Professional Documents

Culture Documents

2 - Ian Hogarth, TWI - Why Is It Important and What's in It For You

Uploaded by

BHARANI0 ratings0% found this document useful (0 votes)

67 views28 pagestwi

Original Title

2 - Ian Hogarth, TWI - Why is It Important and What's in It for You

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttwi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

67 views28 pages2 - Ian Hogarth, TWI - Why Is It Important and What's in It For You

Uploaded by

BHARANItwi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 28

Eur Ing Ian Hogarth

CEng CIWE CEWE EWIE FWeldI

Principle Compliance Verification Engineer

TWI Certification Ltd.

Nuclear Supply Chain

TWI Aberdeen 8 October 2015

BS EN ISO 3834

Why is it important, and what’s in it for you

Copyright © 2015, TWI Certification Ltd

EN ISO 3834

The TWI scheme is designed to allow welding

fabricators to demonstrate compliance with EN ISO

3834 Quality Requirements for Fusion Welding of

Metallic Materials and also satisfies EWF/IIW criteria for

EN ISO 3834 certification.

The EN ISO 3834 certification scheme focuses

specifically on the company’s welding activities

Copyright © 2015, TWI Certification Ltd

EN ISO 3834 Parts 1 to 6 (2005)

EN ISO 3834 Parts 1 to 6 (2005)

Quality Requirements

for

Fusion Welding of Metallic Materials

Copyright © 2015, TWI Certification Ltd

EN ISO 3834

Quality requirements for fusion welding of metallic materials

• Part 1: Criteria for selection and use

• Part 2: Comprehensive quality requirements

• Part 3: Standard quality requirements

• Part 4: Elementary quality requirements

• Part 5: Normative references for the requirements

of ISO 3834-2. ISO 3834-3 and ISO 3834-4

ISO 3834 Part 6: Guidance on implementing ISO 3834 Defines the

requirements for the processes associated with welding to ensure

quality in welding is achieved

Copyright © 2015, TWI Certification Ltd

ISO 3834-6

(Guidance on implementing ISO 3834)

This document should be recognised as a guide for manufacturers

implementing ISO 3834 and is not to be used as a requirement for

company assessment

ISO 3834-6 identifies procedures for the control of welding activities,

it states may have been found useful by some manufacturers.

• It notes that the procedures may be informal (not specified in

writing) or described in written specifications.

• For certification purposes, the minimum requirements of ISO

3834 augmented by the requirements of EA-6/02 need to be in

place. ea-6-02-m.pdf http://european-accreditation.org

Copyright © 2015, TWI Certification Ltd

Selecting the ISO 3834 Requirement Part

ISO 3834 may be applied in a variety of situations.

The manufacturer selects one of the three Parts (2, 3 or

4) based on the following criteria

• the extent and significance of safety critical products

• the complexity of manufacture

• the range of products manufactured

• the range of different materials used

• the extent to which metallurgical problems may occur

• the extent fabrication imperfections affect performance

Copyright © 2015, TWI Certification Ltd

Selecting the ISO 3834 Requirement Part

There is no specific guidance .

If it is not already specified in the product application

standard, it is left to the client or the manufacturer to

decide which requirements part of the standard

should be adopted

Copyright © 2015, TWI Certification Ltd

Selecting the ISO 3834 Requirement Part

As an unofficial guide, the following may be adopted

Part 2 is relevant for specialist welding fabricators where the

welding technology, materials and contractual requirements are

technically demanding and vary from contract to contract

Part 3 is appropriate in situations where the welding technology

and materials used are technically demanding but the variety and

range of product types is restricted

Part 4 would apply to companies using welding as an ancillary

process. The materials, processes, designs and configurations

would be simple and largely repetitive

Copyright © 2015, TWI Certification Ltd

Normative References

ISO 3834-5 identifies the ISO standards that provide

compliance with parts 2, 3 and 4

Overview_fusion_welding_standards.pdf

• However, alternative standards may be adopted

provided they form part of, or are called up as

normative references, in the product standard used

by the manufacturer

Copyright © 2015, TWI Certification Ltd

Alternative Normative References

Where a manufacturer uses supporting standards other

than those given in ISO 3834-5, then the manufacturer

has to demonstrate that they provide equivalent

technical conditions.

This has to be documented.

It should be noted the use of alternative standards is

only permitted when these standards are referenced in

the product standards for items being fabricated by the

manufacturer

Copyright © 2015, TWI Certification Ltd

Alternative Normative References

For example if you are working to ASME IX

i.e. welding procedures, welder qualifications

Your NDT procedures and operators MUST be

certified to ASNT

Note! Or alternative certification as specified by

the client

Copyright © 2015, TWI Certification Ltd

Quality Management Systems

• ISO 3834 does not specifically require manufacturers

to implement a quality management system.

• However, ISO 3834-1 identifies a number of

elements that a manufacturer may implement to

strengthen its ISO 3834 control system.

• What are these elements??

Copyright © 2015, TWI Certification Ltd

Quality Management Systems

These elements are:

• Control of documents and records

• Management responsibility

• Provision of resources

• Competence, awareness ant training of personnel

• Planning of product realisation

• Determination of requirements related to the product

• Review of requirements related to the product

• Purchasing

• Validation of processes

• Customer property

• Internal audit

• Monitoring and measurement of product

Copyright © 2015, TWI Certification Ltd

Key Technical Aspects of ISO 3834; Part 2

• Review of requirements

• Technical review

• Subcontracting

• Welding personnel – welders and welding operators

• Welding coordination personnel

• Inspection and testing personnel

• Production and testing equipment

• Description of equipment

• Suitability of equipment

• New equipment

• Equipment maintenance

• Production planning

• Welding procedure specifications

Copyright © 2015, TWI Certification Ltd

Key Technical Aspects of ISO 3834; Part 2

• Qualification of welding procedures

• Work instructions

• Procedures for the preparation and control of documents

• Welding consumables: batch testing, storage and control

• Storage of parent materials

• Post weld heat treatment

• Inspection and testing

• Inspection and test status

• Non-conformance and corrective actions

• Calibration and validation of measuring, inspection and testing

equipment

• Identification and traceability and Quality records

Copyright © 2015, TWI Certification Ltd

Documentation

Whilst, the need for formal control documentation in ISO3834 is

limited and relates only to document control and the contract and

product records required, the EWF Regulations and European co-

operation for Accreditation requirements (EA-6/02) are more

rigorous.

These bodies expect written procedures for:

• How the manufacturer reviews the contract

• Coordination to be in accordance with ISO 14731

• Ensuring subcontracted activities comply with contract

• Maintenance and calibration of production equipment

• The control of welding consumables

• Storage of parent materials

• Identifying non-conformance and remedial activity

• Product identification and traceability

Copyright © 2015, TWI Certification Ltd

Typical Audit Activities in Fabrication Shops

• Material store • Weld specification requirements

• Welding consumable store • Drawings

• Electrode baking • Weld appearance

• Welding processes • Weld quality

• WPS application • Weld dimensions

• Qualified welders • Weld checks

• Operable welding equipment • Visual inspection

• Material identification • Quality plans

• Description of facilities • Manufacturing instructions

• Inspection status • Inspection plans

• Nonconforming product • Route cards

• Heat treatment • Production records

Copyright © 2015, TWI Certification Ltd

So What’s in it for me

Copyright © 2015, TWI Certification Ltd

Reasons for using ISO 3834

• Incorporation of ISO 3834 in product standards

• Utilisation of the normative references in ISO 3834

• Structured documentation and quality systems

• Establishing the level of quality required

• All aspects of welding reviewed for best practice

• Ensuring satisfactory control of welder certification

Copyright © 2015, TWI Certification Ltd

Reasons for using ISO 3834

Compliance with specific parts of EN ISO 3834 is being made a

requirement in a number of European product standards, e.g.:

• EN 13445: 2002 Unfired pressure vessels

• EN 15085: Railway applications – Welding of railway vehicles

and components

• EN 1090 Execution of steel structures

• EN 12732: 2000 Gas supply systems –Welding steel pipework –

Functional requirements

• EN 12952: 2001 Water tube boilers and auxiliary installations

Copyright © 2015, TWI Certification Ltd

Reasons for using ISO 3834

• A system audited by competent welding Engineers

• Structured requirements review and technical review

• Robust control of your Subcontracted activities

• RWC Interviewed as competent for the role

• A system of control of Equipment Calibration and

Validation

• Identification and traceability of materials

Copyright © 2015, TWI Certification Ltd

The Benefits for Certificated Companies

• Clear, high profile independent verification of

compliance with EN ISO 3834

• Independent confirmation of competence for its welding

and fabricating capabilities and staff in a defined scope

• Welding quality management and fabrication capability

assessments are carried out by specialist assessors

• Increased national and international business potential

through demonstrated compliance with internationally

recognised welding quality requirements

Copyright © 2015, TWI Certification Ltd

The Benefits for Certificated Companies

• European and International Standards have a

profound effect on manufacturing and fabricating

companies.

• Many companies have achieved certification to ISO

9001. But where significant use is made of a special

process like WELDING, such certification is unlikely

to provide the required demonstration of capability of

the company to manufacture products of the required

quality.

23

Copyright © 2015, TWI Certification Ltd

The Benefits for Certificated Companies

• EN ISO 3834 can overcome this shortfall and boost

the manufacturing company's ability to sell its

products in both domestic and overseas markets.

• Independent certification to EN ISO 3834 benefits

manufacturers by providing an authoritative third

party statement of commercial value. Certification

can be achieved alongside an ISO 9001 certification

or it can stand alone. The stand-alone option may be

attractive to companies in which the welding

operations are simple.

• People are the key to EN ISO 3834

Copyright © 2015, TWI Certification Ltd

The Benefits for Certificated Companies

Accredited Scheme

Backed by The Welding Institute (TWI), TWI Certification Ltd offers

the only scheme of its kind in the UK that is authorised for EN ISO

3834 certification by the European Federation for Welding, Joining

and Cutting (EWF).

The Scheme is also accredited by the United Kingdom

Accreditation Service (UKAS) and is called the Welding Fabricator

Certification Scheme.

• For further details please visit the following web pages:

• http://www.iso3834.org

• Companies that have received certification are listed on the

EWF website at www.ewf.be If you want to open the door to

wider recognition and greater business success, contact us

now!

25

Copyright © 2015, TWI Certification Ltd

Certificates

Copyright © 2015, TWI Certification Ltd

End of Presentation

Thank you for your participation

Any Questions?

Copyright © 2015, TWI Certification Ltd

Responsible Welding Coordinator

• Confirmation as an RWC can only be made as a result of a

formal manufacturer assessment

• Interviewed to understand how you apply your knowledge to the

role and responsibilities you have been allocated and how you

discharge those responsibilities relative to the role of RWC.

• Chris Eady will now explain the Who, What and Why? Busting

the Myths

28

Copyright © 2015, TWI Certification Ltd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Procedure For Determining Conformance To Steel Profile/Surface Roughness/Peak Count RequirementsDocument7 pagesProcedure For Determining Conformance To Steel Profile/Surface Roughness/Peak Count Requirementssarath100% (1)

- 9001-2008 To 9001-2015 To IATF 16949 - Rev1 - 02-17-17Document8 pages9001-2008 To 9001-2015 To IATF 16949 - Rev1 - 02-17-17normalNo ratings yet

- Cleaning Validation Master PlanDocument4 pagesCleaning Validation Master Planapi-50088250% (2)

- Safety Requirements For Welding Job at Confined SpacesDocument6 pagesSafety Requirements For Welding Job at Confined SpacesBHARANINo ratings yet

- Strength of Material-Shear Force and Bending MomentsDocument25 pagesStrength of Material-Shear Force and Bending MomentszakeriyaNo ratings yet

- AWS D1.1 Guide to Essential Welding VariablesDocument10 pagesAWS D1.1 Guide to Essential Welding Variableskhadtarp100% (1)

- Overview of Welding Technology& NDT (F)Document1 pageOverview of Welding Technology& NDT (F)BHARANINo ratings yet

- NBS18 Heat TreatmentDocument46 pagesNBS18 Heat Treatmentshailesh_tiwari_mechNo ratings yet

- Optimum Weld - Metal Strength For High Strength: Ship Structure CommitteeDocument129 pagesOptimum Weld - Metal Strength For High Strength: Ship Structure CommitteeBHARANINo ratings yet

- Lamellar TearingDocument8 pagesLamellar TearingBHARANINo ratings yet

- Paid Welding Webinar on Process ControlDocument1 pagePaid Welding Webinar on Process ControlBHARANINo ratings yet

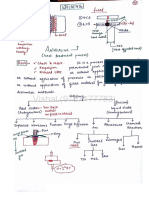

- Welding Hand Writing Book PDFDocument61 pagesWelding Hand Writing Book PDFDark LordNo ratings yet

- Consumables For Welding of (Very) High Strength Steels - Mechanical Properties of Weldments in As-Welded and Stress-Relieved ApplicationsDocument13 pagesConsumables For Welding of (Very) High Strength Steels - Mechanical Properties of Weldments in As-Welded and Stress-Relieved ApplicationsBHARANINo ratings yet

- Quench Hardening and Tempering Behaviour of A Low Carbon SteelDocument3 pagesQuench Hardening and Tempering Behaviour of A Low Carbon SteelBHARANINo ratings yet

- Classifications: For 560mpa Low Temperature Service Steel (1.5% Ni)Document1 pageClassifications: For 560mpa Low Temperature Service Steel (1.5% Ni)BHARANINo ratings yet

- Bloxide®: An Aluminum-Base Weldable PrimerDocument1 pageBloxide®: An Aluminum-Base Weldable PrimerBHARANINo ratings yet

- Recent Advances in Artificial Cracks For NDT Development and QualificationDocument10 pagesRecent Advances in Artificial Cracks For NDT Development and QualificationBHARANINo ratings yet

- DOI: 10.1515/amm-2016-0198Document8 pagesDOI: 10.1515/amm-2016-0198BHARANINo ratings yet

- Effects of Heat Control On The Stress Build Up During High-Strength Steel Welding Under Defined Restraint ConditionsDocument8 pagesEffects of Heat Control On The Stress Build Up During High-Strength Steel Welding Under Defined Restraint ConditionsBHARANINo ratings yet

- Quench Hardening and Tempering Behaviour of A Low Carbon SteelDocument3 pagesQuench Hardening and Tempering Behaviour of A Low Carbon SteelBHARANINo ratings yet

- EFFECT OF TEMPERATURE FIELDS HETEROGENEITYDocument7 pagesEFFECT OF TEMPERATURE FIELDS HETEROGENEITYBHARANINo ratings yet

- Weatherford Welding EngineerDocument1 pageWeatherford Welding EngineerBHARANINo ratings yet

- Effect of Welding Processes and Consumables On Fatigue Crack Growth Behaviour of Armour Grade Quenched and Tempered Steel JointsDocument13 pagesEffect of Welding Processes and Consumables On Fatigue Crack Growth Behaviour of Armour Grade Quenched and Tempered Steel Jointsbharani dharanNo ratings yet

- Recent Advances in Artificial Cracks For NDT Development and QualificationDocument10 pagesRecent Advances in Artificial Cracks For NDT Development and QualificationBHARANINo ratings yet

- Tubes PipesDocument320 pagesTubes Pipessapta tomoNo ratings yet

- Thirst For KN Wledge: Professional Development and CompetenceDocument5 pagesThirst For KN Wledge: Professional Development and CompetenceBHARANINo ratings yet

- Job Description - Scaffolding SupervisorDocument1 pageJob Description - Scaffolding SupervisorBHARANINo ratings yet

- 8-5a How To Write A Good Professional Review Report For CEngDocument22 pages8-5a How To Write A Good Professional Review Report For CEngGabriel PanaNo ratings yet

- Eversendai Offshore RMC Fze: Welding & Allied Processess Consumables Specification Doc Ref: Fcaw Rev: 00Document4 pagesEversendai Offshore RMC Fze: Welding & Allied Processess Consumables Specification Doc Ref: Fcaw Rev: 00BHARANINo ratings yet

- Example of CEng Qualifying Report (Avionics)Document9 pagesExample of CEng Qualifying Report (Avionics)BoubakerBaazizNo ratings yet

- Worksheet 5 AnswersDocument4 pagesWorksheet 5 AnswersBHARANINo ratings yet

- Cooling Rates and Hardness in Welded Carbon SteelDocument9 pagesCooling Rates and Hardness in Welded Carbon SteelBHARANINo ratings yet

- Welding TMCP Steels PDFDocument7 pagesWelding TMCP Steels PDFBHARANINo ratings yet

- John Deere Process Verification Audit - Instructions: BackgroundDocument6 pagesJohn Deere Process Verification Audit - Instructions: BackgroundTAPANNo ratings yet

- Validation of Water SystemDocument25 pagesValidation of Water Systemsukanya100% (2)

- Vertex70 Brochure enDocument8 pagesVertex70 Brochure enValentina RoznovNo ratings yet

- Message Specification V1.3 BDocument41 pagesMessage Specification V1.3 Bsuy uy100% (1)

- Workboat Guidelines IAGC 5Document20 pagesWorkboat Guidelines IAGC 5Paul H TampubolonNo ratings yet

- Syringe Tech. File ChecklistDocument3 pagesSyringe Tech. File ChecklistdearistyaNo ratings yet

- NABL 130 Specific Criteria for Site Testing and Calibration LaboratoriesDocument11 pagesNABL 130 Specific Criteria for Site Testing and Calibration LaboratoriesitisprasanthNo ratings yet

- Surface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningDocument2 pagesSurface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningKrishna VachaNo ratings yet

- Validation Documentation Requirements and Responsibilities For Drug Fabricators, Importers, EtcDocument6 pagesValidation Documentation Requirements and Responsibilities For Drug Fabricators, Importers, EtcsgNo ratings yet

- European Quality Assurance Standards in New Approach LegislationDocument90 pagesEuropean Quality Assurance Standards in New Approach LegislationCarlos AlvarezNo ratings yet

- CLEANROOM PramoteDocument28 pagesCLEANROOM Pramotedavincicode888100% (2)

- Handover ChecklistDocument6 pagesHandover ChecklistAbith GaneshNo ratings yet

- Naveen Chandra 1Document5 pagesNaveen Chandra 1NaveenchdrNo ratings yet

- Contamination Control MethodsDocument15 pagesContamination Control Methodsvan tung NguyenNo ratings yet

- Afra Self Audit Checklst Blank Editable PDFDocument17 pagesAfra Self Audit Checklst Blank Editable PDFDave MurphyNo ratings yet

- Validation Master PlanDocument33 pagesValidation Master PlanisralmayoorNo ratings yet

- Fluid Power Machinery Safety Guidebook ROSS VALVESDocument96 pagesFluid Power Machinery Safety Guidebook ROSS VALVESJason CardellNo ratings yet

- Central BAC compliance update to project boardDocument61 pagesCentral BAC compliance update to project boardRojen PadasasNo ratings yet

- Computer System Validation Complete Guide 1710042264Document105 pagesComputer System Validation Complete Guide 1710042264My TalentNo ratings yet

- 04 SOC1.3 Acoustic-ComfortDocument12 pages04 SOC1.3 Acoustic-ComfortfedaNo ratings yet

- Assessment Internal VerificationDocument8 pagesAssessment Internal VerificationKoshalNo ratings yet

- PDA Technical Documents LibraryDocument3 pagesPDA Technical Documents Librarymahesh thakorNo ratings yet

- Auditing Application ControlDocument18 pagesAuditing Application ControlSrie ZanraNo ratings yet

- PHA Quality Review ChecklistDocument8 pagesPHA Quality Review ChecklistRonak MotaNo ratings yet

- Software Engineering PDFDocument162 pagesSoftware Engineering PDFMark Hentony0% (1)

- 2012 International Performance Measurement and Verification Protocol (IPMVP®)Document143 pages2012 International Performance Measurement and Verification Protocol (IPMVP®)Ravi ShankarNo ratings yet

- Process Validation From An FDA Perspective - Part 2Document4 pagesProcess Validation From An FDA Perspective - Part 2Darren Tan100% (1)