Professional Documents

Culture Documents

FT Primepox

Uploaded by

mastercssi0 ratings0% found this document useful (0 votes)

31 views1 pageFt Primepox data sheet

Original Title

Ft Primepox

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFt Primepox data sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views1 pageFT Primepox

Uploaded by

mastercssiFt Primepox data sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

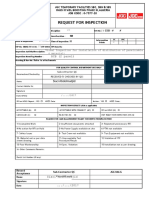

TECHNICAL CARD | Edition of : 10.03.09 KR é |

Tear

ERSION.

BROWN RED PRIMEPOX

216209000

INDUSTRY

Nature

Utilization

Properties

Characteristies

Preparation of surface

Application

Advices of use

Epoxy/Polyamino-amid

‘Two component anti-corroding undercoat contains zine phosphate for steel structures in marine and

industrial environments.

Good corrosion resistance

Good adhesion

Fast drying

Density : 1.512 £0.05,

Viscosity at 20-25 °C (Brookfield M3/V2) : 275 Po #25 Po

Solid content of the mixture EA+EB : 702.9%

Coverage : 9.5 0,5 milkg or 14 ml fr a humid film of 120-130 p (40-50 wt dry film)

Drying at 20-25 °C : Touche free : 23h

Dry: 16-18h

Compete reticulation : 7 t0 10 days at 20-25 °C

Minimum : 16 24h

Recovery duration at 20 —

Maximum : 01 ~02 months

Limit temperature of service : 160 °C

Measure of mixture in weight EWEB 91/9

Life span in pot at 20-25 °C :7-8h

Aspect : Mat

‘Storage duration under shelter : 6 months in its original closed packing

Packaging: Brown red primepox EA (216209000) ; 18.2 kg

primepox EB (hardener) (216212100) : 0,9 kg ,1.8kg

Well Derusted, degreased and dry support

Spray gun, Brush, roller

Mix well the two elements A and B at a measure of 91/9

Dilute with Epoxamine diluent and filter

Let to mature 101-15! before use

Do not apply at temperatures < $ °C and > 40 °C and ata rate of humidity > 80 %

[NB : Indications above are given as basis information, Cireumstances of use escaping to our control, we are only responsible for a

constant quality of our products . For all particular cases, it is necessary to consult us.

Address : EPE/ENAP/SPA National Road N° § POB78, Lakhdaria 10200 Bouira Algeria

Tel : + 213 (0) 26.90.11.44/90.12.44 Fax: +213 (0) 26.90.10.93/90.10.04 E~ mail : peinture @ algeriainfo.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDocument11 pagesSSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDavid Aliaga Sayas100% (1)

- Painting DFT Rules-SSPC-PA-2Document16 pagesPainting DFT Rules-SSPC-PA-2Michael AlbuquerqueNo ratings yet

- Materials: The Influence of The Aircraft Operating Fluids On The Mechanical Parameters of The Airport Surface ConcreteDocument15 pagesMaterials: The Influence of The Aircraft Operating Fluids On The Mechanical Parameters of The Airport Surface ConcretemastercssiNo ratings yet

- Basf MasterEase 3500 TdsDocument2 pagesBasf MasterEase 3500 TdsAchmad Syifa'ul Qolbi Al Faruq100% (1)

- Surface Preparation Standards Comparison ChartDocument2 pagesSurface Preparation Standards Comparison ChartajuhaseenNo ratings yet

- CT 30GBDocument74 pagesCT 30GBmojgfdNo ratings yet

- BS 4320 - 1968Document19 pagesBS 4320 - 1968mastercssiNo ratings yet

- ETABS 2nd tutorialDocument47 pagesETABS 2nd tutorialRamilArtates100% (1)

- Evaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestDocument7 pagesEvaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestJorge Vanegas100% (1)

- Operation 3dDocument1 pageOperation 3dmastercssiNo ratings yet

- AdvancedDocument2 pagesAdvancedmastercssiNo ratings yet

- Fri TelecomDocument1 pageFri TelecommastercssiNo ratings yet

- The Concrete Producer Article PDF - Understanding ASTM C 94 PDFDocument5 pagesThe Concrete Producer Article PDF - Understanding ASTM C 94 PDFJoelNo ratings yet

- Msds 4 Cement - LafargeDocument11 pagesMsds 4 Cement - LafargeMahmoud AhmedNo ratings yet

- Msds CPD SikaLatex UsDocument8 pagesMsds CPD SikaLatex UsmastercssiNo ratings yet

- Msds 4 Cement - LafargeDocument11 pagesMsds 4 Cement - LafargeMahmoud AhmedNo ratings yet

- FT PolyraneDocument1 pageFT PolyranemastercssiNo ratings yet

- FT Primepox PDFDocument1 pageFT Primepox PDFmastercssiNo ratings yet

- The Concrete Producer Article PDF - Understanding ASTM C 94 PDFDocument5 pagesThe Concrete Producer Article PDF - Understanding ASTM C 94 PDFJoelNo ratings yet

- Method Statement Wet Areas (600) NDocument16 pagesMethod Statement Wet Areas (600) NmastercssiNo ratings yet