Professional Documents

Culture Documents

Nondestructive Natural Gas Hydrate Recovery Driven by Air and Carbon Dioxide

Uploaded by

Fomalhaut AdityaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nondestructive Natural Gas Hydrate Recovery Driven by Air and Carbon Dioxide

Uploaded by

Fomalhaut AdityaCopyright:

Available Formats

OPEN Nondestructive natural gas hydrate

SUBJECT AREAS:

recovery driven by air and carbon

ENVIRONMENTAL

CHEMISTRY dioxide

CHEMICAL ENGINEERING

Hyery Kang1*, Dong-Yeun Koh1* & Huen Lee1,2

Received 1

24 April 2014 Department of Chemical and Biomolecular Engineering, Korea Advanced Institute of Science and Technology, 291 Daehak-ro,

Guseong-dong, Yuseong-gu, Daejeon 305-701, South Korea, 2Graduate School of EEWS, Korea Advanced Institute of Science and

Accepted Technology, 291 Daehak-ro, Guseong-dong, Yuseong-gu, Daejeon 305-701, South Korea.

24 September 2014

Published Current technologies for production of natural gas hydrates (NGH), which include thermal stimulation,

14 October 2014 depressurization and inhibitor injection, have raised concerns over unintended consequences. The

possibility of catastrophic slope failure and marine ecosystem damage remain serious challenges to safe

NGH production. As a potential approach, this paper presents air-driven NGH recovery from permeable

marine sediments induced by simultaneous mechanisms for methane liberation (NGH decomposition) and

Correspondence and

CH4-air or CH4-CO2/air replacement. Air is diffused into and penetrates NGH and, on its surface, forms a

requests for materials boundary between the gas and solid phases. Then spontaneous melting proceeds until the chemical

should be addressed to potentials become equal in both phases as NGH depletion continues and self-regulated CH4-air replacement

H.L. (hlee@kaist.ac.kr) occurs over an arbitrary point. We observed the existence of critical methane concentration forming the

boundary between decomposition and replacement mechanisms in the NGH reservoirs. Furthermore, when

CO2 was added, we observed a very strong, stable, self-regulating process of exchange (CH4 replaced by CO2/

* These authors air; hereafter CH4-CO2/air) occurring in the NGH. The proposed process will work well for most global gas

contributed equally to hydrate reservoirs, regardless of the injection conditions or geothermal gradient.

this work.

N

atural gas hydrates (NGHs) are solid, non-stoichiometric compounds containing a large amount of

natural gas in deep sea sediments or permafrost regions and they have strong potential as a next-

generation energy source1,2. How to efficiently and safely exploit the tremendous amount of natural

gas stored as gas hydrate underneath the surface of the earth remains an urgent challenge, and fortunately several

field trials for NGH production have suggested a hopeful new prospect for using gas hydrates as energy resources.

Recently, one onshore field trial was carried out in 2012 on the Alaska North Slope in the United States of

America3, and the first offshore field trial was attempted in 2013 in the Eastern Nankai Trough in Japan4,5.

Meanwhile, in Korea, two Ulleung Basin Gas Hydrate (UBGH) Drilling Expeditions were carried out (2007 and

2010), and they confirmed the existence of considerable amounts of NGH in the deep-sea sediments there6–8. A

UBGH field production test is scheduled for mid-2015 at the sites (UBGH 2–6) with geological conditions

providing the greatest potential8.

The currently proposed technologies for marine NGH production are generally derived from standard meth-

ods used in conventional oil and gas industries. These take advantage of the driving potential of differences in

temperature, pressure and chemical potential, which cause significant changes in the conditions within NGH

reservoirs. Thermal stimulation causes vacillation between NGH formation and dissociation temperatures (DT),

depressurization shifts the reservoir pressure to much lower than NGH-formation pressure (DP), and inhibitor

injection alters the chemical environment (Dm) of the NGH to inhibit the stable formation of gas hydrates9.

However, these methods are all dissociation-based technologies, which can raise serious concerns about reper-

cussions such as slope failure and seabed ecosystem destruction10. A CH4-replacement mechanism driven by CO2

injection has recently been suggested as a plausible new approach to production11,12. It has the potential of being a

nondestructive means by which energy production and carbon dioxide sequestration might be achieved simul-

taneously. However, under the harsh conditions of naturally occurring gas hydrate sites, injected CO2 gas readily

transforms to a liquid state, slowing and weakening its soaking and migration. Undesirable fluctuation between

the two CO2 phases (gas and liquid) makes injection and diffusion very unstable, which can possibly lead to a low

replacement rate and recovery yield. To overcome such weaknesses, in previous reports, we proposed the use of a

gaseous mixture of N2 and CO213–15. The overall recovery of methane was greatly improved by specific attack of

SCIENTIFIC REPORTS | 4 : 6616 | DOI: 10.1038/srep06616 1

www.nature.com/scientificreports

CH4 molecules in the small cages of structure (sI) with added N2 the molar ratio between methane in the NGH and air (nCH4/nair)

molecules. In a field production test on the Alaska North Slope in according to the initial NGH amount. The temperature was fixed at

2012, the CO2/N2 injection method was adopted as the main process 288.15 K and air was injected at 200 bar to match closely the con-

and was successfully performed3. ditions found in the UBGH in the East Sea of Korea. When a large

At this stage, we note that each NGH reservoir around the globe amount of air (nCH4 = nair) was present, complete NGH decom-

has its own distinctive geological characteristics, and that these need position occurred (Fig. 1b, left part of dotted line), thus leading to

to be fully examined to determine compatible production techniques. NGH depletion. In other words, the continuous supply of fresh air to

These NGH geological characteristics also vary with formation depth NGH will make it possible for the gaseous phase to be in a more CH4-

and are determined by reservoir pressure and temperature. For dilute state, maintaining its value lower than the CMC, and thereby

example, the temperature and pressure ranges around 278 K and favorably leading to full decomposition of methane hydrates. Here, it

70 bar on the Alaska North Slope. The NGH site in the Nankai becomes quite interesting to see what occurred above the CMC. We

Trough of Japan is located at a depth near 1000 m and ,287 K. In observed the partial NGH decomposition (Fig. 1b, right part of

the UBGH site, the ranges of temperature and pressure are 288– dotted line). Thus, we identify three phenomenological stages:

293 K and 200–220 bar, respectively. The pressure exerted on an release of methane molecules from NGH, NGH structure destruction

NGH site is determined by the hydraulic pressure exerted by the via melting and increase in the concentration of gaseous methane,

water column (depth), but the surrounding temperature may be which are all caused by the chemical potentials of guest-molecules.

much higher than expected because of a geothermal gradient of the Approaching the dynamic equilibrium between solid NGH and gas-

NGH bearing sediment. The two exchange approaches using CH4- eous air-methane, the vigorous escape of methane from NGH is

CO2 and CH4-CO2/N2 are to a certain degree adaptable, but in suppressed and eventually ceases. Accordingly, it is interesting to

reality, we still need to develop a more feasible approach to deal with determine the lowest methane concentration (CMC) that limits

huge amounts of NGH at various conditions. methane production from NGH. The complete NGH decomposition

In this work, we demonstrate an NGH production method using at the CMC can readily be confirmed visually, but above the CMC, a

air and CO2/air. Air is abundant and is available at any time and at noticeable amount of NGH still remains (Fig. 1c).

any location, which makes it the most attractive element for practical When the ratio of CH4-air is greater than CMC, some methane

production of NGH. It is known that N2 and O2 gases can play a role hydrates dissociate and water is produced. Simultaneously, the

in breaking down methane hydrates because of the chemical potential formation of gas hydrate is initiated by the gas mixture of injected

difference (Dm) between their gas and solid phases16–18. Earlier such gas and released CH4. Finally, there is methane contained in the

methods for replacement and dissociation were only considered for hydrate phase but it is inseparable between initially existent CH4

use in systems with very dilute methane hydrates13–18. Accordingly, a and reformed CH4 in hydrate. To obtain more detailed structural

continuous supply of fresh air into the NGH can make it melt com- and compositional information above the CMC, NGH samples

pletely. However, the methane concentration in the recovered gas remaining after sufficient exposure to air (nCH4 ? nair) have to

becomes quite small, requiring additional separation facilities. The be carefully quenched (see Methods) and analyzed for clear iden-

use of pure air contributes to methane production by NGH melting, tification of solid phases that might form with the aid of air. The

but the key issue arises as to whether replacement can occur when we Raman spectra (Fig. 2a) of two samples formed from different meth-

further extend the systems with concentrated methane hydrates or ane-air mole ratios (.CMC) reveal that the injected N2 and O2

injection of CO2-enriched air (CO2/air). To address in detail the molecules are continuously encaged in NGH until the equilibrium

process of releasing methane from NGH using air or CO2/air, we state is reached19,20. Stable capture of air components in sI-S and sI-L

defined the new variable ‘critical methane concentration’ (CMC), strongly implies that NGH decomposition, after gas injection, causes

which consists of the number of methane and injected molecules, chemical replacement even at high temperatures, in the UBGH con-

and performed experiments to reveal the mechanisms involved dition. In addition, the corresponding PXRD patterns (Fig. 2b) con-

(Fig. 1a). firm that a mixed hydrate structure remains in the Cubic Structure I

(sI) phase. These two spectroscopic results suggest that guest-

Results replacement is likely to occur beyond the CMC. The water coming

The initial stage of air injection is intended to strongly decompose the from partial dissociation of the hydrate by air injection is represented

NGH, release the methane and finally alter the gas-phase composi- as hexagonal ice (Ih) because the PXRD patterns were analyzed at

tion around the NGH. Meanwhile, the guest species of nitrogen and 93 K. Quantitative analysis was conducted to find the relative

oxygen are expected to possess strong potential for forming pure, as contributions of the two key mechanisms, decomposition and

well as mixed, hydrates. At this point, the following issue arises and replacement. The main peak intensities were determined by pro-

needs to be addressed. How does air drive the NGH to melt? The file-matching the whole-pattern within the space group correspond-

fresh air might have the maximum potential for decomposing NGH, ing to structures ice Ih and sI.

but gradually weakens and eventually loses its methane recovery Now we will focus on extending the phenomenological concept of

capacity at a certain methane concentration. The NGH is continu- air-based NGH decomposition to the CH4-CO2/air approach.

ously depleted until the chemical potentials of methane in both the Carbon dioxide is known to be a strong hydrate former and thus

solid NGH and gas phases are equal, and right after an arbitrary carbon dioxide mixed with air (20 mol% of CO2) slows the NGH

point, decomposition of methane hydrate stops and anomalous pre- decomposition rate. We note that the CMC is dramatically lowered

servation of the hydrate phase occurs. to 0.418 when CO2 is added as a second guest (solid diamond in

Now, we define the ratio between the methane concentration in Fig. 1b). Fig. 3 shows the incorporations of N2, O2 and CO2 into the

hydrate (nCH4) and the injected gaseous air (or CO2/air; nair or gas hydrate structure when the ratio of CH4-CO2/air exceeds CMC.

nCO2/air) at equal chemical potentials as the ‘critical methane con- Furthermore, we conducted the same experiment using real UBGH

centration’ (CMC). The CMC plays a central role in determining samples from the core section of UBGH-2-6-C. SEM images of the

methane recovery from NGH and can be influenced by complex sediments are presented in Fig. 4. When the CH4-to-CO2/air ratios

surrounding factors such as the depth of marine NGH, geothermal are greater than 0.418, which is the CMC for CO2/air (20 mol% of

gradient, sediment geochemistry and amount of saturated pore water. CO2), incorporation of gases in the gas hydrate structure is observed

For precise CMC analysis we, above all, limited the experimental in the both pure gas hydrate system (Fig. 3a–d) and the UBGH

scope to the achievement of either complete or partial NGH decom- system (Fig. 3e–h). Each of eight figures is presented in

position. We used a fixed-volume high-pressure reactor, controlling Supplementary Fig. S1–8.

SCIENTIFIC REPORTS | 4 : 6616 | DOI: 10.1038/srep06616 2

www.nature.com/scientificreports

Figure 1 | NGH production method using air and CO2/air. (a) Schematic illustration of the described air (or CO2/air) driven NGH production method

composed of two distinct steps: NGH decomposition caused by injected air (or CO2/air); subsequent decomposition driven guest exchange process.

(b) Discovery of the concept of critical methane concentration (CMC) depending on the molar ratio between CH4 and injected air and CO2/air.

(c) Methane hydrate at 288.15 K and 200 bar before air injection (top), and mixed hydrate crystals coexist with water at 288.15 K after air injection above

the critical concentration (bottom).

Another important aspect of this research was to explore the effect of dioxide is added to pure air, its CMC shows a reduction of 10–18%

temperature and pressure on CMC-related behavior. We demonstrated compared with pure air alone, depending on surrounding conditions at

the potential applicability of air and CO2/air injection to three NGH the NGH sites. Several more tests revealed that the CMC generally

production test sites on the Alaska North Slope (USA), Nankai Trough decreases with increasing CO2. The lowering of the CMC by the activity

(Japan) and Ulleung Basin (Korea), and the results are shown in Fig. 5. of carbon dioxide results in a noticeable reduction of the NGH decom-

Representative pressures and temperatures from those sites were spe- position rate, and is probably linked closely to its potential for guest-

cified for the upcoming CMC analysis. To see the degree of NGH exchange with methane. We thus conclude that use of high-CO2 in air

decomposition, we first injected pure air into the NGH and found a leads to replacement-dominant NGH recovery.

relatively high CMC of 0.53–0.65. The CMC gradually decreased as the Here, we notice that both CO2 and CH4 form sI hydrates, while air

NGH pressure and temperature decreased. It is again worth noting that composed of N2 and O2 forms sII structures. Thus, we need to

the injection of pure air and CO2/air can simultaneously drive the two carefully analyze the structural patterns resulting from the complex

distinct mechanisms (decomposition and replacement) needed for interactions of the injected guest species of CO2, N2 and O2.

NGH recovery. Through such a concept (combined hybrid production), According to the PXRD pattern (see Supplementary Fig. S9a), the

we need to establish the process boundaries of the predominant sII hydrates prevail in 1 mol% CO2 in air gas, but in 3–20 mol%

mechanisms occurring in real NGH fields. When 5 mol% of carbon CO2, sI hydrate formation becomes possible. For verification of

SCIENTIFIC REPORTS | 4 : 6616 | DOI: 10.1038/srep06616 3

www.nature.com/scientificreports

Figure 2 | Formation of mixed sI hydrate beyond the critical molar ratio. Red line represents the hydrate phase when methane-air mole ratio is 2.01.

Green line corresponds to the hydrate phase when the ratio is 5.65. (a) The Raman spectra of the mixed N2 1 O2 1 CH4 hydrate at 77 K. (b) PXRD

patterns of each hydrate at 93 K. Asterisks in (b) indicate reflections from hexagonal ice (Ih) phase.

stability we measured three phase (H 1 L 1 V) equilibria using the for the quantitative analysis can be found in Methods. CH4 recovery

isochoric process (see Supplementary Fig. S9b)21. Additionally, we by decomposition is shown as gray bars and CH4 recovery by replace-

observed that just a small increase in the carbon dioxide concentra- ment is shown as shaded bars. The sum of these two bars is the rate of

tion in the vapor phase causes a significant increase of it in the mixed total CH4 recovery. Solid lines represent the ratio between ‘CH4

CO2/air hydrate phase (see Supplementary Table S1). recovery by decomposition’ and ‘CH4 recovery by replacement’ in

To see patterns for mixed hydrates that have larger CH4-CO2/air each sample. Interestingly, directly above the CMC, considerable

mole ratios than at CMC, we carried out ex-situ HRPD experiments amounts of CO2, N2, and O2 initiated replacement of CH4 in the

using the 9B beam line of the Pohang Accelerator Laboratory (see NGH, even under harsh, deep-sea conditions. Particularly, we note

Supplementary Fig. S10). First, we determined the CMC of 0.418 in that the contribution of replacement to NGH recovery (versus the

the ratio of CO2/air (258) and then observed the chemical exchange contribution of decomposition) became more significant as the ratio

that occurred above the CMC. For comparison, the HRPD pattern at of methane to CO2/air increased. Another notable feature is that the

a CH4-air mole ratio of 2.53 is represented by the black line. From NGH production concept based on the CMC can be unrestrainedly

structural analysis we confirmed the coexistence of Structure I gas applicable to a variety of geological settings with site-specific

hydrate and hexagonal ice when either air or CO2/air was injected hydraulic pressures and geothermal gradients (red line in Fig. 6

into the NGH and we obtained their relative amounts by entire- shows UBGH sediment effect).

pattern fitting. The compositions of the sI gas hydrates were analyzed

using GC. Thus the combined refined HRPD (ice to sI ratio) and GC Discussion

results (replacement efficiency revealed by remaining gas composi- The formation of pure N2 or/and O2 hydrate requires harsh p-T

tion in the hydrate phase) are shown as relative contributions of conditions compared to the mild formation condition for pure

decomposition and replacement (Fig. 6). The detailed descriptions CH4 hydrate. However, when the CH4 hydrates are pre-existing

SCIENTIFIC REPORTS | 4 : 6616 | DOI: 10.1038/srep06616 4

www.nature.com/scientificreports

Figure 3 | Direct visualization of guest-exchange analyzed by the Raman spectra after the injection of CO2/air (20 mol% CO2 and 80 mol% air) into

pure CH4 hydrate (a–d) and NGH (e–h). CO2/air injection was performed at 288.15 K and 200 bar. As the CH4-CO2/air ratio increased, significant

encapsulation of CO2, N2, and O2 molecules in the hydrate cages were detected. (a, e) C-O stretching and bending vibrational modes of CO2 molecules

in the large cages of the hydrate; (b, f) C-H stretching vibrational modes of CH4 molecules in the hydrate; (c, g) N-N stretching vibrational modes

of N2 molecules in the hydrate; (d, h) O-O stretching vibrational modes of O2 molecules in the hydrate.

Figure 4 | SEM images on dry sediments selected from the core section UBGH2-6-C.

SCIENTIFIC REPORTS | 4 : 6616 | DOI: 10.1038/srep06616 5

www.nature.com/scientificreports

Figure 5 | CMC observed in the three representative NGH reservoirs with different CO2 concentrations. Solid squares indicate pure air injection. Solid

circles, triangles and diamonds indicate 5, 10 and 20 mol% CO2 in air gas, respectively. The dotted lines are the guides to the eyes.

and gases are injected into the pre-existing CH4 hydrates, as the When the ratio of CH4 to air or CO2/air is less than or equal to the

NGH reservoirs, the circumstance is different from that of pure gas CMC, all CH4 hydrates dissociate. However, when the ratio is higher

hydrate formation condition. When pre-existing CH4 hydrates come than CMC, partial decomposition of methane hydrate is observed

into contact with the foreign gases such as air or CO2/air, slight and injected air or CO2/air form many gas hydrates. That is to say, we

decomposition of the CH4 hydrate is inevitable. Moreover, CH4 note that the phase equilibrium data of the injected gas is not the only

released from the pre-existing gas hydrates changes the composition criterion for determining whether or not the replacement can occur.

of the gas phase (CH4 1 N2 1 O2 or CH4 1 N2 1 O2 1 CO2 gas The most urgent task to advance NGH production is to find an

mixture), and eventually the change in gas composition causes the economically feasible means that can proceed by spontaneous, nat-

injected air or CO2/air gas to form the hydrates after all. This is why ural processes. As a major future energy resource, NGH may com-

we introduced the concept of the ‘Critical Methane Concentration’. pete with shale gas only if we can reduce the cost of primary

Figure 6 | Decomposition/replacement ratio beyond the CMC observed under the conditions in the East Sea using CO2/air (20 mol% CO2 and

80 mol% air) gas. Black and yellow bars represent total CH4 recovery rates based on combination of decomposition and replacement in the pure GH and

UBGH, respectively. When CH4 to CO2/air ratio exceeds the CMC, replacement between CH4 and CO2/air initiates. Shaded areas represent the fraction of

replacement in the total CH4 recovery and solid lines represent relative contributions of replacement in each case.

SCIENTIFIC REPORTS | 4 : 6616 | DOI: 10.1038/srep06616 6

www.nature.com/scientificreports

production from large NGH deposits. Depressurization has been methane gas in the reactor was rapidly exchanged with air (or CO2/air) using a syringe

pump (ISCO, model 260D). To prevent the dissociation of methane hydrates during

attempted in NGH field tests, most recently in the Nankai Trough the gas exchange, we used a back-pressure regulator to maintain a constant pressure

(Japan). We understand that, by whatever method we choose, meth- (e.g., 200 bar). Also, in order to eliminate the heating effect of air, air pre-cooled to a

ane gas will be released from solid NGH by melting, by decomposi- temperature of 288.15 K was used. When we performed the gas exchange of methane

tion or by replacement via chemical exchange. A number of strongly with air or CO2/air, we used another high-pressure reservoir cell in the same

influential variables that drive methane extraction control the two temperature-controlled bath (see Supplementary Fig. S11). The inner volume of the

gas reservoir cell is 500 ml, and it served as a container for pre-cooled gas. During

different NGH production mechanisms, while which of the two every exchange process, the container and an ISCO pump were pressurized 25%

mechanisms is predominant remains to be determined. higher (20–50 bar) than each target pressure before the injection process. For

From the insights gained from this study, we suggest a plausible example, we pressurized the precooled reactor and ISCO pump at 250 bar when the

strategy for extracting fuels from NGH. In the first phase, CO2 target pressure was 200 bar. The back pressure regulator was set at an exact target

pressure. Before performing the gas exchange experiments, we pre-tested the gas

(transported from inland sources) and compressed air is mixed in- exchange capacity of our experimental setup with the empty cell (50 ml) and

situ to prepare for injection into the NGH layer. This ‘in-situ mixing’ confirmed the complete gas exchange (.99%) via GC. It takes 30 seconds completely

concept allows a very effective preparation procedure for injecting to replace the CH4 in the reactor with air (or CO2/air). Once the volume of methane

gas mixtures. Liquid CO2 transported from the inland sources is then hydrate was obtained using the density of methane hydrate (930 kg m23)23, the

volume occupied by the injected gas became known, and the mole of the injected gas

mixed with compressed air captured above the production test field was calculated by applying an ideal gas law. In this way, the mole ratio between CH4

to produce the CO2/air gas mixture. The CO2/air gas mixture is then and air (or CO2/air) was determined. In case of the UBGH sample, the physical

injected into the sediment and diffused throughout the NGH layers. properties of porosity and grain density for sand were acquired from KIGAM (the

The first contact between the CO2/air gas mixture and the gas UBGH drilling expedition team), which was 70% and 2650 kg m23. The pressure and

temperature during the entire process was monitored using a custom-built Labview

hydrates will induce decomposition of a certain portion of NGH in program, and we periodically checked if the pressure and temperature had reached

the sediments. This decomposition step eventually increases the par- constant values. We initially assessed the decomposition of hydrate using a look-

tial pressure of CH4 inside the NGH layer and induces a ‘decomposi- through quartz window on the high-pressure reactor. When the ratio of CH4 to air (or

tion driven-replacement process’. The increased population of CH4 CO2/air) was smaller than the CMC, we confirmed the disappearance of the last

molecules significantly reduces the thermodynamic barrier for hydrate crystal, as visual observation is widely used in determining the hydrate

equilibrium conditions.

replacement reactions. This replacement process enhances the geo-

mechanical stability of the NGH layer by forming stable hydrate Mixed-phase gas hydrate sampling using liquid nitrogen quenched helium gas.

lattices. Here, we again note that the nondestructive replacement When the reaction of the gas hydrate and air (or CO2/air) was completed (confirmed

process preserves host water-lattices in the NGH-bearing sediments by PT monitoring; finished within 72 hours), we took representative samples of the

product for further spectroscopic analyses. To keep the original phase intact, we used

as part of the newly formed air or CO2/air hydrates. In contrast, NGH rapid cooling method using liquid-nitrogen quenched helium gas and liquid nitrogen.

decomposition by depressurization requires large volumes of water If the gas in the reactor is vented to atmospheric pressure under ambient conditions,

to be displaced from the NGH. Furthermore, the ensuing endo- the original composition of the product would significantly change. Therefore, we

thermic temperature drop caused by decomposition can result in rapidly exchanged the gas phase in the reactor with pre-cooled helium gases. Because

undesirable formation of secondary methane hydrate or ice in the helium retains its gaseous phase at the liquid-nitrogen temperature (,77 K), the gas

phase in the reactor was effectively exchanged to helium gas at the near-liquid

well and near the wellbore. The chemical exchange of dissimilar guest nitrogen temperature. At the same time, the reactor was immersed in liquid nitrogen

molecules does not involve significant cooling22, and thus the geo- to freeze the whole reaction product rapidly. In this way, we kept the original phase

mechanical stability of gas hydrate-bearing sediments is less composition of the product during the sampling procedure. When the product was

threatened. completely frozen, it was ground into particles of less than 200 microns, and they were

analyzed using spectroscopic tools (XRD/HRPD, Raman) and gas chromatography.

We present three key aspects of our findings: 1) We defined a new A quantitative analysis for decomposition/replacement beyond the critical meth-

factor (CMC) related to the methane recovery rate from natural gas ane concentration was performed by a combination of XRD/HRPD and GC results.

hydrates, 2) We obtained CMC values for three distinct conditions When mole ratio of CH4 to CO2/air was greater than the CMC, the solid phase (mixed

(simulating three representative reservoirs) experimentally, and 3) gas hydrate) and water coexisted. These products were acquired by a rapid sampling

method, and water phase turns into ice phase. Therefore, the amount of the ice phase

We verified that starting decomposition leads to replacement of corresponds to the amount of decomposition. The recovery by replacement was

methane by injected air or CO2/air in NGH. According to the present determined by a GC analysis of the hydrates using same method used in the literat-

outcomes, we conclude that the proposed process is likely the effi- ure13–15. In this way, the total CH4 recovery and relative CH4 recovery depending on

cient, nondestructive and commercially-viable means (compared to the ratio of CH4 to CO2/air were calculated.

conventional ones) for onshore and offshore methane production

Spectroscopic analysis. For Raman measurements we used the Horiba Jobin Yvon

from NGH, and it can be widely adapted to diverse geological con- LabRAM HR UV/Vis/NIR high resolution dispersive Raman microscope in which a

ditions. We acknowledge that the CH4 cage occupancies of naturally CCD detector was equipped and cooled by liquid nitrogen. Samples were kept at 77 K

occurring gas hydrates may differ depending on the surrounding during measurements. The excitation source was an Ar-ion laser emitting a

conditions, such as the sediment type, the methane saturation per- 514.53 nm line. The laser intensity was typically 30 mW.

The XRD patterns were obtained using a Rigaku D/max-IIIC diffractometer with

centage in the pore water, and the macroscopic morphology of the CuKa as a light source (l 5 1.5406 Å) at a generator voltage of 40 kV and a generator

gas hydrate, among others. Therefore, to apply CMC fully in the field current of 300 mA. A low-temperature stage attached to the XRD unit maintained the

of gas hydrate production, general trends pertaining to the cage working temperature at 93 K, and a step-scan mode was applied (0.02u step-size and

occupancy of target production sites are required. 3 s per step).

The HRPD patterns were collected using PAL (Pohang Accelerator Laboratory,

Republic of Korea) Synchrotron. During the measurements, the h/2h scan mode with

Methods a fixed time of 3 s and a step size of 0.005u for 2h 5 0 , 120u and the beam line with a

Materials. Water of ultrahigh purity was obtained from a Millipore purification unit. wavelength of 1.5472 Å were used for each sample. The loading of the samples was

CH4, air (O2 21 mol% and N2 balance) and CO2/air gas were purchased from the performed at 77 K to minimize possible sample damage.

Special Gas Company (Daejeon, Republic of Korea), with a stated minimum purity of The concentration of gaseous guest-molecules in the hydrate sample was measured

99.95 mol%. using a Young-Lin 6000 (Young-Lin, Republic of Korea) gas chromatography. The

samples were moved to a precooled reactor (,77 K) each time, and it was evacuated

Sample preparation and gas injection procedures. To assess the effect of the molar using a vacuum pump. The gas phase was analyzed after being held at room tem-

ratio of CH4 and air (or CO2/air), we used a fixed-volume high-pressure stirred perature until the hydrate samples completely dissociated. Helium was used as the

reactor. First, we charged the reactor with the desired volume of water and charged carrier gas, and the GC column was maintained at 55 kPa and 353 K.

200 bar of methane gas at 288.15 K. The formation of methane hydrate was achieved

by decreasing the temperature in an isochoric condition. The heating-cooling cycle

was repeated to confirm the complete conversion of water to methane hydrate. When 1. Makogon, Y. F., Holditch, S. A. & Makogon, T. Y. Natural gas-hydrates – A

the methane hydrate was fully formed, additional methane gas was supplied to potential energy source for the 21st Century. J. Pet. Sci. Eng. 56, 14–31 (2007).

recover pressure reduction due to hydrate formation. When the pressure and 2. Sloan, E. D. Fundamental principles and applications of natural gas hydrates.

temperature were stabilized at the desired conditions (e.g., 200 bar and 288.15 K), Nature 426, 353–359 (2003).

SCIENTIFIC REPORTS | 4 : 6616 | DOI: 10.1038/srep06616 7

www.nature.com/scientificreports

3. Schoderbek, D. & Boswell, R. IgN nIk SIkumI #1, Gas Hydrate test Well, Successfully 18. Panter, J. L., Ballard, A. L., Sum, A. K., Sloan, E. D. & Koh, C. A. Hydrate Plug

Installed on the alaska north Slope. Methane hydrate newsletter. US DOE, Fire in Dissociation via Nitrogen Purge: Experiments and Modeling. Energy & Fuels 25,

the ice 11, 1–5 (2011). 2572–2578 (2011).

4. Tsuji, Y., Ishida, H., Nakamizu, M., Matsumoto, R. & Shimizu, S. Overview of the 19. Sloan, E. D. & Koh, C. A. Clathrate Hydrates of Natural Gases (CRC press, 2008).

MITI Nankai Trough wells: a milestone in the evaluation of methane hydrate 20. Sum, A. K., Burruss, R. C. & Sloan, E. D. Measurement of clathrate hydrates via

resources. Resour. Geol. 54, 3–10 (2004). Raman spectroscopy. J. Phys. Chem. B 101, 7371–7377 (1997).

5. Japan Oil, Gas and Metals National Corporation (JOGMEC). Gas production 21. Mohammadi, A. H., Tohidi, B. & Burgass, R. W. Equilibrium data and

from methane hydrate layers confirmed. ,www.jogmec.go.jp/english/news/ thermodynamic modeling of nitrogen, oxygen, and air clathrate hydrates.

release/release0110.html., (2013) (Date of access: 24/04/2014). J. Chem. Eng. Data 48, 612–616 (2003).

6. Bahk, J.-J. et al. Occurrence of near-seafloor gas hydrates and associated cold vents 22. Lee, S., Lee, Y., Lee, J., Lee, H. & Seo, Y. Experimental verification of methane-

in the Ulleung Basin, East Sea. Geosci. J. 13, 347–385 (2009). carbon dioxide replacement in natural gas hydrates using a differential scanning

7. Lee, J. Y. et al. Physical properties of sediments from the Ulleung Basin, East Sea: calorimeter. Environ. Sci. Technol. 47, 13184–13190 (2013).

results from second Ulleung Basin gas hydrate drilling expedition, East Sea 23. Davie, M. K. & Buffett, B. A. A numerical model for the formation of gas hydrate

(Korea). Mar. Petrol. Geol. 47, 43–55 (2013). below the seafloor. J. Geophys. Res. 106, 497–514 (2001).

8. Bahk, J.-J. et al. Characterization of gas hydrate reservoirs by integration of core

and log data in the Ulleung Basin, East Sea. Mar. Petrol. Geol. 47, 30–42 (2013).

9. Demirbas, A. Methane hydrates as potential energy resource: part 2 - methane

production processes from gas hydrates. Energy Convers. and Manage. 51,

1562–1571 (2010).

Acknowledgments

This research was supported by a grant from the National Research Foundation Korea

10. Kvenvolden, K. A. Potential effects of gas hydrate on human welfare. Proc. Natl.

Acad. Sci. USA 96, 3420–3426 (1999). funded by the Korean government (No. 2010-0029176).

11. Ohgaki, K., Takano, K., Sangawa, H., Matsubara, T. & Nakano, S. Methane

exploitation by carbon dioxide from gas hydrates-phase equilibria for CO2-CH4 Author contributions

mixed hydrate system. J. Chem. Eng. Japan 29, 478–483 (1996). K.H., K.D.-Y. and L.H. designed the research; K.H. and K.D.-Y. performed the research;

12. Lee, H., Seo, Y., Seo, Y.-T., Moudrakovski, T. L. & Ripmeester, J. A. Recovering K.D.-Y. and K.H. analyzed the data and K.H., K.D.-Y. and L.H. wrote the paper.

methane from solid methane hydrate with carbon dioxide. Angew. Chem. Int. Ed.

42, 5048–5051 (2003).

13. Park, Y. et al. Sequestering carbon dioxide into complex structures of naturally Additional information

occurring gas hydrates. Proc. Natl. Acad. Sci. USA 103, 12690–12694 (2006). Supplementary information accompanies this paper at http://www.nature.com/

14. Shin, K. et al. Swapping phenomena occurring in deep-sea gas hydrates. Energy & scientificreports

Fuels 22, 3160–3163 (2008).

Competing financial interests: The authors declare no competing financial interests.

15. Koh, D.-Y. et al. Recovery of methane from gas hydrates intercalated within

natural sediments using CO2 and a CO2/N2 gas mixture. ChemSusChem 5, How to cite this article: Kang, H., Koh, D.-Y. & Lee, H. Nondestructive natural gas hydrate

1443–1448 (2012). recovery driven by air and carbon dioxide. Sci. Rep. 4, 6616; DOI:10.1038/srep06616 (2014).

16. Haneda, H., Sakamoto, Y., Kawamura, T. & Komai, T. Experimental study on

dissociation behavior of methane hydrate by air. Proceedings of the 5th This work is licensed under a Creative Commons Attribution 4.0 International

International Conference on Gas Hydrates. Trondheim, Norway: ICGH (2005, License. The images or other third party material in this article are included in the

June 13–16). article’s Creative Commons license, unless indicated otherwise in the credit line; if

17. Masuda, Y. et al. Prediction of methane hydrate dissociation behavior by nitrogen the material is not included under the Creative Commons license, users will need

injection. Proceedings of the 6th International Conference on Gas Hydrates. to obtain permission from the license holder in order to reproduce the material. To

Vancouver, Canada: ICGH (2008, July 6–20). view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

SCIENTIFIC REPORTS | 4 : 6616 | DOI: 10.1038/srep06616 8

You might also like

- Tccs 2021 Energizers 20022021Document7 pagesTccs 2021 Energizers 20022021kuba.jasinskiNo ratings yet

- Molecular Insights Into Carbon Dioxide Enhanced Multi-Component ShaleDocument17 pagesMolecular Insights Into Carbon Dioxide Enhanced Multi-Component Shale荣健淇No ratings yet

- Processes 11 00164 v2Document15 pagesProcesses 11 00164 v2Hồng ÂnNo ratings yet

- Applied Catalysis B: Environmental: Matej Hu S, Venkata D.B.C. Dasireddy, Neja Strah Stefan Ci C, Bla Z LikozarDocument12 pagesApplied Catalysis B: Environmental: Matej Hu S, Venkata D.B.C. Dasireddy, Neja Strah Stefan Ci C, Bla Z LikozarAminNo ratings yet

- Numerical simulation of gas production from permafrost hydrate depositsDocument17 pagesNumerical simulation of gas production from permafrost hydrate depositsLígia BrumNo ratings yet

- Formic Acid SynthesisDocument7 pagesFormic Acid SynthesisJoeNo ratings yet

- 1 s2.0 S0360544217314081 MainDocument17 pages1 s2.0 S0360544217314081 Maindorian.axel.ptNo ratings yet

- High-Pressure Methane and Carbon Dioxide Adsorption on CoalsDocument24 pagesHigh-Pressure Methane and Carbon Dioxide Adsorption on CoalsSonali SwagatikaNo ratings yet

- Modeling CO2 Storage in Aquifers With A Fully-CoupDocument17 pagesModeling CO2 Storage in Aquifers With A Fully-CoupFatimah Az ZahraNo ratings yet

- Uamerica 23 01.196Document16 pagesUamerica 23 01.196Rimy Cruz GambaNo ratings yet

- Aplicações para o Dióxido de CarbonoDocument18 pagesAplicações para o Dióxido de CarbonoThiago Rodrigues SantosNo ratings yet

- Modelling Co Solubility in Pure Water and Nacl-Type Waters From 0 To 300 8C and From 1 To 300 Bar Application To The Utsira Formation at SleipnerDocument13 pagesModelling Co Solubility in Pure Water and Nacl-Type Waters From 0 To 300 8C and From 1 To 300 Bar Application To The Utsira Formation at SleipnerzibaNo ratings yet

- Jeong Jang Shim Han Roh Jung Yoon 2014 Low-Temperature Water-Gas Shift Reaction Over Supported Cu CatalystsDocument6 pagesJeong Jang Shim Han Roh Jung Yoon 2014 Low-Temperature Water-Gas Shift Reaction Over Supported Cu CatalystsAnonymous uCYIu1No ratings yet

- CO2Storage Acad JourlDocument13 pagesCO2Storage Acad JourlgorleNo ratings yet

- A - Phase-Partitioning - Model - For - CO2-Brine - Mixtures - Spycher&Pruess 2010Document26 pagesA - Phase-Partitioning - Model - For - CO2-Brine - Mixtures - Spycher&Pruess 2010F SedighiNo ratings yet

- Synergistic Effect of MgH2 Doping With Ni and Carbon N 2022 International JoDocument15 pagesSynergistic Effect of MgH2 Doping With Ni and Carbon N 2022 International JoPrashant HNo ratings yet

- Dynamic Operation of Water Gas Shift Reaction Over Fe O /CR O /cuo Catalyst in Pd/Al O Membrane ReactorDocument7 pagesDynamic Operation of Water Gas Shift Reaction Over Fe O /CR O /cuo Catalyst in Pd/Al O Membrane ReactorClementia CatherineNo ratings yet

- Matsui Et Al. - 2020 - Microsecond Simulation Study On The Replacement of Methane in Methane Hydrate by Carbon Dioxide, Nitrogen, and CaDocument11 pagesMatsui Et Al. - 2020 - Microsecond Simulation Study On The Replacement of Methane in Methane Hydrate by Carbon Dioxide, Nitrogen, and CaMuhammad Syaugi Arif NugrahaNo ratings yet

- Applied Energy: Won-Jun Jang, Dae-Woon Jeong, Jae-Oh Shim, Hak-Min Kim, Hyun-Seog Roh, in Hyuk Son, Seung Jae LeeDocument12 pagesApplied Energy: Won-Jun Jang, Dae-Woon Jeong, Jae-Oh Shim, Hak-Min Kim, Hyun-Seog Roh, in Hyuk Son, Seung Jae LeeWassachol SumarasinghaNo ratings yet

- Ceriacatalyst Zerva 2006Document8 pagesCeriacatalyst Zerva 2006leonardoNo ratings yet

- Syngas Production From Methane Dry Reforming Over Ni/SBA-15 Catalyst: Effect of Operating ParametersDocument12 pagesSyngas Production From Methane Dry Reforming Over Ni/SBA-15 Catalyst: Effect of Operating ParametersWassachol SumarasinghaNo ratings yet

- GTL Conversion ProcessesDocument4 pagesGTL Conversion Processesslidey1No ratings yet

- Expeerimental DtatDocument10 pagesExpeerimental DtatGeorge FuryNo ratings yet

- Improved Methanol Yield and Selectivity From CO2 Hydrogenation Using A Novel Cu-ZnO-ZrO2 Catalyst Supported On Mg-Al Layered Double Hydroxide (LDH)Document8 pagesImproved Methanol Yield and Selectivity From CO2 Hydrogenation Using A Novel Cu-ZnO-ZrO2 Catalyst Supported On Mg-Al Layered Double Hydroxide (LDH)Nguyễn TuânNo ratings yet

- Samanta 2011Document8 pagesSamanta 2011SanaNo ratings yet

- Syngas Production Via Combined Steam and Carbon Dioxide Reforming of Methane Over Ni-Ce - MgAl2O4 Catalysts With Enhanced Coke ResistanceDocument7 pagesSyngas Production Via Combined Steam and Carbon Dioxide Reforming of Methane Over Ni-Ce - MgAl2O4 Catalysts With Enhanced Coke ResistanceWassachol SumarasinghaNo ratings yet

- CO2 Conversion To CO by Auto-Thermal Catalyst-Assisted Chemical LoopingDocument9 pagesCO2 Conversion To CO by Auto-Thermal Catalyst-Assisted Chemical LoopingNguyễn TuânNo ratings yet

- Benefits of Using Active Reservoir Management During CO - Plume Development For CO - Plume Geothermal (CPG) SystemsDocument10 pagesBenefits of Using Active Reservoir Management During CO - Plume Development For CO - Plume Geothermal (CPG) SystemsTroy ModiNo ratings yet

- 2009 - Catalytic Conversion of NaHCO3 Into Formic Acid in Mild Hydrothermal Conditions For Co2 UtilizationDocument6 pages2009 - Catalytic Conversion of NaHCO3 Into Formic Acid in Mild Hydrothermal Conditions For Co2 UtilizationMaría Andérez FernándezNo ratings yet

- Co As Carbon Source For Fuel Synthesis: SciencedirectDocument5 pagesCo As Carbon Source For Fuel Synthesis: SciencedirectDanCosminNo ratings yet

- J Ijhydene 2018 06 123Document12 pagesJ Ijhydene 2018 06 123Wassachol SumarasinghaNo ratings yet

- Polyurethane Foam: A Novel Support For Metal Oxide Packing Used in The Non-Thermal Plasma Decomposition of CO2Document12 pagesPolyurethane Foam: A Novel Support For Metal Oxide Packing Used in The Non-Thermal Plasma Decomposition of CO2korope8705No ratings yet

- Surface Thermodynamics of HydrocarbonDocument10 pagesSurface Thermodynamics of HydrocarbonRandy AswinNo ratings yet

- Structural Effects On The High Temperature Adsorption of CO2 On A Synthetic HydrotalciteDocument9 pagesStructural Effects On The High Temperature Adsorption of CO2 On A Synthetic HydrotalciteMahmood KhanNo ratings yet

- Carbon Dioxide Storage: Geological Security and Environmental Issues - Case Study On The Sleipner Gas Field in NorwayDocument20 pagesCarbon Dioxide Storage: Geological Security and Environmental Issues - Case Study On The Sleipner Gas Field in NorwayThay VaniaNo ratings yet

- Storage of CO2 As Hydrate in Depleted Gas Reservoirs-PA-PDocument11 pagesStorage of CO2 As Hydrate in Depleted Gas Reservoirs-PA-PBolsec14No ratings yet

- Journal of Natural Gas Science and Engineering: Yuefa Wang, Zhongxi Chao, Hugo A. JakobsenDocument9 pagesJournal of Natural Gas Science and Engineering: Yuefa Wang, Zhongxi Chao, Hugo A. JakobsenDaniel Z JucaNo ratings yet

- Oxygen Nonstoichiometry Defect Equilibria and Thermodynamic Characterization of Lamno3 Perovskites With Ca SR A Site and Al B Site DopingDocument11 pagesOxygen Nonstoichiometry Defect Equilibria and Thermodynamic Characterization of Lamno3 Perovskites With Ca SR A Site and Al B Site DopingJags BuddyNo ratings yet

- Geological Sequestration of CO2 in Western Canada BasinDocument23 pagesGeological Sequestration of CO2 in Western Canada BasinKaren Kaczala BelottiNo ratings yet

- Acs JPCC 5b06515Document20 pagesAcs JPCC 5b06515hemedi kitilaNo ratings yet

- Kinetics of CO 2 Absorption in To Aqueous MEA Solutions Near EquilibriumDocument9 pagesKinetics of CO 2 Absorption in To Aqueous MEA Solutions Near EquilibriumMuchammad AdriyanNo ratings yet

- 1 s2.0 S0021961420300987 MainDocument19 pages1 s2.0 S0021961420300987 Mainabhisheknemade9765No ratings yet

- s12182 021 00548 ZDocument13 pagess12182 021 00548 ZRamadhan KusumaNo ratings yet

- Donazzi 2008Document18 pagesDonazzi 2008Monika MartinezNo ratings yet

- Numerical Simulations of The Thermal Impact of Supercritical CO2 Injection On Chemical Reactivity in A Carbonate Saline Reservoir - Andre - AzaroualDocument45 pagesNumerical Simulations of The Thermal Impact of Supercritical CO2 Injection On Chemical Reactivity in A Carbonate Saline Reservoir - Andre - AzaroualwordindustriesNo ratings yet

- Development of A Zero-Emissions Sulfur-Recovery Process. 1.Document12 pagesDevelopment of A Zero-Emissions Sulfur-Recovery Process. 1.Soroosh ZareNo ratings yet

- Thermal ManagementDocument15 pagesThermal ManagementKiran JojiNo ratings yet

- Low Temperature Catalytic Reverse Water-Gas Shift ReactionDocument14 pagesLow Temperature Catalytic Reverse Water-Gas Shift ReactionRen FengNo ratings yet

- Energies: First-Order Estimation of In-Place Gas Resources at The Nyegga Gas Hydrate Prospect, Norwegian SeaDocument26 pagesEnergies: First-Order Estimation of In-Place Gas Resources at The Nyegga Gas Hydrate Prospect, Norwegian SeaPirKhalilUrRehmanNo ratings yet

- Combined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessDocument8 pagesCombined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessKeysler PonceNo ratings yet

- An Integrated Catalytic Approach For The Production of Hydrogen by GlycerolDocument6 pagesAn Integrated Catalytic Approach For The Production of Hydrogen by GlycerolMahdy HajienayatiNo ratings yet

- Underground Coal Gasification ReportDocument21 pagesUnderground Coal Gasification ReportPrabhu PrasadNo ratings yet

- Bongole et al. 2020; Combination of double and single cyclic pressure alternation technique to increase CO2 sequestration with heat mining in enhanced geothermal reservoirs by thermohydro- mechanical coupling methodDocument19 pagesBongole et al. 2020; Combination of double and single cyclic pressure alternation technique to increase CO2 sequestration with heat mining in enhanced geothermal reservoirs by thermohydro- mechanical coupling methodjamesNo ratings yet

- 1 s2.0 S1876610217316478 MainDocument10 pages1 s2.0 S1876610217316478 Main是sherry吖No ratings yet

- Journal of Environmental Chemical Engineering: 2 2 Yan Resing Dias, Oscar W. Perez-LopezDocument8 pagesJournal of Environmental Chemical Engineering: 2 2 Yan Resing Dias, Oscar W. Perez-Lopezfarah al-sudaniNo ratings yet

- CO2 Methanation - The Effect of Catalysts and Reaction ConditionsDocument6 pagesCO2 Methanation - The Effect of Catalysts and Reaction ConditionsBen PowersNo ratings yet

- 10 1016@j Jphotochem 2019 111933Document10 pages10 1016@j Jphotochem 2019 111933zmaxprom5No ratings yet

- PAPER#12Document27 pagesPAPER#12Valentina Rubio MendozaNo ratings yet

- Chinese Journal of Chemical Engineering: Wei Yang, Xiaodan Yu, Jianguo Mi, Wanfu Wang, Jian ChenDocument8 pagesChinese Journal of Chemical Engineering: Wei Yang, Xiaodan Yu, Jianguo Mi, Wanfu Wang, Jian ChenDiana Marcela UribeNo ratings yet

- A State-Dependent Critical State Model For Methane Hydrate-Bearing SandDocument11 pagesA State-Dependent Critical State Model For Methane Hydrate-Bearing SandFomalhaut AdityaNo ratings yet

- Tight Gas SandDocument7 pagesTight Gas SandFomalhaut AdityaNo ratings yet

- Tight Gas Reservoirs - An Unconventional Natural Energy Source For The Future G.C.NaikDocument32 pagesTight Gas Reservoirs - An Unconventional Natural Energy Source For The Future G.C.NaikNurgul KosnazarovaNo ratings yet

- ShapeDocument1 pageShapeFomalhaut AdityaNo ratings yet

- The Internet: Chinese Pinyin English ExampleDocument2 pagesThe Internet: Chinese Pinyin English ExampleFomalhaut AdityaNo ratings yet

- Thickening Time vs Additives GraphicDocument2 pagesThickening Time vs Additives GraphicFomalhaut AdityaNo ratings yet

- Studi Kasus Pencemaran Gas BatubaraDocument9 pagesStudi Kasus Pencemaran Gas BatubaraFomalhaut AdityaNo ratings yet

- Grafik Bab Thickening TimeDocument2 pagesGrafik Bab Thickening TimeFomalhaut AdityaNo ratings yet

- Holiday 4th SemesterDocument4 pagesHoliday 4th SemesterFomalhaut AdityaNo ratings yet

- Chinese Pinyin English Example: Verbs For Beginners: Part 1Document2 pagesChinese Pinyin English Example: Verbs For Beginners: Part 1Fomalhaut AdityaNo ratings yet

- BP Oil Spill 2010Document9 pagesBP Oil Spill 2010Winn SannNo ratings yet

- BP Oil Spill 2010Document9 pagesBP Oil Spill 2010Winn SannNo ratings yet

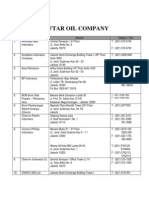

- Daftar Dan Alamat Oil CompanyDocument16 pagesDaftar Dan Alamat Oil Companysetia wirawan100% (7)

- BP Oil Spill 2010Document9 pagesBP Oil Spill 2010Winn SannNo ratings yet

- BP Oil Spill 2010Document9 pagesBP Oil Spill 2010Winn SannNo ratings yet

- BP Oil Spill 2010Document9 pagesBP Oil Spill 2010Winn SannNo ratings yet

- BP Oil Spill 2010Document9 pagesBP Oil Spill 2010Winn SannNo ratings yet

- Solar Mounting SystemDocument25 pagesSolar Mounting SystemapaneagraNo ratings yet

- The Removal of Tetracycline From Water Using Biochar Produced From Agricultural Discarded MaterialDocument10 pagesThe Removal of Tetracycline From Water Using Biochar Produced From Agricultural Discarded MaterialRoshanNo ratings yet

- Stripline Transmission Line PropertiesDocument10 pagesStripline Transmission Line PropertiesRakshit PantNo ratings yet

- Jeremy's Night at the ObservatoryDocument5 pagesJeremy's Night at the ObservatoryYineysi Peña0% (4)

- Ch1 MTFDocument7 pagesCh1 MTFAnuradha PradhanNo ratings yet

- Chapter 09961 - 4.1 An Introductory Overview of Metal Matrix Composites Systems, Types and DevelopmentsDocument21 pagesChapter 09961 - 4.1 An Introductory Overview of Metal Matrix Composites Systems, Types and DevelopmentsFlor GINo ratings yet

- Elec Magnetism GsDocument29 pagesElec Magnetism GsRegine BuscaNo ratings yet

- B567 PDFDocument9 pagesB567 PDFCarlos Alberto Oviedo100% (1)

- Monte Carlo Simulation Assignment - Metrology and Instrumentation 2023Document5 pagesMonte Carlo Simulation Assignment - Metrology and Instrumentation 2023devgyanNo ratings yet

- Exp 2 G7 1Document13 pagesExp 2 G7 1Glenda Lizel BiceraNo ratings yet

- An Analysis of Extended and exponentially-Fed-Batch CulturesDocument9 pagesAn Analysis of Extended and exponentially-Fed-Batch CulturesScourge BlackthornNo ratings yet

- Complexiometric TitrationsDocument4 pagesComplexiometric Titrationskasonde.musonda8No ratings yet

- Types of SolutionDocument7 pagesTypes of Solutionmark bendanoNo ratings yet

- Fluid Mechanics - Chapter 1 - Flow in PipesDocument13 pagesFluid Mechanics - Chapter 1 - Flow in PipesHazzim HamdanNo ratings yet

- Fundamental Concepts and Principles of Mechanics - Newtonian Mechanics - Civil Engineering NotesDocument2 pagesFundamental Concepts and Principles of Mechanics - Newtonian Mechanics - Civil Engineering NotesJemerald MagtanongNo ratings yet

- Answer Key ThermodynamicsDocument18 pagesAnswer Key ThermodynamicsAnant DwivediNo ratings yet

- Ammonium Persulfate - MSDSDocument7 pagesAmmonium Persulfate - MSDSMohamed HalemNo ratings yet

- Page 2 - Group 3 - Class 11-5Document1 pagePage 2 - Group 3 - Class 11-5Yuke DjuliantiNo ratings yet

- Analisis Lineal y de FatigaDocument10 pagesAnalisis Lineal y de FatigaFranco AlberiNo ratings yet

- LookDocument6 pagesLookStanley SibandaNo ratings yet

- Ch16-18 Powder MetallurgyDocument38 pagesCh16-18 Powder Metallurgyمالك كرجهNo ratings yet

- Ee8711 Set1Document14 pagesEe8711 Set1St. Anne's CET (EEE Department)No ratings yet

- Short Circuit CalculationsDocument7 pagesShort Circuit CalculationsMohamedNo ratings yet

- Challenges of Tribology in Space Mechanisms-LG V2 PDFDocument48 pagesChallenges of Tribology in Space Mechanisms-LG V2 PDFasantori6133No ratings yet

- Question ReportDocument18 pagesQuestion ReportnptidksharmaNo ratings yet

- Matthew Correia Group II WorksheetDocument5 pagesMatthew Correia Group II WorksheetFrank MassiahNo ratings yet

- Fire Resistance Properties 1 / 12Document12 pagesFire Resistance Properties 1 / 12alpersakirmetinNo ratings yet

- Numerical Problems-1Document2 pagesNumerical Problems-1Hur ZaheerNo ratings yet

- Cambridge Ordinary LevelDocument16 pagesCambridge Ordinary Levelkashaf saleemNo ratings yet

- (L6) - (JLD 3.0) - NLM - 22nd June.Document63 pages(L6) - (JLD 3.0) - NLM - 22nd June.Aditya BiswasNo ratings yet