Professional Documents

Culture Documents

001 - JHA Survey Setting Out - REV000

Uploaded by

Venkadesh PeriathambiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

001 - JHA Survey Setting Out - REV000

Uploaded by

Venkadesh PeriathambiCopyright:

Available Formats

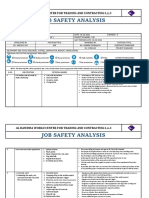

DATE: 00/0/2015

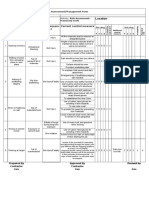

JOB HAZARD ANALYSIS (JHA)

JHA No:

EPCM: BPJV CONTRACTOR NAME:SAIF BIN DARWISH

PROJECT: Al Taweelah Alumina Underground Services WORK LOCATION: Al Taweelah Alumina Underground services

JOB DESCRIPTION:

Survey and setting out for Pipe line and chamber trenching

EMERGECY PLAN (include First Response):

Make the area safe , Inform EGA emergency response team (02-5092111) , Follow site emergency protocol

PERMITS

Confined Space Excavation Floor/Wall opening Hot Work HV Access Isolation (LOTO) Lift Study NDT Workbox Working at heights

PLANNED HIGH RISK CONSTRUCTIONACTIVITIES

Confined Space Entry Excavation <1.2m Isolation (LOTO) Road Work Work at Heights

Crane Activities Flammable / Contaminated atmosphere Mobile Plant Movement Tilt Up / Precast Installation NDT

Energised Electrical Work Gas / Chemical Fuel Line Work Pressure testing Vertical Rebar Other:

ADDITIONAL PPE PLANT, TOOLS & EQUIPMENT BARRICADE / SIGNS

Goggles Sun Screen Compactor Hand Tools Excavator Barrier Mesh

Face Shield Welding Jacket Drill Ladder Backhoe Yellow & Black Chain

Hearing Protection Welding Helmet Extension Leads Scaffold Crane Concrete Barriers

Safety Harness Other- Fans Power Source EWP / Scissor Lift Hard Barricade

Respirator Other - Fire Extinguisher Welding Machine Shade Red & White

Hand Protection Other - Grinder Other - Other - Other -

JHA DEVELOPED BY: JHA APPROVAL:

No Name Signature Position Date No Name Signature Position Date

1 Site engineer 1 DPM

2 Supervisor 2 Lead Engineer

Tamil Vanan Surveyor Sr.ES&H

3 3 Shadab Hasan

Advisor

4 4

5 5

EPCM ESH MANAGER REVIEW:

Name: Signature: Position: Date //

EPCM AREA SUPERINTENDENT REVIEW:(work shall not proceed until the JHA is signed &dated bytheEPCMESH and Area Superintendent ortheirdesignees)

Name: Signature: Position: Date://

25875-000-GFX-GHX-00040 Page 1 of 5 Rev 000

14 June 2014

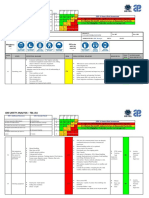

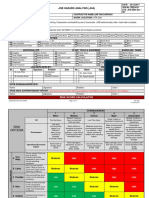

RISK SCORE CALCULATOR

CONSEQUENCES

1 2 3 4 5

Minor Medium Serious Major Catastrophic

Medical Treatment Multiple Fatalities or

Single Fatality or

`1C1 First Aid Injury Injury or restricted Lost Time Injury Multiple Permanent

Permanent Impairment

work day case Impairment

Low level

Major environmental Catastrophic

environmental Minor effects on Moderate short-term

RISK impact, e.g. biological or physical environmental impact,

event, e.g. pollution - environmental event,

impact that is e.g. pollution – impact

CRITERIA pollution– environment, e.g. e.g. pollution – near

unconfined &requiring that is widespread,

Environment near source pollution – near source source confined &

long term recovery, unconfined &requiring

confined & confined &short-term medium term recovery

leaving residual long term recovery,

promptly reversible impact. impact.

damage. leaving major residual

reversible impact.

damage.

Minor damage to Major damage; loss of Serious problems with

Easily fixed up Loss of less than one

Operational/Economic equipment; no loss of less than six months future operation of the

straight away weeks production

Impact production production facility

<$10k $100k - $1M

$10k - $100k $1M - $10M >$10M

Occurs several times per

year at similar

Very projects/reasonably

A expected to occur under

Moderate High High High High

likely

normal operating

conditions

Has occurred several

LIKELIHOOD

times / likely to occur at

B Likely some time under normal

Moderate Moderate High High High

operating conditions

Has occurred/may occur

C Possible under normal operating Low Moderate Moderate High High

conditions

Known to have occurred

in the construction

D Rare industry/unlikely to occur Low Low Moderate Moderate High

under normal operating

conditions

25875-000-GFX-GHX-00040 Page 2 of 5 Rev 000

14 June 2014

Unheard of/not known to

E Unlikely have occurred

Low Low Low Moderate Moderate

Inherent Control Methods & Monitoring Residual

Step Hazard Risk Risk Action By

What control measures will be used?

Describe the job step by step What are the hazards of each step?

Score How will the effectiveness of the controls be determined? Score

Manual handling training shall be conducted

Survey tripod & rebar’s sharp edges shall be

covered by caps

Manual handling of survey

instruments Survey instruments and materials shall be

1. Supervisor

stored properly while transporting in the pick-up

Loading and unloading the survey Puncture 2. Chain man

cabin.

instruments and materials from 4×4 Pick- Hit by vehicle &surveyor

Moderate No operatives allowed to work with in the Low

up (survey tripod , marking rebar’s , hand Vehicle collision 3. Chainman

proximity of 10 meter from the vehicle (Pick –

tools and instruments) vehicle / plant interface up)movement

& driver

uncontrolled movement Site speed limit shall be adhered

work needs to be barricade exclusive zone

All equipment are slow down

Training shall be conducted for the hand tools

Substandard hand tools

users

Puncture, crushing,

User must wear adequate all required

hammering, etc.

PPE(helmet, goggles, hand gloves, safety 1. Supervisor

Lack of knowledge of hand

shoes) 2. Surveyor&

Use of hand tools (hammer)for fixing tools safety Low

Moderate CAT scan shall be carried out prior to driving the chain man

rebar’s of identify survey marking Not using PPE

rebar if required 3. Supervisor

Contact with underground

excavation permit shall be applied if more than RA

services while driving rebar

150mm depth

Impalement from rebar

Reinforced rebar caps will be placed on rebar

Hazardous substances approval form shall be

submitted along with MSDS to BPJV PEL for

approval

Paint spray shall be restricted as much as practically 1. Supervisor

Inhalation possible, use alternate marking methods of marking 2. Surveyor

& chain

Skin contact identification.

Using colour spray for identification survey man

Eye contact Moderate MSDS shall be communicated to the operatives Low

marking 3. Users

Ingestion working with it and readily available in case of 4. Store

Acute emergency keeper

PPE assessment shall be conducted, the need for eye and users.

protection in addition gloves and respiratory

protection and other protective clothing or devices for

those marking with sprays

25875-000-GFX-GHX-00040 Page 3 of 5 Rev 000

14 June 2014

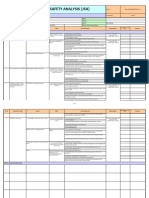

Storage of materials shall be followed as per MSDS

Excavation permits shall be in place when trench

depth exceeds 60 CM

Spoils shall be stored 1 Mtr away from edge

Trenches more than 1.2 Mts shall be battered or

benched or shored

Level -2 Barricades will be installed around the

excavation when trench depth exceeds 1.5 Mts

Persons falling into Trench depth 1.8 Mtr onwards fall

excavations 1. Supervisor

prevention/protection measures shall be in place

Buried, engulfment 2. Surveyor

Entering inside the excavation to measure Separate access and egress for operatives and

Struck by operating High Moderate & chain

the levels of the trench vehicles

equipment man

Every 7.5 Mts entry and egress for men entry

Fall of materials

Suitable signs will be provided to alert the work

groups

Machines must be shut down before workers enter

the trench.

Machine slew areas shall be level barricading

Competent person shall inspect the trench on daily

basis.

STARRT card briefing to be done for all surveyors

25875-000-GFX-GHX-00040 Page 4 of 5 Rev 000

14 June 2014

NOTE: If the conditions or controls used to conduct the job changeswork group members are toeitheruse the re-STARRT

process (for one off changes) or amend and re-sign onto the JHA (for permanent changes).

NOTE: Any significant changerequires Contractor & EPCM Management authorisation prior to continuing the job.

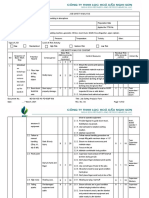

PRINCIPAL CONTRACTOR: BPJV CONTRACTOR NAME:SBD

PROJECT: Al Taweelah Alumina Underground services SUPERVISOR NAME:

JOB DESCRIPTION:

JHA SIGN OFF REGISTER

I have read and understoodthis JHA …

No. First Name Surname Employer Signature Date

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

25875-000-GFX-GHX-00040 Page 5 of 5Rev 000 14 June 2014

You might also like

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- PTW272 - Asphalt Paving 17-01-2023Document22 pagesPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseDocument5 pages3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- Brick WorkDocument1 pageBrick WorkGyanendra Narayan NayakNo ratings yet

- Job Safety Analysis: 10.06.2017 Page 1 of 7Document7 pagesJob Safety Analysis: 10.06.2017 Page 1 of 7Raghava RichhuNo ratings yet

- Back FillingDocument2 pagesBack FillingChandruNo ratings yet

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 pagesSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabNo ratings yet

- Job Steps Potential Hazards Recommended Safe Job ProceduresDocument3 pagesJob Steps Potential Hazards Recommended Safe Job ProceduresDJadee Anuppur AmlaiNo ratings yet

- Project JHA For Grading Compacting WorksDocument27 pagesProject JHA For Grading Compacting WorksBasker Balu100% (1)

- Job Safety Analysis for Pipeline LoadingDocument8 pagesJob Safety Analysis for Pipeline LoadingMoaatazz NouisriNo ratings yet

- Diesel Filling JSADocument6 pagesDiesel Filling JSAMohammed Ali QaziNo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadNo ratings yet

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- Excavations: Job Safety AnalysisDocument5 pagesExcavations: Job Safety AnalysisJICKNo ratings yet

- (SWMS-01) Loading, Unloading and ShiftingDocument5 pages(SWMS-01) Loading, Unloading and ShiftingPRATEEK SINGH100% (2)

- JSA For RCC, Foundation & Generator Installation (R-00)Document14 pagesJSA For RCC, Foundation & Generator Installation (R-00)Suju RajanNo ratings yet

- JSA For Hydrotesting PDFDocument6 pagesJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- RISK ASSESSMENT AND ANALYSISDocument6 pagesRISK ASSESSMENT AND ANALYSISabhinav dj50% (2)

- JSA For Concrete PouringDocument8 pagesJSA For Concrete Pouringfayaz fayazhotmail.com100% (1)

- JHA - Survey WorksDocument3 pagesJHA - Survey WorksNazirul Syazwan100% (3)

- HIRA No. 08 Rev 04 - Lifting ActivityDocument7 pagesHIRA No. 08 Rev 04 - Lifting ActivityVenkadesh PeriathambiNo ratings yet

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- RA-For Tile & Granite WorksDocument9 pagesRA-For Tile & Granite Worksfaizan khan67% (3)

- JSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyDocument4 pagesJSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyMuhammad TariqNo ratings yet

- JOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKDocument3 pagesJOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKba ratnaparkheNo ratings yet

- HIRA FOR Equipment Instalation.Document8 pagesHIRA FOR Equipment Instalation.Deepak G100% (1)

- 5.confined Space EntryDocument6 pages5.confined Space EntryMohammad Fazal KhanNo ratings yet

- Excavation SafetyDocument11 pagesExcavation SafetyDenease CrummieNo ratings yet

- JHA Scaffolding ErectionDocument12 pagesJHA Scaffolding ErectionChayank TiwariNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- SWMS - HVAC ShiftingDocument6 pagesSWMS - HVAC ShiftingParas100% (1)

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- JOB SAFETY ANALYSISDocument21 pagesJOB SAFETY ANALYSISThái Đạo Phạm Lê100% (1)

- Sarawak JSA for Concrete CuttingDocument4 pagesSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNo ratings yet

- Risk Assessment - Placing of Transformer - TTSDocument6 pagesRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- Hira Plastering Finishing WorkDocument2 pagesHira Plastering Finishing WorkDwitikrushna Rout0% (1)

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- JSA Excavation PDFDocument6 pagesJSA Excavation PDFmohamedamine.zemouriNo ratings yet

- JSA Electrical Maintenance LCSDocument8 pagesJSA Electrical Maintenance LCSmohamed yasinNo ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdfNo ratings yet

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentDocument4 pagesJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- HIRA - Night Work Hazard ControlDocument3 pagesHIRA - Night Work Hazard ControlHiralal PattanayakNo ratings yet

- Plumbing Work JSA HSE ProfessionalsDocument1 pagePlumbing Work JSA HSE ProfessionalsStansilous Tatenda NyagomoNo ratings yet

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- Machine excavation hazard analysisDocument7 pagesMachine excavation hazard analysisVenkadesh Periathambi100% (1)

- 04 - HDPE Pipe Laying - REV 000Document6 pages04 - HDPE Pipe Laying - REV 000Venkadesh Periathambi100% (1)

- Civil Demolition Work East of PL3 Rev01Document30 pagesCivil Demolition Work East of PL3 Rev01Venkadesh PeriathambiNo ratings yet

- Portion 1A Summary Sheet BreakdownDocument46 pagesPortion 1A Summary Sheet BreakdownVenkadesh PeriathambiNo ratings yet

- Rescue Plan Working at HeightDocument11 pagesRescue Plan Working at HeightHernandito Rahmat Kusuma100% (1)

- Adhesive-Bonded Joints Method Statement (TB-TS) : Field Services DepartmentDocument25 pagesAdhesive-Bonded Joints Method Statement (TB-TS) : Field Services DepartmentVenkadesh PeriathambiNo ratings yet

- Pro Forma Change Approval FormDocument1 pagePro Forma Change Approval FormVenkadesh PeriathambiNo ratings yet

- Clarification # 1Document1 pageClarification # 1Venkadesh PeriathambiNo ratings yet

- Grade:8 Date: 12/12/19 Choose The Correct Vocabulary To Complete The SentencesDocument2 pagesGrade:8 Date: 12/12/19 Choose The Correct Vocabulary To Complete The SentencesVenkadesh PeriathambiNo ratings yet

- Read The Following Passages and Then Answer The Questions That FollowDocument9 pagesRead The Following Passages and Then Answer The Questions That FollowVenkadesh PeriathambiNo ratings yet

- Asset Practice QuestionsDocument6 pagesAsset Practice QuestionsVenkadesh PeriathambiNo ratings yet

- Key Preventive Measures - COVID 19Document2 pagesKey Preventive Measures - COVID 19Venkadesh PeriathambiNo ratings yet

- Site Office BOQDocument4 pagesSite Office BOQVenkadesh PeriathambiNo ratings yet

- Pro Forma Change Approval FormDocument1 pagePro Forma Change Approval FormVenkadesh PeriathambiNo ratings yet

- JSS International School Dubai document on mole concept and stoichiometryDocument3 pagesJSS International School Dubai document on mole concept and stoichiometryVenkadesh PeriathambiNo ratings yet

- Stress Management Policy: Occupational Health and Safety StaffDocument2 pagesStress Management Policy: Occupational Health and Safety StaffVenkadesh PeriathambiNo ratings yet

- Drug and Alcohol PolicyDocument1 pageDrug and Alcohol PolicyVenkadesh PeriathambiNo ratings yet

- Adverse Weather Condition HIRADocument5 pagesAdverse Weather Condition HIRAVenkadesh PeriathambiNo ratings yet

- Method Statement For Laying of MCC Duct and Civil Works For MCC NetworkDocument26 pagesMethod Statement For Laying of MCC Duct and Civil Works For MCC NetworkVenkadesh PeriathambiNo ratings yet

- Web Sling DetailsDocument2 pagesWeb Sling DetailsVenkadesh PeriathambiNo ratings yet

- Jss International School-Dubai Second Term Portions - 2020-21Document22 pagesJss International School-Dubai Second Term Portions - 2020-21Venkadesh PeriathambiNo ratings yet

- Summer Projects - 2020-21: Jss International School, DubaiDocument6 pagesSummer Projects - 2020-21: Jss International School, DubaiVenkadesh PeriathambiNo ratings yet

- 1578771297224924501Document2 pages1578771297224924501Venkadesh PeriathambiNo ratings yet

- Scanned by CamscannerDocument12 pagesScanned by CamscannerVenkadesh PeriathambiNo ratings yet

- Daily AttendanceDocument2 pagesDaily AttendanceVenkadesh PeriathambiNo ratings yet

- Meeting Details: # Notes and Actions Arising Action Date 1. HSEDocument6 pagesMeeting Details: # Notes and Actions Arising Action Date 1. HSEVenkadesh PeriathambiNo ratings yet

- Sri Ram Kushwaha Incident Report at 08 July 19.45Document1 pageSri Ram Kushwaha Incident Report at 08 July 19.45Venkadesh PeriathambiNo ratings yet

- Greetings, Your Test Result From 02-07-2020 Is Negative. Please StaysafeDocument1 pageGreetings, Your Test Result From 02-07-2020 Is Negative. Please StaysafeVenkadesh PeriathambiNo ratings yet

- Site Observation Report: Infrastructure & Streetscape Works - Neighborhood-6&7Document2 pagesSite Observation Report: Infrastructure & Streetscape Works - Neighborhood-6&7Venkadesh PeriathambiNo ratings yet

- Incident Investigation Meeting MinutesDocument2 pagesIncident Investigation Meeting MinutesVenkadesh PeriathambiNo ratings yet

- Contact NumberDocument1 pageContact NumberVenkadesh PeriathambiNo ratings yet

- Riyadh City South Phase 5 - Infrastructure and Streetscape - C 418Document2 pagesRiyadh City South Phase 5 - Infrastructure and Streetscape - C 418Venkadesh PeriathambiNo ratings yet

- SKF PDFDocument112 pagesSKF PDFAlvaro IgnacioNo ratings yet

- The Use of GPT Chat Among Students in Ukrainian Universities Olena StepanenkoDocument6 pagesThe Use of GPT Chat Among Students in Ukrainian Universities Olena StepanenkomaracaprimcNo ratings yet

- History of CMU A Brief Historical BackgroundDocument1 pageHistory of CMU A Brief Historical BackgroundMariane Rae AndrionNo ratings yet

- In An Assembly Model, Components Are Brought Together To Define A Larger, More Complex Product RepresentationDocument34 pagesIn An Assembly Model, Components Are Brought Together To Define A Larger, More Complex Product Representationpalaniappan_pandianNo ratings yet

- Contemporary World Final Quiz 2Document5 pagesContemporary World Final Quiz 2James Marasigan Ambas100% (1)

- DPI Report On IDEA ComplianceDocument15 pagesDPI Report On IDEA ComplianceKeung HuiNo ratings yet

- Effects of Facebook on Academic Performance in Maputi Senior High SchoolDocument17 pagesEffects of Facebook on Academic Performance in Maputi Senior High SchoolSeven De Los Reyes100% (3)

- Cognitive Development and Language DevelopmentDocument17 pagesCognitive Development and Language DevelopmentCik Fatin ChocoholicNo ratings yet

- Understanding Randomised Controlled TrialsDocument5 pagesUnderstanding Randomised Controlled TrialsWafiy AkmalNo ratings yet

- Diass 23,24,25,26Document47 pagesDiass 23,24,25,26Marc Joseph Olegario50% (2)

- 27 - SITXWHS002 Assessment Student VersionDocument49 pages27 - SITXWHS002 Assessment Student VersionShopee Lazada100% (1)

- Assessment Updated 2021Document41 pagesAssessment Updated 2021ziadNo ratings yet

- Hacking The MindDocument38 pagesHacking The Mindbigwill35100% (1)

- Burnout in Organizational Life: Jonathon R.B. HalbeslebenDocument21 pagesBurnout in Organizational Life: Jonathon R.B. HalbeslebenShaya RamrakhanNo ratings yet

- IALA Guideline 1018 Ed.3 Risk Management - May2013Document43 pagesIALA Guideline 1018 Ed.3 Risk Management - May2013songkkNo ratings yet

- Swati MaitraDocument29 pagesSwati Maitranajuka ghodvindeNo ratings yet

- ACD Guidelines For Product Information File (PIF)Document7 pagesACD Guidelines For Product Information File (PIF)NukiAdelaNo ratings yet

- Sri Venkateswara College National Conference on Advances in Electrical and Electronics Engineering (NCAEEE-2018Document2 pagesSri Venkateswara College National Conference on Advances in Electrical and Electronics Engineering (NCAEEE-2018chandranmuthuswamyNo ratings yet

- 12 Ac December 01-31 2019 by @naukriaspirant PDFDocument442 pages12 Ac December 01-31 2019 by @naukriaspirant PDFAmit PrasadNo ratings yet

- Teaching of SanskritDocument2 pagesTeaching of SanskritBineet Kumar100% (2)

- Philadelphia City Council Resolution Condemning Academic Boycott of IsraelDocument4 pagesPhiladelphia City Council Resolution Condemning Academic Boycott of IsraelLegal InsurrectionNo ratings yet

- Statistics Assignment Sample With SolutionsDocument10 pagesStatistics Assignment Sample With SolutionsHebrew JohnsonNo ratings yet

- Bahir Dar University School of Civil and Water Resource EngineeringDocument40 pagesBahir Dar University School of Civil and Water Resource EngineeringMichael AssefaNo ratings yet

- ELTU2020 English For Social Science Students I: Tentative Course Schedule (2021-2022 Term 1) - Mondays and WednesdaysDocument2 pagesELTU2020 English For Social Science Students I: Tentative Course Schedule (2021-2022 Term 1) - Mondays and Wednesdaysdebate spsltNo ratings yet

- Group 7 (Revision)Document72 pagesGroup 7 (Revision)John TampugaoNo ratings yet

- Syllabus: Maharashtra University of Health Sciences, NashikDocument5 pagesSyllabus: Maharashtra University of Health Sciences, NashikRuchi HumaneNo ratings yet

- CLASE 4 Ledesma, MDocument3 pagesCLASE 4 Ledesma, MJMB BANE0% (1)

- Gr12 Research Task 2024Document9 pagesGr12 Research Task 2024sanelisiwedywili473No ratings yet

- The Up To 21-Year Clinical Outcome and Survival of Feldspathic Porcelain Veneers: Accounting For ClusteringDocument9 pagesThe Up To 21-Year Clinical Outcome and Survival of Feldspathic Porcelain Veneers: Accounting For ClusteringAlexander L. Contreras PairaNo ratings yet

- MARKETING STRATEGY EXPLORATIONDocument64 pagesMARKETING STRATEGY EXPLORATIONuday sai bolluNo ratings yet