Professional Documents

Culture Documents

Dow Corning 993 Product Info

Uploaded by

Lloyd R. Ponce0 ratings0% found this document useful (0 votes)

389 views4 pagesSpecification

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSpecification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

389 views4 pagesDow Corning 993 Product Info

Uploaded by

Lloyd R. PonceSpecification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

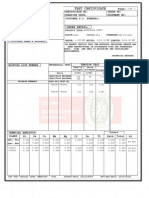

Product Information

Dow Corning® 993 Structural

Glazing Sealant

FEATURES Two-part silicone rubber

• Meets European standard for

structural glazing as developed by APPLICATIONS

EOTA working groups • Two-part silicone sealant for structural glazing

• Excellent adhesion to a wide range

of substrates including coated, TYPICAL PROPERTIES

enamelled and reflective glasses, Specification Writers: These values are not intended for use in preparing

anodised and polyester paint specifications. Please contact your local Dow Corning sales office or your Global

coated aluminium and stainless Dow Corning Connection before writing specifications on this product.

steel

• High level of mechanical Test method* Property Unit Value

properties Base: as supplied

• Odorless and non-corrosive cure Color and consistency Viscous white paste

• Excellent stability through wide Specific gravity 1.32

temperature range: -50ºC to 150ºC Viscosity (100s-1) mPa.s 150,000

• Resistant to ozone Curing agent: as supplied

• Stable viscosity for A & B Consistency Viscous paste

Specific Gravity

components, no heating required - Catalyst black 1.05

• Suitable for use in impact-resistant - HV/GER black 1.06

window systems in new - Clear & grey catalyst 1.01

construction and retrofit in existing Viscosity (20s-1)

buildings - Catalyst black mPa.s 25000

- HV/GER black mPa.s 100000

- Clear & grey catalyst mPa.s 25000

BENEFITS ASTM D93 Flash point - closed cup ºC 28

• Structural capability As mixed

Color and consistency White / black / grey**

• The cured product exhibits

non-slump paste

excellent weathering Specific gravity 1.30

characteristics, and a high Viscosity (100s-1) mPa.s 40,000

resistance to ultra-violet radiation, Working time (25ºC/77ºF, minutes 10 to 30

heat and humidity 50% R.H.)

• Lot matching of base and curing Tack-free time (25ºC/77ºF, minutes 80 to 100

agent not necessary 50% R.H.)

• Different grey shades available Corrosiveness Non-corrosive

As cured - after 7 days at 25°C and 50% RH

(please refer to our color card)

ISO 8339 Tensile strength MPa 0.95

ASTM D624 Tear strength kN/m 6.0

ISO 8339 Elongation at break % 130

ASTM D2240 Durometer hardness, shore A 40

Sealant dynamic design load Pa 140,000

Sealant static design load Pa 15,000

Service temperature range ºC -50 to +150

*

ASTM: American Society for Testing and Materials.

ISO: International Standardisation Organisation.

**

Please refer to our color card (ref. 62-1633a-01).

DESCRIPTION is important when selecting components suitable for meter mix equipment

Dow Corning® 993 Structural Glazing for a project that adhesion and that uses a follower plate system for

Sealant is a two-component, neutral compatibility tests are carried out, and the catalyst.

curing silicone formulation specifically found to be successful, before the Preparatory work

developed for the structural bonding of project starts. Clean all joints and glazing pockets,

glass, metal and other building removing all foreign matter and

components. Neutral alkoxy; cures at Mixing and dispensing contaminants such as grease, oil, dust,

room temperature giving off a small To obtain the ultimate physical water, frost, surface dirt, old sealants, or

amount of alcohol. properties from Dow Corning 993 glazing compounds and protective

Structural Glazing Sealant it is coatings.

TECHNICAL recommended that the base and curing

agent are thoroughly mixed using an Metal, glass and plastic surfaces should

SPECIFICATIONS AND airless mixing system found on most be cleaned by mechanical or solvent

STANDARDS existing commercially available two- procedures. Where used, solvent should

Dow Corning 993 Structural Glazing part silicone dispensing machines. In be wiped on and off with clean, oil- and

Sealant combines excellent unprimed case of smaller applications only special lint-free cloths.

adhesion to a wide range of building two-part hand-mixing cartridge systems

substrates with high levels of physical (Semco/CAS) should be used to avoid Priming

properties over a wide range of incorporation of air into the material. Priming is not usually required when

temperature. It exhibits excellent using Dow Corning 993 Structural

retention of adhesive and mechanical Dow Corning 993 Structural Glazing Glazing Sealant. However, it is essential

properties after ageing as detailed by Sealant should be mixed in a ratio of that adhesion be tested prior to use.

the EOTA Technical guide: 10:1 base to curing agent by weight, or Specific primer recommendations will

• 1000 hours exposure to ultra equivalent 7.8:1 by volume for optimal be made by Dow Corning Technical

• violet radiation in hot water properties. At this mix ratio, the sealant Services Department on a project basis.

immersion (ISO DIS 11431) typically exhibits a working time of 10- Please contact Dow Corning for further

• Resistance to salt spray 30 minutes and allows units to be advice.

(ISO 9227 NSS)* handled within two hours. Small

• Resistance to SO2(ISO 3231) variations in mixing ratio can be Masking and tooling

• Resistance to extreme temperature tolerated, but these should not exceed Areas adjacent to joints may be masked

(ISO 8339) 11:1 to 9:1 by weight or 8.9:1 to 7.3:1 to ensure a neat sealant line. Do not

• Document ATG 98/H680 (UBAtc) by volume to ensure minimum allow masking tape to touch clean

• CE Marked as structural glazing properties are obtained. surfaces to which the silicone sealant is

sealant component according to to adhere. Tooling should be completed

ETAG002, the European Technical Lot matching of Dow Corning 993® in one continuous stroke within 5

Guidelines for structural glazing Base and Dow Corning 993® Curing minutes after sealant application.

with a level of attestation of 1. Agent is not required. Before use it is Masking tape should be removed

(external quality audit) valid in all recommended that the curing agent be immediately after tooling.

EC countries stirred to ensure homogeneity of all

• Meets structural glazing sealant components. Dow Corning 993 Curing Equipment cleaning

requirements according to Agent will react with atmospheric When not being used it is recommended

EN13022, SNJF VEC + VI VEC moisture and therefore should not be that the dispensing equipment be purged

exposed to air for prolonged periods of either with the base component, or

HOW TO USE time. flushed with a suitable solvent such as

Dow Corning 993 Structural Glazing Dow Corning® 3522 Concentrated

Sealant offers unprimed adhesion to Different catalysts are available for Cleaning Solvent. If cured sealant has

most coated and uncoated glasses as Dow Corning 993 Structural Glazing built up inside the equipment, flush the

well as most metal spacers. The sealant Sealant: equipment for the appropriate time with

is compatible with Dow Corning® • Dow Corning 993® Structural Dow Corning 3522 Concentrated

Neutral Curing Construction Sealants Glazing Catalyst is a medium Cleaning Solvent, using a solvent

such Dow Corning® 791 Silicone viscosity paste, fast cure, which is recirculation system. This solvent

Weatherproofing Sealant, and suitable for meter mix equipment dissolves cured silicone sealant and

Dow Corning® Neutral Curing using a pressure pot or follower provides optimum cleaning

Insulating Glass Sealants such as plate system for the catalyst. performance.

Dow Corning® 3362 HD Insulating • Dow Corning 993® HV/GER

Glass Sealant, as well as most Structural Glazing Catalyst is a

commonly used glazing components. It viscous paste, fast cure, which is

Dow Corning is a registered trademark of Dow Corning Corporation.

We help you invent the future is a trademark of Dow Corning Corporation.

2011, December 15 XIAMETER is a registered trademark of Dow Corning Corporation.

Ref. No. 62-0918L-01 SEMCO LCC is a registered trademark of a Fläkt Woods Company.

©1998-2011 Dow Corning Corporation. All rights reserved.

2

MAINTENANCE at dowcorning.com. You can also obtain be accurate. However, because

No maintenance is needed. If sealant a copy from your local Dow Corning conditions and methods of use of our

becomes damaged, replace damaged sales representative or Distributor or by products are beyond our control, this

portion. Dow Corning 993 Structural calling your local Dow Corning Global information should not be used in

Glazing Sealant will adhere to Connection. substitution for customer’s tests to

compatible cured silicone sealant which ensure that our products are safe,

exhibits a clean knife-cut or abraded USABLE LIFE AND effective, and fully satisfactory for the

surface. STORAGE intended end use. Suggestions of use

shall not be taken as inducements to

When stored at or below 30ºC ,

infringe any patent.

TECHNICAL SERVICES Dow Corning 993 Curing Agent has a

Your Dow Corning contact details usable life of 14 months from the date

of production. When stored at or below Dow Corning’s sole warranty is that our

(e-mails): products will meet the sales

Technical inquiries: 30ºC , Dow Corning 993 Base has a

usable life of 14 months from the date specifications in effect at the time of

eutech.info@dowcorning.com

of production. shipment.

Marketing: Your exclusive remedy for breach of

construction.marketing@ PACKAGING such warranty is limited to refund of

dowcorning.com INFORMATION purchase price or replacement of any

Dow Corning 993 Base is product shown to be other than as

Quality Bond: available in 250kg drums and 20 liter warranted.

qualitybond@dowcorning.com pails.

DOW CORNING SPECIFICALLY

EHS inquiries: DISCLAIMS ANY OTHER

Dow Corning 993 Curing Agent is

europe.ehs@dowcorning.com EXPRESS OR IMPLIED

available in 25kg pails. Beside black

and clear, the curing agent is offered in WARRANTY OF FITNESS FOR A

Reach inquiries: PARTICULAR PURPOSE OR

a variety of grey shades. Custom colors

reachsupport@dowcorning.com MERCHANTABILITY.

may be available on request. Please

refer to our color card (ref. 62-1633a-

Your Technical Service contact 01). DOW CORNING DISCLAIMS

details (phone): LIABILITY FOR ANY

Toll Free Numbers: INCIDENTAL OR

From Belgium 0800 80 522 LIMITATIONS

CONSEQUENTIAL DAMAGES.

From France 0805 54 04 39 This product is neither tested nor

From Germany 0800 52 50 258 represented as suitable for medical or

pharmaceutical uses. We help you invent the future. ™

From Italy 800 92 83 30

From Spain 900 813161

dowcorning.com

From United Kingdom HEALTH AND

0800 9172 071 ENVIRONMENTAL

INFORMATION

All other countries: To support Customers in their product

For English +32 64 51 11 59 safety needs, Dow Corning has an

For French +32 64 51 11 59 extensive Product Stewardship

For German +49 611 237503 organization and a team of Product

For Italian +32 64 51 11 73 Safety and Regulatory Compliance

For Spanish +32 64 51 11 66 (PS&RC) specialists available in each

For Russian +7 495 725 43 19 area.

Fax number from all countries:

+32 64 88 86 86

For further information, please see our

Web site, dowcorning.com or consult

HANDLING PRECAUTIONS your local Dow Corning representative.

Product safety information required for

safe use is not included. Before

LIMITED WARRANTY

handling, read product and safety data

sheets and container labels for safe use, INFORMATION – PLEASE

physical and health hazard information. READ CAREFULLY

The material safety data sheet is The information contained herein is

available on the Dow Corning Web site offered in good faith and is believed to

Dow Corning is a registered trademark of Dow Corning Corporation.

We help you invent the future is a trademark of Dow Corning Corporation.

2011, December 15 XIAMETER is a registered trademark of Dow Corning Corporation.

Ref. No. 62-0918L-01 SEMCO LCC is a registered trademark of a Fläkt Woods Company.

©1998-2011 Dow Corning Corporation. All rights reserved.

3

Application Examples Figure 2: Section DD: 4-sided Legend

Design – supported insulating glass 1. Insulating glass unit

2. Silicone structural seal

Figure 1: System for 4 sided unit. (Dow Corning 993 Structural Glazing

structural glazing. Sealant)

3. Silicone rubber spacer block

4. Silicone setting block

5. Aluminium profile

6. Backer rod

7. Structural sealant width dimension

8. Structural sealant bite dimension

9. Weatherseal dimension

10. Silicone weatherseal

(Dow Corning 791 Silicone

Weatherproofing Sealant)

11. Silicone insulated glass seal

Figure 3: Dow Corning® 993

Figure 1B: Section CC: 4-sided

Structural Glazing Sealant – Tack-

Design – unsupported glass.

free time range.

Figure 1B: Section DD: 4-sided

Design – unsupported glass. Figure 4: Dow Corning® 993

Structural Glazing Sealant –

Snaptime range.

Dow Corning is a registered trademark of Dow Corning Corporation.

We help you invent the future is a trademark of Dow Corning Corporation.

2011, December 15 XIAMETER is a registered trademark of Dow Corning Corporation.

Ref. No. 62-0918L-01 SEMCO LCC is a registered trademark of a Fläkt Woods Company.

©1998-2011 Dow Corning Corporation. All rights reserved.

4

You might also like

- TN 76Document6 pagesTN 76Lloyd R. Ponce100% (3)

- TN 76Document6 pagesTN 76Lloyd R. Ponce100% (3)

- Concrete Expansion JointsDocument80 pagesConcrete Expansion JointsDiana Sekar Sari100% (1)

- Planning Process 12 Step CLUPDocument10 pagesPlanning Process 12 Step CLUPLloyd R. Ponce100% (1)

- Al-Amoudi - Saudi Building CodeDocument38 pagesAl-Amoudi - Saudi Building CodedinoNo ratings yet

- 419 - Composites Catalogue-AtulDocument12 pages419 - Composites Catalogue-AtulVaittianathan Mahavapillai100% (1)

- Filled Composite ColumnDocument1 pageFilled Composite ColumnLloyd R. PonceNo ratings yet

- SteelKote EP ZN HS: High-Build Zinc-Rich Epoxy PrimerDocument3 pagesSteelKote EP ZN HS: High-Build Zinc-Rich Epoxy Primerprasanth cp100% (1)

- British Standard document reviewDocument23 pagesBritish Standard document reviewLloyd R. PonceNo ratings yet

- EnP Ultimate Reviewer No. 2ADocument22 pagesEnP Ultimate Reviewer No. 2ALloyd R. Ponce0% (1)

- Sikagard - 62Document4 pagesSikagard - 62bassem kooliNo ratings yet

- DIN 17007-4-1963, Material Type NumberDocument9 pagesDIN 17007-4-1963, Material Type NumberLloyd R. PonceNo ratings yet

- Zinc Flake Coating Ex GeometDocument7 pagesZinc Flake Coating Ex GeometRoter DiamNo ratings yet

- 62 0918 Dowsil 993 Structural GlazingDocument4 pages62 0918 Dowsil 993 Structural GlazingJozsef LukaNo ratings yet

- Carbohydrate in Honey (AOAC-977.20)Document1 pageCarbohydrate in Honey (AOAC-977.20)Khalid100% (1)

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PonceNo ratings yet

- UltraTech Powergrout NS2Document2 pagesUltraTech Powergrout NS2Savalia HardikNo ratings yet

- 993 STRL Glazing Sealant-Product InfoDocument4 pages993 STRL Glazing Sealant-Product InfocurlyjockeyNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Epofine 556 FR/ FInehard 951Document3 pagesEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- Understanding Pre-Painted MetalDocument69 pagesUnderstanding Pre-Painted MetalErick Quan LunaNo ratings yet

- BXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQDocument6 pagesBXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQEmanuel Ciprian CiucurNo ratings yet

- Basf Masterbrace 4500 TdsDocument2 pagesBasf Masterbrace 4500 TdsShivanan SinghNo ratings yet

- Akfix Eng Technical Catalog 2022 Rev16Document211 pagesAkfix Eng Technical Catalog 2022 Rev16ahmed.serefNo ratings yet

- Basf Masterbrace 2200 Tds PDFDocument2 pagesBasf Masterbrace 2200 Tds PDFkrishna dhageNo ratings yet

- Epofine 404 - Finehard 2404Document3 pagesEpofine 404 - Finehard 2404Karishma PrabhuNo ratings yet

- SYNTRAN WE1401 Technical Data SheetDocument1 pageSYNTRAN WE1401 Technical Data SheetEdgardo VillaNo ratings yet

- Apcosil - PC 2568Document3 pagesApcosil - PC 2568Naren SudarsanNo ratings yet

- Intro Hardness PDFDocument2 pagesIntro Hardness PDFCali Tamagnini100% (1)

- DS 443 Duraglaze QD HBPF CoatingDocument2 pagesDS 443 Duraglaze QD HBPF CoatingSomak DuariNo ratings yet

- Nox-Rust 311 HMDocument1 pageNox-Rust 311 HMNavin JoshiNo ratings yet

- TiO2 Technical Data Sheet: SR-2377 PigmentDocument2 pagesTiO2 Technical Data Sheet: SR-2377 PigmentMauricioNo ratings yet

- Epofine 4859 - Finehard 4859Document3 pagesEpofine 4859 - Finehard 4859Karishma PrabhuNo ratings yet

- JOINLEADER 880 Weatherproof Silicone Sealant TDSDocument5 pagesJOINLEADER 880 Weatherproof Silicone Sealant TDSdasaNo ratings yet

- Protect Aluminum Facades with Corro-Coat PE-F Powder CoatingsDocument2 pagesProtect Aluminum Facades with Corro-Coat PE-F Powder Coatingsgirlie fabroNo ratings yet

- POLYPOXY-NF Technical Data SheetDocument2 pagesPOLYPOXY-NF Technical Data SheetCommando crawlerNo ratings yet

- PU Recoatable Finish NipponDocument4 pagesPU Recoatable Finish Nipponyarth880% (1)

- VELOSIT-Watertight-Concrete AF Egy Army Corps of EngineersDocument33 pagesVELOSIT-Watertight-Concrete AF Egy Army Corps of EngineersHsaam HsaamNo ratings yet

- 3M Cold Shrink Pre-Stretched Tubes Silicone RubberDocument4 pages3M Cold Shrink Pre-Stretched Tubes Silicone RubberJovelino SimãoNo ratings yet

- Celite® 281 (TDS)Document1 pageCelite® 281 (TDS)Carlos PosasNo ratings yet

- Ydfc-Mde English IomDocument13 pagesYdfc-Mde English IomMichael FutolNo ratings yet

- National Guard Epoxy Red Oxide PrimerDocument3 pagesNational Guard Epoxy Red Oxide PrimerCyril J PadiyathNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Sillitin Z89 PDFDocument2 pagesSillitin Z89 PDFAngga PratamaNo ratings yet

- Armaflex Class 1: Engineered To Prevent CondensationDocument6 pagesArmaflex Class 1: Engineered To Prevent CondensationTeoxNo ratings yet

- Carbomastic 801 PDFDocument2 pagesCarbomastic 801 PDFkayNo ratings yet

- (PDS) Nitoproof RS (Green Label)Document3 pages(PDS) Nitoproof RS (Green Label)Hendra WahyuNo ratings yet

- Benjamin Moore - ULTRA SPEC ® SCUFF-X PDFDocument3 pagesBenjamin Moore - ULTRA SPEC ® SCUFF-X PDFaboali8686No ratings yet

- Poxeecote-D: High - Build Epoxy CoatingDocument2 pagesPoxeecote-D: High - Build Epoxy CoatingSibgathullahNo ratings yet

- Product Submittal - MasterSeal 730 UVSDocument66 pagesProduct Submittal - MasterSeal 730 UVSTrầnDuyNo ratings yet

- Epikure 8537-w-60Document7 pagesEpikure 8537-w-60Cloudy DayNo ratings yet

- Thermobreak AcoustiplusDocument4 pagesThermobreak Acoustiplusdody andiNo ratings yet

- PIPE ROLLS - New packaging for pipe insulationDocument7 pagesPIPE ROLLS - New packaging for pipe insulationAndrow KhairyNo ratings yet

- Nitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesDocument2 pagesNitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesKishore Nayak kNo ratings yet

- FW-12.5mm Gypsum Board Fire ResistanceDocument2 pagesFW-12.5mm Gypsum Board Fire ResistanceRaghad GNo ratings yet

- Armacell Armaflex Sheet Roll Data SheetDocument4 pagesArmacell Armaflex Sheet Roll Data SheetDoniNo ratings yet

- Paint Data Sheet - National Synthetic Enamel Gloss IDocument3 pagesPaint Data Sheet - National Synthetic Enamel Gloss Iaakh0% (1)

- 118 WJDocument3 pages118 WJAmin HunzaiNo ratings yet

- Desmodur PrimersDocument2 pagesDesmodur PrimersArmando Van BuurenNo ratings yet

- Yellow Metal Primer GuideDocument2 pagesYellow Metal Primer GuidenishantNo ratings yet

- SABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDiana SarmientoNo ratings yet

- Dichtol Sealer Broschure ENDocument12 pagesDichtol Sealer Broschure ENgersom100% (1)

- Carbomastic 15 PDSDocument2 pagesCarbomastic 15 PDSAnonymous 4fVUDODNo ratings yet

- Glass: Submitted By: Manav Batch19Document23 pagesGlass: Submitted By: Manav Batch19manavNo ratings yet

- Prodorlac SPLDocument2 pagesProdorlac SPLkhrisna.dipa.utama50% (2)

- Nitocote PE135 : Constructive SolutionsDocument2 pagesNitocote PE135 : Constructive SolutionsMPS KALIBARUNo ratings yet

- Eggshell Antifungal Coating Technical Data SheetDocument3 pagesEggshell Antifungal Coating Technical Data SheetPJ PJNo ratings yet

- Evotherm M1 - Jan20 - 2013Document2 pagesEvotherm M1 - Jan20 - 2013Erick Escobedo Bragagnini100% (1)

- HOMEY 8800 Two Parts Structural Sealant: Technical Data SheetDocument2 pagesHOMEY 8800 Two Parts Structural Sealant: Technical Data SheetKelly WuNo ratings yet

- DC 995Document3 pagesDC 995Andrea Nicola TurcatoNo ratings yet

- HOMEY 6600 Insulating Glass Sealant: Technical Data SheetDocument2 pagesHOMEY 6600 Insulating Glass Sealant: Technical Data SheetKelly WuNo ratings yet

- Winds Peed To Pressure ConversionDocument1 pageWinds Peed To Pressure ConversionLloyd R. PonceNo ratings yet

- Braided Hose Expansion JointDocument1 pageBraided Hose Expansion JointLloyd R. PonceNo ratings yet

- BS 957-1-1941, Specification For Feeler Gauges PDFDocument14 pagesBS 957-1-1941, Specification For Feeler Gauges PDFLloyd R. PonceNo ratings yet

- FanEffectPPT2 PDFDocument41 pagesFanEffectPPT2 PDFJoel AlcantaraNo ratings yet

- What plumbing designers need to know about valve materials and ratingsDocument4 pagesWhat plumbing designers need to know about valve materials and ratingsLloyd R. PonceNo ratings yet

- Calculating Fiber Loss and DistanceDocument4 pagesCalculating Fiber Loss and DistanceroomforsquaresNo ratings yet

- DIN 17155-1983, Creep Resistant Steel Plate and StripDocument16 pagesDIN 17155-1983, Creep Resistant Steel Plate and StripLloyd R. Ponce100% (1)

- CLASS NOTES Chap 10 1 Bond & AnchorageDocument13 pagesCLASS NOTES Chap 10 1 Bond & Anchoragekohatian27796105No ratings yet

- Galvalume Rolling ShuttersDocument40 pagesGalvalume Rolling ShuttersLloyd R. PonceNo ratings yet

- TSSC 65 - 410Document1 pageTSSC 65 - 410Lloyd R. PonceNo ratings yet

- Directive 2006-42-CE - Machinery PDFDocument63 pagesDirective 2006-42-CE - Machinery PDFeng13No ratings yet

- Planning Mandates of Local GovernmentsDocument20 pagesPlanning Mandates of Local GovernmentsLloyd R. PonceNo ratings yet

- CrackDocument83 pagesCrackSeba Roskopf100% (1)

- Fulltext01 Early Age ConcreteDocument18 pagesFulltext01 Early Age ConcreteLloyd R. PonceNo ratings yet

- Jet FansDocument15 pagesJet FansLloyd R. PonceNo ratings yet

- FanEffectPPT2 PDFDocument41 pagesFanEffectPPT2 PDFJoel AlcantaraNo ratings yet

- CrackDocument83 pagesCrackSeba Roskopf100% (1)

- A R A T I o N A L I Z e D L o C A L P L A N N I N G S y S T e M I N T H e P H I L I P P I N e SDocument25 pagesA R A T I o N A L I Z e D L o C A L P L A N N I N G S y S T e M I N T H e P H I L I P P I N e SLloyd R. PonceNo ratings yet

- M-Bloc Type C SubmittalDocument2 pagesM-Bloc Type C SubmittalLloyd R. PonceNo ratings yet

- MTC AluminumDocument1 pageMTC AluminumLloyd R. PonceNo ratings yet

- Finishing MaterialsDocument13 pagesFinishing MaterialsLloyd R. PonceNo ratings yet

- Superhydrophobic and Super Oleophilic Natural Spong 2022 Journal of Water PRDocument10 pagesSuperhydrophobic and Super Oleophilic Natural Spong 2022 Journal of Water PRDavid NavarreteNo ratings yet

- CH 4Document41 pagesCH 4Soji AdimulaNo ratings yet

- Journal of CO Utilization: Dia Milani, Rajab Khalilpour, Gholamreza Zahedi, Ali AbbasDocument11 pagesJournal of CO Utilization: Dia Milani, Rajab Khalilpour, Gholamreza Zahedi, Ali AbbasSheera SyaninditaaNo ratings yet

- Hydraulic Water TreatmentDocument5 pagesHydraulic Water TreatmentHolaNo ratings yet

- Sutures Tests (ISO Standard)Document26 pagesSutures Tests (ISO Standard)Doaa KhalilNo ratings yet

- Introduction To The Structure and The Structural Role of Elements in GlassesDocument84 pagesIntroduction To The Structure and The Structural Role of Elements in GlassesBiswanath senNo ratings yet

- XI IIT IR FTM-03 24.07.2023 Key SolDocument9 pagesXI IIT IR FTM-03 24.07.2023 Key Soliitb.akkharcheNo ratings yet

- SRP Research Paper PH of VinegarDocument7 pagesSRP Research Paper PH of Vinegarapi-551561394No ratings yet

- Determining Integrity of Seals For Medical Packaging by Visual InspectionDocument4 pagesDetermining Integrity of Seals For Medical Packaging by Visual Inspectionรอคนบนฟ้า ส่งใครมาให้ สักคนNo ratings yet

- Effect of Water Hardness and TDS On Dyeing Quality: International Dyer April 2019Document7 pagesEffect of Water Hardness and TDS On Dyeing Quality: International Dyer April 2019Limario reeNo ratings yet

- Bio Oil From Pyrolysis of Cashew Nut Shell-Characterisation and Related PropertiesDocument11 pagesBio Oil From Pyrolysis of Cashew Nut Shell-Characterisation and Related PropertiesPhúc Võ ĐìnhNo ratings yet

- New Release Agent Free From Wax and Siloxane: Wax-Free Water Dispersion With Water-Repellent EffectDocument1 pageNew Release Agent Free From Wax and Siloxane: Wax-Free Water Dispersion With Water-Repellent EffectFadhli KusumaNo ratings yet

- Drug DesignDocument18 pagesDrug DesignMallineni Sri MounikaNo ratings yet

- Jan 21 - Evaporation Demo Lesson PlanDocument2 pagesJan 21 - Evaporation Demo Lesson Planapi-484413318No ratings yet

- United States Patent: Ca (OH) 2, P7 CasoDocument8 pagesUnited States Patent: Ca (OH) 2, P7 CasoViolanda PranajayaNo ratings yet

- 1.2.1 (Discussion) Hooke's Law and Young's Modulus of Elasticity - Group 4Document3 pages1.2.1 (Discussion) Hooke's Law and Young's Modulus of Elasticity - Group 4Monique Angela Dela CruzNo ratings yet

- Copper Selenide (CuSe and Cu2Se) Nanocrystals - Controllable Synthesis Through A Facile Ultrasonic Chemical RouteDocument3 pagesCopper Selenide (CuSe and Cu2Se) Nanocrystals - Controllable Synthesis Through A Facile Ultrasonic Chemical RoutejacoboNo ratings yet

- Ke2007 PDFDocument13 pagesKe2007 PDFDaniel VillablancaNo ratings yet

- Water Budget EquationDocument10 pagesWater Budget Equationlindsay.sabarNo ratings yet

- auto-BILIRUBIN-T LiquicolorDocument1 pageauto-BILIRUBIN-T LiquicolorMaher100% (1)

- Lab Test Report (ABS Parts)Document1 pageLab Test Report (ABS Parts)PrabhakarNo ratings yet

- Lab Report Exp 2 chm432Document9 pagesLab Report Exp 2 chm432pufff witchesNo ratings yet

- Lab Report - CarbohydratesDocument7 pagesLab Report - CarbohydratesMICAH SOQUIATNo ratings yet

- Viscosity and Phase Behaviour of Petroleum Fluids With High Asphaltene ContentsDocument14 pagesViscosity and Phase Behaviour of Petroleum Fluids With High Asphaltene ContentsAbraham SilesNo ratings yet

- Transient ConductionDocument20 pagesTransient ConductionTom TambeNo ratings yet

- Acc9500 2258Document4 pagesAcc9500 2258Noodles CaptNo ratings yet

- Food Analysis-4Document33 pagesFood Analysis-4MD. Humayun KobirNo ratings yet

- Vacuum Leaf FilterDocument4 pagesVacuum Leaf Filterinstrutech100% (1)