Professional Documents

Culture Documents

Airbus A320 Inst Power Plant PDF

Uploaded by

Pinaki GhoshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Airbus A320 Inst Power Plant PDF

Uploaded by

Pinaki GhoshCopyright:

Available Formats

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

** ON A/C ALL

TASK 71-00-20-400-040-A

Installation of the Power Plant

WARNING: MAKE SURE THAT THE LANDING GEAR GROUND SAFETIES AND THE WHEEL CHOCKS

ARE IN POSITION.

WARNING: MAKE SURE THAT ALL THE CIRCUITS IN MAINTENANCE ARE ISOLATED BEFORE YOU

SUPPLY ELECTRICAL POWER TO THE AIRCRAFT.

CAUTION: DO A CHECK OF THE ENGINE DATA PLATE TO MAKE SURE THAT THE ENGINE IS COR-

RECT FOR THE AIRCARFT.

IF YOU INSTALL AN ENGINE THAT DOES NOT HAVE THE CORRECT CONFIGURATION FOR

THE AIRCRAFT.

- DAMAGE TO EQUIPMENT CAN OCCUR IF YOU OPERATE THE ENGINE. - THE TEST

AFTER THE INSTALLATION WILL TELL YOU THE ENGINE CONFIGURATION IS NOT COR-

RECT AND MORE WORK WILL BE NECESSARY.

CAUTION: MAKE SURE THAT THE EEC STANDARDS INSTALLED ARE CORRECT. SOME EEC STAND-

ARDS CANNOT BE INTERMIXED ON A SAME AIRCRAFT.

FIN : 1000EM1 , 1000EM2

1. Reason for the Job

Self explanatory

2

Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR ACCESS PLATFORM 1M(3 FT)

No specific 1 DRILL - NO 21 (DIA 0.159 IN - 4.039 MM)

No specific 1 DYNAMOMETER 15 DAN (33 LBF) - PULL

No specific 1 MAGNIFYING GLASS POWER 10X

No specific AR PENCIL

No specific AR PLATE - STEEL, 500X500X3 MM (19.68X19.68X0.12 IN)

No specific AR WARNING NOTICE(S)

No specific 1 WRENCH - STRAP

No specific Torque wrench: range

to between 15.00 and 150.00 lbf.ft (2.00 and 20.00 m.daN)

No specific Torque wrench: range

to between 0.00 and 50.00 lbf.in (0.00 and 0.56 m.daN)

No specific Torque wrench: range

to between 62.00 and 900.00 lbf.in (0.70 and 10.00 m.daN)

No specific Torque wrench: range

to between 0.20 and 3.60 m.daN (2.00 and 26.00 lbf.ft)

No specific Torque wrench: range

to between 2.00 and 20.00 m.daN (15.00 and 150.00 lbf.ft)

No specific Torque wrench: range

to between 36.00 and 135.00 m.daN (260.00 and 1000.00 lbf.ft)

Print Date: October 27, 2015 Page 1 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

REFERENCE QTY DESIGNATION

(98D71203001000) 1 CHEST,TORQUE SET-ENGINE R I

(S1787CR) 1 ENGINE CRADLE

(S487ETT2) 1 ENGINE TROLLEY

(TMHEC29-00-00) 1 CRADLE,V2500 ENGINE

(TMHET06-00-00) 1 TRAILER,ENGINE GROUND HANDLING(CFM56-5 AND IAE V2500)

B. Consumable Materials

REFERENCE DESIGNATION

(Material No. V01-457) solvent

(Material No. V02-126) lockwire

(Material No. V02-147) lockwire

(Material No. V02-158A) release agent

(Material No. V02-272) safety cable

(Material No. V02-273) safety cable

(Material No. V02-274) safety cable

(Material No. V02-275) safety cable

(Material No. V02-276) safety cable

(Material No. V02-277) safety cable

(Material No. V02-278) safety cable

(Material No. V02-279) safety cable

(Material No. V02-280) safety cable

(Material No. V02-281) safety cable

(Material No. V02-282) safety cable

(Material No. V02-283) safety cable

(Material No. V02-283A) safety cable

(Material No. V02-284) safety cable

(Material No. V02-285) safety cable

(Material No. V02-286) safety cable

(Material No. V02-287) safety cable

(Material No. V02-288) safety cable

(Material No. V02-289) safety cable

(Material No. V02-290) safety cable

(Material No. V08-030) sealant

(Material No. V08-032) primer

(Material No. V10-085) anti seize compound

(Material No. 14-SBA1) Textile-Lint free Cotton -

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

FOR 1000EM1 (ENGINE-1)

437AL, 438AR,

451AL, 452AR

FOR 1000EM2 (ENGINE-2)

447AL, 448AR,

461AL, 462AR

D. Expendable Parts

Print Date: October 27, 2015 Page 2 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

FIG.ITEM DESIGNATION IPC-CSN

17 screws 71-51-46-80-010

16 seal assembly 71-51-46-80-020

15 seal assembly 71-51-46-80-030

3 gasket 73-11-48-80-080

11 gasket 73-11-48-80-120

E. Referenced Information

REFERENCE DESIGNATION

** ON A/C 001-018, 025-025, 027-028, 053-100, 251-450, 513-700

(Ref. 05-57-00-200-001-A). Aircraft Stability

** ON A/C 101-104, 108-200, 451-500

(Ref. 05-57-00-200-001-B). Aircraft Stability

** ON A/C 201-250

(Ref. 05-57-00-200-001-C). Aircraft Stability

** ON A/C ALL

(Ref. 12-13-24-612-011-A). IDG Servicing - Filling of the IDG with Oil or Addition of Oil after a

Level Check

(Ref. 12-13-79-610-012-A). Prime the Engine Oil System

(Ref. 12-13-80-600-010-B). Replenishment of Starter Oil System

(Ref. 20-28-00-720-005-A). Check of the Electrical Bonding of the Different Components (But not

Fluid Systems and Components Installed on Composite materials)

(Ref. 22-97-00-710-001-A). Operational Test of the LAND CAT III Capability

(Ref. 24-21-00-710-042-A). Operational Test of the IDG Disconnect and Reconnect (Reset) Func-

tion - Engine Static

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

(Ref. 30-21-00-710-002-A). Operational Test of the Engine Air Intake Ice Protection (with the En-

gines in operation)

(Ref. 31-36-00-740-014-A). Update of the Engine Hours and Cycles in the Flight Data Interface

and Management Unit (FDIMU)

(Ref. 31-60-00-860-001-A). EIS Start Procedure

(Ref. 31-60-00-860-002-A). EIS Stop Procedure

** ON A/C 001-018, 025-025, 027-028, 053-104, 301-500, 513-700

PRE SB 36-1055 for A/C 001-018, 025-025, 027-028, 053-054, 101-104, 301-302, 401-401, 451-452,

513-513, 601-601

(Ref. 36-11-49-400-016-A). Installation of the Sense Line between the Bleed Pressure-Regulator

Valve (PRV) and the Pylon Interface

Print Date: October 27, 2015 Page 3 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

REFERENCE DESIGNATION

** ON A/C ALL

(Ref. 70-11-50-100-802-A). Local Swab or Wipe Cleaning with Solvent

(Ref. 70-23-11-911-013-A). General Torque Tightening Techniques

(Ref. 70-23-13-911-010-A). Procedures for the Installation of Preformed Packings

(Ref. 70-23-15-912-010-A). Connection of Electrical Connectors

(Ref. 70-40-11-911-014-A). Locking Devices General Information

(Ref. 70-40-11-911-016-A). General Instructions for Uses of Safety Cable

(Ref. 71-00-00-700-011-B). Test No.13 : Pretested Replacement Engine Test

(Ref. 71-00-00-710-012-B). Test No.3 : Idle Leak Check

(Ref. 71-00-00-710-022-B). Test No.6 : ELectronic Engine Control (EEC) System Idle Test

(Ref. 71-00-00-710-046-B). Test No.2 : Wet Motor Leak Check

(Ref. 71-13-00-010-010-A). Opening of the Fan Cowls 437AL(447AL),438AR(448AR)

(Ref. 71-13-00-410-010-A). Closing of the Fan Cowls 437AL(447AL),438AR(448AR)

(Ref. 71-13-00-800-010-A). Functional Check of Fan Cowl Latch Tension

(Ref. 71-21-12-200-010-A). Detailed Inspection of FWD Engine Mount Installation

(Ref. 71-22-11-200-010-A). Detailed Inspection of AFT Engine Mount Installation

(Ref. 71-71-42-400-010-A). Installation of the Drains Mast

(Ref. 72-61-49-400-010-B). Installation of the Gearbox Breather Outlet Duct (GBOD)

(Ref. 73-13-42-720-010-A). Functional Test of the Fuel Recirculation Cooling System without Bar-

field Tester and without AIDS

(Ref. 73-13-42-720-010-A-01). Functional Test of the Fuel Recirculation Cooling System with Barfield

Tester and without AIDS

(Ref. 73-13-42-720-010-A-02). Functional Test of the Fuel Recirculation Cooling System without Bar-

field Tester and with AIDS

(Ref. 73-13-42-720-010-A-03). Functional Test of the Fuel Recirculation Cooling System with Barfield

Tester and with AIDS

(Ref. 73-22-34-710-040-A). Operational Test of the EEC

(Ref. 78-30-00-040-012-A). Deactivation of the Thrust Reverser Hydraulic Control Unit (HCU) for

Ground Maintenance

(Ref. 78-30-00-440-012-A). Re-activation of the Thrust Reverser Hydraulic Control Unit (HCU) after

Ground Maintenance

(Ref. 78-30-00-820-010-A). Rig of the Thrust Reverser System

(Ref. 78-32-00-010-010-A). Opening of the Thrust Reverser Halves

(Ref. 78-32-00-410-010-A). Closing of the Thrust Reverser Halves

(Ref. 80-13-49-820-010-B). Rig the Starter Ducts

(Ref. 80-13-51-710-040-B). Operational Test of the Pneumatic Starter Valve and FMU with the CF-

DS

Ref. ESPM 20-48-23

Ref. ESPM 20-48-24

SPM 702304

(Ref. 05-59-00-00). SPECIAL FLIGHTS - DESCRIPTION AND OPERATION

Forward Engine Mount SHEET 1

Aft Engine Mount SHEET 1

Bootstrap Installation

Hinge Crossover Beam SHEET 1

Fan Cowl and Thrust Reverser Braces

TAI Location and Hydraulic Reservoir Pressurization Tube Location SHEET 1

Power Plant, Left Side SHEET 1

Left Connectors Location SHEET 1

Print Date: October 27, 2015 Page 4 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

REFERENCE DESIGNATION

Power Plant, Right Side SHEET 1

Forward Junction Box SHEET 1

Upper/Lower Link Starter Duct and Link Assembly SHEET 1

Forward Junction Box SHEET 1

Left Interface Junction Box SHEET 1

Inspection for the Thrust Reverser Brackets and Inspection for/Installation of the Engine Fire

Seals SHEET 1

Fire Seal Installation SHEET 1

Hydraulic Control Unit SHEET 1

FOR 1000EM1 (ENGINE-1)

(Ref. 29-11-51-860-040-A). Hydraulic Maintenance Procedure after an Engine Installation (with En-

gine Pump Installed) or after an Engine Pump Installation

FOR 1000EM2 (ENGINE-2)

(Ref. 29-13-51-860-001-A). Hydraulic Maintenance Procedure after an Engine Installation (with En-

gine Pump Installed) or after an Engine Pump Installation

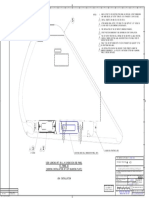

1 BOLT

A 2 WASHER

3 PYLON

B

B

19 SHEAR PIN

(2 OFF)

B

C

4 forward

ENGINE MOUNT

B

18 BOLT

9 BOLT

17 WASHER

C

10 WASHER

5 NUT

11 RETAINER

6 RETAINER

16 NUT

12 RETAINER

7 WASHER

8 NUT

13 RETAINER

14 WASHER

15 NUT 16865C

N_MM_710020_4_XVM0_01_00

Figure 71(IAE)-00-20-991-91000-A / SHEET 1/1 - Forward Engine Mount

** ON A/C ALL

Print Date: October 27, 2015 Page 5 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

2 BOLT

1 PYLON

3 WASHER

5 SHEAR PIN

4 AFT MOUNT

UP

6 BARREL NUT

N_MM_710020_4_XZM0_01_00

Figure 71(IAE)-00-20-991-91200-A / SHEET 1/1 - Aft Engine Mount

** ON A/C ALL

Print Date: October 27, 2015 Page 6 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

B

1 2 1

3

5

4

2

B

N_MM_710020_4_XXM0_01_00

Figure 71(IAE)-00-20-991-91100-A / SHEET 1/2 - Bootstrap Installation

** ON A/C ALL

Print Date: October 27, 2015 Page 7 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

N_MM_710020_4_XXM0_02_00

Figure 71(IAE)-00-20-991-91100-A / SHEET 2/2 - Bootstrap Installation

** ON A/C ALL

Print Date: October 27, 2015 Page 8 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

HINGE CROSS-OVER BEAM (1)

FAN CASE B

HINGE CROSS-OVER BEAM (1)

FAN CASE

V-GROOVE (2)

C

N_MM_710020_4_XZN0_01_00

Figure 71(IAE)-00-20-991-19600-A / SHEET 1/1 - Hinge Crossover Beam

** ON A/C ALL

Print Date: October 27, 2015 Page 9 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

T/R OPENING ACTUATOR

(1) ADJUSTABLE (2) ADJUSTABLE

STRUT PYLON STRUT

T/R COWL DOOR

N_MM_710020_4_YCN0_01_00

Figure 71(IAE)-00-20-991-91400-A / SHEET 1/3 - Fan Cowl and Thrust Reverser Braces

** ON A/C ALL

Print Date: October 27, 2015 Page 10 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

THRUST REVERSER ADJUSTABLE T/R OPENING

COWL DOOR STRUT ACTUATOR PYLON

N_MM_710020_4_YCN0_02_00

Figure 71(IAE)-00-20-991-91400-A / SHEET 2/3 - Fan Cowl and Thrust Reverser Braces

** ON A/C ALL

Print Date: October 27, 2015 Page 11 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

THRUST REVERSER

COWL DOOR

FAN COWL

3

DOOR

BRACKETS

4

SUPPORT ARM

N_MM_710020_4_YCN0_03_00

Figure 71(IAE)-00-20-991-91400-A / SHEET 3/3 - Fan Cowl and Thrust Reverser Braces

** ON A/C ALL

Print Date: October 27, 2015 Page 12 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

A

PYLON

TAI DUCT

E

19 COUPLING

HYDRAULIC TANK

PRESSURISATION TUBE

E

11 THERMOSTAT

SENSOR TUBE

18 DUCT

D

B

20 PRV

SENSOR TUBE

PYLON

BLEED AIR

DUCT

TAI DUCT

7 COUPLING

C 19 COUPLING

10 BLEED AIR DUCT

17156A

N_MM_710020_4_XNM0_01_00

Figure 71(IAE)-00-20-991-90600-A / SHEET 1/1 - TAI Location

and Hydraulic Reservoir Pressurization Tube Location

** ON A/C ALL

Print Date: October 27, 2015 Page 13 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

1 HYDRAULIC 2 HYDRAULIC

SUCTION PRESSURE

HOSE TUBE

A

B

FLUID DISCONNECT

PANEL C

B C D E

F

11 GASKET

3 GASKET

10 WASHER

D

5 WASHER

9 BOLT

6 BOLT

F

E

4 FUEL RETURN

TO TANK

TUBE

8 FUEL SUPPLY 7 HYDRAULIC CASE

TUBE DRAIN TUBE

16913

N_MM_710020_4_XJM0_01_00

Figure 71(IAE)-00-20-991-90400-A / SHEET 1/1 - Power Plant, Left Side

** ON A/C ALL

Print Date: October 27, 2015 Page 14 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

CONNECTOR

4101KS-B

CONNECTOR

4101KS-A

CONNECTOR

4004VC

14006

N_MM_710020_4_XLM0_01_00

Figure 71(IAE)-00-20-991-90500-A / SHEET 1/1 - Left Connectors Location

** ON A/C ALL

Print Date: October 27, 2015 Page 15 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

FORWARD PYLON

JUNCTION BOX

FORWARD

JUNCTION BOX

CONNECTOR

4005VC

14047

N_MM_710020_4_XEM0_01_00

Figure 71(IAE)-00-20-991-90200-A / SHEET 1/1 - Power Plant, Right Side

** ON A/C ALL

Print Date: October 27, 2015 Page 16 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

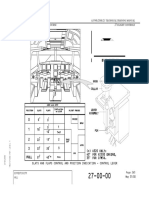

457VC 448VC

406VC 402VC

405VC 404VC

447VC

A 408VC

407VC

401VC

6 PYLON STARTER

DUCT 400VC 409VC

403VC

20° 1 PYLON

TAI DUCT

7

T-BOLT

3

COUPLING

5

COUPLING

4 STARTER

DUCT

2 TAI DUCT

gc00a5m155

N_MM_710020_4_XCM0_01_02

Figure 71(IAE)-00-20-991-90100-A / SHEET 1/1 - Forward Junction Box

** ON A/C ALL

Print Date: October 27, 2015 Page 17 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

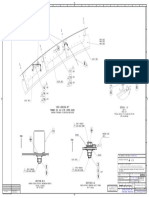

A

17 UPPER LINK

ASSEMBLY

16 UPPER LINK

UPPER/LOWER ASSEMBLY

LINK ASSEMBLY

9 WASHER

7 NUT

BOLT 8

7 NUT

8 BOLT

7 NUT

9 WASHER

13 NUT

12 LOWER LINK

8 BOLT ASSEMBLY

18 BOLT

UPPER/LOWER

LINK ASSEMBLY

FAN CASE

BRACKET

8 BOLT

7 NUT

11 LOWER LINK

13 NUT ASSEMBLY

18 BOLT

pwzxxe9397

N_MM_710020_4_XDM0_01_00

Figure 71(IAE)-00-20-991-94200-A / SHEET 1/1 - Upper/Lower Link Starter Duct and Link Assembly

** ON A/C ALL

Print Date: October 27, 2015 Page 18 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

D

FLANGE A1

A

E

TYPICAL

14

13

D 11

16 B

15

17

FLANGE A

9

17 9

E

7

7

7

B

10

7

9 8

16 10 9

8 10 7 10

9

7 7

E E 11

8 8

10 10

C C

8

8 9 10

13 12

A5M029

8

14

N_MM_710020_4_XFM0_01_00

Figure 71(IAE)-00-20-991-94300-A / SHEET 1/1 - Forward Junction Box

** ON A/C ALL

Print Date: October 27, 2015 Page 19 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

A

CONNECTOR

450VC-A

A CONNECTOR

454VC CONNECTOR

452VC-A

GP5 CONNECTOR

4001HA-A

14054

N_MM_710020_4_XGM0_01_00

Figure 71(IAE)-00-20-991-90300-A / SHEET 1/1 - Left Interface Junction Box

** ON A/C ALL

Print Date: October 27, 2015 Page 20 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

BLOCK SEAL

A FIRE SHIELD

15 FIRE SEAL

ASSEMBLY

THRUST REVERSER

BRACKET

16 FIRE SEAL

ASSEMBLY

BLOCK SEAL

B8373

N_MM_710020_4_XAA0_01_00

Figure 71(IAE)-00-20-991-19700-A / SHEET 1/1 - Inspection for the Thrust

Reverser Brackets and Inspection for/Installation of the Engine Fire Seals

** ON A/C ALL

Print Date: October 27, 2015 Page 21 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

A

POST-SB-ENG-72-0230

15 FIRE SEAL ASSEMBLY

FIRE SHIELD

17 SCREWS (4 PLACES)

16 FIRE SEAL ASSEMBLY

GC00A5M073

N_MM_710020_4_XAB0_01_00

Figure 71(IAE)-00-20-991-19800-A / SHEET 1/1 - Fire Seal Installation

** ON A/C ALL

Print Date: October 27, 2015 Page 22 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

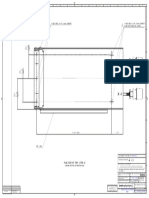

A

PYLON

1 HCU

2 LOCKPIN

4 WARNING

FLAG

3 LOCKOUT

A LEVER

13480A

N_MM_710020_4_XAM0_01_00

Figure 71(IAE)-00-20-991-90000-A / SHEET 1/1 - Hydraulic Control Unit

** ON A/C ALL

Print Date: October 27, 2015 Page 23 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

3. Job Set-up

Subtask 71-00-20-860-052-B

A. Aircraft Maintenance Configuration

(1) Make sure the aircraft is stable (Ref. AMM TASK 05-57-00-200-001) .

NOTE: If the aircraft is on jacks, make sure it is leveled before you install the engine.

(2) On the center pedestal, on the ENG panel 115VU, make sure that a WARNING NOTICE(S) is in

position to tell persons not to start the engine.

(3) On the overhead maintenance panel 50VU, make sure that the ON legend of the ENG/FADEC GND

PWR/1(2) pushbutton switch is off. Make sure that a WARNING NOTICE(S) is in position to tell

persons not to energize the FADEC 1(2).

(4) On the panel 30VU, make sure that the APU BLEED pushbutton switch is released (ON legend

off). Make sure that a WARNING NOTICE(S) is in position to tell persons not to press the APU

BLEED pushbutton switch. Make sure that a WARNING NOTICE(S) is in position on the HP ground

connector to tell persons not to pressurize the pneumatic system.

(5) Make sure that the ACCESS PLATFORM 1M(3 FT) is in position.

Subtask 71-00-20-010-053-A

B. Make sure that the fan cowl doors are open (Ref. AMM TASK 71-13-00-010-010) :

(1) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(2) FOR 1000EM2 (ENGINE-2)

447AL, 448AR

Subtask 71-00-20-040-051-A

C. Make sure that the thrust reverser Hydraulic Control Unit (HCU) is deactivated

(Ref. AMM TASK 78-30-00-040-012) .

Subtask 71-00-20-865-051-A

WARNING: MAKE SURE THAT YOU OPEN THE CIRCUIT BREAKERS AS FOLLOWS:

- 1JH, 2JH1 AND 3JH1 BEFORE 2KS1

- 1JH, 2JH2 AND 3JH2 BEFORE 2KS2.

IF YOU DO NOT OBEY THIS SEQUENCE, THERE IS A RISK OF ELECTROCUTION. THIS IS

BECAUSE YOU WILL START CONTINUOUS IGNITION IF YOU OPEN CIRCUIT BREAKER

2KS1 OR 2KS2 FIRST.

WARNING: OPEN THE PROBE HEATER CIRCUIT-BREAKERS 1DA1(2), 3DA1(2,3), 4DA1(2,3) AND

5DA1(2,3) BEFORE YOU OPEN THE PHC CIRCUIT BREAKERS 2DA1(2,3). IF YOU DO NOT

OBEY THIS SEQUENCE:

- THE PROBES WILL BECOME TOO HOT.

- THIS CAN CAUSE DAMAGE TO EQUIPMENT AND INJURY TO MAINTENANCE PER-

SONNEL.

D. Make sure that this(these) circuit breaker(s) is(are) open, safetied and tagged:

PANEL DESIGNATION FIN LOCATION

** ON A/C 001-018, 025-025, 027-028, 053-104, 108-500, 513-650

49VU COM/CVR/SPLY 2RK E14

Print Date: October 27, 2015 Page 24 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

PANEL DESIGNATION FIN LOCATION

49VU COM/CVR/CTL 4RK E13

** ON A/C ALL

49VU ENGINE/1 AND 2/IGN/SYS A 1JH A03

49VU ANTI ICE/PROBES/AOA/1 4DA1 D04

49VU ANTI ICE/PROBES/PITOT/1 3DA1 D02

49VU ANTI ICE/RAIN/RPLNT/CAPT 1DB1 D01

** ON A/C 651-700

49VU COM/CVR/SPLY 23RK E14

49VU COM/CVR/CTL 26RK E13

** ON A/C ALL

121VU ENGINE/ENG1 AND 2 FIRE EX- 2WE1 Q44

TIG/BTL1/SQUIB/B

121VU ENGINE/ENG1 AND 2 FIRE EX- 1WE1 Q43

TIG/BTL1/SQUIB/A

121VU ENGINE/ENG1 AND 2 FIRE EX- 2WE2 Q42

TIG/BTL2/SQUIB/B

121VU ENGINE/ENG1 AND 2 FIRE EX- 1WE2 Q41

TIG/BTL2/SQUIB/A

122VU ANTI ICE/WINDOWS/R 4DG2 W14

122VU ANTI ICE/RAIN/RPLNT/F/O 1DB2 W11

122VU ANTI ICE/WINDOWS/L 4DG1 X14

122VU ANTI ICE/PROBES/2/TAT 1DA2 Y15

122VU ANTI ICE/PROBES/2/PITOT 3DA2 Y14

122VU ANTI ICE/PROBES/2/AOA 4DA2 Y13

122VU ANTI ICE/PROBES/2/STATIC 5DA2 Y11

122VU ANTI ICE/PROBES/3/PITOT 3DA3 Z16

122VU ANTI ICE/PROBES/3/AOA 4DA3 Z15

122VU ANTI ICE/PROBES/3/STATIC 5DA3 Z14

122VU ANTI ICE/PROBES/1/STATIC 5DA1 Z13

122VU ANTI ICE/PROBES/1/TAT 1DA1 Z12

123VU ANTI ICE/L/WHSLD 1DG1 AF10

123VU ANTI ICE/R/WHSLD 1DG2 AF03

FOR FIN 1000EM1 (ENGINE-1)

49VU ENGINE/1/FIRE DET/LOOP A 7WD1 A06

49VU ENGINE/1/FADEC A/AND EIU 1 2KS1 A04

121VU RCDR/DFDR 7TU K16

121VU ENGINE/IGN/ENG1/SYS B 3JH1 P41

121VU ENGINE/IGN/ENG1/SYS A BAT 2JH1 P39

121VU ENGINE/ENG1/FIRE DET/LOOP B 8WD1 Q38

121VU ENGINE/ENG1/FADEC B/AND EIU 1 4KS1 R41

122VU ELEC/GCU/1 2XU1 T26

122VU ANTI ICE/ENG/1 1DN1 X10

FOR FIN 1000EM2 (ENGINE-2)

49VU ENGINE/2/FIRE DET/LOOP B 8WD2 A07

49VU ENGINE/2/FADEC A/AND EIU 2 2KS2 A05

121VU HYDRAULIC/HYD POWER/Y 3803GX N30

121VU ENGINE/IGN/ENG2/SYS B 3JH2 P42

Print Date: October 27, 2015 Page 25 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

PANEL DESIGNATION FIN LOCATION

121VU ENGINE/IGN/ENG2/SYS A BAT 2JH2 P40

121VU ENGINE/ENG2/FADEC B/AND EIU 2 4KS2 Q40

121VU ENGINE/ENG2/FIRE DET/LOOP A 7WD2 Q39

122VU ELEC/GCU/2 2XU2 T27

122VU ANTI ICE/ENG/2 1DN2 W10

123VU Y HYD/ELEC/PUMP 3802GX AB06

123VU Y HYD/ELEC/ELEC PUMP/NORM 3801GX AB03

Subtask 71-00-20-865-070-A

WARNING: OPEN THE PROBE HEATER AND WINDOW HEATER CIRCUIT-BREAKERS BEFORE

YOU OPEN THE PHC AND WHC CIRCUIT BREAKERS. IF YOU DO NOT OBEY THIS SE-

QUENCE:

- THE PROBES WILL BECOME TOO HOT.

- THIS CAN CAUSE DAMAGE TO EQUIPMENT AND INJURY TO MAINTENANCE PER-

SONNEL.

E. Make sure that this(these) circuit breaker(s) is(are) open, safetied and tagged:

PANEL DESIGNATION FIN LOCATION

49VU ANTI ICE/PROBES/PHC/1 2DA1 D03

122VU ANTI ICE/WHC/2 5DG2 W13

122VU ANTI ICE/WHC/1 5DG1 X13

122VU ANTI ICE/PROBES/PHC/3 2DA3 Y16

122VU ANTI ICE/PROBES/PHC/2 2DA2 Y12

Subtask 71-00-20-210-050-A

F. Check of the Cowling for Correct Condition

(1) Do a check of the electrical connectors of the aft and forward junction boxes, for correct condition.

(2) Make sure that these parts are not damaged:

(a) The forward engine mount (Ref. AMM TASK 71-21-12-200-010)

(b) The aft engine mount (Ref. AMM TASK 71-22-11-200-010)

(c) The pylon structure that you can see.

Subtask 71-00-20-110-052-A

G. Clean Components

(1) Clean these parts by (Ref. AMM TASK 70-11-50-100-802) .

(a) The mating faces and the shear pins and the fastener holes on the forward and aft engine

mounts

(b) The forward and aft mount pads on the pylon.

(2) Clean the bolts (1), (18) and (2), the nuts (16) and (5) and the barrel nuts (6) by

(Ref. AMM TASK 70-11-50-100-802) .

(Ref. Fig. Forward Engine Mount SHEET 1)

(Ref. Fig. Aft Engine Mount SHEET 1)

(3) Make sure that there are no traces of seizure or wear.

Subtask 71-00-20-230-051-A

H. Do an ultra-high sensitivity fluorescent penetrant inspection of the engine mount bolts (1), (2) and (18)

SPM 702304. No cracks are permitted.

Print Date: October 27, 2015 Page 26 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

(Ref. Fig. Forward Engine Mount SHEET 1)

(Ref. Fig. Aft Engine Mount SHEET 1)

Subtask 71-00-20-240-051-A

J. Visual Inspections

(1) Do a visual inspection of the forward engine mount nuts (5) and (16) with a MAGNIFYING GLASS

POWER 10X. Do not remove the silver plating.

(Ref. Fig. Forward Engine Mount SHEET 1)

If an engine nut is cracked, reject it.

(2) Do a visual inspection of the barrel nuts (6) with a MAGNIFYING GLASS POWER 10X . No cracks,

nicks, scratches or gouges are allowed. If any damage is found, replace the barrel nut. Silver plating

missing from the external surface of the barrel nut is acceptable.

The threads must be in good condition and no silver plating is allowed to be missing from the threads.

If silver plating is missing from the barrel nut threads, the barrel nut must be replaced.

Subtask 71-00-20-210-060-A

K. Do a Check of the Running Torque of the Forward and Aft Mount Bolts

(1) Do a check of the running torque of the forward engine mount bolts as follows:

(Ref. Fig. Forward Engine Mount SHEET 1)

(a) Apply a thin layer of anti seize compound (Material No. V10-085) to the threads of the engine

mount bolts, the nuts and the washers.

(b) Install the washers under the head of the bolts (1) and (18).

(c) Install the bolts (1) and (18) through holes in the pylon and the forward mount.

(d) Install the nuts (5) and (16) on the bolts (1) and (18).

(e) Tighten the nuts by hand until they are hard to turn.

NOTE: Make sure that the nuts are correctly threaded on the bolts.

(f) Use a torque wrench to tighten the nuts until at least two full threads show on the other side of

the nuts (Ref. AMM TASK 70-23-11-911-013) .

1 Measure the torque required to tighten the bolt (Ref. AMM TASK 70-23-11-911-013) . The

minimum torque should be to 70 lbf.in (0.79 m.daN). The maximum torque should be

to 600 lbf.in (6.78 m.daN).

2 If the bolt torque is less than 70 lbf.in (0.79 m.daN), replace the nut (5) or (16) and do steps

(a) thru (f) 1_ again.

3 If the torque is more than 600 lbf.in (6.78 m.daN), remove the bolt and the nut and look for

damaged threads. If the threads are damaged, replace the bolt and nut and do steps (a) thru

(f) 2_ again.

(g) Remove the forward mount bolts and nuts.

(2) Do a check of the running torque of the aft engine mount bolts as follows:

(Ref. Fig. Aft Engine Mount SHEET 1)

(a) Apply a thin layer of anti seize compound (Material No. V10-085) to the threads of the engine

mount bolts, the nuts and the washers.

(b) Install the washers (3) under the head of the bolts (2).

(c) Install the aft engine mount bolts (2) into the barrel nuts (6).

(d) Tighten the bolts by hand until they are hard to turn.

Print Date: October 27, 2015 Page 27 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

NOTE: Make sure that the nuts are correctly threaded on the bolts.

(e) Use a torque wrench to tighten the nuts until at least two full threads show on the other side of

the nuts (Ref. AMM TASK 70-23-11-911-013) .

1 Measure the torque required to tighten the bolt (Ref. AMM TASK 70-23-11-911-013) . The

minimum torque should be to 90 lbf.in (1.02 m.daN). The maximum torque should be

to 800 lbf.in (9.04 m.daN).

2 If the bolt torque is less than 90 lbf.in (1.02 m.daN), replace the nut (6) and do steps (a) thru

(e) 1_ again.

3 If the torque is more than 800 lbf.in (9.04 m.daN), remove the bolt and the nut and look for

damaged threads. If the threads are damaged, replace the bolt and nut and do steps (a) thru

(e) 2_ again.

(f) Remove the aft mount bolts and nuts.

Subtask 71-00-20-420-050-A

L. If replacement engine does not have all its equipment, remove the accessories from the removed engine

and install them on the replacement engine.

4. Procedure

Subtask 71-00-20-420-051-A

A. Put the replacement engine in position under the pylon

(1) Put the ENGINE TROLLEY (S487ETT2) or TRAILER,ENGINE GROUND HANDLING(CFM56-5

AND IAE V2500) (TMHET06-00-00) and ENGINE CRADLE (S1787CR) or CRADLE,V2500

ENGINE (TMHEC29-00-00) with the replacement engine in position under the pylon.

(2) Install the forward hinge arm (4) and (5) with the ball pins (1) on the forward bootstrap system.

(Ref. Fig. Bootstrap Installation)

(3) Install the dynamometers and chain pulley blocks on the bootstrap system.

(4) Attach the chain hooks to the engine cradle.

(5) Remove the pins that attach the engine cradle to the engine trolley.

(6) Put the locking levers of the handling hoist in UP position. Lift the engine cradle to disengage it from

the trolley.

(7) Slightly raise the forward section of the engine cradle then the aft section.

NOTE: Make sure that the differential load read on the dynamometers is less than:

- 600 daN (1350 lbf) (611.6 Kg) between the 2 front chains.

- 200 daN (450 lbf) (203.9 Kg) between the 2 rear chains.

NOTE: Use the level indicators on the forward hinge arms of the bootstrap to keep the hinge arms as

near as possible to the horizontal position.

Subtask 71-00-20-210-052-A

B. Make certain that the hinge crossover beam (1) is correctly engaged in the V-groove (2).

(Ref. Fig. Hinge Crossover Beam SHEET 1)

Subtask 71-00-20-420-052-A

C. Put the Power Plant in position

Print Date: October 27, 2015 Page 28 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

WARNING: DEATH OR SERIOUS INJURY MAY RESULT IF THE POWER PLANT FALLS ON PER-

SONNEL. THE POWER PLANT WEIGHS APPROXIMATELY 7300 POUNDS.

CAUTION: DO NOT INSERT THE SHEAR PINS OF ONE MOUNT BEFORE THE OTHER OR DAM-

AGE TO THE MOUNTS AND PYLON CAN RESULT.

(1) Keep the pylon and engine face of the forward and aft attach fittings parallel so as to put the locating

pins easily in their location.

NOTE: Rear lifts give the roll attitude.

NOTE: At the forward end you can move the engine laterally by plus or minus 20 mm (0.79 in.).

(a) To move the engine to the left side, lift with the right hand hoist and/or lower with the left hand

hoist.

(b) To move the engine to the right side, lift with the left hand hoist and/or lower with the right hand

hoist.

(2) Lift the engine:

CAUTION: DO NOT INSTALL THE LOCATING PINS OF ONE MOUNT BEFORE THE OTHER OR

DAMAGE TO MOUNTS AND PYLON COULD RESULT.

(a) Slowly lift the engine to the pylon. Make sure that the shear pins on the engine mounts engage

with the holes in the pylon.

(3) Lift the engine chain continuously until a mating load of 200 daN (450 lbf) (203.9 Kg) maximum for

each chain is shown on the dynamometers.

Subtask 71-00-20-420-053-A

D. Installation of the Forward and Aft Engine Mounts

(1) Install the forward engine mount.

(Ref. Fig. Forward Engine Mount SHEET 1)

(a) Lubricate the bolts (1) and (18), the washers (2) and (17), the nuts (5) and (16) and the shear

pins (19) with anti seize compound (Material No. V10-085).

NOTE: The forward center bolt has no upper retainer, it is locked by lockwire.

(b) Install the bolts (18), the washers (17), the retainers (12) and the nuts (16).

(c) Put the nut (5) and the retainer (6) in position.

(d) Install the washer (7) and the nut (8).

(e) TORQUE the nut (8) to between 35 and 40 lbf.in (0.40 and 0.45 m.daN).

(f) Install the bolt (1) and the washer (2) on the middle front engine mount.

(g) Tighten the bolts (1) and (18) with a standard wrench.

NOTE: You must install the washers (17) and (2) with the recessed side against bolt head.

(h) Torque the forward engine mount bolts.

CAUTION: THIS IS NOT THE FINAL TORQUE FOR THE FORWARD ENGINE MOUNT

BOLTS.

Print Date: October 27, 2015 Page 29 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

1 Hold the nut (16) stable with a wrench and TORQUE the bolts (1) and (18)

to between 88.49 and 132.74 lbf.ft (12.00 and 18.00 m.daN).

(i) Remove the padding from between the engine and the engine mount.

(2) Install the aft engine mount attach fittings.

(Ref. Fig. Aft Engine Mount SHEET 1)

(a) Lubricate the bolts (2), the washers (3) and the shear pins (5) with anti seize

compound (Material No. V10-085).

(b) Installation of the barrel nut:

CAUTION: BARREL NUT MUST BE INSTALLED WITH ROUNDED SIDE UP.

1 Install the barrel nut (6), the bolts (2) and washers (3).

NOTE: You must install the washers (3) with the recessed side against bolt head.

(c) TORQUE (final value) the bolts (2) to between 65 and 70.5 m.daN (479.35 and 519.91 lbf.ft)

(Ref. AMM TASK 70-23-11-911-013) .

NOTE: After you tighten the engine mount bolts to the final torque, make sure that the surfaces

between the pylon and the aft engine mount are in contact.

(d) Install safety cable (Material No. V02-275) (Ref. AMM TASK 70-40-11-911-016) on bolts (2).

Alternate: Use lockwire (Material No. V02-147) (Ref. AMM TASK 70-40-11-911-014) ,

safety cable (Material No. V02-272), safety cable (Material No. V02-273),

safety cable (Material No. V02-274), safety cable (Material No. V02-276), safety

cable (Material No. V02-277), safety cable (Material No. V02-278),

safety cable (Material No. V02-279), safety cable (Material No. V02-280) or safety

cable (Material No. V02-281) (Ref. AMM TASK 70-40-11-911-016) .

NOTE: If the pylon flexible seals were removed, install them.

Subtask 71-00-20-080-050-A

E. Removal of the Lifting Equipment and Bootstrap Assembly

(1) Remove the lifting equipment.

(a) Put the pulley locking levers in the DOWN position.

(b) Reduce the load on the engine cradle using the pulley blocks.

(c) Disconnect the engine cradle from the engine.

(d) Lower the engine cradle. Make sure that the engine cradle does not hit the engine.

(e) Install the engine cradle on the engine trolley.

(f) Remove the four chain hooks from the engine cradle.

(g) Remove the engine trolley rearwards.

(2) Remove the bootstrap assembly as follows:

(Ref. Fig. Bootstrap Installation)

(a) Remove the four chain pulley blocks and the dynamometers from the rear beam (9) and the

forward hinge arms (4) and (5).

(b) Remove the pins (8) and remove the rear beam (9).

(c) Remove the pins (1) and remove the link (2).

Print Date: October 27, 2015 Page 30 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

(d) Remove the pins (3) and remove the left and right hinge arms (4) and (5).

(e) Release the left and right clamps (7) and remove the spacer and the center hinge clamp from the

pylon.

Subtask 71-00-20-760-050-A

F. Do a check of the electrical bonding

(1) Measure the resistance value (ohmic) (Ref. AMM TASK 20-28-00-720-005) . Make sure that the

resistance between the engine and the pylon is not more than 1.5 milliohm.

Subtask 71-00-20-420-054-A

G. Final Torque of the Bolts of the Forward Mount

CAUTION: MAKE SURE THAT THE TORQUE WRENCH DOES NOT TOUCH THE FORWARD EN-

GINE MOUNT DURING TIGHTENING TO NOT CHANGE THE TORQUE APPLIED TO

THE BOLTS.

(1) Use the special tool CHEST,TORQUE SET-ENGINE R I (98D71203001000)

to TORQUE the forward mount bolts to the final torque value

to between 43.39 and 47.45 m.daN (319.99 and 349.93 lbf.ft)

(Ref. AMM TASK 70-23-11-911-013) .

NOTE: The given torque values take into account the length of the torque wrench.

(a) Use the Torque Wrench to torque the four forward mount bolts (18).

(b) Use the Torque Wrench and Load Reducer to torque the center bolt (1) of the forward mount.

NOTE: The use of the load reducer (P/N GA184A) with the torque wrench (P/N TQFRM14)

changes the value of the torque selected. You must set a value between 13 m.daN (96

lbf.ft) and 14 m.daN (103 lbf.ft) on the wrench to get the torque required for the forward

center mount bolt.

NOTE: After you tighten the engine mount bolts to the final torque, make sure that the surfaces

between the pylon and the forward engine mount are in contact.

(2) Install safety cable (Material No. V02-275) (Ref. AMM TASK 70-40-11-911-016) on bolt (1).

Alternate: Use lockwire (Material No. V02-147) (Ref. AMM TASK 70-40-11-911-014) ,

safety cable (Material No. V02-272), safety cable (Material No. V02-273),

safety cable (Material No. V02-274), safety cable (Material No. V02-276), safety

cable (Material No. V02-277), safety cable (Material No. V02-278),

safety cable (Material No. V02-279), safety cable (Material No. V02-280) or safety

cable (Material No. V02-281) (Ref. AMM TASK 70-40-11-911-016) .

NOTE: You can use lockwire diameters ranging from 0.8mm to 1.2mm to safety the bolt (1).

(3) Install the retainers (11) and (13) secured with the bolt (9), the washers (10) and (14) and the nut

(15).

(4) TORQUE the bolts (9) to between 24 and 36 lbf.in (0.27 and 0.41 m.daN)

(Ref. AMM TASK 70-23-11-911-013) .

(5) Remove the fan cowl and thrust reverser braces

(Ref. Fig. Fan Cowl and Thrust Reverser Braces)

(a) Put the fan cowl hold-open rods into position to hold the weight of the fan cowls

(Ref. AMM TASK 71-13-00-010-010) .

Print Date: October 27, 2015 Page 31 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

(b) Put the thrust reverser half hold-open rods into position to hold the weight of the thrust reverser

halves (Ref. AMM TASK 78-32-00-010-010) .

(c) Remove the support arms (5) and (6) from the fan cowls and the thrust reverser halves.

(d) Remove the adjustable struts (1) and (2).

5. Close-up

Subtask 71-00-20-020-081-A

A. Remove ballast installed for aircraft stability.

(1) If all engines are in place, remove all ballast installed for aircraft stability.

Subtask 71-00-20-630-050-A

B. Remove caps from the open ends.

** ON A/C 001-018, 025-025, 027-028, 053-104, 301-500, 513-700

PRE SB 36-1055 for A/C 001-018, 025-025, 027-028, 053-054, 101-104, 301-302, 401-401, 451-452, 513-513,

601-601

Subtask 71-00-20-420-096-A

C. Installation of the Bleed Pressure Regulator Valve (PRV) Sense Line.

(1) Install the sense line between the bleed pressure regulator valve (PRV) and the pylon interface

(Ref. AMM TASK 36-11-49-400-016) .

** ON A/C ALL

Subtask 71-00-20-420-055-A

D. Installation of Components on the Left and the Right Sides of the Engine

(1) Install these components on the left side of the engine.

(a) Connect the sensor tubes.

(Ref. Fig. TAI Location and Hydraulic Reservoir Pressurization Tube Location SHEET 1)

1 Connect the pressure regulating valve sensor tube (20).

2 TORQUE the tube union nut to between 2.0 and 2.3 m.daN (14.75 and 16.96 lbf.ft).

3 Connect the thermostat sensor tube (11).

4 TORQUE the union nut to between 1.5 and 1.7 m.daN (11.06 and 12.54 lbf.ft)

(Ref. AMM TASK 70-23-11-911-013) .

(b) Connect the fuel tubes to the fluid disconnect panel.

(Ref. Fig. Power Plant, Left Side SHEET 1)

1 Install a new IPC -CSN (73-11-48-80-120) gasket (11) on the fuel supply tube (8)

(Ref. AMM TASK 70-23-13-911-010) .

2 Put the fuel supply tube in position on the fluid disconnect panel and install the four bolts (9)

and the washers (10).

3 TORQUE the bolts to 100 lbf.in (1.13 m.daN) (Ref. AMM TASK 70-23-11-911-013) .

4 Safety the bolts (9) with lockwire (Material No. V02-147)

(Ref. AMM TASK 70-40-11-911-014) .

Alternate: Use safety cable (Material No. V02-272), safety cable (Material No. V02-273),

safety cable (Material No. V02-274), safety cable (Material No. V02-275),

safety cable (Material No. V02-276) safety cable (Material No. V02-277), safety

cable (Material No. V02-278),

Print Date: October 27, 2015 Page 32 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

safety cable (Material No. V02-279), safety cable (Material No. V02-280) or safety

cable (Material No. V02-281) (Ref. AMM TASK 70-40-11-911-016) .

5 Install a new IPC -CSN (73-11-48-80-080) gasket (3) on the fuel return to tank tube (4).

6 Put the fuel return to tank tube in position on the fuel disconnect panel and install the four

bolts (6) and the washers (5).

7 TORQUE the bolts (6) to between 0.38 and 0.42 m.daN (33.63 and 37.17 lbf.in)

(Ref. AMM TASK 70-23-11-911-013) .

8 Safety the bolts (6) with lockwire (Material No. V02-147)

(Ref. AMM TASK 70-40-11-911-014) .

Alternate: Use safety cable (Material No. V02-272), safety cable (Material No. V02-273),

safety cable (Material No. V02-274), safety cable (Material No. V02-275),

safety cable (Material No. V02-276) safety cable (Material No. V02-277), safety

cable (Material No. V02-278),

safety cable (Material No. V02-279), safety cable (Material No. V02-280) or safety

cable (Material No. V02-281) (Ref. AMM TASK 70-40-11-911-016) .

(c) Connect the hydraulic tubes to the fluid disconnect panel.

1 Connect the hydraulic case drain connector (7) to the fluid disconnect panel.

2 TORQUE the connector (7) to between 215 and 245 lbf.in (2.43 and 2.77 m.daN)

(Ref. AMM TASK 70-23-11-911-013) .

3 Connect the hydraulic pressure tube connector (2) to the fluid disconnect panel.

4 TORQUE the connector (2) to between 9.7 and 10.7 m.daN (71.53 and 78.91 lbf.ft)

(Ref. AMM TASK 70-23-11-911-013) .

5 Connect the hydraulic suction tube connector (1) to the fluid disconnect panel. Handtighten

the connector.

(d) Connect the cabin air duct.

(Ref. Fig. TAI Location and Hydraulic Reservoir Pressurization Tube Location SHEET 1)

1 Position the duct and install the coupling (7).

2 TORQUE the coupling to between 0.85 and 0.96 m.daN (75.22 and 84.96 lbf.in).

3 Install the coupling. To do this, tap the coupling with a mallet.

4 TORQUE the coupling again to between 0.79 and 0.9 m.daN (69.91 and 79.65 lbf.in).

5 Tap the coupling again.

6 TORQUE the coupling again to between 0.79 and 0.9 m.daN (69.91 and 79.65 lbf.in).

(e) Connect the Thermal Anti-Ice (TAI) duct.

(Ref. Fig. TAI Location and Hydraulic Reservoir Pressurization Tube Location SHEET 1)

1 Position the TAI duct and install the couplings (19).

2 TORQUE the coupling (19)

to between 0.5084 and 0.6214 m.daN (44.99 and 54.99 lbf.in).

3 Install the coupling. To do this, tap the coupling with a mallet.

4 TORQUE the coupling again

to between 0.5084 and 0.6214 m.daN (44.99 and 54.99 lbf.in)

(Ref. AMM TASK 70-23-11-911-013) .

5 Tap the coupling again.

6 TORQUE the coupling again

to between 0.5084 and 0.6214 m.daN (44.99 and 54.99 lbf.in).

Print Date: October 27, 2015 Page 33 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

(f) On the fan case near the V-groove at 11 o'clock, connect the electrical connector 4004VC.

(Ref. Fig. Left Connectors Location SHEET 1)

(g) Connect the thrust reverser harness connector 4101KS-A and 4101KS-B on the thrust reverser

Hydraulic Control Unit (HCU).

(Ref. Fig. Left Connectors Location SHEET 1)

(2) Install these components from the right side of the engine.

(Ref. Fig. Power Plant, Right Side SHEET 1)

(a) Connect the TAI duct (2).

(Ref. Fig. Forward Junction Box SHEET 1)

CAUTION: MAKE SURE THE COUPLINGS DO NOT TOUCH ADJACENT COMPONENTS

OR FAN COWL DOORS (WHEN CLOSED). DAMAGE TO COMPONENTS CAN

OCCUR.

1 Position the duct on the pylon and install the coupling (3).

2 Connect the duct (2) with the couplings (3). Make sure the seal is installed correctly. Make

sure that the t-bolt (7) on the coupling (3) is installed 20°angle from the top of the duct so

that it does not touch the fan cowl door hinge when closed.

3 TORQUE the coupling to between 0.51 and 0.62 m.daN (45.13 and 54.87 lbf.in).

4 Install the coupling. To do this, tap the coupling with a mallet.

5 TORQUE the coupling again to between 0.51 and 0.62 m.daN (45.13 and 54.87 lbf.in).

6 Tap the coupling again.

7 TORQUE the coupling again to between 0.51 and 0.62 m.daN (45.13 and 54.87 lbf.in).

(b) Connect the starter duct.

(Ref. Fig. Forward Junction Box SHEET 1)

(Ref. Fig. Upper/Lower Link Starter Duct and Link Assembly SHEET 1)

(Ref. Fig. Forward Junction Box SHEET 1)

NOTE: Adjust the link assemblies when the engine is installed on the pylon.

1 Remove the four nuts (7), washers (9) and bolts (8) from the two upper link assemblies (16)

and (17). Remove the upper link assemblies.

2 Remove the four nuts (7), washers (9) and bolts (8) from the lower link assemblies (11) and

(12). Remove the lower link assemblies.

NOTE: It may be necessary to loosen the coupling at the valve. If this is required, torque the

coupling nut as explained in steps 4_ thru 7_.

3 Position the starter duct (4) on the pylon starter duct (6) and install the coupling (5).

4 TORQUE coupling (5) to between 0.79 and 0.9 m.daN (69.91 and 79.65 lbf.in).

5 Lightly hit around the outside of the coupling with a fiber hammer.

6 TORQUE coupling (5) again to between 0.79 and 0.9 m.daN (69.91 and 79.65 lbf.in).

7 Repeat steps 4_ thru 6_ two more times.

8 Connect the lower link assemblies (11) and (12) to the Fan case brackets with bolts (8),

washers (9) and nuts (7). Do not torque the nuts at this time.

9 Connect the upper link assemblies (16) and (17) to the Fan case brackets with bolts (8),

washers (9) and nuts (7). Do not torque the nuts at this time.

Print Date: October 27, 2015 Page 34 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

10 Loosen the nuts (13) on the bolts (18) on the support links (11), (12), (16) and (17).

11 Adjust the links as needed to attach to the starter duct (4) without preload.

12 Install the four link assemblies (11), (12), (16) and (17) onto the starter duct (4) with bolts (8),

washers (9) and nuts (7).

13 TORQUE the eight nuts (7) to between 0.6 and 0.8 m.daN (53.10 and 70.80 lbf.in).

14 TORQUE the four nuts (13) on the bolts (18) on the link assemblies (11), (12), (16)

and (17) to between 1 and 1.2 m.daN (88.50 and 106.19 lbf.in). The link threads

must block the safety holes in the link assemblies. This can be checked with a piece of

lockwire (Material No. V02-126).

Alternate: Use safety cable (Material No. V02-282), safety cable (Material No. V02-283),

safety cable (Material No. V02-283A), safety cable (Material No. V02-284),

safety cable (Material No. V02-285), safety cable (Material No. V02-286), safety

cable (Material No. V02-287),

safety cable (Material No. V02-288), safety cable (Material No. V02-289) or safety

cable (Material No. V02-290) (Ref. AMM TASK 70-40-11-911-016) .

Put the lockwire or safety cable into each safety hole. The lockwire or safety cable must not

go through.

15 Rig the starter duct (Ref. AMM TASK 80-13-49-820-010) .

(c) On the fan case near the V-groove at 1 o'clock, connect the electrical connector 4005VC.

(Ref. Fig. Power Plant, Right Side SHEET 1)

(d) On the forward pylon junction box, connect the electrical connectors 402VC, 404VC, 405VC,

406VC, 408VC, 447VC, 448VC and 457VC (Ref. AMM TASK 70-23-15-912-010) .

(Ref. Fig. Forward Junction Box SHEET 1)

(e) On the pylon junction box, connect the electrical connectors 401VC, 403VC, 407VC and 409VC

(Ref. AMM TASK 70-23-15-912-010) .

(Ref. Fig. Forward Junction Box SHEET 1)

(f) On the pylon junction box, connect the generator harness connector 400VC.

CAUTION: CONTACTS HAVE TO BE REPLACED IN CASE OF ANY WEAR AND TEAR

SIGNS (HOLES, SCRATCH, DISCOLORATION, TEARS, PITTED MARKS).

1 Do not clean the contacts with abrasive material.

2 Connect a DYNAMOMETER 15 DAN (33 LBF) - PULL to the test pin to do a pin retention

check of the sockets.

a The minimum extraction force value must be 1.2 daN (2.7 lbf) for a CANNON contact

Ref. ESPM 20-48-23.

b The minimum extraction force value must be 2.8 daN (6.3 lbf) for a FRAMATOME

(former SOURIAU) contact Ref. ESPM 20-48-24.

3 Tighten the connector with a WRENCH - STRAP until the orange colour is shown in

the window of the coupling nut and safety the generator harness connector 400VC with

lockwire (Material No. V02-147) (Ref. AMM TASK 70-40-11-911-014) .

Alternate: Use safety cable (Material No. V02-272), safety cable (Material No. V02-273),

safety cable (Material No. V02-274), safety cable (Material No. V02-275),

safety cable (Material No. V02-276), safety cable (Material No. V02-277),

safety cable (Material No. V02-278), safety cable (Material No. V02-279), safety

cable (Material No. V02-280) or

safety cable (Material No. V02-281) (Ref. AMM TASK 70-40-11-911-016) .

(Ref. Fig. Forward Junction Box SHEET 1)

Print Date: October 27, 2015 Page 35 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

(g) On the aft interface junction box, connect the electrical connectors 450VC, 452VC and 454VC.

(Ref. Fig. Left Interface Junction Box SHEET 1)

(h) On the forward section of the combustion case at 11 o'clock, connect the hydraulic reservoir

pressurization tube to the union (engine 1 only).

NOTE: The elbowed union of the hose must be connected to the engine.

(Ref. Fig. TAI Location and Hydraulic Reservoir Pressurization Tube Location SHEET 1)

TORQUE the union to between 1.5 and 1.7 m.daN (11.06 and 12.54 lbf.ft)

(Ref. AMM TASK 70-23-11-911-013) .

(i) Install the drains mast (Ref. AMM TASK 71-71-42-400-010) .

Subtask 71-00-20-410-062-B

E. If the engine fire seals are not present, install them as follows:

(Ref. Fig. Inspection for the Thrust Reverser Brackets and Inspection for/Installation of the Engine Fire

Seals SHEET 1)

(Ref. Fig. Fire Seal Installation SHEET 1)

(1) Close the relevant thrust reverser half (Ref. AMM TASK 78-32-00-410-010) :

(2) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(3) FOR 1000EM2 (ENGINE-2)

461AL, 462AR

(4) Put the fire IPC -CSN (71-51-46-80-030) seal assembly (15) or IPC -CSN (71-51-46-80-020) seal

assembly (16) on the heatshield so there is full contact between the seal and the thrust reverser

bracket assembly. The fire seal should rest against the bracket with no compression.

(5) Mark the forward and bottom outline of the fire seal on the heatshield with a PENCIL.

(6) Open the relevant thrust reverser half (Ref. AMM TASK 78-32-00-010-010) :

(7) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(8) FOR 1000EM2 (ENGINE-2)

461AL, 462AR

(9) Measure 0.125 in. (3.18 mm) aft of the fire seal forward outline and make a parallel line on the

heatshield with a PENCIL.

(10) Align the fire seal with the aft outline and bottom outline on the heatshield.

(11) Put a PLATE - STEEL, 500X500X3 MM (19.68X19.68X0.12 IN) between the strut fairing and the

heatshield before you drill the holes to protect the strut fairing.

(12) Drill through the three fire seal pilot holes into the heatshield. Enlarge the holes with a DRILL - NO 21

(DIA 0.159 IN - 4.039 MM).

(13) Remove the burrs from the holes in the fire seal and the heatshield.

(14) Cleaning

WARNING: DO NOT GET CLEANING FLUID ON YOUR SKIN OR IN YOUR EYES. PUT ON PRO-

TECTIVE CLOTHING, GOGGLES AND A FACE MASK. USE THE FLUID IN A WELL

VENTILATED AREA. DO NOT BREATHE THE VAPOR. IF YOU GET THE CLEANING

FLUID ON YOUR SKIN OR IN YOUR EYES FLUSH IT AWAY WITH WATER. GET

MEDICAL AID IF YOUR SKIN OR EYES BECOME IRRITATED.

Print Date: October 27, 2015 Page 36 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

(a) Clean the fire seal and the aft and inboard surfaces of the heatshield and block seal with a

Textile-Lint free Cotton - (Material No. 14-SBA1) made moist with solvent (Material No. V01-457).

Wipe the surfaces dry before the cleaning solvent evaporates.

(15) Applying of primer

WARNING: DO NOT GET THE PRIMER ON YOUR SKIN OR IN YOUR EYES. PUT ON PRO-

TECTIVE CLOTHING, GOGGLES AND A FACE MASK. USE THE PRIMER IN

A WELL VENTILATED AREA. DO NOT BREATHE THE GAS. IF YOU GET THE

PRIMER ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET

MEDICAL AID IF YOUR SKIN OR EYES BECOME IRRITATED.

(a) Apply primer (Material No. V08-032) to the mating surfaces of the fire seal assembly. Allow to air

dry for twenty minutes.

(16) Apply release agent (Material No. V02-158A) to the aft surface and inboard corner of the block seal.

(17) Applying of sealant

WARNING: DO NOT GET THE SEALANT ON YOUR SKIN OR IN YOUR EYES. PUT ON PRO-

TECTIVE CLOTHING, GLOVES, GOGGLES AND A FACE MASK. USE THE SEAL-

ANT IN A WELL VENTILATED AREA. DO NOT BREATHE THE GAS. IF YOU GET

THE SEALANT ON YOUR SKIN OR IN YOUR EYES GET MEDICAL AID IMMEDI-

ATELY.

(a) Apply sealant (Material No. V08-030) to the mating surfaces of the fire seal.

(18) Put the fire seal into position on the heatshield.

(19) Installation of the fire seals as follows:

(a) Install the fire IPC -CSN (71-51-46-80-030) seal assembly (15) and IPC -

CSN (71-51-46-80-020) seal assembly (16) on the fire shield with IPC -

CSN (71-51-46-80-010) screws (17).

(b) TORQUE the screws (17) to between 6 and 8 lbf.in (0.07 and 0.09 m.daN).

(20) Using of sealant

WARNING: DO NOT GET THE SEALANT ON YOUR SKIN OR IN YOUR EYES. PUT ON PRO-

TECTIVE CLOTHING, GLOVES, GOGGLES AND A FACE MASK. USE THE SEAL-

ANT IN A WELL VENTILATED AREA. DO NOT BREATHE THE GAS. IF YOU GET

THE SEALANT ON YOUR SKIN OR IN YOUR EYES GET MEDICAL AID IMMEDI-

ATELY.

(a) Fill all the voids in the fire seal with sealant (Material No. V08-030). Allow the sealant to cure for

24 hours at 77 deg. F (25 deg.C) and 50 percent humidity.

Subtask 71-00-20-820-050-A

F. Do the Adjustment

(1) Adjust the thrust reverser latches, bumpers and compression struts

(Ref. AMM TASK 78-30-00-820-010) .

(2) Adjust the fan cowls (Ref. AMM TASK 71-13-00-800-010) .

NOTE: Make sure that the gearbox breather outlet duct (GBOD) aligns with the gearbox breather out-

let vent on the right fan cowl. If it does not align, loosen the GBOD fasteners, align the GBOD

with the vent and torque the fasteners (Ref. AMM TASK 72-61-49-400-010) .

Print Date: October 27, 2015 Page 37 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

Subtask 71-00-20-410-051-A

G. Close access

(1) Check the HP bleed and pressure regulating valves configuration.

NOTE: Make sure that HP bleed and pressure regulating valves are not mechanically locked and can

operate freely.

(2) Close the thrust reverser cowls (Ref. AMM TASK 78-32-00-410-010) :

(3) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(4) FOR 1000EM2 (ENGINE-2)

461AL, 462AR

Subtask 71-00-20-440-050-A

H. Activate the thrust reverser Hydraulic Control Unit (HCU) (Ref. AMM TASK 78-30-00-440-012) .

(Ref. Fig. Hydraulic Control Unit SHEET 1)

Subtask 71-00-20-611-050-A

J. Do a Check of the Engine Oil System and Prime It

(1) Prime the engine oil system (Ref. AMM TASK 12-13-79-610-012) .

(2) Fill the Integrated Drive Generator (IDG) oil system (Ref. AMM TASK 12-13-24-612-011) .

Subtask 71-00-20-612-050-B

K. Service the Starter with Oil (Ref. AMM TASK 12-13-80-600-010) .

NOTE: The starter may have been drained when the engine was removed.

Subtask 71-00-20-410-053-A

L. Close Access

(1) Close the fan cowl (Ref. AMM TASK 71-13-00-410-010) :

(2) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(3) FOR 1000EM2 (ENGINE-2)

447AL, 448AR

(4) Remove the access platform(s).

(5) Remove the warning notice(s).

Subtask 71-00-20-865-072-A

WARNING: CLOSE THE PHC AND WHC CIRCUIT BREAKERS BEFORE YOU CLOSE THE PROBE

HEATER AND WINDOW HEATER CIRCUIT-BREAKERS. IF YOU DO NOT OBEY THIS SE-

QUENCE:

- THE PROBES WILL BECOME TOO HOT.

- THIS CAN CAUSE DAMAGE TO EQUIPMENT AND INJURY TO MAINTENANCE PER-

SONNEL.

M. Remove the safety clip(s) and the tag(s) and close this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU ANTI ICE/PROBES/PHC/1 2DA1 D03

Print Date: October 27, 2015 Page 38 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

PANEL DESIGNATION FIN LOCATION

122VU ANTI ICE/WHC/2 5DG2 W13

122VU ANTI ICE/WHC/1 5DG1 X13

122VU ANTI ICE/PROBES/PHC/3 2DA3 Y16

122VU ANTI ICE/PROBES/PHC/2 2DA2 Y12

Subtask 71-00-20-865-052-A

N. Remove the safety clips and tags and close these circuit breakers in this sequence:

PANEL DESIGNATION FIN LOCATION

122VU ANTI ICE/PROBES/1/TAT 1DA1 Z12

122VU ANTI ICE/PROBES/2/TAT 1DA2 Y15

49VU ANTI ICE/PROBES/PITOT/1 3DA1 D02

122VU ANTI ICE/PROBES/2/PITOT 3DA2 Y14

122VU ANTI ICE/PROBES/3/PITOT 3DA3 Z16

49VU ANTI ICE/PROBES/AOA/1 4DA1 D04

122VU ANTI ICE/PROBES/2/AOA 4DA2 Y13

122VU ANTI ICE/PROBES/3/AOA 4DA3 Z15

122VU ANTI ICE/PROBES/1/STATIC 5DA1 Z13

122VU ANTI ICE/PROBES/2/STATIC 5DA2 Y11

122VU ANTI ICE/PROBES/3/STATIC 5DA3 Z14

49VU ANTI ICE/RAIN/RPLNT/CAPT 1DB1 D01

122VU ANTI ICE/RAIN/RPLNT/F/O 1DB2 W11

123VU ANTI ICE/L/WHSLD 1DG1 AF10

123VU ANTI ICE/R/WHSLD 1DG2 AF03

122VU ANTI ICE/WINDOWS/L 4DG1 X14

122VU ANTI ICE/WINDOWS/R 4DG2 W14

121VU ENGINE/ENG1 AND 2 FIRE EX- 1WE1 Q43

TIG/BTL1/SQUIB/A

121VU ENGINE/ENG1 AND 2 FIRE EX- 2WE1 Q44

TIG/BTL1/SQUIB/B

121VU ENGINE/ENG1 AND 2 FIRE EX- 1WE2 Q41

TIG/BTL2/SQUIB/A

121VU ENGINE/ENG1 AND 2 FIRE EX- 2WE2 Q42

TIG/BTL2/SQUIB/B

121VU RCDR/DFDR 7TU K16

** ON A/C 001-018, 025-025, 027-028, 053-104, 108-500, 513-650

49VU COM/CVR/SPLY 2RK E14

49VU COM/CVR/CTL 4RK E13

** ON A/C 651-700

49VU COM/CVR/SPLY 23RK E14

49VU COM/CVR/CTL 26RK E13

** ON A/C ALL

FOR FIN 1000EM1 (ENGINE-1)

49VU ENGINE/1/FADEC A/AND EIU 1 2KS1 A04

121VU ENGINE/ENG1/FADEC B/AND EIU 1 4KS1 R41

121VU ENGINE/IGN/ENG1/SYS B 3JH1 P41

121VU ENGINE/IGN/ENG1/SYS A BAT 2JH1 P39

Print Date: October 27, 2015 Page 39 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

PANEL DESIGNATION FIN LOCATION

49VU ENGINE/1/FIRE DET/LOOP A 7WD1 A06

121VU ENGINE/ENG1/FIRE DET/LOOP B 8WD1 Q38

122VU ELEC/GCU/1 2XU1 T26

122VU ANTI ICE/ENG/1 1DN1 X10

FOR FIN 1000EM2 (ENGINE-2)

49VU ENGINE/2/FADEC A/AND EIU 2 2KS2 A05

121VU ENGINE/ENG2/FADEC B/AND EIU 2 4KS2 Q40

121VU ENGINE/IGN/ENG2/SYS B 3JH2 P42

121VU ENGINE/IGN/ENG2/SYS A BAT 2JH2 P40

49VU ENGINE/1 AND 2/IGN/SYS A 1JH A03

121VU ENGINE/ENG2/FIRE DET/LOOP A 7WD2 Q39

49VU ENGINE/2/FIRE DET/LOOP B 8WD2 A07

122VU ELEC/GCU/2 2XU2 T27

122VU ANTI ICE/ENG/2 1DN2 W10

123VU Y HYD/ELEC/ELEC PUMP/NORM 3801GX AB03

123VU Y HYD/ELEC/PUMP 3802GX AB06

121VU HYDRAULIC/HYD POWER/Y 3803GX N30

FOR FIN 1000EM1 (ENGINE-1)

49VU ENGINE/1 AND 2/IGN/SYS A 1JH A03

Subtask 71-00-20-861-050-A

P. Energize the aircraft electrical circuits (Ref. AMM TASK 24-41-00-861-002) .

Subtask 71-00-20-740-057-A

Q. Update the engine hours and cycles (Ref. AMM TASK 31-36-00-740-005) or

(Ref. AMM TASK 31-36-00-740-014) .

NOTE: Some tasks will possibly not be applicable depending on whether a Data Management Unit (DMU)

or a Flight Data Interface and Management Unit (FDIMU) is installed on the aircraft.

Subtask 71-00-20-860-050-A

R. Do the EIS start procedure (Ref. AMM TASK 31-60-00-860-001) .

Subtask 71-00-20-720-050-B

S. On the MCDU do the following Test:

(1) Push the line key adjacent to the ENG indication. The SYSTEM REPORT/TEST ENG menu comes

into view.

(2) Push the line key adjacent to the FADEC 1(2) A(B) indication. The ENGINE 1(2) MAIN MENU page

comes into view.

(3) Push the line key adjacent to the TROUBLE SHOOTING indication. The FADEC 1(2) A(B) TROUBLE

SHOOTING MENU page comes into view.

(4) Push the line key adjacent to the EEC CONFIGURATION indication. The FADEC 1(2) EEC

CONFIGURATION page comes into view.

(5) Read the data that come on the MCDU (EEC P/N, ENGINE RATING, BUMP LEVEL, EPR MODIFIER

and ENGINE SERIAL NUMBER) to make sure they are the same as written on the EEC, data entry

plug and engine identification plate using the following engine ratings comparison table.

MCDU (EEC CONFIG Menu) ENGINE DATA PLATE (Engine Model)

22000 lbs V2522

24000 lbs V2524

Print Date: October 27, 2015 Page 40 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

MCDU (EEC CONFIG Menu) ENGINE DATA PLATE (Engine Model)

24000E lbs V2524E

27000 lbs V2527

27000E lbs V2527E

27000M lbs V2527M

30000 lbs V2530

30000 lbs V2530

33000 lbs V2533

(6) On the MCDU, push the line key adjacent to the RETURN indication until the CFDS menu page

comes into view.

(7) Stop the MCDU.

Subtask 71-00-20-710-051-A

T. Do an operational test of the EEC (Ref. AMM TASK 73-22-34-710-040) .

NOTE: If the aircraft operates in correct CAT III conditions, do a land test

(Ref. AMM TASK 22-97-00-710-001) .

Subtask 71-00-20-710-061-B

U. Do the operational test of the Starter valve and FMU (Ref. AMM TASK 80-13-51-710-040) .

Subtask 71-00-20-710-050-A

V. Do these Tests

(1) Do a functional test of the IDG disconnect system (Ref. AMM TASK 24-21-00-710-042) .

(2) Do an operational test of the anti-ice protection system of the engine air intake

(Ref. AMM TASK 30-21-00-710-002) .

(3) Do the Hydraulic Maintenance Procedure after an engine installation:

(a) FOR 1000EM1 (ENGINE-1)

· Do the maintenance procedure for Green Hydraulic System

(Ref. AMM TASK 29-11-51-860-040) .

(b) FOR 1000EM2 (ENGINE-2)

· Do the maintenance procedure for Yellow Hydraulic System

(Ref. AMM TASK 29-13-51-860-001) .

Subtask 71-00-20-790-050-B

W. Do these Leak Checks

(1) Do a wet motor leak check (Ref. AMM TASK 71-00-00-710-046) .

(2) Do a leak check of the fuel return valve (Ref. AMM TASK 73-13-42-720-010) to make sure that there

are no leaks at pylon connection.

(3) Do a minimum idle leak check and do a check for leaks (Ref. AMM TASK 71-00-00-710-012) .

(4) Do an Electronic Engine Control (EEC) system idle test (Ref. AMM TASK 71-00-00-710-022) .

** ON A/C 108-200, 251-300

Subtask 71-00-20-210-053-A

X. Do a check of the IDG system as follows:

(1) On the lower ECAM DU, get the ELEC page.

(2) Make sure that the frequency and voltage indications are correct with engine running.

Print Date: October 27, 2015 Page 41 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : AEE Manual : AMM

Type : TF-N Selected applicability : ALL

Rev. Date : Aug 01, 2015

71-00-20-400-040-A - Installation of the Power Plant

** ON A/C 001-018, 025-025, 027-028, 053-104, 201-250, 301-500, 513-700

Subtask 71-00-20-210-053-B

X. Make sure that the IDG is connected:

(1) If the IDG is not connected, make sure that the maintenance message "IDG1(2) (E1(2)-4000XU)

RECONFIG" is shown on the EPGS GROUND REPORT page.

(a) Make sure that the related GCU is energized.

(b) Reset the GCU:

1 On the ELEC control panel 35VU, release (OFF) then push the related ELEC/GEN

pushbutton switch 3XU.

(c) On the ELEC page of the lower ECAM DU, make sure that the line connection between the

IDG1(2) and the related busbar is shown green. Make sure that the frequency and voltage

indications are correct.

(2) If the IDG1(2) is not connected after the GCU reset, do a check for other maintenance messages

related to the IDG.

** ON A/C ALL

Subtask 71-00-20-720-055-A

Y. Do this Test

(1) Do a pretested replacement engine test (Ref. AMM TASK 71-00-00-700-011) .

(2) Do not stop the engine at this step.

Subtask 71-00-20-710-052-A

AA. While the Engine is Running Do this Test

(1) On the lower ECAM DU, get the BLEED page.

(2) On the panel 30VU:

Push the ENG 1 (2) BLEED pushbutton switch

· on the ENG 1 (2) pushbutton switch, the OFF legend goes off.

· on the lower ECAM DU, the PRV and HP valves are shown open.

· Monitor the nacelle temperature for unsatisfactory indication. If the temperature increases

incorrectly, do the inspection of the bleed air duct connections.

(3) On the panel 30VU:

Release the ENG 1(2) BLEED pushbutton switch

· on the ENG 1(2) pushbutton switch the OFF legend comes on.

· on the lower ECAM DU, the PRV and HP valves are shown closed.

Subtask 71-00-20-860-051-A

AB. Do the EIS stop procedure (Ref. AMM TASK 31-60-00-860-002) .

Subtask 71-00-20-862-050-A

AC. De-energize the aircraft electrical circuits (Ref. AMM TASK 24-41-00-862-002) .

Subtask 71-00-20-869-058-A

AD. Installation of the two engines.

(1) If the two engines were installed simultaneously refer to (Ref. AMM D/O 05-59-00-00) for specific

recommendations.

End of document

Print Date: October 27, 2015 Page 42 of 42

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

You might also like

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document6 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- Ata 9Document15 pagesAta 9chinna_jetNo ratings yet

- Airbus-AC A320 PDFDocument431 pagesAirbus-AC A320 PDFsolnegro7No ratings yet

- NwaDocument20 pagesNwaNandlal PrasadNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument48 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- SB - 27 - 1199 - 02 Service BuletinDocument69 pagesSB - 27 - 1199 - 02 Service BuletinKerol MansorNo ratings yet

- Troubleshoot Electrical Issues on American Airlines A319 and A321 AircraftDocument27 pagesTroubleshoot Electrical Issues on American Airlines A319 and A321 AircraftA WongNo ratings yet

- AMM Task May 20Document1,657 pagesAMM Task May 20sreejithNo ratings yet

- AMM Insp Checks of Wheel and Tires PDFDocument12 pagesAMM Insp Checks of Wheel and Tires PDFVincent RadityaNo ratings yet

- B Band FaultDocument3 pagesB Band FaultJay R SVNo ratings yet

- Fonctionnement Différents Systèmes - CFM56-5AB ATA74+75Document105 pagesFonctionnement Différents Systèmes - CFM56-5AB ATA74+75ValentinNo ratings yet

- SVC A330Document9 pagesSVC A330Maria Amparo Corredor TorresNo ratings yet

- 21 20 DistributionDocument22 pages21 20 DistributionJay R SVNo ratings yet

- A321 Checklist PDFDocument18 pagesA321 Checklist PDFpopooNo ratings yet

- Circut BreakDocument19 pagesCircut BreakEvanildoLealNo ratings yet

- HP Bleed Valve FaultDocument9 pagesHP Bleed Valve FaultSuman BajracharyaNo ratings yet

- Aircraft ManualsDocument1 pageAircraft ManualsAlyana Sophia CerdaNo ratings yet

- InstallationDocument12 pagesInstallationhammad ahmedNo ratings yet

- AIR PACK 1 or 2 OVERHEAT WarningDocument2 pagesAIR PACK 1 or 2 OVERHEAT WarningIbrahim KhalilNo ratings yet

- Winsheld PDFDocument34 pagesWinsheld PDFAnonymous FAa4A3akdNo ratings yet

- LEAP Weekly Issue 01 Rev 03Document22 pagesLEAP Weekly Issue 01 Rev 03Ankit KaushikNo ratings yet