Professional Documents

Culture Documents

Turbocharged Single Cylinder Si Engine: Abstract

Uploaded by

Kartikey GuptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbocharged Single Cylinder Si Engine: Abstract

Uploaded by

Kartikey GuptaCopyright:

Available Formats

International Journal of Advanced Technology & Engineering Research (IJATER)

1st International Conference on Research in Science, Engineering & Management (IOCRSEM 2014)

TURBOCHARGED SINGLE CYLINDER SI

ENGINE

Abhishek Saini

Indian Institute of Technology, Patna

makeabhishek@gmail.com

Prakash Shakti

Doon College of Engineering & technology,Dehradun (U.K.)

E-mail- prakashshakti91@gmail.com

Himanshu Kulshrestha

Doon College of Engineering & technology,Dehradun (U.K.)

E-mail- hkul08@gmail.com

Abstract— as Stunner in the Indian market. In India, it has two

variants, the carburetor version simply called Stunner.

To start with, a study on the effect of turbocharger on a

single cylinder is made. The design and installation of

turbocharger in a single cylinder is available in this

literature.

We have designed and fabricated a prototype of the

Turbocharger was implemented in Two- wheeler, In

which the efficiency of the Engine can be increased .

KEYWORDS: Gasoline Engine, Exhaust Manifold,

Intake Manifold, Turbocharger, Nozzle, Flanges, K &

N Air Filter, Carburetor, Turbine, Compressor.

Volumetric Efficiency of a S.I. or C.I. Engine is

increased by providing combustion chamber with

maximum amount of air. This is achieved by

installation of Turbocharger or Supercharger.

Supercharger uses engine power to run itself whereas a

Turbocharger doesn’t utilize any engine power it runs

by Exhaust gases.

In present work we’ll be increasing the volumetric

efficiency of a 125cc single cylinder bike by installation Figure No. 1 Assembled Turbocharger

of turbocharger.

To start with, a study on the effect of turbocharger on a

single cylinder is made. The design and installation of

WORKING OF TURBOCHARGER

turbocharger in a single cylinder is available in this Since the power a piston engine can produce is directly

literature. dependent upon the mass of air it can ingest, the

purpose of forced induction (turbo-supercharging and

supercharging) is to increase the inlet manifold pressure

INTRODUCTION and density so as to make the cylinders ingest a greater

In turbocharging, the turbocharger is being driven by a mass of air during each intake stroke. A supercharger is

gas turbine using the energy in exhaust gases. The an air compressor driven directly by the engine

major parts of turbocharger are turbine wheel, turbine crankshaft, and as such, consumes some of the power

housing, turbo shaft, comp. wheel, comp. housing & produced by the combustion of fuel, thereby increasing

bearing housing. BSFC and engine wear for a given amount of produced

A 4-stroke S.I. Engine is an engine that uses gasoline as power.

fuel. S.I.engine is a spark ignited engine that is the A turbocharger consists of a single-stage radial-flow

combustion is carried out by spark ignition, it is (―centrifugal‖) compressor (air pump), which is driven

achieved by installation of spark plug on cylinder head. by a single-stage radial-flow turbine, instead of being

In this project we are using Honda Stunner CBF 125cc driven directly by the crankshaft. The turbine extracts

for the installation of turbocharger. The CBF125 is a wasted kinetic and thermal energy from the high-

motorcycle manufactured by Honda's Indian temperature exhaust gas flow and produces the power to

subsidiary HMSI. The motorcycle is known drive the compressor, at the cost of a slight increase in

pumping losses.

© IJATER (IOCRSEM- 2014) 110

International Journal of Advanced Technology & Engineering Research (IJATER)

1st International Conference on Research in Science, Engineering & Management (IOCRSEM 2014)

HOW TURBOCHARGER WORKS WORKING PRINCIPLE

A turbocharger consists of a turbine and a compressor

on a shared shaft. The turbine converts heat to rotational

force, which is in turn used to drive the compressor.

The compressor draws in ambient air and pumps it in to

the intake manifold at increased pressure, resulting in a

greater mass of air entering the cylinders on each intake

stroke.

The output of the engine exhaust gas is given to the

input of the turbine blades, so that the pressurized air

produced. This power, the alternate power must be

much more convenient in availability and usage. The

next important reason for the search of effective,

unadulterated power are to save the surrounding

environments including men, machine and material of

both the existing and the next fourth generation from

pollution, the cause for many harmful happenings and

to reach the saturation point.

We have designed and fabricated a prototype of the

Turbocharger was implemented in Two- wheeler, In

which the efficiency of the Engine can be increased.

Figure No. 2 Turbocharger Working Thus we have developed a method to increase the

efficiency of the engine and at the same time to control

INSTALLATION OF the Emissions from the engine. The experimental setup

of block diagram shows the arrangement of

TURBOCHARGER turbocharger in two- wheeler. This type of engine will

Steps for installation be more efficient than existing engine

1. Connect the turbo inlet with engine exhaust port

with the help of studd nut & welding.

2. The turbine shaft is connected to a compressor,

which draws in combustion air, compresses it, and

then supplies it to the engine.

3. Now connect air filter with turbo compressor

section.

4. Connect turbo air inlet with hos pipe with bike air

cleaner.

5. Now connect carburetor with air cleaner & with

engine.

6. Connect silencer with waste gate from where the

waste gas will flow.

Figure No.4 Installed Turbocharger

PART USED

Here is the list of hardware used in our project.

125cc Engine Bike

Turbocharger

Air Filter

Radiator

Oil line & Oil Pump

Figure No. 3 Turbocharger layout Batter

© IJATER (IOCRSEM- 2014) 111

International Journal of Advanced Technology & Engineering Research (IJATER)

1st International Conference on Research in Science, Engineering & Management (IOCRSEM 2014)

I.C ENGINE

Internal combustion engines are those heat engines that

burn their fuel inside the engine cylinder. In internal

combustion engine the chemical energy stored in their

operation. The heat energy is converted in to

mechanical energy by the expansion of gases against

the piston attached to the crankshaft that can rotate.

SPARK IGNITION ENGINE

A spark ignition (SI) engine runs on an Otto cycle—

most gasoline engines run on a modified Otto cycle.

This cycle uses a homogeneous air-fuel mixture which Figure No.6 Radiator

is combined prior to entering the combustion chamber.

Once in the combustion chamber, the mixture is OIL LINE & OIL PUMP

compressed, and then ignited using a spark plug (spark

ignition). The SI engine is controlled by limiting the We are using oil line for good & smooth working of

amount of air allowed into the engine. This is turbocharger. In this case we are using 10W40 mineral-

accomplished through the use of a throttling valve based oil. Oil pump is used to supply of oil into the

placed on the air intake (carburetor or throttle body). turbocharger.

AIR FILTER

For instance the air filters in your bike; their basic

function is to prevent dust from entering the engine,

which could cause serious damage to the performance

of the bike. And if your bike is fitted with paper filter

then change it regularly according to the instructions

given by the manufacturer.

Figure No. 7 Oil Line

BATTERY

Battery is use to supply of current into the oil line & in

oil pump. We are using 12v lead acid battery for supply

of current.

Figure No. 5 Air Filter

RADIATOR

Radiators are heat exchangers used for cooling internal

combustion engines, mainly in automobiles but also Figure No. 8 Battery

in aircraft, railway, motorcycles, stationary generating

plant or any similar use of such an engine. ANALYSIS OF TURBOCHARGER

Internal combustion engines are often cooled by

circulating a liquid called engine coolant through Here Analysis of Turbocharger done with Ansys for

the engine block, where it is heated, then through a determining the variation of stresses, strains and

radiator where it loses heat to the atmosphere, and then deformation across turbo. An attempt has been made to

returned to the engine. Engine coolant is usually water- investigate the effect of temperature, pressure and

based, but may also be oil. It is common to employ a induced stresses on the impeller. By identifying the true

water pump to force the engine coolant to circulate, and design feature, the extended service life and long term

also for an axial fan to force air through the radiator. stability is assured.

© IJATER (IOCRSEM- 2014) 112

International Journal of Advanced Technology & Engineering Research (IJATER)

1st International Conference on Research in Science, Engineering & Management (IOCRSEM 2014)

Table No.3 Model > Static Structural > Solution >

Results

Object Name Equivalent Total

Stress Deformation

State Solved

Scope

Geometry All Bodies

Definition

Type Equivalent

Total Deformation

(von- Mises) Stresses

Display Time End Time

Results

Minimum 39.904 Pa 0. m

Figure No. 9 Analysis Maximum 2.454e+007 Pa 2.9491e-006

m

Table No.2 Aluminium Alloy > Strain-Life Parameters Minimum Occurs On Solid

Maximum Occurs On Solid

Strength Coefficient Pa 9.2e+008

Strength Exponent -0.106 Information

Ductility Coefficient 0.213

Ductility Exponent -0.47 Time 1. s

Load Step 1

Cyclic Strength Coefficient Pa Sub step 1

1.e+009 Iteration Number 1

Cyclic Strain Hardening

Exponent Graph No. 2 Alternating Stresses

0.2

Table No.1 Aluminium Alloy > Constants

Structural

Young's Modulus 2.e+011 Pa

Poisson's Ratio 0.3

Density 7850. kg/m³

Thermal Expansion 1.2e-005 1/°C

Tensile Yield Strength 2.5e+008 Pa

Compressive Yield Strength 2.5e+008 Pa

Tensile Ultimate Strength 4.6e+008 Pa

Compressive Ultimate Strength 0. Pa

Thermal

Thermal Conductivity 237. W/m·°C

Specific Heat 434. J/kg·°C

Electromagnetics

Relative Permeability 10000

Resistivity 1.7e-007 Ohm

or Turbocharger 1 materials investigation is done using

static analysis.

© IJATER (IOCRSEM- 2014) 113

International Journal of Advanced Technology & Engineering Research (IJATER)

1st International Conference on Research in Science, Engineering & Management (IOCRSEM 2014)

Graph No.1 Strain Life Parameters the compressor material is withstand up to the (482.61

HZ) with the minimum stress (32.981 MPA) for the

compressor material incoloy alloy 909 and the turbine

material is withstand up to the (773.58 HZ)

With the minimum stress (171.01 MPA) for the turbine

material Inconel alloy 740.

Table No.4 Model > Static Structural > Loads

Figure No. 10 analysis for compressor

State Fully Defined

Scope

Scoping Method Geometry Selection

Geometry 16 Faces 2 Faces

Definition

Type Fixed Support Pressure

Suppressed No

Define By Normal To

Magnitude 4.e+005 Pa

(ramped)

3.5464e+005 Pa (ramped) 25000 Pa (ramped) Figure No. 11 Analysis of Turbine Wheel

AIR INLET & EXHAUST PRESSURE ENGINE ANALYSIS

Air inlet pressure into air cleaner & in engine = 0.3 Engine Ideal RPM: - 1400 RPM

bar ( Normal Condition ) Maximum Engine RPM: - 12000 RPM

Air inlet pressure into air cleaner & in engine = 0.2 Turbocharger RPM: - 20000 RPM

bar ( Turbocharged Condition ) Average Increased: - 8 Km*

For our analysis it is 0.25 bar or 25000.0 Pa (Under Specific Conditions)

Engine exhaust gas pressure = 4 bar or 400000.0 Pa

Air inlet through Air filter = .35 Atm or 35000.0 Pa Specific Conditions

Engine RPM = 3000 RPM

COMPRESSOR & TURBINE ANALYSIS Turbocharger RPM = 18000 RPM

For Compressor the minimum von mises stress (32.981 Weight on Bike = 40 kgs

MPA) is obtained for the material incoloy alloy Vehicle Speed = 40 Kmph

909.And the maximum frequency (482.61 HZ) is Tested in Vacuum & Frictionless Surface.

obtained for the material incoloy alloy 909.For Turbine 1. A nozzle whose big end dia is equal to dia of

the minimum von mises stress (171.01 MPA) is exhaust manifold.

obtained for the material Inconel alloy 740.And in the 2. Nozzle dia is equal to ¼ of exhaust valve dia which

frequency comparing to the compressor maximum is equal to 7.475 mm.

frequency (482.61 HZ) for incoloy alloy 909. And the 3. Nozzle attached with 2 flanges equivalent to dia of

turbine three materials frequencies Inconel alloy 740 – exhaust manifold.

(773.58 HZ); Inconel alloy 783- (679.12 HZ); wrought 4. Nozzle attached to exhaust side inlet of T.C.

aluminum alloy 2219 – (887.16 HZ); are more than 5. Exhaust attached to outlet side of T.C.

compressor maximum frequency (482.61 HZ). so that 6. A.F attached to inlet side of comp. side of T.C.

© IJATER (IOCRSEM- 2014) 114

International Journal of Advanced Technology & Engineering Research (IJATER)

1st International Conference on Research in Science, Engineering & Management (IOCRSEM 2014)

7. Pipe attached to carb. Just before carb. From outlet which do not require pre-mixing of mobile oil in petrol

side of comp. side of T.C. as lubricant.

RESULT & CONCLUSION The characteristic curve for Honda engine with and

without turbocharger (Improving efficiency) is shown

The Carbon monoxide Hydrocarbon and Nitrogen oxide in Graph below.

at full acceleration conditions and (Air fuel) at idling Graph No. 3 Characteristics Curve for Honda Engine

conditions for some selected gasoline vehicles were with & Without Turbocharger

also monitored to access the change in emission

characteristics. The emission measurement of Honda

Engine (withoutTurbo-charger) by using gas analyzer.

Table No. 5 Emission Measurement of Honda Engine

(Without Turbocharger)

During full throttling 52%ofscootersand

47%ofmotorbikeswere found emitting HC not within

The exhaust emissions of gasoline-powered vehicles for the prescribed national standard of 2000PPM.

CO and Hydrocarbon were monitored using an The low percentage of scooters emitting Hydrocarbon

Automotive Emission Analyzer MEXA-584L idling in the said range might be attributed to the fact that all

conditions, 1/4 throttling, 1/2 throttling, 3/4 throttling scooter stested were having two stroke engines while

and full throttling conditions. The MEXA-584L a few models of motor bikes had four strokes engine as

simultaneously measures CO, HC, CO (non-dispersive well which do not require pre-mixing of mobile oil in

infrared: NDIR) and air-to- fuel ratio (AFR) or excess petrol as lubricant.

air ratio (A) in idle state. It optionally measures O, NO,

engine speed (RPM) and oil temperature (TEMP) CONCLUSION

Table No. 6 Emission Measurement of Honda Engine We have designed and fabricated a prototype of the

(With Turbocharger) Turbocharger was implemented in Two- wheeler, In

which the efficiency of the Engine can be increased

.Thus we have developed a method to increase the

efficiency of the engine and at the same time to control

the Emissions from the engine. The experimental setup

of block diagram shows the arrangement of

turbocharger in two- wheeler. This type of engine will

be more efficient than existing engines.

This work is an attempt to reduce our dependency on

foreign oil and reduce the tailpipe emission from

automobiles and this was an attempt to design and

implement this new technology that will drive us into

the future. Use of production turbo charger will reduce

smog- forming pollutants over the current national

average. The first hybrid on the market will cut

emissions of global-warming pollutants by a third to a

During half throttling about 90% of scooters and 93% half and later modes may cut emissions by even more.

of motor bikes were found emitting HC within the

prescribed national standard of 2000 PPM. The low

percentage of scooters emitting Hydrocarbon in the said

range might be attributed to the fact that all scooters

tested were having two stroke engines while a few

models of motor bikes had four strokes engine as well

© IJATER (IOCRSEM- 2014) 115

International Journal of Advanced Technology & Engineering Research (IJATER)

1st International Conference on Research in Science, Engineering & Management (IOCRSEM 2014)

ADVANTAGES

BENEFITS OF • More power compared to the same size naturally

TURBOCHARGING aspirated engine.

• Better thermal efficiency over naturally aspirated

• Increased engine power output (in the region of

engine and super charged engine, because the

50%increase).

engine exhaust is being used to do the useful work

• Improved fuel consumption on (improved pressure

which otherwise would have been wasted.

balance across the engine.

• Better Fuel Economy by the way of more power

• Altitude compensation.

and torque from the same sized engine. A century

• A very high percentage of two wheel gasoline

of development and refinement—for the last

vehicles (48%)were found not complying with the century the SI engine has been developed and used

prescribed National Emission Standards. The widely in automobiles.

increase in Carbon monoxide and Hydro carbon • Continual development of this technology has

emissions by two wheel gasoline engine sat

produced an engine that easily meets emissions and

accelerated engine speed was quite significant.

fuel economy standards. With current computer

• About90%ofscootersand85%ofmotorbikes were

controls and reformulated gasoline, today’s engines

found emitting CO within the prescribed national

are much more efficient and less polluting than

standard of 4.5%. About 33% of scooters and 83%

those built 20 years ago.

of motor bikes were found emitting Hydrocarbon

• Low cost–The SI engine is the lowest cost engine

within 2000ppm.

because of the huge volume currently produced.

• Duringhalfthrottlingabout90%ofscooters and • High Thermal efficiency.

93%ofmotorbikes were found emitting HC within

• Better Volumetric efficiency.

the prescribed national standard of 2000PPM.

• High speed obtained.

• Duringfullthrottlingabout52%ofscootersand

• Better average obtained.

47%ofmotorbikeswerefoundemittingHC not within

• Eco-friendly

the prescribed national standard of 2000PPM.

• It was observed that the Carbon monoxide

emissions from two wheel vehicles increased from DISADVANTAGES

two to three times at the full acceleration engine

Bike cost will increase.

conditions.

Engine weight will increase.

• It was observed that the Hydrocarbon emissions

If there will be improper maintenance then there will be

from two wheel vehicles increased from two to

problem in turbo such as turbo lag.

four times at the full acceleration engine

conditions.

• By the use of turbo charging in two wheelers the REFERENCE

power can be enhanced. A properly tuned turbo 1. Books of Automobile Engineering

engine can produce 20% + more power compared 2. BGuide From Internet

to stock but expect an increase in fuel consumption. 3. Books of IC Engine

• More power compared to the same size naturally

aspirated engine.

• Better thermal efficiency over naturally aspirated

engine and super charged engine because the

engine exhaust is being used to do the useful work

which otherwise would have been wasted.

• Automotive oil condition monitoring is far from a

mature technology. As this technology progresses

and becomes more popular in the auto motive

industry, there will be many generations of sensors

developed to improve accuracy and range of

capability.

• While some vehicles come standard with oil

change technologies today, the majority do not.

The companies developing these sensor

technologies must be able to convince the

automotive industry and the public of their general

reliability and value. If this is successful, we may

see condition-based oil changes become the latest

trend in vehicle technology over the next few years.

© IJATER (IOCRSEM- 2014) 116

You might also like

- Turbocharged Single Cylinder Si Engine: October 2014Document8 pagesTurbocharged Single Cylinder Si Engine: October 2014Aditya SomakNo ratings yet

- Turbocharged Single Cylinder Si Engine: October 2014Document8 pagesTurbocharged Single Cylinder Si Engine: October 2014vineet nangiaNo ratings yet

- Performance Analysis of Ic Engine Using Supercharger and Turbocharger-A ReviewDocument6 pagesPerformance Analysis of Ic Engine Using Supercharger and Turbocharger-A ReviewSOMESH SHARMA (B15ME036)No ratings yet

- Design and Analysis of Turbochargers: March 2016Document12 pagesDesign and Analysis of Turbochargers: March 2016Irah ZinirahNo ratings yet

- 17ME655-Module 4 PDFDocument40 pages17ME655-Module 4 PDFVinayakNo ratings yet

- researchpaper2016Document7 pagesresearchpaper2016Aditya YadavNo ratings yet

- Turbocharging of Ic EnginesDocument5 pagesTurbocharging of Ic EnginesKrishna MurthyNo ratings yet

- TurbochargingDocument18 pagesTurbochargingmhawan104No ratings yet

- Me66 Plate 4 CaseresDocument17 pagesMe66 Plate 4 CaseresVan Eldridge Kyle CaseresNo ratings yet

- Performance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol EngineDocument8 pagesPerformance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol Engineashan19800217No ratings yet

- A. R. Gunaki, "Analysis of Diesel Engine Turbocharger & Its Optimization", International Journal For Scientific Research & Development PDFDocument6 pagesA. R. Gunaki, "Analysis of Diesel Engine Turbocharger & Its Optimization", International Journal For Scientific Research & Development PDFvignesh ranaNo ratings yet

- Mechanical Project TurbochargerDocument12 pagesMechanical Project Turbochargerinduscad100% (6)

- 8 1turbochargerDocument24 pages8 1turbochargerkedir67No ratings yet

- Supercharging and Turbocharging SystemDocument22 pagesSupercharging and Turbocharging SystemArif Nur Cahyono O9373No ratings yet

- Himanshu Singh Turbocharger-SeminarDocument20 pagesHimanshu Singh Turbocharger-SeminarHimanshu SinghNo ratings yet

- Seminer 6TH Sem PDFDocument22 pagesSeminer 6TH Sem PDFChievete pfunoNo ratings yet

- Turbocharger WorkshopDocument22 pagesTurbocharger Workshop2K20CO287 Naman JainNo ratings yet

- 001 Turbo ChargerDocument26 pages001 Turbo ChargerfrankNo ratings yet

- Turbo Jet EngineDocument22 pagesTurbo Jet Engineb.vishwa.nayakNo ratings yet

- Vtec and Ivtec ComparisionDocument12 pagesVtec and Ivtec ComparisionAjithNo ratings yet

- Boost Engine Power with Turbochargers & SuperchargersDocument21 pagesBoost Engine Power with Turbochargers & SuperchargersB Bala Venkata GaneshNo ratings yet

- Mechanical Superchargers Presentation ReportDocument15 pagesMechanical Superchargers Presentation ReportPranjal Choudhary100% (1)

- Supercharger ReportDocument24 pagesSupercharger ReportRohit RajNo ratings yet

- Week 2-Topic 4-PPlantsME406 PDFDocument11 pagesWeek 2-Topic 4-PPlantsME406 PDFMuhammad MustafaNo ratings yet

- Seminar Report On "Turbocharger and Performances of IC Engines" Submitted To TheDocument24 pagesSeminar Report On "Turbocharger and Performances of IC Engines" Submitted To TheTejas UpadhyeNo ratings yet

- AkooDocument14 pagesAkooHASHIMU BWETENo ratings yet

- Turbocharger Characteristics Analysis of 93 KW Marine Diesel EngineDocument6 pagesTurbocharger Characteristics Analysis of 93 KW Marine Diesel EngineFrank ChukwujiNo ratings yet

- Supercharger & TUrbocharger - HemanshuDocument14 pagesSupercharger & TUrbocharger - HemanshuDnyaneshwar AkhareNo ratings yet

- Design of Turbocharger in Petrol Engine With Intercooler and Discharger ChamberDocument8 pagesDesign of Turbocharger in Petrol Engine With Intercooler and Discharger ChamberDeadman RoyNo ratings yet

- Mihir SuperchargeDocument21 pagesMihir Superchargecewaja2731No ratings yet

- 5-Supercharging and Turbocharging of I-C Engine - GROUP 9-1Document38 pages5-Supercharging and Turbocharging of I-C Engine - GROUP 9-1azlaljamil17No ratings yet

- Turbocharger Basics - What is a TurbochargerDocument18 pagesTurbocharger Basics - What is a TurbochargerShrwan Gyawali100% (3)

- Gas Turbine Engine Efficiency AnalysisDocument12 pagesGas Turbine Engine Efficiency AnalysisSaad mubeenNo ratings yet

- Ch-12 - Turbocharger & Super MecDocument29 pagesCh-12 - Turbocharger & Super Mecahmed jemalNo ratings yet

- What Is Forced Induction?Document15 pagesWhat Is Forced Induction?Fugaru Paul - AlexandruNo ratings yet

- Turbocharger Mini Project FinalDocument33 pagesTurbocharger Mini Project FinalNaveenNo ratings yet

- DRDO - Improvements in Aircraft Gas Turbine EnginesDocument4 pagesDRDO - Improvements in Aircraft Gas Turbine EnginesSouravkavinannanNo ratings yet

- Supercharger PDFDocument20 pagesSupercharger PDFrishirajtomar87% (30)

- Design Methodology For Compressed Air EngineDocument7 pagesDesign Methodology For Compressed Air EngineShashank SrivastavaNo ratings yet

- Feasibility of A Thrust Control Mechanism by Regulating The Flow at The EngineDocument9 pagesFeasibility of A Thrust Control Mechanism by Regulating The Flow at The EngineIJRASETPublicationsNo ratings yet

- Kumaran 3Document4 pagesKumaran 3HANUMANT MORENo ratings yet

- Turbocharger Analysis: October 2017Document8 pagesTurbocharger Analysis: October 2017Wai YanNo ratings yet

- Final Year Technical Seminar: Department of Mechanical EngineeringDocument10 pagesFinal Year Technical Seminar: Department of Mechanical EngineeringNagabhushanaNo ratings yet

- Supercharging: Superchargers & TurbochargersDocument11 pagesSupercharging: Superchargers & TurbochargersAkhil Here100% (1)

- Supercharger and TurbochargerDocument24 pagesSupercharger and Turbochargerihtisham reshamNo ratings yet

- Turbo Charger - ProjectDocument36 pagesTurbo Charger - ProjectSam Sams100% (2)

- Technical Seminar On: "SuperchargersDocument17 pagesTechnical Seminar On: "SuperchargersSiddarth NNo ratings yet

- Description: Necessity of Turbocharger and SuperchargerDocument16 pagesDescription: Necessity of Turbocharger and SuperchargerMelvin MhdsNo ratings yet

- Air Induction For Diesel Engines3Document8 pagesAir Induction For Diesel Engines3Musa TandiarrangNo ratings yet

- Final SuperchargerDocument20 pagesFinal SuperchargerSuraj nayakNo ratings yet

- Everything You Need to Know About SuperchargersDocument20 pagesEverything You Need to Know About SuperchargersAnand KumarNo ratings yet

- Internal Combustion Engine Turbocharger and Supercharger GuideDocument65 pagesInternal Combustion Engine Turbocharger and Supercharger Guidezia malikNo ratings yet

- Stress Analysisofa Centrifugal Super ChargerImpeller BladeDocument5 pagesStress Analysisofa Centrifugal Super ChargerImpeller BladeInternational Journal of computational Engineering research (IJCER)No ratings yet

- TurbochargingDocument7 pagesTurbochargingTsihatesfaNo ratings yet

- Abstract:: Supercharging of I.C. EnginesDocument15 pagesAbstract:: Supercharging of I.C. Enginesjui100% (1)

- Supercharging System Chap 4 Fall 2019 PDFDocument10 pagesSupercharging System Chap 4 Fall 2019 PDFSergen SerinNo ratings yet

- Hybrid TurbochargersDocument7 pagesHybrid Turbochargersanon_47328873429% (7)

- MOTOCHARGER - MOTORCYCLE WITH TURBOCHARGERDocument14 pagesMOTOCHARGER - MOTORCYCLE WITH TURBOCHARGERshathakhassanNo ratings yet

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Kalinga Colleges of Science and Technology Inc Provincial RD, P5 Bulanao, Tabuk City Kalinga 3800Document5 pagesKalinga Colleges of Science and Technology Inc Provincial RD, P5 Bulanao, Tabuk City Kalinga 3800Jaden Fate SalidaNo ratings yet

- Chains and BeltsDocument14 pagesChains and BeltsJoselito GarciaNo ratings yet

- Effectiveness of PNP Checkpoint in Reducing Road ViolationDocument29 pagesEffectiveness of PNP Checkpoint in Reducing Road ViolationRonel DayoNo ratings yet

- YamahaDocument10 pagesYamahakoolmanojsainiNo ratings yet

- AE Paper B TechDocument3 pagesAE Paper B TechgoreabhayNo ratings yet

- Daytona 675 OHB ENDocument130 pagesDaytona 675 OHB ENAdrián CasarrubiasNo ratings yet

- Extra Unit-Highway CodeDocument5 pagesExtra Unit-Highway CodeBelen MartinezNo ratings yet

- Zusatz-Bedienungsanleitung Supplementary Instructions: CUBE EPO PedelecDocument54 pagesZusatz-Bedienungsanleitung Supplementary Instructions: CUBE EPO PedelecCarlos ChiaNo ratings yet

- Tuneecu Android: Warning !! Use Tuneecu Only For Motorcycle Listed On The Compatibility ListDocument4 pagesTuneecu Android: Warning !! Use Tuneecu Only For Motorcycle Listed On The Compatibility ListfebriNo ratings yet

- Designing and Calculation of foldable e-bicycleDocument29 pagesDesigning and Calculation of foldable e-bicycleRohini ShindeNo ratings yet

- AD-8 Design Brief 28.04.2023Document4 pagesAD-8 Design Brief 28.04.2023kareemulllahNo ratings yet

- Intro Chem Processes Regina Murphy SolutionsDocument2 pagesIntro Chem Processes Regina Murphy SolutionsLaura Perez Niño0% (2)

- Emailing 2017-bmw-r-1200-gs-71547 PDFDocument229 pagesEmailing 2017-bmw-r-1200-gs-71547 PDFsok panNo ratings yet

- Fsae 2009 Report FINALDocument8 pagesFsae 2009 Report FINALHridheek Reddy100% (1)

- Arsenates: ENGG302 Coursework Assessment 4Document2 pagesArsenates: ENGG302 Coursework Assessment 4Safeer IqbalNo ratings yet

- XII Class field trip bus schedule and observation groupsDocument3 pagesXII Class field trip bus schedule and observation groupsMuhammad Ihsan HabibullohNo ratings yet

- Electronic ScotorDocument33 pagesElectronic ScotorNitinAgnihotriNo ratings yet

- Designing an Electric Scooter for Rural and Urban AreasDocument17 pagesDesigning an Electric Scooter for Rural and Urban AreasVarun KumarNo ratings yet

- Fitting Instruction Fitting Instructions: From ManufacturerDocument2 pagesFitting Instruction Fitting Instructions: From ManufacturerTash LNo ratings yet

- Blackstone TEK: 5 Split Spoke Carbon Fiber WheelsDocument6 pagesBlackstone TEK: 5 Split Spoke Carbon Fiber Wheels杨广斌No ratings yet

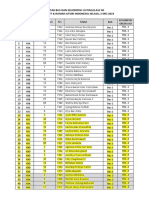

- Data of Strategic Grouping Bike IndustryDocument4 pagesData of Strategic Grouping Bike IndustryAjinkya AdhikariNo ratings yet

- Assignment Week 14 by Anki PagamoDocument11 pagesAssignment Week 14 by Anki PagamoAnki pagamoNo ratings yet

- JASO Engine Oil Standards Implementation Panel Document Motorcycle Oil ListDocument45 pagesJASO Engine Oil Standards Implementation Panel Document Motorcycle Oil ListPacific LibertyNo ratings yet

- The Man Who EscapedDocument18 pagesThe Man Who EscapedPaulo MorsNo ratings yet

- Automatic Pneumatic Stand For Two WheelerDocument34 pagesAutomatic Pneumatic Stand For Two WheelerTanvi100% (1)

- E-bike Drives for Maximum EfficiencyDocument22 pagesE-bike Drives for Maximum EfficiencyArjun Pawase100% (2)

- Sheet1. VibrationsDocument3 pagesSheet1. Vibrationskhaled mohamed100% (1)

- Grammar Examination Week 2Document4 pagesGrammar Examination Week 2Inshan MaulanaNo ratings yet

- Indian Motorcycle 2015-2017 Scout & Scout Sixty Service ManualDocument508 pagesIndian Motorcycle 2015-2017 Scout & Scout Sixty Service Manualtom63% (8)

- The Velomobile As A Vehicle For More Sustainable TransportationDocument104 pagesThe Velomobile As A Vehicle For More Sustainable TransportationWete_K100% (2)