Professional Documents

Culture Documents

Astm F905

Uploaded by

JorgeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm F905

Uploaded by

JorgeCopyright:

Available Formats

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles

for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F905 − 04 (Reapproved 2011) An American National Standard

Standard Practice for

Qualification of Polyethylene Saddle-Fused Joints1

This standard is issued under the fixed designation F905; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 DOT Document:

1.1 This practice describes test criteria suitable for qualifi- 49 CFR, Part 192, Minimum Federal Safety Standards for

--````,`,```,,,`,,``,`,-`-``,```,,,`---

cation of polyethylene saddle-fused joints. These tests may be Gaslines3

conducted by suppliers or users to qualify saddle-fused joints 2.3 PPI Technical Report:

in accordance with the requirements found in the Department TR-41/2002 Generic Saddle Fusion Joining Procedure for

of Transportation (DOT) Code of Federal Regulations (CFR) Polyethylene Gas Piping

Title 49, Part 192.283. At the discretion of the end user, these

tests may also be conducted by users to qualify personnel 3. Significance and Use

making saddle fusion joints per DOT CFR 49, Part 192.285. 3.1 The tests described in this practice are intended to

1.2 The impact resistance test described is a nonstandard present a method of satisfying the requirements of DOT CFR

test. This is not the only test that may be used to qualify saddle Title 49, Parts 192.283 and 192.285.

fusion joints per DOT regulations. 3.2 The sustained pressure test is intended to meet the burst

1.3 The values stated in inch-pound units are to be regarded test requirements of Part 192.283.

as the standard. The values given in parentheses are mathemati- 3.3 The impact resistance test is intended to meet the force

cal conversion to SI units that are provided for information requirements of Part 192.283 as follows:

only and are not considered standard. 3.3.1 “. . . For procedures intended for lateral pipe

1.4 This standard does not purport to address all of the connections, subject a specimen joint made from pipe sections

safety concerns, if any, associated with its use. It is the joined at right angles according to the (joining) procedure to a

responsibility of the user of this standard to establish appro- force on the lateral pipe until failure occurs in the specimen. If

priate safety and health practices and determine the applica- failure initiates outside the joint area, the (joining) procedure

bility of regulatory limitations prior to use. qualifies for use.”

2. Referenced Documents 4. Materials

2.1 ASTM Standards:2 4.1 Pipe and fittings shall meet the requirements of Speci-

D1598 Test Method for Time-to-Failure of Plastic Pipe fication D2513.

Under Constant Internal Pressure

4.2 The outlet portion of a saddle fitting shall conform to

D2513 Specification for Polyethylene (PE) Gas Pressure

Specification D2683 for socket-fusion outlets or Specification

Pipe, Tubing, and Fittings

D3261 for butt-fusion outlets.

D2683 Specification for Socket-Type Polyethylene Fittings

for Outside Diameter-Controlled Polyethylene Pipe and 4.3 The radius of the saddle portion of the fitting shall fit the

Tubing pipe size to which it is intended to be joined. The surface

D3261 Specification for Butt Heat Fusion Polyethylene (PE) contact area of the saddle portion of the fitting and the

Plastic Fittings for Polyethylene (PE) Plastic Pipe and thickness of saddle portion shall be sufficient to meet the

Tubing qualification requirements of this practice.

4.4 Qualification tests shall be conducted on all saddle

1

fittings with different base areas. Only the largest outlet

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas. diameter shall be tested per fitting type if base areas are the

Current edition approved April 1, 2011. Published June 2011. Originally same.

approved in 1984. Last previous edition approved in 2004 as F905 – 04. DOI:

10.1520/F0905-04R11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from U.S. Government Printing Office Superintendent of Documents,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS Markit under license with ASTM

1Order Number: W2013338

Sold to:TECHINT S.A. [674173100003] - BAIAFA@TECHINT.NET,

No reproduction or networking permitted without license from IHS Not for Resale,2017-09-26 20:51:39 UTC

F905 − 04 (2011)

5. Procedure fitting has a higher SDR than the pipe, cap the saddle fitting

5.1 General: outlet and do not use the tubing.

5.1.1 Conduct each qualification test with the polyethylene 5.2.2 Test specimens for 1000 h using the equipment,

saddle fitting fused to a polyethylene pipe that has a maximum procedures, and failure definition as specified in Test Method

pressure rating equal to or greater than that for which the gas D1598 at 23°C (73°F). Hold systems having a hydrostatic

distribution system is designed. design basis of 1250 psi (8.6 MPa) at a hoop stress of 1320 psi

NOTE 1—It is recommended that the Generic Saddle Fusion Joining (9.1 MPa) based on the actual pipe dimensions. Hold systems

Procedure, developed by PPI (TR-41/2002), be used for selected polyeth- having a hydrostatic design basis of 1600 psi (11.0 MPa) at a

ylene gas piping products. While other joining procedures can also be hoop stress of 1600 psi (11.0 MPa) based on the actual pipe

used, the use of this PPI procedure is intended to help DOT expedite the dimensions.

qualification of gas pipeline operators and add some uniformity to the

industry. 5.3 Impact Resistance Test:

5.1.2 Allow the saddle-fused joint to cool to room tempera- 5.3.1 Center and fuse the saddle fitting on a piece of

ture prior to testing. unreinforced pipe that has a minimum length on both sides of

5.1.3 For each qualification test, tap the polyethylene pipe any saddle fitting equal to three times the diameter of the pipe,

with the largest size hole used in the gas distribution system for but in no case less than 12 in. (305 mm).

that fitting.

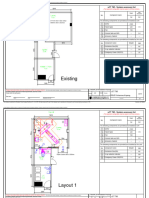

5.3.1.1 Firmly secure the pipe so that movement does not

5.1.4 Quantity of specimens to be tested in each test

occur during impact. Suggested methods of securing the pipe

described in this practice has been omitted due to the varied

goals of users of these tests. When these tests are utilized for are shown in Fig. 1. Other methods for securing the pipe may

qualification of a joining procedure (Part 192.283), a minimum also be used.

of six specimens should be evaluated with each test type used. 5.3.2 Drop a weight in a vertical free-fall from a height of at

For qualification of a joiner (Part 192.285), a minimum of one least 10 in. (250 mm). Position the weight so that it strikes the

specimen should be evaluated for each test type used. For stack of the saddle fitting 2 in. (50 mm) from the pipe. For large

qualification of the joint design by the manufacturer, as many diameter saddle fittings, that is, 3-in. (76-mm) outlet or greater,

tests as are needed may be run, but not less than six of each test socket or butt fuse a nipple (whose length is five times the

type. outside diameter) to the outlet and position the weight so that

5.2 Sustained Pressure Test: it strikes the center of the nipple. Adjust the drop height or

5.2.1 The minimum length of unreinforced pipe on both weight, or both, until failure occurs in the specimen by either

sides of any saddle fitting shall be equal to three times the tearing out the pipe wall, tearing the fitting, or bending the

diameter of the pipe, but in no case less than 12 in. (305 mm). nipple at least 45° from the horizontal axis. Conduct impact

Test multiple saddle fittings, if desired, on the same pipe evaluations on large diameter saddle fittings in two ways: (1)

specimen as long as they are separated by at least three pipe with the pipe parallel (axial) to the vertical path of the falling

diameters. Make all saddle-fused joints with the pipe at the weight; and (2) with the pipe perpendicular (radial) to the path

maximum allowable operating pressure of the gas distribution of the falling weight. The fused joint made between the pipe

system. If tubing intended to be fused to the outlet of the saddle and saddle fitting shall not fail when impacted with a force

--````,`,```,,,`,,``,`,-`-``,```,,,`---

FIG. 1 Suggested Methods of Securing Pipe Assembly

Copyright ASTM International

Provided by IHS Markit under license with ASTM

2Order Number: W2013338

Sold to:TECHINT S.A. [674173100003] - BAIAFA@TECHINT.NET,

No reproduction or networking permitted without license from IHS Not for Resale,2017-09-26 20:51:39 UTC

F905 − 04 (2011)

sufficient to break the body or other portion of the specimens. 7. Precision and Bias

Tests of 500 ft·lbf or higher impact with no failures shall be

7.1 The impact test described in this practice is a nonstan-

considered as “pass.”

dard test. Reproducibility between test laboratories is not

NOTE 2—Specimens that appear to fail at the joint may actually be required because the end result of this test is qualitative (that is,

tearing out the pipe wall. If the failure mode is questionable, the fitting a type of failure mode), not quantitative. A precision and bias

supplier should be consulted.

statement is, therefore, not required for this nonstandard test.

6. Qualification Requirements

6.1 Qualification requirements are outlined in DOT CFR 8. Keywords

Title 49, Part 192.283. 8.1 fusion; joints; polyethylene; qualification; saddle

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222

Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

--````,`,```,,,`,,``,`,-`-``,```,,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

3Order Number: W2013338

Sold to:TECHINT S.A. [674173100003] - BAIAFA@TECHINT.NET,

No reproduction or networking permitted without license from IHS Not for Resale,2017-09-26 20:51:39 UTC

You might also like

- Astm F3190-16 PDFDocument6 pagesAstm F3190-16 PDFdiego andres100% (1)

- Astm D1599 PDFDocument3 pagesAstm D1599 PDFChemical Engineer100% (3)

- ASTM D6392 2012 Rev 2018 PDFDocument6 pagesASTM D6392 2012 Rev 2018 PDFWard BentNo ratings yet

- Astm F2620-13Document25 pagesAstm F2620-13Najib100% (3)

- Astm D2122-2004 3Document5 pagesAstm D2122-2004 3Tanvir HasanNo ratings yet

- F1055 15708Document15 pagesF1055 15708Alejandro ValdesNo ratings yet

- Astm D1599-18Document4 pagesAstm D1599-18Parewa Scorp100% (1)

- Polyethylene (PE) Plastic Pipe (DR-PR) Based On Outside DiameterDocument12 pagesPolyethylene (PE) Plastic Pipe (DR-PR) Based On Outside DiameterBayron Parra100% (2)

- ASTM F412 12 Terminology PDFDocument18 pagesASTM F412 12 Terminology PDFBinodh DanielNo ratings yet

- D 2447 - 01 - Rdi0ndctukve PDFDocument9 pagesD 2447 - 01 - Rdi0ndctukve PDFAndre CasteloNo ratings yet

- Astm D3212 PDFDocument3 pagesAstm D3212 PDFdamithNo ratings yet

- Guided Side Bend Evaluation of Polyethylene Pipe Butt Fusion JointDocument11 pagesGuided Side Bend Evaluation of Polyethylene Pipe Butt Fusion JointdnavarroNo ratings yet

- D2412-11 Standard Test Method For Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate LoadingDocument7 pagesD2412-11 Standard Test Method For Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loadingjavier perezNo ratings yet

- Astm F 1290Document3 pagesAstm F 1290محمود أبو الحسنNo ratings yet

- ASTM F610F610M - Heat ReversionDocument4 pagesASTM F610F610M - Heat ReversionJen ChavezNo ratings yet

- Tr-9 Design Factors For Presser ApplicationsDocument12 pagesTr-9 Design Factors For Presser ApplicationsJose BustosNo ratings yet

- Pexgol Pipes and FittingsDocument30 pagesPexgol Pipes and FittingsFlorin StanciuNo ratings yet

- Astm F402Document2 pagesAstm F402Hernando Andrés Ramírez GilNo ratings yet

- Astm D 3035 PDFDocument7 pagesAstm D 3035 PDFSushil GambhirNo ratings yet

- F405-13 Standard Specification For Corrugated Polyethylene (PE) Pipe and FittingsDocument5 pagesF405-13 Standard Specification For Corrugated Polyethylene (PE) Pipe and Fittingssharon blushtein100% (1)

- Plastic Piping Handbook PDFDocument359 pagesPlastic Piping Handbook PDFJorgeNo ratings yet

- Cadman, Inc AdmixturesDocument2 pagesCadman, Inc Admixturesajmalhasan28No ratings yet

- Temp-Rise Testing For Synch GeneratorsDocument4 pagesTemp-Rise Testing For Synch GeneratorsdazzawNo ratings yet

- Astm F2634 2015Document13 pagesAstm F2634 2015Ricardo PeraltaNo ratings yet

- Astm F2620-11Document21 pagesAstm F2620-11Gianfranco Niquín100% (3)

- Astm-F 2164Document5 pagesAstm-F 2164damithNo ratings yet

- Astm F2769Document10 pagesAstm F2769Hernando Andrés Ramírez GilNo ratings yet

- Poly (Vinyl Chloride) (PVC) Gaskets For Drain, Waste, and Vent (DWV), Sewer, Sanitary, and Storm Plumbing SystemsDocument3 pagesPoly (Vinyl Chloride) (PVC) Gaskets For Drain, Waste, and Vent (DWV), Sewer, Sanitary, and Storm Plumbing SystemsveintavoNo ratings yet

- Time-to-Failure of Plastic Pipe Under Constant Internal PressureDocument4 pagesTime-to-Failure of Plastic Pipe Under Constant Internal PressurehashemNo ratings yet

- Astm d2444 21 落锤试验机标准Document10 pagesAstm d2444 21 落锤试验机标准Avin WangNo ratings yet

- D3350Document7 pagesD3350Luis Fernando Morales100% (1)

- Astm F 477 - 02 PDFDocument4 pagesAstm F 477 - 02 PDFRaul Humberto Mora Villamizar100% (8)

- gm19 - GEOMEMBRANASDocument13 pagesgm19 - GEOMEMBRANASIsaias Quispe RuizNo ratings yet

- TR 33 Generic Butt Fusion Joining Gas PipeDocument40 pagesTR 33 Generic Butt Fusion Joining Gas PipeRamonezeNo ratings yet

- Normas Tuberia PEDocument2 pagesNormas Tuberia PEAnonymous wze4zUNo ratings yet

- Comparison Pe4710 Pe3608Document1 pageComparison Pe4710 Pe3608Rene CALLIRI MAQUERANo ratings yet

- ASTM D3167 Method-for-Floating-Roller-Peel-Resistance-of-Adhesives PDFDocument4 pagesASTM D3167 Method-for-Floating-Roller-Peel-Resistance-of-Adhesives PDFJesse KrebsNo ratings yet

- Din 8063-4 (1983) PDFDocument12 pagesDin 8063-4 (1983) PDFVictor MacoveiNo ratings yet

- Astm D3982Document7 pagesAstm D3982Gene DiJoseph100% (1)

- ASTM D-2513 - 04 Thermoplastic Gas Pressure Pipe, Tubing, and Fittings PDFDocument25 pagesASTM D-2513 - 04 Thermoplastic Gas Pressure Pipe, Tubing, and Fittings PDFDedi Kartiwa100% (2)

- TR 4 062017Document51 pagesTR 4 062017david francoNo ratings yet

- Contact-Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Corrosion Resistant Pipe and FittingsDocument7 pagesContact-Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Corrosion Resistant Pipe and Fittingshasan syukur100% (1)

- Astm E96.9061 PDFDocument8 pagesAstm E96.9061 PDFgaso99No ratings yet

- D 1599 PDFDocument3 pagesD 1599 PDFrickatmanNo ratings yet

- Astm D2837 (2001)Document14 pagesAstm D2837 (2001)Muzammil Khalil100% (3)

- Astm D-3840 - 01Document9 pagesAstm D-3840 - 01Bipin SasikumarNo ratings yet

- Astm C0969 - 1 (En)Document3 pagesAstm C0969 - 1 (En)Dinesh Sai100% (1)

- ASTM D 4227-99 - Qualification of Coating Applicators For ADocument3 pagesASTM D 4227-99 - Qualification of Coating Applicators For AalansirqueiraNo ratings yet

- Soldaduras Varios PDFDocument54 pagesSoldaduras Varios PDFCristhian AndresNo ratings yet

- Astm d3350Document7 pagesAstm d3350Erick Escobedo BragagniniNo ratings yet

- F439Document7 pagesF439cenkunal100% (1)

- ASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónDocument14 pagesASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónalexagoNo ratings yet

- D2513 04Document25 pagesD2513 04calidad1340100% (1)

- Astm d6392Document6 pagesAstm d6392Danilo Rojas MartinezNo ratings yet

- Astm D2657 - 07Document7 pagesAstm D2657 - 07dsalguero_2100% (2)

- Astm D3517 PDFDocument12 pagesAstm D3517 PDFsomphong.bkk5576No ratings yet

- Astm F894-19Document11 pagesAstm F894-19JC BoulangerNo ratings yet

- Astm F894Document11 pagesAstm F894Emre AkınayNo ratings yet

- Astm-F2206 2014Document5 pagesAstm-F2206 2014ricardo gutierrezNo ratings yet

- F2600 PDFDocument10 pagesF2600 PDFAhmad Zubair RasulyNo ratings yet

- Astm F438Document7 pagesAstm F438Hernando Andrés Ramírez GilNo ratings yet

- F 1055 - 98 RjewntutotgDocument9 pagesF 1055 - 98 RjewntutotgMMNo ratings yet

- Chlorinated Poly (Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80Document7 pagesChlorinated Poly (Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80mohanrulesNo ratings yet

- Method Janssen PDFDocument308 pagesMethod Janssen PDFJorgeNo ratings yet

- Trav L Cutter - CATALOGO PDFDocument2 pagesTrav L Cutter - CATALOGO PDFJorgeNo ratings yet

- Strainer Y TypeDocument2 pagesStrainer Y TypeJorgeNo ratings yet

- Inside Clamping Beveling Machine Type US30: 01.04.2009 Revision A ISO 9001 April 2009 1/1Document1 pageInside Clamping Beveling Machine Type US30: 01.04.2009 Revision A ISO 9001 April 2009 1/1JorgeNo ratings yet

- Chapter D UKDocument20 pagesChapter D UKxuantienhtNo ratings yet

- Method JanssenDocument308 pagesMethod JanssenJorgeNo ratings yet

- Sistemas de Sujeción de Carga: Abierto / Plataforma .. Cerrado / Furgon - Ferroviario - AereoDocument8 pagesSistemas de Sujeción de Carga: Abierto / Plataforma .. Cerrado / Furgon - Ferroviario - AereoJorgeNo ratings yet

- Trav L Cutter - CATALOGO PDFDocument2 pagesTrav L Cutter - CATALOGO PDFJorgeNo ratings yet

- Tube Fitting For DIN2353 PDFDocument68 pagesTube Fitting For DIN2353 PDFJorgeNo ratings yet

- Guillotine Pipe Saw: Model C, Super C, Model D and Super D Fast Accurate Cuts Under Partically All ConditionsDocument3 pagesGuillotine Pipe Saw: Model C, Super C, Model D and Super D Fast Accurate Cuts Under Partically All ConditionsJorgeNo ratings yet

- Trav L Cutter - CATALOGO PDFDocument2 pagesTrav L Cutter - CATALOGO PDFJorgeNo ratings yet

- Arduino DisassemblyDocument2 pagesArduino DisassemblyJose100% (1)

- 1-On-1 Meeting Agenda TemplateDocument1 page1-On-1 Meeting Agenda Templatemydirects100% (3)

- Municipal Emergency Services, Inc. Completes Acquisition of River Country Rescue in LouisianaDocument2 pagesMunicipal Emergency Services, Inc. Completes Acquisition of River Country Rescue in LouisianaPR.comNo ratings yet

- ECE Course DescriptionDocument10 pagesECE Course Descriptionengshimaa100% (1)

- Evaluation of Digital Divide.Document8 pagesEvaluation of Digital Divide.Jojie Mae GabunilasNo ratings yet

- Research Project ReportDocument21 pagesResearch Project ReportinternationalbankNo ratings yet

- 1PX12PSCNARMDDocument1 page1PX12PSCNARMDJainam ShahNo ratings yet

- Bomb Oil AisinDocument38 pagesBomb Oil AisinMAURICIONo ratings yet

- Exc Cat #17 320 CuDocument2 pagesExc Cat #17 320 CuWashington Santamaria100% (4)

- TQM Unit - 5Document11 pagesTQM Unit - 5Sukanth KannanNo ratings yet

- 3102354-EN R015 VS Series Compatibility ListDocument20 pages3102354-EN R015 VS Series Compatibility ListFrancisco CanoNo ratings yet

- All Passenger Car Dealers/TascsDocument9 pagesAll Passenger Car Dealers/TascssouravNo ratings yet

- 独家奉献 2009CDCS 考试真题集体回忆录Document18 pages独家奉献 2009CDCS 考试真题集体回忆录sreeks456No ratings yet

- Objective TestsDocument4 pagesObjective TestsBabita DhruwNo ratings yet

- Desain Ruangan CT-ScanDocument3 pagesDesain Ruangan CT-ScannewmanonmarsNo ratings yet

- References PDFDocument7 pagesReferences PDFresigjeflinNo ratings yet

- Siebel Certification QBankDocument85 pagesSiebel Certification QBankSoj SurajNo ratings yet

- GMDSS Handouts by VasuDocument23 pagesGMDSS Handouts by VasuSwaroopkunnath100% (2)

- IOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 5 OF 5-REV.01Document1 pageIOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 5 OF 5-REV.01subudhiprasannaNo ratings yet

- Passenger Terminal Building ProposalDocument6 pagesPassenger Terminal Building ProposalHimawan Aryo DewantoroNo ratings yet

- StepShot User GuideDocument46 pagesStepShot User GuideDeep SachdevaNo ratings yet

- Motion-Sensing Home Automation With VocalizationDocument7 pagesMotion-Sensing Home Automation With VocalizationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Least Common MultipleDocument4 pagesLeast Common MultipleWilliam BaileyNo ratings yet

- Chapter 3 Dec 50143Document29 pagesChapter 3 Dec 50143Kohilan VenugopalNo ratings yet

- A Report On An Automated Whistle Blowing System For Aiding Crime InvestigationDocument68 pagesA Report On An Automated Whistle Blowing System For Aiding Crime InvestigationXavier Francis S. LutaloNo ratings yet

- Rec Erc 78 08Document22 pagesRec Erc 78 08Jerry PellerNo ratings yet

- From Łukasiewicz-Moisil Logic To Computers by Ioana MoisilDocument9 pagesFrom Łukasiewicz-Moisil Logic To Computers by Ioana MoisilMarin VladaNo ratings yet

- DR External Axis Controller (1L4805A-E-3) PDFDocument160 pagesDR External Axis Controller (1L4805A-E-3) PDFdavidNo ratings yet