envelope is small, and the part must be located at an angle in order to

fit the machine.

(2) Features that are easily programmed orthogonally are at an angle.

Dr. R. Jill Urbanic 37

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

35

10

Figure 2.22: Feature Coordinate Rotation Example

Miscellaneous Operations – M Codes

Miscellaneous or M-codes are used to start and stop the coolant, and spindle, execute a

tool or pallet change, stop the program, perform material handling operations and other

miscellaneous functions. The miscellaneous functions are machine manufacturer, type

and configuration dependent. A partial list of common M codes follows.

Milling Turning

M00 Compulsory program stop M00 Compulsory program stop

M01 Optional program stop M01 Optional program stop

M02 End of program (reset no rewind) M02 End of program

M03 Spindle rotation normal (CW) M03 Spindle rotation normal (CW)

M04 Spindle rotation reverse (CCW) M04 Spindle rotation reverse (CCW)

M05 Spindle stop M05 Spindle stop

M06 Automatic Tool Change M06

M07 Coolant mist ON M07 Coolant mist ON

M08 Coolant ON (pump motor ON) M08 Coolant ON (pump motor ON)

M09 Coolant OFF (pump motor OFF) M09 Coolant OFF (pump motor OFF)

M10 . M10 Chuck open

M11 . M11 Chuck closed

M12 . M12 Tailstock quill IN

M13 Spindle ON CW + coolant ON M13 Tailstock quill OUT

M14 Spindle ON CCW + coolant ON M14 .

M15 Spindle OFF + coolant OFF M15 .

M16 . M16 .

Dr. R. Jill Urbanic 38

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

M17 . M17 Turret indexing forward

M18 . M18 Turret indexing reverse

M19 Spindle Orientation M19 .

M20 . M20 .

M21 . M21 Tailstock forward

M22 . M22 Tailstock backward

M30 Program end (reset & rewind) M30 Program end

M40 . M40 .

M41 . M41 Low Gear Selection

M42 . M42 Medium Gear Selection 1

M43 . M43 Medium Gear Selection 2

M44 . M44 High Gear Selection

M48 Feedrate override cancel OFF M48 Feedrate override cancel OFF

M49 Feedrate override cancel ON M49 Feedrate override cancel ON

M60 Automatic Pallet Change M60 .

M98 Subprogram call M98 Subprogram call

M99 Subprogram end M99 Subprogram end

M functions activated at the start of a block

M03 Spindle rotation normal (CW)

M04 Spindle rotation reverse (CCW)

M06 Automatic Tool Change

M07 Coolant mist ON

M08 Coolant ON (pump motor ON)

M functions activated at the end of a block

M00 Compulsory program stop

M01 Optional program stop

M02 End of program

M05 Spindle stop

M09 Coolant OFF (pump motor OFF)

M30 Program end

M60 Automatic Pallet Change

Dr. R. Jill Urbanic 39

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

M functions ACTIVE until CANCELED or ALTERED

M03 Spindle rotation normal (CW)

M04 Spindle rotation reverse (CCW)

M06 Automatic Tool Change

M07 Coolant mist ON

M08 Coolant ON (pump motor ON)

M09 Coolant OFF (pump motor OFF)

M functions COMPLETED in one block

M00 Compulsory program stop

M01 Optional program stop

M02 End of program

M05 Spindle stop

M30 Program end

M60 Automatic Pallet Change

Only one M code can be programmed in a single block.

M00 – program is stopped, and the spindle and coolant turned off. When the cycle start

button is pressed on the console, the program is resumed.

M01- if the optional stop on the console is on, the M01 function is identical to the M00

function, else it is ignored.

M03 / M04 – turn the spindle on CW or CCW respectively. The rpm must be

previously defined by the spindle speed command (S).

M05 – stops the spindle irrespective of the direction

M30 – this indicates the end of the program. The spindle and coolant are turned off, and

the program reset to the beginning.

Tool Function Txx

Machining Centres (both mill and lathe) have a multiple tool storage in a tool magazine

(machining centre) or a turret (lathe) and the ability to change tooling automatically a

feature called automatic tool change. Each pocket has a number associated with it; hence,

when tool 1 is chosen, the tool loaded in pocket 1 will be placed in the spindle or rotated

into position if using a lathe.

Programming a tool change is easy. For a machining centre, to bring tool in pocket four

into the spindle, one programs:

N## T04 M06 or N## M06 T04

Dr. R. Jill Urbanic 40

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

To load a tool into a waiting position (to reduce waiting time on the machine), on the next

line, program the address of the next tool to be used.

N## T04 M06;

N## T06; The tool magazine will rotate T06 into a waiting position

For a lathe, you use the T function in a standalone manner.

N ## TXXYY

XX – turret position and work offset number

YY – wear offset number

You cannot pre-stage a lathe tool unless it has a tool carrousel.

Program Structure

Program Number

Comments to describe the program, part, and other critical information such as revisions.

Start up block

Comment for tool 1

Program cutting motions for tool 1

Comment for tool 2

Program cutting motions for tool 2

.

.

Clear / cancel all settings

End of program

Stop code

O####

(COMMENT TO DESCRIBE THE PROGRAM SUCH AS MACHINE,

CONTROLLER, UNITS, JOB NUMBER, …)

(PART DESCRIPTION SUCH AS STOCK MAT’L, PROGRAM DATUM POINT)

(PROGRAMMER / DATE / REVISIONS………………)

N1 G17 G21 G40 G49 G54 G64 G80 G90 G94; (start up block)

N2 (½ INCH HSS DRILL)

N2 T01 M06;

N3 G00 X.. Y.. Z.. S.. M03 T02; (select a spindle speed, start up spindle, setup tool 2 to

be ready for tool change)

N4 G43 Z2.0 H01; (use tool length offset for tool 1)

.

.

N## cancel settings

N## M30;

%

Dr. R. Jill Urbanic 41

Computer Aided Manufacturing and Measurements 91-590-21/92-590-11 Winter 2016

Sample Program:

%

O0000

(PROGRAM NAME - MACHINE_GROUP_1_COMPG42 )

N1 G21

N2 G0 G17 G40 G49 G80 G90

( 8. FLAT ENDMILL TOOL - 8 DIA. OFF. - 8 LEN. - 8 DIA. - 8. )

( 3 flute endmill )

N3 T8 M6

N4 G0 G90 G54 X16. Y17. A0. S537 M3

N5 G43 H8 Z50.

N6 Z10.5

N7 G1 Z-13. F4.

N8 G42 D8 X8. F8.1

N9 G2 X0. Y25. R8.

N10 G1 Y50.

N11 X100.

N12 Y0.

N13 X0.

N14 Y25.

N15 G2 X8. Y33. R8.

N16 G1 G40 X16.

N17 Z-3. F4.

N18 G0 Z50.

N19 M5

N20 G91 G28 Z0.

N21 G28 X0. Y0. A0.

N22 M30

%

Dr. R. Jill Urbanic 42

You might also like

- Developments in Large Scale Additive Manufacture - The Potential and Limitations of Wire Arc Additive Manufacture and Associated TechnologiesDocument5 pagesDevelopments in Large Scale Additive Manufacture - The Potential and Limitations of Wire Arc Additive Manufacture and Associated TechnologiesBita MohajerniaNo ratings yet

- FeatureCAM Fundamentals - Turning PDFDocument11 pagesFeatureCAM Fundamentals - Turning PDFBita MohajerniaNo ratings yet

- Welding Training Intro 20151010 PDFDocument74 pagesWelding Training Intro 20151010 PDFBita MohajerniaNo ratings yet

- CBUSHDocument4 pagesCBUSHBita MohajerniaNo ratings yet

- Exercise 7.1 PT Bending HyperCrashDocument31 pagesExercise 7.1 PT Bending HyperCrashBita MohajerniaNo ratings yet

- Analogy of Strain Energy Density Based Bone-Remodeling Algorithm and Structural Topology OptimizationDocument7 pagesAnalogy of Strain Energy Density Based Bone-Remodeling Algorithm and Structural Topology OptimizationBita MohajerniaNo ratings yet

- 08m13e11 - Update Training FARO CAM2 Measure X Workbook For The Student - June 2005Document146 pages08m13e11 - Update Training FARO CAM2 Measure X Workbook For The Student - June 2005Bita MohajerniaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MUDPRO Plus Advanced Mud ReportingDocument2 pagesMUDPRO Plus Advanced Mud ReportinglarasNo ratings yet

- Cidtt The GuideDocument268 pagesCidtt The GuideAbdul Shameem100% (1)

- DD The Superior College Lahore: Bscs 5CDocument15 pagesDD The Superior College Lahore: Bscs 5CLukeNo ratings yet

- Attempt 1 OrgDocument19 pagesAttempt 1 OrgMohammed Irfan SheriffNo ratings yet

- REA 101 Proteccion de Arco EléctricoDocument64 pagesREA 101 Proteccion de Arco EléctricoIngJGMNo ratings yet

- 300Mbps/150Mbps Wireless LAN Broadband Router: Quick Installation GuideDocument2 pages300Mbps/150Mbps Wireless LAN Broadband Router: Quick Installation GuideLuis AngelNo ratings yet

- CS467-textbook-Machine Learning-Ktustudents - in PDFDocument226 pagesCS467-textbook-Machine Learning-Ktustudents - in PDFAmmu MoleNo ratings yet

- V$SESSIONDocument8 pagesV$SESSIONCristiano Vasconcelos BarbosaNo ratings yet

- Awareness and Application of Ms Iec - Iso 31010 - 2011 Risk Assessment Techniques1 PDFDocument21 pagesAwareness and Application of Ms Iec - Iso 31010 - 2011 Risk Assessment Techniques1 PDFasushk0% (1)

- CMR900Document6 pagesCMR900Time To Use BrainNo ratings yet

- Compressor Service ProcedureDocument22 pagesCompressor Service ProcedureFriget Rusianto100% (2)

- Graphics Display Resolution - Wikipedia, The Free EncyclopediaDocument15 pagesGraphics Display Resolution - Wikipedia, The Free EncyclopediaKarun KumarNo ratings yet

- Presentation On Market Potential of Tag TasteDocument10 pagesPresentation On Market Potential of Tag TasteRajaNo ratings yet

- 7ML19981GC61 1Document59 pages7ML19981GC61 1Andres ColladoNo ratings yet

- GSM Network Hash CodesDocument5 pagesGSM Network Hash CodesMd.Bellal HossainNo ratings yet

- A Study On Welding Defects of Pressure VesselDocument24 pagesA Study On Welding Defects of Pressure Vesseladamahmad1992100% (1)

- Process Hazard Analysis DM Plant - 25.01.18Document51 pagesProcess Hazard Analysis DM Plant - 25.01.18Debabrata TantubaiNo ratings yet

- Toshiba NB520 Compal LA-6859PDocument38 pagesToshiba NB520 Compal LA-6859Pash thonNo ratings yet

- Nexus 1262 & 1272 CatalogueDocument12 pagesNexus 1262 & 1272 CataloguenaveenNo ratings yet

- Process Simulation in Refineries SamplerDocument30 pagesProcess Simulation in Refineries SamplerNagendra HNo ratings yet

- Norma para Tuercas Hexagonales y Cuadradas (Inch Series) ASME-ANSI B18.2.2-1987Document42 pagesNorma para Tuercas Hexagonales y Cuadradas (Inch Series) ASME-ANSI B18.2.2-1987Jorge Roman SantosNo ratings yet

- Fibretherm FT12Document47 pagesFibretherm FT12Dana Iulia Moraru50% (2)

- Mathematical Description of OFDMDocument8 pagesMathematical Description of OFDMthegioiphang_1604No ratings yet

- 800ma Low Dropout Positive Regulator: Features DescriptionDocument12 pages800ma Low Dropout Positive Regulator: Features DescriptionmarcianocalviNo ratings yet

- Characteristics of Supercritical Flow in Rectangular ChannelDocument10 pagesCharacteristics of Supercritical Flow in Rectangular ChannelFatihNo ratings yet

- Voltage - V - Salna-T-662-16-Order - and - Reasons OCR PDFDocument58 pagesVoltage - V - Salna-T-662-16-Order - and - Reasons OCR PDFHoward KnopfNo ratings yet

- DataDocument4 pagesDataQuế SươngNo ratings yet

- CatalogDocument42 pagesCatalogOnerom LeuhanNo ratings yet

- Bill of Materials SampleDocument31 pagesBill of Materials SampleOcsi YeahNo ratings yet

- 4455770110e1 Parts ManualDocument31 pages4455770110e1 Parts ManualSimon AlbertNo ratings yet