Professional Documents

Culture Documents

IWCF Workbook Instructor Solution Part 2

Uploaded by

ElrohirPendragon100%(1)100% found this document useful (1 vote)

964 views24 pagesSolução de Exercícios de Well Control

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSolução de Exercícios de Well Control

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

964 views24 pagesIWCF Workbook Instructor Solution Part 2

Uploaded by

ElrohirPendragonSolução de Exercícios de Well Control

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

Intertek Consulting & Training, IWCF Student Exercise Book

58. _ While tripping out of the hole from 12,000 feet TVD the hole does not take the proper amount of fill.

With the bit at 9000 feet TVD the well flows and is shut in with 215 psi SICP. A float is in the drill string,

Drill collar length is 1200 feet and the average length of each stand is 93 feet. Assume the gas is on

bottom and does not migrate.

Drill pipe capacity 01776 bbi/ft

Drill pipe displacement 0076 bbi/ft

Open hole capacity 0702 bbi/ft

DC/Open hole capacity 0291 bbI/ft

DP/Open hole capacity 046 bbI/ft

Pit gain 30 bbl

Gas gradient -12 psi/ft

mw 12.0 ppg

58a. How much volume is required to fill the drill pipe after stripping one stand into the hole?

1.65 _bbl

Capacity bb! = Stand Length ft x Drill pipe capacity bbi/ft

93 ft x.01776 = 1.65 bbl

58b, Calculate the height of the influx

427.3 feet

Pit Gain bbls + Open Hole capacity

.0702 = 427.3 ft

Height of influx in open hole

3

58c. Calculate the volume displaced per stand of drill pipe stripped into the hole

2.35 bbl

Displacement per stand bbls = Stand Length ft x (Drill pipe capacity bbi/ft + Drill pipe displacement bbl/ft)

93 x (,01776 + .0076) = 2.35 bbls

58d. After stripping to bottom, what is the height of the influx across the BHA

1031 _feet

Height of Influx around Drill Collars = Pit Gain bbls + Drill Collar capacity bbi/ft

58e. Calculate the SICP once the bit is back on bottom

519 __psi

SICP = Height of Influx x (Mud Grad ~ Gas Grad)

1031 x (0.624 0.12) = 519 psi

Instructor Solution Answer Key Page 50

Intertek Consulting & Training

59. WELL DATA FOR QUESTION

IWCE Student Exercise Book

Well Depth 12,000 feet

DC length 1100 feet

95/8” Csg Shoe 8000 feet

DC capacity .00768 bbi/ft

8%" OH capacity 0702 bbi/ft

DC displacement 033 bbl/ft

mw 12 ppg (.624 psi/ft)

DP capacity 01776 bbI/ft

DP displacement .0076 bbi/ft

DC/OH capacity 0291 bbi/ft

DP/OH capacity 0459 bbI/ft

DP/Csg capacity 0515 bbi/ft

After pulling 33 stands the driller checks the hole fill. The well has not taken the correct amount of

mud. A flow check is made and the well is flowing,

Bit depth 9000 feet

sice 200 psi

Influx volume 30 bbl

Influx gradient (Gi) 156 psifft

59a.

59b.

59c.

Assume that the influx occurred from the bottom of the hole and that no gas migration occurs.

Calculate the volume to bleed off per 98 feet of drill pipe stripped back into the hole.

2.48 _ bbl

Drill Pipe Displacement bbls = Length ft x (Drill pipe capacity bbi/ft + Drill pipe displacement bbi/ft)

Volume to Bleed = 98 x (0.01776 + 0.0076) = 2.48 bbl

What will be the effect on bottom hole pressure of bleeding off too much mud?

Increase Decrease___ Stay the same

How would casing pressure most likely react as the drill string is stripped into the influx?

Increase____

Decrease Stay the same

Instructor Solution Answer Key

Page 51

Intertek Consulting & Training IWCF Student Exercise Book

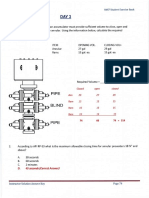

60. Problems that occur during a killing operation may affect the parameters you are monitoring at the,

surface (drill pipe pressure and casing pressure). For each of the following problems state the

immediate effect on each of the parameters listed.

For an increase use this symbol

For a decrease use this symbol

For no change use this symbol =

Bottom Hole

Pressure

J

Drill Pipe

Pressure

Casing

Pressure

J

Problem

A. Choke washout J

B. Hole in string

C. Nozzle blowout

D. Choke plugging

E. Nozzle plugging

=

ul

tl

en

Instructor Solution Answer Key Page 52

Intertek Consulting & Training IWCF Student Exercise Book

61.

62.

63.

65.

During the well kill operation, slowly but regularly you have to reduce the choke size because the drill

pipe and casing pressures keep dropping with constant pump strokes.

What is the likely cause of this?

A. Abit nozzle is washing out

B. The choke is washing out (Correct Answer)

C. You have a washed out pump swab

Which of the following parameters can be affected by a string washout during a well ki

(TWO ANSWERS).

‘A. Bottom hole pressure (Correct Answer)

B. Kick tolerance

Formation fracture pressure

D. Slow circulating pressure (Correct Answer)

The choke has to be closed gradually due to a string washout. What effect does the gradual closing of

the choke have on bottom hole pressure?

A. Decrease

B. _ Increase (Correct Answer)

C. Stay the same

How is a choke washout recognized?

‘A. Rapid rise in casing pressure with no change in the drill pipe pressure

B. __ Increase in drill pipe pressure with no change in casing pressure

C. Continually having to open the choke to maintain drill pipe and casing pressures

D. Continually having to close the choke to maintain drill pipe pressure (Correct Answer)

A kick is being circulated from the well using the Driller's Method. Pumping pressure has been

established as 1000 psi @ 30 SPM. During the operation pressure suddenly increases to 1350 psi. You

are reasonably certain that a nozzle has plugged.

What should you do?

A. Reduce the pump pressure to 1000 psi by adjusting the choke

B. Shut the well in and re-establish the pumping pressure (Correct Answer)

C. Hold casing pressure constant at the value recorded just before the nozzle plugged

D. — A& Bare acceptable courses of action

an nn RE

Instructor Solution Answer Key Page 53

Intertek Consulting & Training IWCE Student Exercise Book

66.

67.

68.

69.

‘Awell is being killed using the Driller’s Method. During the first circulation the drill pipe pressure is

kept constant at 670 psi and the pump speed @ 30 SPM. Halfway through the first circulation the

‘operator on the choke observes a sudden increase in drill pipe pressure. There is no significant change

in choke pressure and the pump speed is still 30 SPM. What could have happened? (THREE ANSWERS)

A. The bit nozzles have partially plugged (Correct Answer)

B. The choke has partially plugged

C. The kick is about to enter the choke

D. — Apartial blockage in the kelly hose (Correct Answer)

E. Pressure has built up in the mud/gas separator

F.— Apartial blockage in the drill string has occurred (Correct Answer)

During a well killing operation using the Driller's Method, the choke pressure suddenly increases by

150 psi. Shortly thereafter the operator observes the same pressure increase on the drill pipe pressure

gauge. What is the most likely cause of this pressure increase?

A. Asecond influx has entered the well

B. Arestriction in the kelly hose

C. Aplugged nozzle in the bit

D. The choke is partially plugged (Correct Answer)

& Awashout in the drill string

What would be the correct action to take for the problem in question #67

A. Reduce the pump rate to reduce the pressure by 150 psi

B. Open the choke a little until the drill pipe pressure returns to the calculated value (Correct

Answer)

C. _Noaction required as this pressure increase has no effect on bottom hole pressure

D. Stop the kill operation, remove the restriction in the kelly hose or change over to a spare kelly

hose

While displacing the drill pipe with Kill Weight Mud a sudden loss in drill pipe pressure occurs, no

change in the choke pressure is seen. The driller continued to pump at the same rate while the

supervisor adjusted the choke to follow the drill pipe pressure graph as originally planned. What

happens to BHP as a result of this?

BHP increases then decreases

BHP remains unchanged

BHP decreases

BHP decrease then increases

BHP increases with the choke adjustment (Correct Answer)

moON@>

Instructor Solution Answer Key Page 54

Intertek Consulting & Training IWCF Student Exercise Book

70. Which of the following would be applicable, ifthe pressures did not respond to opening the choke and

the pumps were shut down and the well secured?

A. Bit nozzle plugged

B. Bit nozzle washout

C. Drill string washout

D. Pump failure

E. Plugged choke (Correct Answer)

F. Choke washed out

71. During a kill operation the choke operator notices the drill pipe pressure rises sharply though the

casing pressure remains steady. He reacts by opening up the choke to maintain correct pumping

pressure. This situation continues with increasing regularity. The choke operator notices that during

this operation the choke has been adjusted from % to % open. What is the most likely cause of this?

A Choke plugging

B. Choke washing out

C. Pipe washed out

D. Bit nozzle plugging (Correct Answer)

72. Inthe above question, what effect has the gradual opening of the choke have on bottom hole

pressure?

A. BHP has decreased (Correct Answer)

8. BHP has increased

C. BHP has remain unchanged

73. Lost circulation during a well control operation is usually detected by:

Monitoring the return flow with a flowshow

Monitoring the mud volume in the pits (Correct Answer)

Monitoring the pump speed

Monitoring the weight indicator

oopP

cr meat

Instructor Solution Answer Key Page 55

Intertek Consulting & Training IWCF Student Exercise Book

74,

75.

16.

77.

78.

While circulating out a kick the choke operator has been continually closing the choke in order to

maintain the correct circulating drill pipe pressure. The mud logger has reported that both drill pipe

and casing pressures have been increasing.

NOTE: The choke operator's gauges operate from different sensor than the mud logger. A check of the

‘gauges on the standpipe and choke manifold confirm the mud logger’s report. What is the most likely

explanation?

The choke is washing out

The choke operator’s gauges are malfunctioning (Correct Answer)

The choke is plugging

‘The mud logger’s gauges are malfunctioning

poR>

Akkick has been taken and it is known that a potential lost circulation zone exists in the open hole.

Select TWO CORRECT ACTIONS which can be taken to minimize pressure in the annulus during the kill

operation.

‘A. Maintain extra back pressure on the choke for safety

B. Use the Wait and Weight Method (Correct Answer)

C. —Choose a lower circulating rate (Correct Answer)

D. Choose a higher circulating rate

Does a kick always occur in the event of total loss of circulation?

‘A. Yes, losses always occur above any potential kick zone

B. No, it depends on the drill string weight reduction noted on the weight indicator

C. No, it depends on the mud level in the annulus and the formation pressure (Correct Answer)

If total losses occur while drilling with water based mud what would you do?

A. Continue drilling blind

B. Stop drilling and fill the annulus with water (Correct Answer)

C. Stop drilling, shut in the well and see what happens

‘While circulating out a kick the mud pump fails. What is the first thing to do?

Shut the well in (Correct Answer)

Fix the pump as soon as possible

Change over to Pump #2

Divert the well

pore

er era at

Instructor Solution Answer Key Page 56

Intertek Consulting & Training IWCF Student Exercise Book

79.

80.

81.

82

If the drill string washed out during a kill operation, providing no action was taken, which of the

following would remain constant? (TWO ANSWERS)

‘A. Bottom hole pressure (Correct Answer)

B. Casing pressure (Correct Answer)

C. Slow circulating pressure

D. Drill pipe pressure

Which THREE of the following are proper practices for drilling an anticipated H,S environment?

A Use $-135 drill pipe

B. Use X-95 drill pipe (Correct Answer)

Use HzS scavenger (Correct Answer)

D. Use high ph mud to neutralize the hydrogen sulfide (Correct Answer)

E. Use a low pH mud to neutralize the hydrogen sulfide

F. Always reverse out prior to round trips

How would you determine the Initial Circulating Pressure if no slow pump rate pressure were

available? Assume the rig is on land, a kick has been taken and the well is shut in.

‘A. Add 300 psi to the casing pressure and bring the pump up to the kill speed while using the

choke to keep casing pressure at (SICP + 300 psi)

B. Bring the pump up to the kill rate while keeping casing pressure constant by choke

‘manipulation (Correct Answer)

C. Circulate at the kill rate holding 200 psi back pressure on the drill pipe side with the choke

During a kill operation a pump swab starts leaking, The choke operator knows nothing about the leak

and is maintaining the standpipe pressure in accordance with the pressure schedule on the kill sheet.

What will be the affect on BHP?

A. BHP stays constant

B. BHP decreases

C. BHP increases (Correct Answer)

ion Answer Key Page 57

Intertek Consulting & Training

IWCF Student Exercise Book

KILL SHEET EXERCISES

Complete a SURFACE IWCF KILL SHEET using the data given below and answer the questions on the page

following the data.

Well Data

Hole 1D 12%"

MD 10,975 feet

Tv 10,550 feet

Csg Set @ 6250 feet; 12.515" ID

Internal Capacities

oP 0174 bbi/ft

HW .0088 bbi/ft (465 feet in length)

oc .0087 bbI/ft (900 feet in length)

Volume from mud pumps to rig floor: 7.2 bbl

‘Annular Capacities

DCin Open Hole

DP & HW in open hole

DP & HW in cased hole

Mud Pumps Output:

Slow Circulating Pump Data

0836 bbi/ft

1215 bbl/ft

1279 bbl/ft

11 bbi/stk

Pump #1 30SPM @ 620psi_ 40 SPM @ 1100 psi

Pump #2 30 SPM @ 610 psi 40SPM @ 1080 psi

Active Surface Volume 525 bbl

Formation Strength Test Data

Fracture Gradient @ Casing Shoe (6250 feet) 75 psi/ft

Kick Data

SIDPP 525 psi

sice 750 psi

Pit Gain 18 bbl

MW at the time of the kick 11.5 ppg,

NOTE: The well will be killed with pump #2 at 40 SPM using the Wait and Weight Method

Instructor Solution Answer Key

Page 58

Intertek Consulting & Training, IWCF Student Exercise Book

1. Calculate the MAASP using the mud weight of 11.5 ppg

942-950 psi Equation #11 - MAMW = (.75 x 6250) + 0.052 + 6250 = 14.42 ppg

Equation #12 - MAASP = (14.42 — 11.5) x 0.052 x 6250 = 949 psi

2. What mud weight is required to balance formation pressure (round off to 1 decimal)?

125 ppg Equation #13 - Kill Mud Density = (SIDPP = 0.052 + TVD ft) + OMW

(525 + 0.052 + 10550) + 11.5 = 12.45 = 12.5 ppg

3. Calculate the Initial Circulating Pressure (ICP).

1605 psi Equation #14 — ICP = Kill Rate Circulating psi +SIDPP psi

41080 + 525 = 1605 psi

4. Calculate the Final Circulating Pressure (FCP).

1174 __psi Equation #15 — FC arene

125

FE ¥ 1080 = 1174 psi

x Kill Rate Circulating psi

5. Calculate the pump strokes from surface to bit.

1613 - 1645_ strokes Surface to Bit strokes = Drillstring Volume + Pump Output

Drill Collar Vol = .0087 x 900 =7.8 bbls 179.1 + .11 = 1628 strokes

HWOP Vol = .0088 x 465 = 4.1

Drill Pipe Vol = .0174 x 9610 = 167.2

6. Calculate the pump strokes from the mud pump to the bit.

1675 - 1707_ strokes (Drillstring Volume + Surface Lines Volume) + Pump Output

(179.1 + 7.2) +.11 = 1694 strokes

7. Calculate the time in minutes from surface to the bit.

40-41 minutes Circulating Time = Strokes from surface to bit + SPM.

1628 + 40 = 40.7 min

8. Calculate in minutes to pump from the mud pump to the bit.

42-43 minutes Circulating Time = Strokes from mud pump to bit + SPM

1694 + 40 = 42.3 min

9. Calculate the strokes required to pump from the bit to the shoe.

4860-4958 _ strokes Bit to Shoe strokes = Open Hole Annular Volume +

540.2 +11

1911 strokes

10. How many minutes are required to circulate the total well system volume at 40 SPM?

345-346 minutes Girculating Time = Surface to Surface strokes + 40 SPM.

13806 + 40 = 345.1 min

11. Calculate the MAASP with KWM in the system.

617-624 _ psi Equation #12 -New MAASP = (MAMW — KMW) x 0.052 x Casing Shoe TVD

(14.42 ~ 12.5) x 0.052 x 6250 = 624 psi

12. What is the pressure loss per 100 strokes as the KWM is pumped from surface to the bit?

26-27 _psi/100stks Pressure Loss = ICP FCP = 431 psi

Pressure Loss + (Surf to Bit strokes + 100)

431 + 16.28 = 26.5 psi/ 100 stks

Instructor Solution Answer Key Page 59

Intertek Consulting & Training IWCF Student Exercise Book

International Well Control Forum

‘Surface BOP Vertical Well Kill Sheet (API Field Units)

‘FORMATION STRENOTH DATA:

SURFACE LEAK CFF PRESSURE

Forvanonatrenam rest [1399 Jo

Myowecet «TEST @ 1s |e

MAKWRA ALLOWABLE MUO WEOHT =

@- = Te

GHOE TV OEPTHNO DED

Mma Maas =

ko) CURRENT WUD WE GET) x SHOE TV. OEPTH x0.082

are

465_*

300.

THO bass 00

0088 =

08

OP xCASBO. Se

ETT fe el eel oa el

romwessrowoue ——J[eweg 918 ]_s180 ee] 2706

Aci surACE OUALE 25 wal 5250

ora Acme a0 Te fo ed soe] rare

© rok Costing & Ting Unpublished Werk igs reer Page eo

Revision~ 1Nov2012 Version 4

International Well Control Forum

‘Surface BOP Kill Sheet - Vertical Well (API Fleld Units)

}

sere (850) pa sxe C50) i roan [22 Dear

cumenrviowecm - Bee

125. + $50

12575 _ ome 13.59

YURICPRESSURE LOSS

620, + 650+

—_—— 1 ONAUE PRESSURE Loss

}o 00 1000 1500 9gng,2170, |

L nosy 04s ann) 2401209

© Intertek Consuling & Training Unpublished work, All rights reserved Page 61

Revision - 1Nov2012 Version 4

Intertek Consulting & Training IWCE Student Exercise Book

Using the Kill sheet on the previous pages answer the following questions. The well be killed using the

Wait and Weight Method with a pump rate of 30 spm.

ds What mud weight is required to balance the formation pressure?

13.5 __ ppg (round off to 1 decimal)

Equation #13 - Kill Mud Density = (SIDPP

.052 + TVD ft) ++ OMW

(650 + 0.052 + 12575) + 12.5 = 13.49 = 13.5 ppg

2 How many strokes will be required to pump from surface to bit?

2170 __ stks

Surface to Bit Strokes = Drillstring Volume +

216.97 + 10 = 2170 strokes

3. How many strokes are required to pump from the bit to the casing shoe?

2465 stks

ump Output

Bit to Shoe Strokes = Open Hole Annular Volume + Pump Output

246.51 + .10 = 2465 strokes

4. What is the MAASP at the time the well is shut in?

931__ psi

Equation #12 - MAASP = (MAMW ppg ~ Current MW ppg) + 0.052 x Csq Shoe TVD

(14.97 ~ 12.5) x 0.052 x 7250 = 931 psi

5. What is the total annular volume?

601___ bbl

Annular Volume bbls = Open Hole Annular Vol + Cased Hole Vol

246.5 + 354.5 = 601 bbls

6. What is the MAASP once kill mud has been circulated around the well?

554 psi

Equation #12 - New MAASP = (MAMW — KMW) x 0.052 x Csg Shoe TVD

(14,97 - 13.5) x 0.052 x 7250 = 554 psi

7. What is the calculated Final Circulating Pressure?

670__ psi

Equation #15 - FCP = ene x Kill Rate Circulating psi

+55 x 620 = 670 psi

a What is the calculated Initial Circulating Pressure?

1270 __psi

Equation #14 — ICP = Kill Rate Circulating psi +SIDPP psi

620 + 650 = 1270 psi

9. Approximately how much time will it take to completely displace the well with KWM?

272__ minutes

Circulating Time = Surface to Surface strokes + 30 SPM

8180+ 30 = 272.6 min

Instructor Solution Answer Key Page 62

Intertek Consulting & Training IWCF Student Exercise Book

GAUGE EXERCISES

Using the completed kill sheet, circle the first action that you would take based on the situations

presented. Take note of all parameters before making your decision

Pump strokes

Pump rate

Drill pipe pressure

Casing pressure

Drill Pipe Pressure Casing Pressure

10, 20, 30. 40

lapsed tit

PT Tol cont 0 ss

Instructor Solution Answer Key Page 63

Intertek Consulting & Training IWCE Student Exercise Book

4. After 2 minutes this

is the situation. What should you do?

‘A. Keep opening the choke slowly

B. Keep closing the choke slowly

C. Increase the pump rate (Correct Answer)

D. Decrease the pump rate

E. Continue, everything is OK

850

Drill Pipe Pressure Casing Pressure

Elapsed time

00 Hrs 02 Mins

Instructor Solution Answer Key Page 64

Intertek Consulting & Training IWCF Student Exercise Book

2. Everything is OK....or is it? Should you

A

B.

e

D.

E,

Continue, everything is OK

Open the choke a little

Close the choke a little (Correct Answer)

Adjust the pump rate

Stop pumping and close the choke

Drill Pipe Pressure Casing Pressure

10, 20, 30. 40

|_| [3{[offo| 00 Hrs 10 Mins

Elapsed time

Instructor Solution Answer Key Page 65

Intertek Consulting & Training.

IWCF Student Exercise Book

3. After about 17 minutes this is what you observe. What action should you take?

A.

B,

Cc.

D.

E

Open the choke a little

Close the choke a little

Inctease the pump rate

Decrease the pump rate

Continue, everything is OK (Correct Answer)

Drill Pipe Pressure Casing Pressure

10, 20, 30, 40

Elapsed ti

LT sof ol) cote urs

Instructor Solution Answer Key

Page 66

Intertek Consulting & Training IWCF Student Exercise Book

4. After 850 strokes this is the situation. What should you do?

Increase the pump speed

Decrease the pump speed

Close the choke slowly (Correct Answer)

Open the choke slowly

moopp

Continue, everything is OK

Drill Pipe Pressure Casing Pressure

10,20, 30. 40

| | lIs|[5]o} 00 Hrs 28 Mins

Elapsed time

Instructor Solution Answer Key Page 67

Intertek Consulting & Training

IWCF Student Exercise Book

5. Everything seems to be going smoothly until you notice a sudden rise in both

pressures. What has caused this problem?

A.

moog

The choke is plugging (Correct Answer)

The choke is washing out

There is a washout in the string

Abit nozzle has plugged

Abit nozzle has washed out

The problem in the case above has been corrected

Drill Pipe Pressure Casing Pressure

10,20, 30. 40

Elapsed time

| }j2}/5}]o}/0| 00 Hrs 50 Mins

Instructor Solution Answer Key

Page 68

Intertek Consulting & Training IWCF Student Exercise Book

6. Based on what you see at right, what action should be taken?

A. Increase the pump speed

Decrease the pump speed

Close the choke slowly (Correct Answer)

Open the choke slowly

Continue, everything is OK

moo®D

750

Drill Pipe Pressure Casing Pressure

10, 20,30. 40

Elapsed time

| |[+][s]/o]/0| 01 Hrs 00 Mins

Instructor Solution Answer Key Page 69

Intertek Consulting & Training IWCF Student Exercise Book

7. This is the situation after 3000 strokes. What should you do?

‘A. Increase the pump speed

B. Decrease the pump speed

C. Close the choke slowly (Correct Answer)

D. Open the choke slowly

E. Continue, everything is OK

Drill Pipe Pressure Casing Pressure

10, 20, 30. 40

>

PVs folfofol} rin sors

Instructor Solution Answer Key Page 70

Intertek Consulting & Training IWCF Student Exercise Book

8. The pit volume is increasing and casing pressure is rising. Should you..

A.

mpoo

Increase the pump speed

Decrease the pump speed

Close the choke slowly

Open the choke slowly (Correct Answer)

Continue, everything is OK

Drill Pipe Pressure Casing Pressure

10 20, 30, 40

| Hs fojfofol} os tes20 mins

Elapsed time

Instructor Solution Answer Key Page 71

Intertek Consulting & Training

IWCF Student Exercise Book

9. This is the situation after 8000 strokes. The pit level is now dropping. You

could have loss of circulation. What are you going to do?

A

B.

c.

D.

E

Increase the pump speed

Decrease the pump speed

Close the choke slowly

Open the choke slowly

Continue, everything is OK (Correct Answer)

50

Drill Pipe Pressure Casing Pressure

10.20, 30. 40

Elapsed time

| Wso]olo}) 04 tes 27 wins

Instructor Solution Answer Key

Page 72

Intertek Consulting & Training IWCF Student Exercise Book

10. The choke is now fully open but it is difficult to determine whether there is any

pressure on the casing. What should you do?

A

moog

Increase the pump speed

Decrease the pump speed

Close the choke a little

Stop pumping and close in the well (Correct Answer)

Continue pumping at 30 spm

Drill Pipe Pressure Casing Pressure

10, 20,30. 40

lapsed tit

LPs sfofol) os tres7 sins

Instructor Solution Answer Key Page 73

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Genesys Character Sheet (Form Fill Dice Pools)Document5 pagesGenesys Character Sheet (Form Fill Dice Pools)ElrohirPendragonNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Global Production Report 2018Document36 pagesGlobal Production Report 2018ElrohirPendragonNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- IWCF Workbook Instructor Solution Key - Day 3 Part IIIDocument20 pagesIWCF Workbook Instructor Solution Key - Day 3 Part IIIElrohirPendragon50% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- IWCF Workbook Instructor Solution KeyDocument32 pagesIWCF Workbook Instructor Solution KeyElrohirPendragon80% (5)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- IWCF Workbook - DB - (All Questions)Document135 pagesIWCF Workbook - DB - (All Questions)ElrohirPendragon100% (2)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 105bbe7a 78a3f9Document2 pages105bbe7a 78a3f9ElrohirPendragonNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- IWCF Workbook Instructor Solution Key - Day 3 Part IIDocument19 pagesIWCF Workbook Instructor Solution Key - Day 3 Part IIElrohirPendragonNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 33 - IWCF Workbook Instructor Solution Key - Day 3 Part I - DB - 23 Dec 14 PDFDocument23 pages33 - IWCF Workbook Instructor Solution Key - Day 3 Part I - DB - 23 Dec 14 PDFElrohirPendragon100% (4)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 31 - IWCF Workbook Instructor Solution KeyDocument17 pages31 - IWCF Workbook Instructor Solution KeyElrohirPendragon100% (3)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Drilling Levels 3 and 4 Syllabus PDFDocument35 pagesDrilling Levels 3 and 4 Syllabus PDFGOKUL PRASADNo ratings yet

- Well Control Pre-Kick Sheet CalculationsDocument4 pagesWell Control Pre-Kick Sheet CalculationsElrohirPendragonNo ratings yet

- Drilling Formula SheetDocument4 pagesDrilling Formula SheetPavin PiromNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 8.IWCF Worked Questions and Answers PDFDocument10 pages8.IWCF Worked Questions and Answers PDFElrohirPendragon67% (6)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Subsea BOP Stack Operations API - Vertical Well Kill SheetDocument2 pagesSubsea BOP Stack Operations API - Vertical Well Kill Sheetittehad100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Subsea BOP Stack Operations API - Deviated Well Kill SheetDocument3 pagesSubsea BOP Stack Operations API - Deviated Well Kill SheetMannattil Krishna KumarNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Fast, Easy To Use Assessment Tool: Bowtie Pro™Document21 pagesThe Fast, Easy To Use Assessment Tool: Bowtie Pro™ElrohirPendragonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)