Professional Documents

Culture Documents

Real-Time Robust Control Using Digital Signal Processor: T. Slavov, L. Mollov, J. Kralev, P. Petkov

Uploaded by

jordanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Real-Time Robust Control Using Digital Signal Processor: T. Slavov, L. Mollov, J. Kralev, P. Petkov

Uploaded by

jordanCopyright:

Available Formats

BALKAN JOURNAL OF ELECTRICAL & COMPUTER ENGINEERING Vol.1, No.

2 56

Real-time Robust Control Using Digital Signal

Processor

T. Slavov, L. Mollov, J. Kralev, P. Petkov

and different type of uncertainties. The high order of the

Abstract—A laboratory system for real-time robust control of controller obtained is usually pointed out as a disadvantage of

multivariable analogue 4th order two input/two output plant is -synthesis. However, with the appearing of powerful

presented. The system consists of Spectrum Digital

eZdspTMF28335 development kit with built in Texas processors in the recent years this peculiarity of the -

Instruments TMS320F28335 Digital Signal Processor (DSP), synthesis does not pose a significant difficulty.

digital to analogue signal converter, voltage divider, and a test In contrast with the theoretical achievements, the practical

analogue plant. A 16th order discrete-time -controller with implementation of robust control laws is still in its beginning.

sampling frequency of 100 Hz is implemented by using a DSP. There is a few real life applications of high order robust

The -controller designed ensures robust performance of the

control laws reported in the literature concerning mainly the

closed-loop system in presence of parametric uncertainty in two control of flying vehicles (see for instance [3] and [4]). The

plant parameters. Frequency domain analysis of the discrete-time

main obstacle of robust control laws implementation is the

closed-loop system is performed. The implementation of high-

order robust control law is facilitated by the usage of technology difficulties related to the development, testing and verification

for automatic code generation. An appropriate software in of the necessary real-time software which is highly dependent

MATLAB®/Simulink® environment is developed which is on the type of digital controller platform used. These

embedded in DSP by using the Simulink Coder®. Experimental difficulties are reduced significantly using the recent

and simulation results are presented which confirm that the technologies for automatic code generation and embedding

control system achieves the prescribed performance.

implemented in MATLAB®/Simulink® program environment

Index Terms— digital signal processor, real-time control,

[5]. A real-time implementation of linear quadratic control law

robust control, -controller by using automatic code generation is reported in [6].

In this paper a laboratory system for real-time robust control

of multivariable analogue 4th order two input/two output plant

I. INTRODUCTION is presented. The system consists of Spectrum Digital

eZdspTMF28335 development kit with built in Texas

The Robust Control Theory now is a mature discipline that Instruments TMS320F28335 DSP, digital to analogue signal

involves powerful methods for analysis and design of control converter, voltage divider, and a test analogue plant. A 16th

systems in presence of signal and parameter uncertainties. The order discrete-time -controller with sampling frequency of

most frequently used techniques for robust control design are

100 Hz is implemented by using a Digital Signal Processor.

the H optimization and the -synthesis [1]. The H

The -controller designed ensures robust performance of the

optimization is usually preferred in robust design because it

closed-loop system in presence of parametric uncertainty in

produces controller of smaller order which facilitates its

two plant parameters. Frequency domain analysis of the

implementation. The common disadvantage of all H

discrete-time closed-loop system is performed. An appropriate

optimization methods is that they are suitable for plants with software in MATLAB®/Simulink® environment is developed

unstructured uncertainties but cannot ensure robust stability which is embedded in DSP by using the Simulink Coder®.

and performance in the general case of unstructured and Experimental and simulation results are presented which

structured (parametric) uncertainties. In contrast, the - confirm that the control system achieves the prescribed

synthesis which aims at minimization of the structured performance.

singular value [2] may ensure robust stability and robust

performance in the presence of exogenous disturbances, noises II. CONTROLLER -SYNTHESIS

T. Slavov is with the Technical University Sofia, Bulgaria, He is now with

The block-diagram of the analog two input/two output plant

the Department of Systems and Control (e-mail: ts_slavov@ tu-sofia.bg). under consideration is shown in Fig. 1.

L. Mollov is with the Technical University Sofia, Bulgaria, He is now with

the Department of Systems and Control (e-mail: l_mollov@abv.bg).

J. Kralev is with the Technical University Sofia, Bulgaria, He is now with

the Department of Systems and Control (e-mail:jkralev@yahoo.com).

P. Petkov is with the Technical University Sofia, Bulgaria, He is now with

the Department of Systems and Control (e-mail: php@ tu-sofia.bg).

BALKAN JOURNAL OF ELECTRICAL & COMPUTER ENGINEERING Vol.1, No.2 57

Ie 6.36 104 .

The analog plant output signals and model output signals

are shown in Fig. 2 and Fig.3. As can be seen the model

outputs coincide very well with the measured plant output

signals.

Fig. 1. Block-diagram of the plant The nominal model parameters determined are presented in

Table 1.

The 4th order plant model is described by the state space

equations

x(t ) Ax(t ) Bu (t )

, (1)

y (t ) Cx(t ) Du (t )

T

where x x1 x2 x3 x4 is the state vector,

T

u(t ) u1 (t ) u2 (t ) is the input vector and

T

y(t ) y1 (t ) y2 (t ) is the output vector,

1

0 0 0 k1

T1 0 Fig. 2. First output signal

T1

k2 1

0 0 k2

T2 T2 0

A ,B T2 ,

k3 1 k k

0 5 3 0 0

T3 T3 T3

k 4 k6

k4 1 0

0 0 T4

T4 T4

0 0 0 1

C , D 022 ,

0 1 0 0

k1, k2 ,..., k6 are coefficients of proportionality, T1, T2 ,..., T4 are

time constants.

Fig. 3. Second output signal

The model parameters are estimated by identification

procedure using the MATLAB® function lsqnonlin based on Further on it is assumed that the coefficient k1 is a subject

the nonlinear least square method. The performance criteria

minimized is TABLE I

NOMINAL PANT PARAMETERS

Parameter Value Parameter Value

t

I e ( y p (t ) y(t )) ( y p (t ) y(t ))dt ,

T

(2) k1 1.0463 T1 0.3308

0 k2 1.5689 T2 0.5291

k3 0.4213 T3 1.1142

where y p (t ) [ y p1 (t ) y p 2 (t )]T is the analog plant output. k4 3.0000 T4 0.7063

The identification input signal is k5 3.0558

k6 1.8970

uident (t ) [1(t ) 1(t )] T

of 25% change around the nominal value and the parameter

where 1(t ) is a step function. The signal y p (t ) is obtained by T4 undergoes 40% change around its nominal value. In this

real time measuring of the two analogue plant outputs with way the plant involves structured (parametric) uncertainty

sample time 100 ms. After minimization of (2) taking t 10s which is set by using the function ureal from Robust Control

we obtain Toolbox® [7]. In order to ensure robust stability and robust

BALKAN JOURNAL OF ELECTRICAL & COMPUTER ENGINEERING Vol.1, No.2 58

performance of the closed-loop system in the presence of such 0.15s 1

0.92 0

0.24s 104

uncertainty and to ensure acceptable suppression of the

disturbances and noises, it is appropriate to design a - Wp

0.18s 1

controller. 0 0.92

The block-diagram of the closed-loop system which 0.30s 104

includes the performance and control weighting functions is

shown in Fig. 4. The transfer function matrix of the uncertain and for the control weighting function

plant is denoted by G and the controller transfer function

matrix -by K . The system has a reference vector ref and an 0.005s 1

0.02 0.001s 1 0

output disturbance vector dist . Wu .

The closed-loop system is described by the equations 0.005s 1

0 0.02

0.001s 1

The performance weighting functions are chosen as low pass

filters to suppress the system error y r , and the control

weighting functions are chosen as high pass filters with

appropriate bandwidth in order to impose constraints on the

high frequency spectrum of the control actions [7].

In order to determine a discrete-time controller the

extended open-loop system including the plant and weighting

functions is discretized with sampling period of 0.01 s

Fig. 4. Closed-loop system with performance requirements corresponding to sampling frequency of 100 Hz. The -

synthesis is performed by using the Robust Control Toolbox®

y To r So d function dksyn [8]. Four iterations are performed that decrease

, (3)

u Si K (r d ) the maximum value of to 1.000. The final controller

obtained is of 16th order.

where the matrix Si ( I KG)1 is the input sensitivity The singular value plot of the discrete-time controller is

shown in Fig.5. The controller has a high low-frequency gains

transfer function matrix, So ( I GK )1 is the output which allows to attenuate efficiently the low-frequency

sensitivity transfer function matrix and To ( I GK )1GK is disturbances and to ensure accurate reference tracking.

the output complementary sensitivity function. (Here and

further on the reference vector is denoted for brevity by r and

the disturbance vector - by d ).

The weighted closed-loop system outputs e y and eu satisfy

the equation

e y W p So W p So r

. (4)

eu Wu Si K Wu Si K d

The performance criterion requires the transfer function

matrix from the exogenous input signals r and d to the

output signals e y and eu to be small in the sense of , for

all possible uncertain plant models G . The transfer function

Fig. 5. Controller singular values

matrices W p and Wu are used to reflect the relative

importance of the different frequency ranges for which the The frequency-response plot of the structured singular value

performance requirements should be fulfilled. for the case of robust stability, obtained by using the function

The -synthesis is done for the performance weighting robuststab is shown in Fig. 6. The closed-loop system can

tolerate up to 201% of the modeled uncertainty which means

function

that the stability is preserved for uncertainty that may be up to

two times larger than the assumed one.

BALKAN JOURNAL OF ELECTRICAL & COMPUTER ENGINEERING Vol.1, No.2 59

Fig. 6. Robust stability for -controller

Fig. 9. Singular values of the output sensitivity function

The frequency response of the structured singular value for

the case of robust performance, obtained by using the function

robustperf is shown in Fig.7. The closed-loop system achieves

a robust performance margin of 1.011 which means that the

system will satisfy the performance requirements for all

possible values of the uncertain parameters. The singular

values of the complementary sensitivity function To plotted in

Fig.8 show that the closed-loop system will track accurately

references with frequencies up to 5 rad/s.

In Fig.9 we show the singular value plot of the output

Fig. 10. Singular values of disturbance-to-control transfer function

matrix

sensitivity function So compared with the singular value plot

of the inverse performance weighting function W p 1 . The plot

confirms that the system attenuates more than 103 times low

frequency output disturbances. The singular value plot of the

transfer function matrix Si K KSo which, according to (3)

determines the control action u , is shown in Fig.10. It is seen

Fig. 7. Robust performance for -controller that the high frequency contents of the control actions is

attenuated in accordance with the requirements imposed by

the inverse control weighting function Wu 1 .

III. IMPLEMENTATION OF THE - CONTROLLER

The experimental setup of the analog plant control system is

shown in Fig. 11. The two input/two output plant (1) is

modeled on an analog modeling board, consisting of a bus on

which functional blocks are operating independently. The bus

is powered by a DC power supply. The linear range of input-

output signals is 10 V. The main linear blocks are adder,

differentiator, inverter, integrator, aperiodic unit and gain unit.

The analog system makes it easy to model plants with a time

constant up to 1 s and gain factor up to 10.

Fig. 8. Singular values of the complementary sensitivity function The block-diagram of developed control system with DSP

BALKAN JOURNAL OF ELECTRICAL & COMPUTER ENGINEERING Vol.1, No.2 60

is shown in Fig. 12. Coder® is implemented. The main advantages of this

The block ``Digital Signal Controller" (DSC) is the technology are the relatively easy implementation of complex

control algorithms and the short time to translate the control

algorithm from the working simulation environment to the real

working environment with physical plants, reducing the

overall time for application testing and verification of the

developed algorithm.

The process of generation and implementation of the

execution code in the Simulink® model is illustrated in Fig.13.

This process relies heavily on the use of Simulink Coder ® and

Embedded Coder®.

Fig. 11. Experimental setup

Fig. 12. Block-diagram of the control system with DSP

Fig. 13. Generation and embedding of the control code

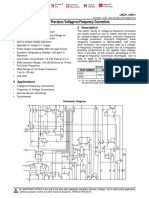

Spectrum Digital eZdspTMF28335 development board with

an integrated Digital Signal Processor Texas Instruments

TMS320F28335 [9(9)]. This controller works at 150 MHz and

may perform single precision (32-bit) computations by using

FPU (Floating-Point Unit). It has 68K bytes on-chip RAM,

256K bytes off-chip SRAM memory, 512K bytes on-chip

Flash memory and on-chip 12 bit Analog to Digital (A/D)

converter with 16 input channels.

The block "Voltage Divider" is a specially designed dual

channel board, which converts linearly two input analog

signals with range -5 to 5 V into two analog output signals

with range 0 to 3 V.

The block "DAC" is a digital to analogue converter

DAC8734EVM produced by Texas Instruments [10]. The

DAC is 16-bit, quad-channel and can be configured to outputs

±10V, ±5V, 0V to 20V or 0V to 10V. It features a standard

high-speed serial peripheral interface (SPI) that operates at

clock rates of up to 50MHz to communicate with a DSP.

The block ``NIDAQ-6009" is a specialized module for data

acquisition NIDAQ-6009 of National Instruments [11]. A

specially developed software provides the user interface,

connection and exchange input/output data with a standard PC

in real time.

The control algorithm is embedded and runs with

frequency 100 Hz on the DSC. The software development

environment includes MATLAB® v.7.11.0.584(R2010b),

\Simulink® v.7.6, Simulink Coder® v.7.6 [5(5)],Embedded

Coder® v. 5.6 [12], Microsoft Visual C++ v.8.0 and

Fig. 14. Block-diagram of the Simulink® model

CodeComposer® (CCS) v.3.3. A technology for automatic

generation and embedding the code using the Simulink

BALKAN JOURNAL OF ELECTRICAL & COMPUTER ENGINEERING Vol.1, No.2 61

The block-diagram of the Simulink® model used to generate The Figures displaying control signals show the presence of

the execution code is shown in Fig. 14. Some blocks are taken some deviations from simulation results whose magnitudes

from the specialized library for Texas Instruments C2000 of may reach values of up to 0.2V. According to the frequency

Simulink®. The experimental results are saved on the PC and responses shown in Fig. 10, small disturbances and errors may

are visualized in MATLAB®. be amplified in the control signals which explain the presence

of relatively large noises in these signals.

IV. EXPERIMENTAL RESULTS

The performance of the developed robust control system

with -regulator implemented using digital signal controller

is confirmed by experimental investigations. Several

experiments are done with the nominal plant and for different

combinations of the uncertain plant parameters.

A. Experiment with the nominal plant

In case of nominal plant parameters, an experiment is done

in which the reference varies every 10 s at three levels: -1V,

0V and 1V. The output and control signals (here and further

on all signals are measured in volts) from simulation and

experiments are shown in Fig. 15-18 (the experimental results

are shown by continuous lines). It is seen from the Fig.15 nd

Fig.16 that the experimental signals coincide well with the

output signals obtained by simulation. Fig.17. First control signal

Fig.15. First output signal Fig.18. Second control signal

B. Experiment with different plant parameters

Five experiments for different values of the uncertain

parameters are performed in order to access the influence of

the uncertainties on the closed-loop system behavior. The set

of uncertain parameters contain combinations of the minimum

and maximum values of the uncertain parameters as shown in

Table II.

TABLE II

PARAMETERS VARIATION

Parameter set k1 T4

1 0.75 0.35

2 0.75 1.05

3 1.25 0.35

4 1.25 1.05

nominal parameters 1.0463 0.7063

Fig.16. Second output signal

BALKAN JOURNAL OF ELECTRICAL & COMPUTER ENGINEERING Vol.1, No.2 62

The set of nominal parameters is also included in order to

estimate the maximum possible deviations of the output and

control signals from their nominal values.

In Fig.19 and Fig.20 we show the output signals of the

system for all five parameter sets. It is seen that the deviations

of the outputs from their nominal values are relatively small

which is a result of the robust performance achieved. The two

control signals shown in Fig.21 and Fig.22 have more

significant deviations from their nominal values which is

again explained by the large gains associated with the transfer

matrix Si K .

Fig.22. Second control signal

V. CONCLUSION

The paper presents a system for robust real-time control of

fourth order plant using Digital System Processor. A

specialized software for automatic generation of the control

code is developed that facilitates the implementation of high

order control algorithms for multivariable plants. The main

conclusion is that the existing technologies allow to

implement easily a 16th order -controller that ensures

robust stability and robust performance of the closed-loop

Fig.19. First output signal system. The experimental results confirm the performance of

the closed-loop system whose parameters vary in prescribed

boundaries. The control code may be easily modified for

control of other plants.

REFERENCES

[1] S. Skogestad, I. Postlethwaite, Multivariable Feedback Control 2nd ed,

John Wiley and Sons Ltd, Chichester, UK, 2005.

[2] K. Zhou, J.C. Doyle, K. Glover. Robust and Optimal Control. Prentice

Hall, Upper Saddle River, NJ, 1996.

[3] M. La Civita, G. Papageorgiou, W.C. Messner, T. Kanade, “Design and

flight testing of a high-bandwidth loop shaping controller for a robotic

helicopter”, Journal of Guidance, Control, and Dynamics, vol.29, no 2,

pp. 485-495, 2006.

[4] X. Wang, X. Zhao. “A practical survey on the flight control system on

small-scale unmanned helicopter”, in Proc.WCICA, Chongqing, China,

2008, pp 364-369.

[5] The MathWorks Inc. (2013, March 15), Simulink Coder, [Online].

Fig.20. Second output signal

Available: http://www.mathworks.com/products/datasheets/pdf/simulink-

coder.pdf

[6] T. Slavov, L. Mollov, P. Petkov, “Real-time quadratic control using

Digital Signal Processor”. TWMS Journal of Pure and Applied

Mathematics, vol.3, no. 2, pp.145-157, 2012.

[7] D.W. Gu, P.Hr. Petkov, M.M. Konstantinov, Robust Control Design with

MATLAB, 2nd ed, Springer-Verlag, London, 2013.

[8] G. Balas, R. Chiang, A. Packard, M. Safonov. (2013, March).

Robust Control Toolbox User's Guide. The MathWorks, Inc.,Natick,

MA. [Online] Available:

http://www.mathworks.com/help/pdf_doc/robust/robust_ug.pdf

[9] Spectrum Digital, Inc.(2013, March 15), eZdspTMF28335 Technical

Reference 2007, [Online] Available :

http://c2000.spectrumdigital.com/ezf28335/docs/ezdspf28335c_techref.p

df.

[10] Texas Instruments. (2013, March 15), DAC8734 Evaluation Module,

[Online] Available: http://www.ti.com/tool/dac8734evm

Fig.21. First control signal

BALKAN JOURNAL OF ELECTRICAL & COMPUTER ENGINEERING Vol.1, No.2 63

[11] National Instruments.(2013, March 15), NI USB-6009 14-Bit, 48 kS/s

Low-Cost Multifunction DAQ. [Online] Available:

http://sine.ni.com/nips/cds/view/p/lang/en/nid/201987

[12] The MathWorks, Inc.(2013, March 15), Embedded Coder. [Online]

Available from:

http://www.mathworks.com/products/datasheets/pdf/embedded-

coder.pdf.

BIOGRAPHIES

Tsonyo Slavov was born in Sofia,

Bulgaria in 1978. He graduated from the

Department of Systems and Control of

the Technical University of Sofia in

2002. He received Ph.D degree in control

engineering from the Technical

University of Sofia in 2007. Presently, he

is an Associated Professor in the

Department of Systems and Control at

the Technical University of Sofia

Luben Mollov graduated from the

Department of Systems and Control of the

Technical University of Sofia in 2008.

Presently, he is a assistant professor in the

same department.

Jordan Kralev has M.S. degree in

Automatics, Information and Control

Technologies. Since 03.2013 he is a Ph.D.

student in the Department of Systems and

Control, Technical University of Sofia.

His work is in the field of implementation

of complex control structures with

programmable platforms.

Petko Petkov received M.S. and Ph.D.

degrees in control engineering from the

Technical University of Sofia in 1971 and

1979. Since 1995, he has been a Professor

of Control Theory in the Department of

Systems and Control at the Technical

University of Sofia. He is coauthoring

Computational Methods for Linear

Control Systems (Prentice Hall, Hemel

Hempstead, U.K., 1991), Perturbation Theory for Matrix

Equations (North-Holland, Amsterdam, 2003), and Robust

Control Design with MATLAB (Springer, London, 2005,

2013).

You might also like

- Automated Measurement of Frequency Response of Electrical Networks Filters and AmplifiersDocument7 pagesAutomated Measurement of Frequency Response of Electrical Networks Filters and AmplifiersDiscrete ComponentNo ratings yet

- 2013 2014 Report1Document64 pages2013 2014 Report1Christian Gonzalez ArandaNo ratings yet

- DSTATCOM ControlDocument5 pagesDSTATCOM ControlabsalnabiNo ratings yet

- Lab 5 - Controls and Feedback: BackgroundDocument6 pagesLab 5 - Controls and Feedback: BackgroundABamisheNo ratings yet

- Digital Control Design Framework for Dynamic Systems Modeling and SimulationDocument6 pagesDigital Control Design Framework for Dynamic Systems Modeling and Simulationsattanic666No ratings yet

- DSP Based Excitation Control System For Synchronous GeneratorDocument5 pagesDSP Based Excitation Control System For Synchronous GeneratorPradeep_VashistNo ratings yet

- HIL Interface USCDocument7 pagesHIL Interface USCSripada ParamahamsaNo ratings yet

- ELEC4632 Lab 4: Real-Time Implementation of Output Feedback Control System For Set-Point ControlDocument4 pagesELEC4632 Lab 4: Real-Time Implementation of Output Feedback Control System For Set-Point ControlZIYI PANNo ratings yet

- Train Test NaunDocument8 pagesTrain Test NaunfvijayamiNo ratings yet

- Implementation and Test Results of A Wide-Area Measurement-Based Controller For Damping Interarea Oscillations Considering Signal-Transmission DelayDocument8 pagesImplementation and Test Results of A Wide-Area Measurement-Based Controller For Damping Interarea Oscillations Considering Signal-Transmission Delaya_almutairiNo ratings yet

- 2 Canada-Us Cansmart Workshop: 10 - 11 October 2002, Montreal, Quebec, CanadaDocument7 pages2 Canada-Us Cansmart Workshop: 10 - 11 October 2002, Montreal, Quebec, CanadaBhuvaneshwar PatilNo ratings yet

- BS Lab Manual R18 PDFDocument113 pagesBS Lab Manual R18 PDFKamarthi VanithaNo ratings yet

- Xilinx Implementation of Pulse Width Modulation Generation Using FpgaDocument5 pagesXilinx Implementation of Pulse Width Modulation Generation Using FpgawigaYeHtetNo ratings yet

- Weekly PP PDFDocument11 pagesWeekly PP PDFDanielHaileNo ratings yet

- Digital Control Systems Lecture Notes: Introduction and Signal ProcessingDocument61 pagesDigital Control Systems Lecture Notes: Introduction and Signal ProcessingHari Pavan0391No ratings yet

- Irjet V3i6175Document4 pagesIrjet V3i6175Alemu EshetuNo ratings yet

- Problem SolutionsDocument6 pagesProblem SolutionsMuhammad Talha AtharNo ratings yet

- Lab 3Document11 pagesLab 3Vulpe FlorianNo ratings yet

- Chapter 2 Discrete Data Control SystemsDocument78 pagesChapter 2 Discrete Data Control SystemsAmruth ThelkarNo ratings yet

- A Digital-Based Optimal AVR Design of Synchronous Generator Exciter Using LQR TechniqueDocument13 pagesA Digital-Based Optimal AVR Design of Synchronous Generator Exciter Using LQR Technique3KaiserENo ratings yet

- Digital Control of a Single-Phase PWM Inverter Using GPCDocument3 pagesDigital Control of a Single-Phase PWM Inverter Using GPCsa920189No ratings yet

- SENSOR FAULT TOLERANT CONTROL DESIGN APPLIED TO A WI - 2007 - IFAC Proceedings VDocument8 pagesSENSOR FAULT TOLERANT CONTROL DESIGN APPLIED TO A WI - 2007 - IFAC Proceedings VsmeykelNo ratings yet

- RTDS - A Fully Digital Power System Simulator PDFDocument6 pagesRTDS - A Fully Digital Power System Simulator PDFLeonardo MarquesNo ratings yet

- Research Inventy: International Journal of Engineering and ScienceDocument5 pagesResearch Inventy: International Journal of Engineering and ScienceresearchinventyNo ratings yet

- Shri Ramdeobaba College of Engineering and Management, NagpurDocument6 pagesShri Ramdeobaba College of Engineering and Management, Nagpursiddhi rathiNo ratings yet

- Event Driven Analog Modeling For The Verification of PLL Frequency SynthesizersDocument6 pagesEvent Driven Analog Modeling For The Verification of PLL Frequency SynthesizersseemabNo ratings yet

- General Purpose Equipment: Me 4053 Mechanical Systems LaboratoryDocument8 pagesGeneral Purpose Equipment: Me 4053 Mechanical Systems Laboratorybill obrienNo ratings yet

- A Low-Cost Hardware-In-The-Loop Real Time Simulation of Control SystemsDocument4 pagesA Low-Cost Hardware-In-The-Loop Real Time Simulation of Control SystemsCarlos de la TorreNo ratings yet

- Sva CDC Paper Dvcon2006Document6 pagesSva CDC Paper Dvcon2006vikkisachdevaNo ratings yet

- Development of Digital Protective Relay Tester Under IEC61850Document5 pagesDevelopment of Digital Protective Relay Tester Under IEC61850violatorNo ratings yet

- Fuzzy microcontroller controls liquid levelDocument6 pagesFuzzy microcontroller controls liquid levelsamyNo ratings yet

- A Hybrid Framework For Fault DetectionDocument10 pagesA Hybrid Framework For Fault DetectionharshaNo ratings yet

- Control Systems U5 (TEL306)Document84 pagesControl Systems U5 (TEL306)Ruvenderan SuburamaniamNo ratings yet

- Design of Ieee 1149.1 Tap Controller Ip CoreDocument12 pagesDesign of Ieee 1149.1 Tap Controller Ip CoreCS & ITNo ratings yet

- Implementing Ball Balancing Beam Using Digital Image Processing and Fuzzy LogicDocument4 pagesImplementing Ball Balancing Beam Using Digital Image Processing and Fuzzy LogicJessica RossNo ratings yet

- Calculations of Frequency Response Functions (FRF) PDFDocument8 pagesCalculations of Frequency Response Functions (FRF) PDFJose PradoNo ratings yet

- 10 1109@tim 2009 2022377 PDFDocument7 pages10 1109@tim 2009 2022377 PDFfahrur rizaNo ratings yet

- Watchdog Timer Using VHDL For Atm System: Gore S.S., Lokhande A.A., Mahajan S.BDocument5 pagesWatchdog Timer Using VHDL For Atm System: Gore S.S., Lokhande A.A., Mahajan S.BRishikesh kumarNo ratings yet

- M. Garcia, A. Barreiro STABILITY OF A NETWORKED CONTROL SYSTEM USINGDocument6 pagesM. Garcia, A. Barreiro STABILITY OF A NETWORKED CONTROL SYSTEM USINGFelix GamarraNo ratings yet

- 10.1007@s00034 020 01521 8Document28 pages10.1007@s00034 020 01521 8Geraud Russel Goune ChenguiNo ratings yet

- Moving Horizon Model Based Control in The Presence of Feedback NoiseDocument3 pagesMoving Horizon Model Based Control in The Presence of Feedback NoiseATSNo ratings yet

- Direct Control and Coordination Using Neural Networks: AbstractDocument12 pagesDirect Control and Coordination Using Neural Networks: AbstractEmilio GarcíaNo ratings yet

- Instituto Tecnológico y de Estudios Superiores de MonterreyDocument24 pagesInstituto Tecnológico y de Estudios Superiores de MonterreyJoseManuelLopezCarmonaNo ratings yet

- PROTECTION PERFORMANCE TESTING IN IEC 61850, Liyang2010Document5 pagesPROTECTION PERFORMANCE TESTING IN IEC 61850, Liyang2010Mohamed Daw HamoudaNo ratings yet

- Monte Carlo Simulation: For Better Yield and PerformanceDocument51 pagesMonte Carlo Simulation: For Better Yield and PerformanceRizwan Shaik PeerlaNo ratings yet

- Digital-Based Optimal AVR Design Using LQR TechniqueDocument13 pagesDigital-Based Optimal AVR Design Using LQR TechniqueHoang Duc ThucNo ratings yet

- A New Interlock System For The Vulcan LaserDocument4 pagesA New Interlock System For The Vulcan LaserMohammad A. BawtagNo ratings yet

- Lab 1Document7 pagesLab 1MoapeNo ratings yet

- Introduction to Digital Control SystemsDocument70 pagesIntroduction to Digital Control SystemsAmruth Thelkar67% (3)

- 3.home AutomationDocument6 pages3.home AutomationI.k. NeenaNo ratings yet

- (Notes) DESIGN FOR TESTABILITYDocument34 pages(Notes) DESIGN FOR TESTABILITYsarathkumarNo ratings yet

- Cadence Monte Carlo Simulation TutorialDocument51 pagesCadence Monte Carlo Simulation Tutorialkuomatt100% (1)

- 1.2 Automatic Load Frequency Control: Department of Electrical Engineering, S.I.E.T, DhenkanalDocument6 pages1.2 Automatic Load Frequency Control: Department of Electrical Engineering, S.I.E.T, DhenkanalManikant MadhusudanNo ratings yet

- Sva CDC Paper Dvcon2006 PDFDocument6 pagesSva CDC Paper Dvcon2006 PDFkrishnaavNo ratings yet

- Reliable True Random Number GeneratorDocument16 pagesReliable True Random Number GeneratorRimon D ChoudhuryNo ratings yet

- Study of Immune Pid Networked Control System Based On TruetimeDocument4 pagesStudy of Immune Pid Networked Control System Based On TruetimeSỹ RonNo ratings yet

- Agilent M9392A PXI Vector Signal Analyzer: Data SheetDocument12 pagesAgilent M9392A PXI Vector Signal Analyzer: Data SheetkienfogNo ratings yet

- PSIM Simulation of DSP-Based Power Electronics ControlDocument6 pagesPSIM Simulation of DSP-Based Power Electronics ControlPasha ZubkovNo ratings yet

- DatasheetDocument3 pagesDatasheetjordanNo ratings yet

- Winbond 25Q64BV PDFDocument61 pagesWinbond 25Q64BV PDFNibiru HercolubusNo ratings yet

- TMRC Mat2 PDFDocument7 pagesTMRC Mat2 PDFjordanNo ratings yet

- DM3 Catalog PDFDocument12 pagesDM3 Catalog PDFjordanNo ratings yet

- Kralev SP IJC2015 PDFDocument27 pagesKralev SP IJC2015 PDFjordanNo ratings yet

- MindstormsDocument69 pagesMindstormsjordanNo ratings yet

- How To Balance A Two-Wheeled RobotDocument48 pagesHow To Balance A Two-Wheeled RobotjordanNo ratings yet

- Model Based System Identification For Hydraulic Deep Drawing PressesDocument11 pagesModel Based System Identification For Hydraulic Deep Drawing PressesjordanNo ratings yet

- Biological PsychiatryDocument7 pagesBiological PsychiatryjordanNo ratings yet

- Bill Williams Chaos TheoryDocument3 pagesBill Williams Chaos TheoryjordanNo ratings yet

- AN2081 Migrating To M25PE From M95 PDFDocument15 pagesAN2081 Migrating To M25PE From M95 PDFjordanNo ratings yet

- Bill Williams Chaos TheoryDocument18 pagesBill Williams Chaos TheoryKhandaker Didar100% (3)

- Internal Processor Which Is Controlled by The External Mix/Select BoxDocument1 pageInternal Processor Which Is Controlled by The External Mix/Select BoxjordanNo ratings yet

- Lm331 Voltaje A FrecuenciaDocument24 pagesLm331 Voltaje A FrecuenciaLeguel LNo ratings yet

- RCF L-Pad 10c - Manual de Utilizare - 40 PagDocument40 pagesRCF L-Pad 10c - Manual de Utilizare - 40 Pagadriana.36No ratings yet

- Networking Design and Implementation For Bio Tek CompanyDocument24 pagesNetworking Design and Implementation For Bio Tek CompanyDiaconu HerminaNo ratings yet

- Product data sheet for variable speed drive ATV12 - 0.18kW - 0.25hpDocument2 pagesProduct data sheet for variable speed drive ATV12 - 0.18kW - 0.25hpmanas jenaNo ratings yet

- An7511 PDFDocument10 pagesAn7511 PDFVenancio GutierrezNo ratings yet

- Gatelevel ModelingDocument13 pagesGatelevel ModelingGiri ReddyNo ratings yet

- Lecture 2 - Digital TelevisionDocument40 pagesLecture 2 - Digital TelevisionGerald Emmanuel100% (1)

- PA-POS-2OC3 Two-Port Packet-over-SONET Port Adapter Installation and ConfigurationDocument100 pagesPA-POS-2OC3 Two-Port Packet-over-SONET Port Adapter Installation and ConfigurationOscar Suazo SantosNo ratings yet

- MDC-7000 7900 OME Rev06Document244 pagesMDC-7000 7900 OME Rev06pppNo ratings yet

- Introduction To Active and Passive Components: Made By: Prof. Rashmi G. PatilDocument23 pagesIntroduction To Active and Passive Components: Made By: Prof. Rashmi G. Patilrashmi patilNo ratings yet

- RF Plan Tables iPASOLINKDocument31 pagesRF Plan Tables iPASOLINKEr Praveen ThakurNo ratings yet

- Semiconductor Devices and Circuits LaboratoryDocument53 pagesSemiconductor Devices and Circuits LaboratoryKaryampudi RushendrababuNo ratings yet

- Site Acceptance Testing For New Insatllation Activtiy: Sector Addition TDD SRA N FDD 2G Sector AdditionDocument20 pagesSite Acceptance Testing For New Insatllation Activtiy: Sector Addition TDD SRA N FDD 2G Sector AdditionkrishkarnNo ratings yet

- W65C02S Microprocessor Data Sheet: The Western Design Center, IncDocument40 pagesW65C02S Microprocessor Data Sheet: The Western Design Center, IncJayath GayanNo ratings yet

- 9A10505 Principles of CommunicationsDocument4 pages9A10505 Principles of CommunicationssivabharathamurthyNo ratings yet

- IEEE - eTD - CPAT - PRO - (NO VIDEO)Document15 pagesIEEE - eTD - CPAT - PRO - (NO VIDEO)Mohamed Atef Abbas ElsahartyNo ratings yet

- 5 A 0105 EE486 DigitalDocument1 page5 A 0105 EE486 DigitalNagarjuna MalladhiNo ratings yet

- Data Sheet 7KG9501-0AA01-2AA1: Measuring FunctionsDocument4 pagesData Sheet 7KG9501-0AA01-2AA1: Measuring FunctionsPằngPằngChiuChiuNo ratings yet

- A Review Paper On Smart Antenna For Mobile Communication IJERTCONV5IS23014Document2 pagesA Review Paper On Smart Antenna For Mobile Communication IJERTCONV5IS23014Sanjana RameshNo ratings yet

- Chapter 1 - Pic16f887 OverviewDocument38 pagesChapter 1 - Pic16f887 OverviewTung NguyenNo ratings yet

- TCC CATV - e Catalgoue VDocument91 pagesTCC CATV - e Catalgoue VlehongphuNo ratings yet

- Fault Passage IndicatorDocument5 pagesFault Passage Indicatorbibhas_samantaNo ratings yet

- 108 Michaels International Diode Equivalents Guide PDFDocument140 pages108 Michaels International Diode Equivalents Guide PDFFrancisco J. Aguilera HiguereyNo ratings yet

- 002.structured Cabling-Training DocumentsDocument18 pages002.structured Cabling-Training DocumentsSathiya Priya NatrajNo ratings yet

- MBSD0 Lab ManualDocument258 pagesMBSD0 Lab ManualbeimanalfredoNo ratings yet

- Basic Electronics, Volumes 1-5, (1955) - Text PDFDocument570 pagesBasic Electronics, Volumes 1-5, (1955) - Text PDFfrankNo ratings yet

- Datasheet - PDF 2 TriacDocument3 pagesDatasheet - PDF 2 TriacFlabio OliveiraNo ratings yet

- EE 308 Apr. 19, 2002Document12 pagesEE 308 Apr. 19, 2002asprillaNo ratings yet

- Walk-Through Metal Detector Installation ManualDocument44 pagesWalk-Through Metal Detector Installation ManualErick Navarrete50% (2)

- Ep450 Motorola UhfDocument2 pagesEp450 Motorola UhfYusuf SonmezNo ratings yet