Professional Documents

Culture Documents

Biofuel

Uploaded by

Fierdaus Fuad0 ratings0% found this document useful (0 votes)

9 views21 pagesBiofuel research

Original Title

biofuel

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBiofuel research

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views21 pagesBiofuel

Uploaded by

Fierdaus FuadBiofuel research

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 21

A biofuel is a fuel that contains energy from

geologically recent carbon fixation. These fuels are

produced from living organisms.

Examples of this carbon fixation occur

in plants and microalgae. These fuels are made by

a biomass conversion (biomass refers to recently

living organisms, most often referring to plants or

plant-derived materials).

This biomass can be converted to convenient

energy containing substances in three different

ways: thermal conversion, chemical conversion, and

biochemical conversion.

This biomass conversion can result in fuel

in solid, liquid, or gas form. This new biomass can be

used for biofuels.

Biofuels have increased in popularity because of

rising oil prices and the need for energy security.

Most transportation fuels are liquids,

because vehicles usually require high energy

density This occurs naturally in liquids and

solids. High energy density can also be

provided by an internal combustion engine.

These engines require clean-burning fuels.

The fuels that are easiest to burn cleanly are

typically liquids and gases. Thus, liquids

meet the requirements of being both energy-

dense and clean-burning. In addition, liquids

(and gases) can be pumped, which means

handling is easily mechanized, and thus less

laborious.

Biodiesel is the most common biofuel in Europe. It is

produced from oils or fats

using transesterification and is a liquid similar in

composition to fossil/mineral diesel. Chemically, it

consists mostly of fatty acid methyl (or ethyl) esters

(FAMEs). Feed stocks for biodiesel include animal fats,

vegetable

oils, soy, rapeseed, jatropha, mahua, mustard, flax, su

nflower, palm oil, hemp, field pennycress, Pongamia

pinnata and algae. Pure biodiesel (B100) currently

reduces emissions with up to 60% compared to

diesel Second generation B100.

Green diesel is produced

through hydro

cracking biological oil feed

stocks, such as vegetable oils

and animal fats. Hydro cracking

is a refinery method that uses

elevated temperatures and

pressure in the presence of a

catalyst to break down

larger molecules, such as those

found in vegetable oils, into

shorter hydrocarbon chains used

in diesel engines.

Green diesel may also be called renewable diesel,

hydro treated vegetable oil or hydrogen-derived

renewable diesel.

Green diesel has the same chemical properties as

petroleum-based diesel. It does not require new

engines, pipelines or infrastructure to distribute

and use, but has not been produced at a cost that

is competitive with petroleum.

Gasoline versions are also being developed. Green

diesel is being developed

in Louisiana and Singapore by ConocoPhillips, Nest

e Oil, Valero, Dynamic Fuels, and Honeywell UOP.

Also by Preem in Gothenburg, Sweden Evolution

Diesel

In 2013 UK researchers developed a

genetically modified strain of Escherichia

coli which could transform glucose into

biofuel gasoline that does not need to be

blended. Later in 2013 UCLA researchers

engineered a new metabolic pathway to

bypass glycolysis and increase the rate of

conversion of sugars into

biofuel, while KAIST researchers

developed a strain capable of producing

short-chain alkanes, free fatty acids, fatty

esters and fatty alcohols through the fatty

acyl (acyl carrier protein (ACP)) to fatty

acid to fatty acyl-CoA pathway in vivo.

Straight

unmodified edible veg

etable oil is generally

not used as fuel, but

lower-quality oil can

and has been used for

this purpose. Used

vegetable oil is

increasingly being

processed into

biodiesel, or (more

rarely) cleaned of

water and

particulates and used Filtered waste

as a fuel. vegetable oil

As with 100% biodiesel (B100), to ensure the fuel

injectors atomize the vegetable oil in the correct

pattern for efficient combustion, vegetable oil fuel

must be heated to reduce its viscosity to that of

diesel, either by electric coils or heat exchangers.

This is easier in warm or temperate climates.

Big corporations like MAN B&W Diesel, Wärtsilä,

and Deutz AG, as well as a number of smaller

companies, such as Elsbett, offer engines that are

compatible with straight vegetable oil, without the

need for after-market modifications.

Vegetable oil can also be used in many older diesel

engines that do not use common rail or unit

injection electronic diesel injection systems.

Bioethers (also referred to as fuel ethers

or oxygenated fuels) are cost-

effective compounds that act as octane

rating enhancers.

"Bioethers are produced by the reaction of reactive

iso-olefins, such as iso-, with bio butylene

ethanol." Bioethers are created by wheat or sugar

beet

They also enhance engine performance, whilst

significantly reducing engine wear and toxic

exhaust emissions .

Though bio ethers are likely to replace petro

ethers in the UK, it is highly unlikely they will

become a fuel in and of itself due to the low energy

density. Greatly reducing the amount of ground-

level ozone emissions, they contribute to air

quality.

Biologically produced alcohols, most

commonly ethanol, and less

commonly propanol and butanol, are

produced by the action of

microorganisms and enzymes through

the fermentation of sugars or starches

, or cellulose .

Biobutanol also called bio gasoline is

often claimed to provide a direct

replacement for gasoline, because it

can be used directly in a gasoline

engine .

Biogas is methane produced by the process

of anaerobic digestion of organic

material by anaerobes. It can be produced either

from biodegradable waste materials or by the use

of energy crops fed into anaerobic digesters to

supplement gas yields. The solid by product ,

digestate, can be used as a biofuel or a fertilizer.

Syngas, a mixture of carbon

monoxide, hydrogen and other hydrocarbons, is

produced by partial combustion of biomass, that is,

combustion with an amount of oxygen that is not

sufficient to convert the biomass completely to

carbon dioxide and water. Before partial

combustion, the biomass is dried, and

sometimes pyrolysed. The resulting gas mixture,

syngas, is more efficient than direct combustion of

the original biofuel; more of the energy contained

in the fuel is extracted.

When raw biomass is already in a suitable form (such

as firewood), it can burn directly in a stove or furnace to

provide heat or raise steam.

When raw biomass is in an inconvenient form (such as

sawdust, wood chips, grass, urban waste wood,

agricultural residues), the typical process is to densify

the biomass. This process includes grinding the raw

biomass to an appropriate particulate size (known as hog

fuel), which, depending on the densification type, can be

from 1 to 3 cm (0 to 1 in), which is then concentrated

into a fuel product.

The current processes produce wood pellets, cubes, or

pucks. The pellet process is most common in Europe,

and is typically a pure wood product.

The other types of densification are larger in size

compared to a pellet, and are compatible with a broad

range of input feed stocks. The resulting densified fuel is

easier to transport and feed into thermal generation

systems, such as boilers.

Future biofuels will be made

from a wide range of hardy and

fast-growing plants, such as

switch grass, perennial grass

native to American prairies.

1. Do Catalytic converters prevent pollution?

Whilst Catalytic converters don’t actually prevent

pollution, they do help to cut it down. Their purpose is to

convert the poisonous carbon monoxide gas, and other

pollutants produced by cars into carbon dioxide. They

don’t, however, work to full effect on short car journeys

since they only work once they have been warmed up.

2. Is it better for the environment to use bio fuels?

This is not really true because they give off less energy per

quantity than ordinary fuels. There is also the environmental

cost of producing bio fuels; intensive farming of the crops,

fertilizers and pesticides used on them, and then the

conversion of the crops into the fuels

3. What kinds of ethanol-blended fuels are available?

• E10 – 10% ethanol and 90% unleaded gasoline – is the most

common way ethanol is available to motorists.

All automakers approve ethanol blends up to this 10% level by

warranty, no matter the make or model of the

vehicle. About 99% of America’s ethanol is retailed as E10.

• E85 – 85% ethanol and 15% unleaded gasoline – is an

alternative fuel for use in Flexible Fuel Vehicles

(FFVs). FFVs can use unleaded gasoline or any blend of ethanol

up to this 85% level.

4. Will my vehicle run on ethanol-blended fuel?

All vehicles are “ethanol-capable” and can use a blend of up to 10%

ethanol. Since the 1980s all automakers have

covered up to 10% ethanol-blended fuel by warranty, no engine

modifications necessary.

5. Can ethanol blends be used in small engines, such as boats,

lawnmowers, or chainsaws?

Yes – manufacturers of small engines realize that up to a 10% blend

of ethanol is very common in gasoline, so they

make their engines compatible with this fuel.

6. What is biogas?

Biogas is a combustible gaseous fuel that is collected from the

microbial degradation of organic matter in anaerobic

conditions. Biogas is principally a mixture of methane (CH4)

and carbon dioxide (CO2) along with other trace gases.

7. Can biogas be used in place of fossil fuels? How?

Methane is the principal gas in biogas. Methane is also the main

component in natural gas, a fossil fuel. Biogas can be used to

replace natural gas in many applications including: cooking,

heating, steam production, electrical generation, vehicular fuel,

and as a pipeline gas.

8. What is biodiesel ?

Biodiesel is a clean-burning diesel replacement fuel

that can be used in compression-ignition (CI)

engines, and which is manufactured from the

following renewable, non-petroleum-based sources:

Virgin vegetable oils such as soy, mustard, canola,

safflower, rapeseed, and palm oils;

Animal fats such as poultry offal, tallow, and fish

oils;

Used cooking oils and trap grease from restaurants.

9. Can I substitute biodiesel for diesel in my trucks and

equipment?

Biodiesel can be used as a pure fuel or blended with petroleum in

any percentage. B20 (a blend of 20 percent by volume biodiesel

with 80 percent by volume petroleum diesel) has demonstrated

significant environmental benefits with a minimal increase in

cost for fleet operations and other consumers. While a diesel

engine can run on B100, it can clog the filters of older engines

quite rapidly, so operators of older engines should be advised to

change the filter more frequently at first. Low level blends (1%-

2%) of biodiesel can restore lubricity to low-sulphur fuels

10. What is cellulosic ethanol ?

Cellulosic ethanol is made from cellulose rather than starch or

sugars. Cellulose is the most common cellular component in

the plant world, and makes up much of the stem and leaves of

many plants. Tapping the energy in cellulose opens a vastly

expanded supply of low-cost feed stocks that farmers and

ranchers can grow.

NAME: ANGELA KHURANA

CLASS: VIII – B

ROLL NO: 05

SCHOOL: RYAN INTERNATIONAL SCOOL

SUBJECT: SCIENCE

SUBJECT TEACHER: MS. CHAVVI BHATNAGAR

TOPIC: “BIOFUELS”

CONTENTS:

1-15 SLIDES = DESCRIPTION OF BIOFUEL

16 -20 SLIDES =QUESTIONS.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- SCIENCE GRADE 6 - ST1-4 Answer KeyDocument4 pagesSCIENCE GRADE 6 - ST1-4 Answer KeyJill Maguddayao100% (7)

- Introduction To Parallel Computing, Second Edition-Ananth Grama, Anshul Gupta, George Karypis, Vipin KumarDocument2 pagesIntroduction To Parallel Computing, Second Edition-Ananth Grama, Anshul Gupta, George Karypis, Vipin KumarjulioNo ratings yet

- TNB Tech Guidebook For The Connection of Generation To The Distn Network PDFDocument188 pagesTNB Tech Guidebook For The Connection of Generation To The Distn Network PDFckwei0910No ratings yet

- Wind Energy and Wind Turbine PDFDocument13 pagesWind Energy and Wind Turbine PDFE Cos LopezNo ratings yet

- Wiring Diagram - MV Switch Gear BPA - CUADocument30 pagesWiring Diagram - MV Switch Gear BPA - CUAAdetunji Taiwo100% (1)

- Technical Data Sheet For DG Sets Contract No:Icb Bid No - Wrmsp/Icb-02 Furkat-1 Pumping Station DG SetDocument4 pagesTechnical Data Sheet For DG Sets Contract No:Icb Bid No - Wrmsp/Icb-02 Furkat-1 Pumping Station DG Setshrikanth5singhNo ratings yet

- 2GCS638015A0070-ESI Inverter Solutions For Battery Energy Storage ApplicationsDocument28 pages2GCS638015A0070-ESI Inverter Solutions For Battery Energy Storage ApplicationsANDYAFANADORNo ratings yet

- LG LW8012ER Air Conditioner Spec SheetDocument2 pagesLG LW8012ER Air Conditioner Spec SheetAbin MeetuNo ratings yet

- 150 Layout 480-505W 21.1% 0 + 5W: PreliminaryDocument2 pages150 Layout 480-505W 21.1% 0 + 5W: PreliminaryKesavanNo ratings yet

- Assignment 01 ProductivityDocument3 pagesAssignment 01 ProductivityRajesh ShuklaNo ratings yet

- TGBS Open Day 2021 Aiman FMD 14 Oct 2021 ZZ Without VideoDocument22 pagesTGBS Open Day 2021 Aiman FMD 14 Oct 2021 ZZ Without VideoAr AimanNo ratings yet

- Lab Manual EE1251 PDFDocument35 pagesLab Manual EE1251 PDFHitesh VijayNo ratings yet

- Dynamics StudentDocument19 pagesDynamics StudentRioNo ratings yet

- Proposal For Pumped StorageDocument12 pagesProposal For Pumped StorageAmrend Prasad ShahNo ratings yet

- TES CBdoc PG VCB 1 (EN) 1.12Document92 pagesTES CBdoc PG VCB 1 (EN) 1.12Medo SoroNo ratings yet

- 2 Magnetic FieldsDocument5 pages2 Magnetic Fieldsrebbieg100% (1)

- Low Voltage DC Distribution 20 1 0.4 KV Systems PDFDocument10 pagesLow Voltage DC Distribution 20 1 0.4 KV Systems PDFTTaanNo ratings yet

- CASE STUDY - Waste To Energy 4MWDocument2 pagesCASE STUDY - Waste To Energy 4MWAli BariNo ratings yet

- Dados Tec - c2500Document5 pagesDados Tec - c2500Sandro MunizNo ratings yet

- RdsoDocument7 pagesRdsoMrinmy ChakrabortyNo ratings yet

- BU-409 - Charging Lithium-Ion - Battery UniversityDocument11 pagesBU-409 - Charging Lithium-Ion - Battery Universitydaniel febrian 58No ratings yet

- A Review On Underwater WindmillDocument26 pagesA Review On Underwater Windmillbhagyashree behera100% (1)

- Physics Research AssignmentDocument7 pagesPhysics Research AssignmentMimi HuynhNo ratings yet

- Report of Sampling and Analysis: Bara Energi Naga Sukses, PTDocument1 pageReport of Sampling and Analysis: Bara Energi Naga Sukses, PTSAHABAT GANJAR SULBARNo ratings yet

- Cummins Hylyzer 500 SpecsheetDocument2 pagesCummins Hylyzer 500 SpecsheetamsukdNo ratings yet

- Rapp Pb3 Project: Training Manual Contents CFBT-582-1 2Document6 pagesRapp Pb3 Project: Training Manual Contents CFBT-582-1 2DangolNo ratings yet

- Energy Audit SyllabusDocument2 pagesEnergy Audit SyllabusPravin KhandveNo ratings yet

- Unit-IV - Voli. 2 Polyphase TransformersDocument74 pagesUnit-IV - Voli. 2 Polyphase Transformersvasu_koneti5124No ratings yet

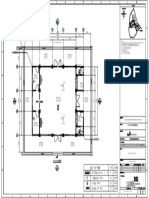

- LGE001-MEC-LAY-005 HVAC Layout - MosqueDocument1 pageLGE001-MEC-LAY-005 HVAC Layout - MosqueRemmo ArdianNo ratings yet

- 3x1Kw Geysers 3000 100% 3000: 1KW For Each Square or Part of A 100 SquareDocument2 pages3x1Kw Geysers 3000 100% 3000: 1KW For Each Square or Part of A 100 SquareShuaibSolomonNo ratings yet