Professional Documents

Culture Documents

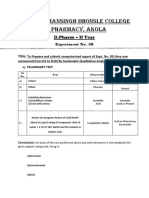

Effect of Alccofine On Flyash Concrete Blocks

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Alccofine On Flyash Concrete Blocks

Copyright:

Available Formats

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 7, Issue 2, February 2018 ISSN 2319 - 4847

EFFECT OF ALCCOFINE ON FLYASH

CONCRETE BLOCKS

R S Naveen Kumar1, M Shadakshari2,Chethan3 ,Anand V R4

1

Assistant professor,Dept. of Civil Engineering ,KVGCE,Sullia,Karnataka, India

2

Assistant professor,Dept. of Civil Engineering ,RYMEC,Bellary,Karnataka, India

3

Post graduate, Dept. of Civil Engineering ,SSE MUKKA,Karnataka, India

4

Assistant professor,Dept. of Civil Engineering ,SMVITM,Udupi,Karnataka, India

Abstract

Construction cost is increasing rapidly due to materials used for it and it can be reduced by using cost effective materials.

Many experiments are done to obtain cost effective concrete with good strength and good quality. The study of cost effective

concrete by using industrial waste product Fly ash. Fly ash is used as cement replacement. In this cement concrete of M40

grade design is carried out as per is codes .The tests are carried out to obtain maximum strength of concrete so cement is

replaced by fly ash of various percentages like 10%,20%,30%,40%,50%,60% and 70% by adding water cement ratio of 0.35 and

hyper plasticizer is used to reduce the water cement ratio to increase workability. Cubes were casted of size 150mm×150mm

and total 84 number of cubes were casted for different curing periods of 7, 14, 28 and 56 days. After curing cubes are tested for

7, 14, 28 and 56 days by using compressive testing machine respectively. For 28 days of curing period, the maximum

compressive strength is obtained for 20% cement replacement by fly ash gives good strength and for these to gain early strength

alccofine is added as additive material of 3%, 6%, 9% and 12% for 28 days curing period. In these 12% alccofine is added and

50% cement replacement by Fly Ash gives better compressive strength. Test results shows that using fly ash can used as cost

effective and good quality of concrete, by using alkofines we can improve the early age strength.

Keywords: Fly Ash, Alccofine, Hyper plasticizers

1. INTRODUCTION

Developing of country depends on fulfilling the basic needs of the man like food, shelter and transportation. The

Growth of country was made by construction of buildings, roads, bridges, tunnels, dams, channels...etc. Now a day the

cost of the construction materials is increasing, these affect the economical growth of the country. The main goal of

civil engineers is to reduce the cost and providing economical growth without changing quality and strength of the

material. From several years so many experiments were conducted to reduce the cost of construction material.

Concrete is the primary material for all building constructions. The basic components of concrete are cement, coarse

aggregates, sand and portable water. If necessary conditions admixtures are added. From several decades concrete is

used as binding material for construction. It exhibits the good property of binding and gains good compressive strength

but weak in tensile strength. Many researches are done by adding mineral admixtures decrease the cost of materials and

increase in performance of concrete. In this study, Fly ash exhibits pozzlonic activity so Fly Ash is used as cement

replacement material to increase the concrete performance.

1.1 INDUSTRIAL WASTE PRODUCTS

The waste materials obtained from industries called as industrial waste products. These waste products can be obtained

in the form of slag or powder form. This material exhibits the pozzolonic activity by adding the suitable chemicals.

There are various forms of industrial wastes are commonly used are as follows Glass powder, Ground Granulated Blast

Furnace Slag (GGBS),Silica fume,Rice husk ash (RHA),Fly ash.

1.2 FLY ASH

Fly Ash the waste product produced in electric power plants. It is made of fine particles and exhibits pozzolonic

activity. so it can be used as cement replacement material in concrete. In electric power plants fly ash is obtained in

large amount it causes the major disposal problem and environmental problem. It is mainly depends on the amount of

calcium present in Fly Ash, it is classified as low calcium Fly Ash called C Fly Ash and high calcium is called F Fly

Ash, the main content of fly ash is CaO and Ca(OH2) which implies the pozzolanic property of cement.

Volume 7, Issue 2, February 2018 Page 35

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 7, Issue 2, February 2018 ISSN 2319 - 4847

2 . METHODOLOGY AND MATERIALS

2.1.1 Cement

Cement is having good binding property. Cement is finely powdered binding material, which acts as a binder. The type

of cement used in this particular project is M43 grade Ordinary Portland Cement (OPC). The basic tests on cement

were conducted in accordance with BIS 8112-1989.

2.1.2 Fine aggregate

Fine aggregate is obtained degradation of rocks. The fine aggregate is of size should be within the range lies in between

4.75mm to 75µ as per codes.

2.1.3 Coarse aggregates

Crushed stones of size 20mm or less are used as coarse aggregates and these coarse aggregates should be tested

accordance with BIS 2386-1963

2.1.4 Fly ash

In this present study Fly Ash was taken from Bellary Thermal Power Plant. Fly ash is finer than 90 micron was used.

The chemical composition of Fly Ash is shown in table

Table :1 Chemical Composition of Alccofine

Parameters Results

Loss on

0.39%

Ignition

Silica 93.61%

Ferric Oxide 2.91%

Alumina Oxide 0.002%

Calcium Oxide 0.83%

2.1.5 Alccofine

Alccofine is a product it contains on high glass it process in high reactivity. The raw materials are composed primary of

low calcium silicates. The particle size range is from 0.1 to 0.17 microns, with an average particle size of 4 microns.

Table:2 Chemical Composition of Alccofine

Alccofine can also be used as a high range water reducer to improve compressive strength or as a super workability aid

to improve flow. Alccofine is known to produce a high-strength concrete and is used in two different ways: as a cement

replacement, in order to reduce the cement content and as an additive to improve concrete properties.

2.1.6 Hyper plasticizers

It is a high range water reducer or it is called as hyper plasticizer which lowers the water cement ratio and provides

required workability thus effects the concrete as easily pump able. Hyper plasticizer should be added to concrete at least

having slump of 25mm without adding any admixtures. It is formulated from synthetic polymers specially designed to

impart the cohesiveness to the concrete mix for easy pumping and placing. It considerably improves the properties of

fresh and hardened concrete. Add 70-80% water to the concrete based on Mix Design by weight. The correct quantity

of Hyper-plasticizer should be measured with recommended dispenser and should be added to the concrete with

Volume 7, Issue 2, February 2018 Page 36

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 7, Issue 2, February 2018 ISSN 2319 - 4847

remaining mixing water. Allow to mix it for recommended mixing time. The addition of Hyper-plasticizer to dry mixes

or cement is not recommended.

Table:3 Physical properties of Hyper plastizer

2.2 METHODOLOGY

In this investigation construction of cubes using cost effective concrete blocks replacing cement by Fly Ash.The

concrete used for blocks is to M40 grade concrete. Casting the concrete cubes of dimension 150×150×150 mm of 84

numbers for curing periods 28days . Casting of cubes of size 150×150×150mm of alkofines as additive material of 3%,

6%, 9% and 12% to the cement replaced by Fly Ash concrete. Three cubes for each percentage of Fly Ash with alkofine

added.

Figure 1: Casting of cubes for Compressive strength

Figure 2: Curing of cubes

3 Test RESULTS

The tests are carried to obtain good strength and cost effective material. To find compressive strength for various

percentages of fly ash in cement concrete. The maximum strength of fly ash concrete is obtained along with various

percentages of fly ash with alccofine is calculated

Volume 7, Issue 2, February 2018 Page 37

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 7, Issue 2, February 2018 ISSN 2319 - 4847

Partial replacement of by fly ash with alccofines

% Fly ash % of Alccofine Comprssive strength

3 81.1

6 83.33

40

9 78.44

12 80.33

3 66.21

6 81.1

50

9 79.33

12 87.55

3 62.66

6 60.29

60

9 63.85

12 69.67

3 48.59

6 55.4

70

9 49.48

12 57.92

Figure -3: Compressive Strength for 28 days

Figure -4: Compressive Strength for 28 days

4. CONCLUSIONS

In conventional concrete cement is replaced by industrial byproduct fly ash for various replacement levels and

exhibits more than required characteristic strength.

The optimum strength by the use of fly ash in the concrete is observed to be at 20% replacement of cement.

Optimum value occurs at 50% replacement of cement by fly ash with 12% of alccofines.

Volume 7, Issue 2, February 2018 Page 38

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 7, Issue 2, February 2018 ISSN 2319 - 4847

The use of fly ash results cost effective and environment friendly concrete and reduces the usage of resources

in the construction.

Fly ash of very fine acts as excellent filler material and also involves in the heat of hydration.

Using of fly ash decreases the disposal of waste hence decreases environmental pollution

REFERENCES

[1]. Ali mardani-Aghabaglou, Kambiz ramyar-“Mechanical properties of high volume fly ash roller compacted

concrete designed by maximum density method”, construction and building materials, vol-38, pp 356-364, 2013.

[2]. Dr. S. L Patil, J.N Kale and S .Suman, fly ash concrete: a technical analysis for compressive strength, IJAERS,Vol.

II,Issue ,pp-128-129,2012.

[3]. J.Paya, J.Monzo, E.Peris-Mora, M.V. Borrachero, R.Tercero, C.Pinilllos-“Early-strength development of Portland

cement mortars containing air classified fly ashes, vol-25, pp-449-456, 1995.

[4]. Medhat H. Shehata, Michael D.A. Thomas, Roland F. Bleszynski-“ The effect f fly ash composition on the

chemistry of pore solution of hydrated cement pastes”, Cement and Concrete Research , vol-29, pp 1915-1920, 1999.

[5]. L. Lam, Y.L. Wong, C.S. Poon –“Degree of hydration and gel/space ratio of high-volume fly ash/cement systems”,

pp 747-756, 2000.

[6]. P.Lorca,R.Calabuig,J.Benlloch,L.Soriano,J.Paya-“Micro concrete with partial replacement of Portland cement by

fly ash and hydrated lime addition”, Material and design, vol-64, pp 535-541, 2014.

[7]ash for use as pozzolona and admixture, Part-I (2003), Part-II (2003).

[8] IS: 456-2000, Indian Standard Code of Practice for Plain and Reinforced Concrete, Indian Standard Institution,

New Delhi.

AUTHOR

Mr. R S Naveen Kumar Working as an assistant professor at KVGCE, Sullia, ,Dakshin

Kannada.He studied B,E in CivilEngineering, at Ghousia college of engineering, Ramnagaram.

He studied the M.tech in structural engineering at SSE,MUKKA, Mangalore. He guiding the

students at graduate level.

Mr. M Shadakshari. ,He is Worked as an assistant professor at RMCE Bellary. He studied B,E

in CivilEngineering, at RMCE,BELLARY. He studied the M.tech in structural engineering at

SSE,MUKKA, Mangalore. He designing the residential buildings as well commercial buildings.

Mr. Chethan , He studied B.E In civil engineering at oxford college of engineering, Mtech in

structures in Srinivasa school of engineering. He is doing construction works of residential

buildings,commercial buildings, roads and construction industries.

Volume 7, Issue 2, February 2018 Page 39

You might also like

- Advances in Materials Science for Environmental and Energy Technologies VIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiNo ratings yet

- Effect On Durability and StrengthDocument8 pagesEffect On Durability and StrengthAvinash PrajapatiNo ratings yet

- 282PDocument6 pages282PNarasimha ReddyNo ratings yet

- Experimental Study On Concrete Using AlccofineDocument7 pagesExperimental Study On Concrete Using AlccofineIJRASETPublicationsNo ratings yet

- Research Paper Fly Ash Concrete: A Technical Analysis For Compressive StrengthDocument2 pagesResearch Paper Fly Ash Concrete: A Technical Analysis For Compressive StrengthsubhasisknkNo ratings yet

- High Performance Concrete Using Quaternary BlendDocument5 pagesHigh Performance Concrete Using Quaternary BlendIJIRAENo ratings yet

- High Performance Concrete With Partial Replacement of Cement by ALCCOFINE & Fly AshDocument6 pagesHigh Performance Concrete With Partial Replacement of Cement by ALCCOFINE & Fly AshvitusstructuresNo ratings yet

- Dec 269Document9 pagesDec 269245120741005No ratings yet

- Utilization of Fly Ash and Lime in PPC Concrete: Sudhir Kumar, Dr. Vikash Srivastava, Dr. V.C. AgarwalDocument4 pagesUtilization of Fly Ash and Lime in PPC Concrete: Sudhir Kumar, Dr. Vikash Srivastava, Dr. V.C. AgarwalerpublicationNo ratings yet

- 2.eng-Effective Utilization of Industrial By-Products in Construction IndustryDocument10 pages2.eng-Effective Utilization of Industrial By-Products in Construction IndustryImpact JournalsNo ratings yet

- A Comparative Study On The High Strength Fibre ReinforcedDocument7 pagesA Comparative Study On The High Strength Fibre ReinforcedDr-Rahul PanditNo ratings yet

- 4N5 Ijeset0202520 PDFDocument8 pages4N5 Ijeset0202520 PDFBia MughalNo ratings yet

- Experimental Investigation On Alccofine Concrete IJERTV8IS040362Document3 pagesExperimental Investigation On Alccofine Concrete IJERTV8IS040362245120741005No ratings yet

- Experimental Investigation On Mineral Content of Fly Bottom Ash and Strength Characteristics of Fly Bottom Ash Bricks - A ReviewDocument8 pagesExperimental Investigation On Mineral Content of Fly Bottom Ash and Strength Characteristics of Fly Bottom Ash Bricks - A ReviewEditor IJTSRDNo ratings yet

- Experimental Study On Concrete With Partial Replacement of Cement by Perlite PowderDocument9 pagesExperimental Study On Concrete With Partial Replacement of Cement by Perlite PowderInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Experimental Study On Behaviour of Concrete by Partial Replacement of Aggregate With Bamboo PiecesDocument7 pagesAn Experimental Study On Behaviour of Concrete by Partial Replacement of Aggregate With Bamboo PiecesIJRASETPublicationsNo ratings yet

- Enhancing The Strength of Pervious Concrete Using Polypropylene FibreDocument12 pagesEnhancing The Strength of Pervious Concrete Using Polypropylene FibreDin M. TorresNo ratings yet

- 40 - Nano Clay - GeopolymerDocument16 pages40 - Nano Clay - Geopolymerfs friedaNo ratings yet

- Sathyan 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012036Document11 pagesSathyan 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012036henryNo ratings yet

- Investigación CientíficaDocument16 pagesInvestigación CientíficaAnalia Sucari CalloNo ratings yet

- A Research Article On "Alccofine Concrete": K Ashwini, P Srinivasa RaoDocument5 pagesA Research Article On "Alccofine Concrete": K Ashwini, P Srinivasa RaoAshwini KotaNo ratings yet

- Usage of Sugarcane Bagasse Ash in Concrete: AbstractDocument7 pagesUsage of Sugarcane Bagasse Ash in Concrete: AbstractRadix CitizenNo ratings yet

- AlccofineDocument9 pagesAlccofineMadan Mohan ReddyNo ratings yet

- Mechanical Properties of Self Compacting Concrete Containing Crushed Sand and Sisal FiberDocument13 pagesMechanical Properties of Self Compacting Concrete Containing Crushed Sand and Sisal FiberKevin ChumánNo ratings yet

- Amit MittalDocument22 pagesAmit MittalVincent VivekNo ratings yet

- Partial Replacement of Fine Aggregate by Using Timber Waste in ConcreteDocument8 pagesPartial Replacement of Fine Aggregate by Using Timber Waste in ConcreteBAVIRISHETTY JAYKUMARNo ratings yet

- Oscar Power PointDocument36 pagesOscar Power PointAbdullahi MuhammadNo ratings yet

- Mechanical Properties of Lightweight Foamed ConcreDocument7 pagesMechanical Properties of Lightweight Foamed Concremalk lokaNo ratings yet

- 790 1867 1 PBDocument7 pages790 1867 1 PBVaasanthika VarmaNo ratings yet

- Effect of Superplasticizer On Workability and PropDocument8 pagesEffect of Superplasticizer On Workability and PropStephen John ClementeNo ratings yet

- The Effect of Nano-Silica and Waste Glass Powder On Mechanical, Rheological, and Shrinkage Properties of Uhpc Using Response Surface MethodologyDocument8 pagesThe Effect of Nano-Silica and Waste Glass Powder On Mechanical, Rheological, and Shrinkage Properties of Uhpc Using Response Surface Methodologyvineetkothari1No ratings yet

- Eng-Green Concrete Efficient and Eco-Friendly-Chirag GargDocument6 pagesEng-Green Concrete Efficient and Eco-Friendly-Chirag GargImpact JournalsNo ratings yet

- The Use of Blast Furnace Slag As A Supplementary CDocument13 pagesThe Use of Blast Furnace Slag As A Supplementary CCivil manNo ratings yet

- Ijciet 08 03 057 PDFDocument8 pagesIjciet 08 03 057 PDFucsproject2017No ratings yet

- An Experimental Investigation On Properties of Concrete by Using Silica Fume and Glass Fibre As AdmixtureDocument4 pagesAn Experimental Investigation On Properties of Concrete by Using Silica Fume and Glass Fibre As AdmixturePattifer ReadeNo ratings yet

- Mix Design Procedure For Self Compacting ConcreteDocument9 pagesMix Design Procedure For Self Compacting ConcretesaxraviNo ratings yet

- Binary and Quaternary Blends in High Strength ConcreteDocument5 pagesBinary and Quaternary Blends in High Strength ConcreteKalashNo ratings yet

- Effect of Superplasticizers On Workability and Strength of ConcreteDocument13 pagesEffect of Superplasticizers On Workability and Strength of ConcreteIyaadanNo ratings yet

- Ijetae 0817 23Document4 pagesIjetae 0817 23ragini singhNo ratings yet

- Irjet V10i447Document9 pagesIrjet V10i447Kothuri KarunaNo ratings yet

- Experimental Study On Flyash and Lime With Gypsum in ConcreteDocument12 pagesExperimental Study On Flyash and Lime With Gypsum in ConcreteInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Effect of Flyash On Strength Properties of Foam Concrete: Akshay Reddy B, Punith A, Mrs. Kalyani DongarkarDocument6 pagesEffect of Flyash On Strength Properties of Foam Concrete: Akshay Reddy B, Punith A, Mrs. Kalyani DongarkarAnuraagNo ratings yet

- 45 Ijmperdfeb201845Document8 pages45 Ijmperdfeb201845TJPRC PublicationsNo ratings yet

- 1 s2.0 S223878542100418X MainDocument9 pages1 s2.0 S223878542100418X Mainanunciano GuterresNo ratings yet

- Paper25117 119Document4 pagesPaper25117 119cibif40663No ratings yet

- Experimental Study On Pollution Control ConcreteDocument9 pagesExperimental Study On Pollution Control ConcreteInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigation On Concrete Paver Block by Adding Silica FumeDocument6 pagesExperimental Investigation On Concrete Paver Block by Adding Silica Fumeucsproject2017No ratings yet

- Use of Rice Husk Ash As Strength-Enhancing Additive in Lightweight Cementitious Composite MortarsDocument12 pagesUse of Rice Husk Ash As Strength-Enhancing Additive in Lightweight Cementitious Composite MortarsFolorunsho AyomideNo ratings yet

- Performance of High Strength Concrete Consisting oDocument10 pagesPerformance of High Strength Concrete Consisting ojayNo ratings yet

- Experimental Investigation On Bendable Concrete Using Natural and Artificial Fibres (Jute and Nylon)Document5 pagesExperimental Investigation On Bendable Concrete Using Natural and Artificial Fibres (Jute and Nylon)anon_884442402No ratings yet

- Partial Replacement of Sand With Sawdust in ConcreteDocument4 pagesPartial Replacement of Sand With Sawdust in Concrete18TPCV008 DONA RENJITHNo ratings yet

- Cauvery Institute of Technology: Experimental Study On Strength of Concrete Using Areca Fiber and Granite PowderDocument43 pagesCauvery Institute of Technology: Experimental Study On Strength of Concrete Using Areca Fiber and Granite PowderNithin BmNo ratings yet

- Experimental Study On Hybrid Fiber Concrete With Banana and Sugarcane FiberDocument10 pagesExperimental Study On Hybrid Fiber Concrete With Banana and Sugarcane FiberInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Influence of Silica Fume On Concrete: Prof. Vishal S. Ghutke, Prof. Pranita S.BhandariDocument4 pagesInfluence of Silica Fume On Concrete: Prof. Vishal S. Ghutke, Prof. Pranita S.BhandariBia MughalNo ratings yet

- Mechanical Properties of Polymer-Modified Porous ConcreteDocument8 pagesMechanical Properties of Polymer-Modified Porous Concreteraul.chiriacNo ratings yet

- A Study of Manufacturing and Experimental Behaviour of Cellular Lightweight Concrete (CLC) BricksDocument8 pagesA Study of Manufacturing and Experimental Behaviour of Cellular Lightweight Concrete (CLC) BricksSankara RaoNo ratings yet

- IJETR032903Document4 pagesIJETR032903erpublicationNo ratings yet

- Optimizing The Utilization Cement Slag and Fly Ash of Concrete QualityDocument5 pagesOptimizing The Utilization Cement Slag and Fly Ash of Concrete QualityMarsel Musa SafkaurNo ratings yet

- Engineered Cementitious Composites For Structural ApplicationsDocument8 pagesEngineered Cementitious Composites For Structural ApplicationsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Meena Bhagat, Ramya Raju Jimit Chotai: Fly Ash Concrete: A Technical Analysis For Compressive StrengthDocument5 pagesMeena Bhagat, Ramya Raju Jimit Chotai: Fly Ash Concrete: A Technical Analysis For Compressive StrengthVIVA-TECH IJRINo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Soil Stabilization of Road by Using Spent WashDocument7 pagesSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 pagesThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Performance of Short Transmission Line Using Mathematical MethodDocument8 pagesPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 pagesDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 pagesA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Impact of Effective Communication To Enhance Management SkillsDocument6 pagesThe Impact of Effective Communication To Enhance Management SkillsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Digital Record For Privacy and Security in Internet of ThingsDocument10 pagesA Digital Record For Privacy and Security in Internet of ThingsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 pagesStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Advanced Load Flow Study and Stability Analysis of A Real Time SystemDocument8 pagesAdvanced Load Flow Study and Stability Analysis of A Real Time SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Challenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19Document10 pagesChallenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 pagesA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 pagesSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 pagesAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 pagesImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Secured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpDocument12 pagesSecured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Predicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsDocument10 pagesPredicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- BahayapenggunaanformalinDocument7 pagesBahayapenggunaanformalinMiqdadNo ratings yet

- Silica and Silanes-II: Muhammad FarooqDocument30 pagesSilica and Silanes-II: Muhammad FarooqRana AnasNo ratings yet

- Appendixes: Appendix Particle Size - 1 - A - AluminumDocument19 pagesAppendixes: Appendix Particle Size - 1 - A - AluminumIbrahim HeaderNo ratings yet

- Analysis of Lubricating Grease: Standard Test Methods ForDocument11 pagesAnalysis of Lubricating Grease: Standard Test Methods ForMarco A. Rodríguez DíazNo ratings yet

- D V V U: T A.II.i.4. M P BS 1178Document4 pagesD V V U: T A.II.i.4. M P BS 1178ShubhamRanjanNo ratings yet

- Telecom Cost Template - New Site Transmission WorkDocument26 pagesTelecom Cost Template - New Site Transmission WorkRanel EspinosaNo ratings yet

- VentisorbDocument2 pagesVentisorbRahmida FadhliaNo ratings yet

- Agentes AntiescalaDocument7 pagesAgentes AntiescalaFabian ArboledaNo ratings yet

- Bearing Steel 100Cr6 AUSA - 2Document3 pagesBearing Steel 100Cr6 AUSA - 2suresh kumarNo ratings yet

- ASTM Fire Standards Table of Contents: Standard TitleDocument14 pagesASTM Fire Standards Table of Contents: Standard TitleKhaledAhmed100% (1)

- Experiment Observation Inference: Analysis of Simple Salt-AnionsDocument8 pagesExperiment Observation Inference: Analysis of Simple Salt-AnionsMayank BhartiNo ratings yet

- Experimental Investigation On TIG Welded Aluminium Alloy 6082 Weldment Using Non Destructive EvaluationDocument4 pagesExperimental Investigation On TIG Welded Aluminium Alloy 6082 Weldment Using Non Destructive EvaluationEditor IJTSRDNo ratings yet

- Worksheet - Types of Chemical ReactionsDocument2 pagesWorksheet - Types of Chemical ReactionsFathia HonoreNo ratings yet

- Eriks Sealing Elements Precision O-Ring Technical Manual PDFDocument221 pagesEriks Sealing Elements Precision O-Ring Technical Manual PDFCarlos Eduardo Flores TorresNo ratings yet

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Pending Material ListDocument24 pagesPending Material ListGopal RaiNo ratings yet

- Nylon Vs PolyesterDocument5 pagesNylon Vs PolyesterBuzzy BeeNo ratings yet

- Chem 2 Prac 28 RidaDocument4 pagesChem 2 Prac 28 RidanikkilakhanNo ratings yet

- Corrosion Prevention and Control Corrosion FundamentalsDocument9 pagesCorrosion Prevention and Control Corrosion FundamentalsbrodyNo ratings yet

- Lighting & MirrorsDocument172 pagesLighting & MirrorsemmataylorcityNo ratings yet

- Enhanced Sintering, Microstructure Evolution and Mechanical Properties of 316LDocument4 pagesEnhanced Sintering, Microstructure Evolution and Mechanical Properties of 316LDaniel SolesNo ratings yet

- USA5892ps 10193Document5 pagesUSA5892ps 10193Mubashar HassanNo ratings yet

- Polyiso SpecsDocument2 pagesPolyiso SpecsmikeNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Hot-Rolled Products TolerancesDocument3 pagesHot-Rolled Products TolerancesAndrew TanNo ratings yet

- Cellulose Degradation in Pulp Fibers Studied As Changes in Molar Mass DistributionsDocument94 pagesCellulose Degradation in Pulp Fibers Studied As Changes in Molar Mass DistributionsValentinaCantillánNo ratings yet

- Belt Conveyor DesignDocument21 pagesBelt Conveyor DesignAjith100% (1)

- UltraTech Master BrochureDocument17 pagesUltraTech Master BrochureHimanshu Kumar100% (1)

- Strain Sensor Reference Guide: Strain Gage Application Checklist Gage Designation SystemDocument6 pagesStrain Sensor Reference Guide: Strain Gage Application Checklist Gage Designation SystemGreens MacNo ratings yet

- A Review Study On Different Properties of Hollow Concrete Blocks IJERTCONV4IS03032 PDFDocument3 pagesA Review Study On Different Properties of Hollow Concrete Blocks IJERTCONV4IS03032 PDFJohn Rhey Lofranco TagalogNo ratings yet