Professional Documents

Culture Documents

Strainer Y Type

Uploaded by

Jorge0 ratings0% found this document useful (0 votes)

49 views2 pagesFiltros Y

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFiltros Y

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views2 pagesStrainer Y Type

Uploaded by

JorgeFiltros Y

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

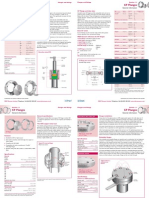

Y” Type Strainers take their name from their configuration.

They are most commonly used in

pressurized lines, gas or liquid, but can also be used in suction or vacuum conditions. They are intended for

applications where small amounts of solid particulates are expected, and where clean-out will be infrequent.

If solids will flush easily from the screen, and fluid can be exhausted to atmosphere, a blow-down valve on

the drain port will allow clean-out without removal of the screen, and without interrupting the process flow.

Features / Benefits

Robust Investment Cast Design

Screwed bonnet

Easy to install

Double screen

General Specification:

End Connection: BSP/NPT Pipe thread (ANSI or DIN

Flanges available on request)

Working Pressure: 40 bar (580 psi)

Temperature: -20 ~ 180˚C

Available Mesh Size: 40 ~ 200 mesh (400 ~ 75 microns)

Overall Dimensions (in mm):

Model Coding:

ST006 6mm ( 1/4" process connection ); 200 mesh (75 microns)

ST008 8mm ( 3/8" process connection ); 200 mesh (75 microns)

ST015 15mm ( 1/2" process connection ); 100 mesh (150 microns)

ST025 25mm ( 1" process connection ); 100 mesh (150 microns)

ST040 40mm ( 11/2" process connection ); 100 mesh (150 microns)

ST050 50mm ( 2" process connection ); 100 mesh (150 microns)

ST080 80mm ( 3" process connection ); 100 mesh (150 microns)

Materials

S 316 Stainless Steel body & screen element, teflon seal

Mesh sizing

1 Standard nominal

9 Customer nominated mesh size

Process connections

1 BSP female threaded

2 NPT female threaded

4 ANSI 150 RF stainless steel flanges

5 ANSI 300 RF stainless steel flanges

9 Customer nominated connections

# For Basket type strainers please consult factory

Model No. Example

ST025 S 1 1

Typical Installation of a Strainer with Flowmeter:

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Sure Flow StrainersDocument13 pagesSure Flow StrainersNinad SherawalaNo ratings yet

- Spirax Sarco Commissioning Strainer 1Document3 pagesSpirax Sarco Commissioning Strainer 1swaraj4uNo ratings yet

- Stainless Steel Cable Ties and AccessoriesDocument5 pagesStainless Steel Cable Ties and AccessoriesAdelChNo ratings yet

- PL 008748Document10 pagesPL 008748ronaldxmenNo ratings yet

- Transducer AccessoriesDocument6 pagesTransducer AccessoriesMohan ArumugavallalNo ratings yet

- Swagelok Hose MS 01 167Document28 pagesSwagelok Hose MS 01 167ashok_04meNo ratings yet

- King 7750 Series FlowmeterDocument2 pagesKing 7750 Series Flowmeterehab8320014413No ratings yet

- Flowmeter DatasheetDocument8 pagesFlowmeter DatasheetBhoopendra SinghNo ratings yet

- Catalogo Tecnico Stud WeldingDocument68 pagesCatalogo Tecnico Stud Weldingalexfc81No ratings yet

- WWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesDocument10 pagesWWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesNilesh MistryNo ratings yet

- T4E Brochure PDFDocument6 pagesT4E Brochure PDFgullenariNo ratings yet

- Aston Fittings BrochureDocument34 pagesAston Fittings BrochurefahedNo ratings yet

- Hansen Strainer - T479eDocument2 pagesHansen Strainer - T479eRikiNo ratings yet

- MeasureMaster Dual Chamber Orifice FittingDocument6 pagesMeasureMaster Dual Chamber Orifice FittingirfanNo ratings yet

- Rosemount 1195 Integral Orifice Primary Element: Product Data SheetDocument18 pagesRosemount 1195 Integral Orifice Primary Element: Product Data Sheetابزار دقیقNo ratings yet

- NUTRON Models T3 and B3 Ball Valves: Forged Steel Floating Ball Valves For Heavy-Duty, Reduced Maintenance PerformanceDocument32 pagesNUTRON Models T3 and B3 Ball Valves: Forged Steel Floating Ball Valves For Heavy-Duty, Reduced Maintenance PerformanceDanny PuchaNo ratings yet

- BrecoFLex Special BeltDocument28 pagesBrecoFLex Special BeltachinvanshNo ratings yet

- Ham-Let Astava Line of ManifoldsDocument24 pagesHam-Let Astava Line of ManifoldsjcestupinanNo ratings yet

- Pascal Pipe Fittings Complete Catalogue 1Document36 pagesPascal Pipe Fittings Complete Catalogue 1Serm Lim100% (1)

- T-Series Thermowells Model TF Flanged Wells, Model TT Threaded Wells, Model TW Weld-In Wells, and Model TS Sanitary WellsDocument12 pagesT-Series Thermowells Model TF Flanged Wells, Model TT Threaded Wells, Model TW Weld-In Wells, and Model TS Sanitary Wellssalmo83:18No ratings yet

- 08 Push in Fittings For PneumaticDocument20 pages08 Push in Fittings For PneumaticNilesh MistryNo ratings yet

- Tube FittingsDocument12 pagesTube FittingsspiritveluNo ratings yet

- 02 Precision Pipe FittingsDocument28 pages02 Precision Pipe FittingsNilesh MistryNo ratings yet

- Spiral Wound Gaskets PDFDocument4 pagesSpiral Wound Gaskets PDFSumit ChaurasiaNo ratings yet

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- 100059s Zvlnena Tesneni (W1A, W11A, W2A ... )Document4 pages100059s Zvlnena Tesneni (W1A, W11A, W2A ... )brkmechNo ratings yet

- Orifice FlangesDocument4 pagesOrifice FlangesdediekosNo ratings yet

- Protective Conductor Terminals and PE TerminalsDocument1 pageProtective Conductor Terminals and PE TerminalsAndré BekkernensNo ratings yet

- Spirax Sarco BTM-7Document3 pagesSpirax Sarco BTM-7Bambang Agung LaxmonoNo ratings yet

- High Pressure Needle ValvesDocument11 pagesHigh Pressure Needle ValvesNilesh MistryNo ratings yet

- 200 Series Check ValvesDocument2 pages200 Series Check ValvesMoanquileNo ratings yet

- MSS SP-6 (2001)Document6 pagesMSS SP-6 (2001)Vijay KumarNo ratings yet

- Mangueras Flexibles SwagelokDocument28 pagesMangueras Flexibles SwagelokCristian OtivoNo ratings yet

- Needle ValveDocument8 pagesNeedle ValveMuhammad Chilmi100% (1)

- Schedule 40 PipeDocument2 pagesSchedule 40 Piperasnowmah2012No ratings yet

- Millermatic 350P: The Power of BlueDocument4 pagesMillermatic 350P: The Power of BlueVic HernandezNo ratings yet

- Gas Filled Dial Thermometer: FeaturesDocument2 pagesGas Filled Dial Thermometer: FeaturesNilesh ChavanNo ratings yet

- Snubber PDFDocument2 pagesSnubber PDFKenon FlemingsNo ratings yet

- Pending Reservation As On 19.01.2024Document1 pagePending Reservation As On 19.01.2024Sagar PatilNo ratings yet

- Schedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Document2 pagesSchedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Caolboy ButchNo ratings yet

- ETIN Tubing ClampsDocument8 pagesETIN Tubing ClampsVijenth VergheseNo ratings yet

- Accessories: Components & SizesDocument1 pageAccessories: Components & SizesChevronelleNo ratings yet

- Universal Y StrainerDocument2 pagesUniversal Y Strainerabdi zakiNo ratings yet

- 5032-6 Fixed Inductors PDFDocument2 pages5032-6 Fixed Inductors PDFRobert NixonNo ratings yet

- Conveyor BeltsDocument22 pagesConveyor BeltsFavorSea Industrial Channel LimitedNo ratings yet

- Navco b2 BrochureDocument16 pagesNavco b2 Brochurejorge28csNo ratings yet

- JCM 452 Stainless Tapping SleeveDocument3 pagesJCM 452 Stainless Tapping SleeveNgô Mạnh TiếnNo ratings yet

- Multimatic 200 MillerDocument4 pagesMultimatic 200 MillerHugo Alfredo Ordóñez ChocanoNo ratings yet

- Double Block Bleed TOSVDocument8 pagesDouble Block Bleed TOSVplanet123No ratings yet

- Bond Strand 5000 eDocument8 pagesBond Strand 5000 eUmar KidaNo ratings yet

- Model: BT600A Any Angle Bi-Metallic Thermometer: Size CaseDocument2 pagesModel: BT600A Any Angle Bi-Metallic Thermometer: Size Casejacob johnNo ratings yet

- Swagelok Flange AdaptersDocument6 pagesSwagelok Flange AdapterstotcsabNo ratings yet

- Ultrahigh-Purity Stainless Steel Tubular Fittings: Metric SizesDocument4 pagesUltrahigh-Purity Stainless Steel Tubular Fittings: Metric Sizesherysyam1980No ratings yet

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- Sec1 1 1Document2 pagesSec1 1 1rajfmc100% (1)

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Ermeto Original Din FittingsDocument130 pagesErmeto Original Din FittingsgkhnbcrNo ratings yet

- DGA452Document76 pagesDGA452JorgeNo ratings yet

- PTS Termofusión PP750 Spanish 9-2008Document32 pagesPTS Termofusión PP750 Spanish 9-2008torresdeepNo ratings yet

- PTS Termofusión PP750 Spanish 9-2008Document32 pagesPTS Termofusión PP750 Spanish 9-2008torresdeepNo ratings yet

- Trav L Cutter - CATALOGO PDFDocument2 pagesTrav L Cutter - CATALOGO PDFJorgeNo ratings yet

- Method Janssen PDFDocument308 pagesMethod Janssen PDFJorgeNo ratings yet

- Chapter D UKDocument20 pagesChapter D UKxuantienhtNo ratings yet

- Strainer Y TypeDocument2 pagesStrainer Y TypeJorgeNo ratings yet

- Piping-Progress-Measurement - (In Dia and in Meter)Document6 pagesPiping-Progress-Measurement - (In Dia and in Meter)bhardwaj_rahul7937100% (2)

- Pipe Support Criteria For ASME B31.3 Metallic PipingDocument11 pagesPipe Support Criteria For ASME B31.3 Metallic PipingUsman Naseem100% (4)

- DGA452Document76 pagesDGA452JorgeNo ratings yet

- Piping-Progress-Measurement - (In Dia and in Meter)Document6 pagesPiping-Progress-Measurement - (In Dia and in Meter)bhardwaj_rahul7937100% (2)

- Gates and HoistsDocument184 pagesGates and HoistsVikas Shrimali86% (7)

- Astm F905Document3 pagesAstm F905JorgeNo ratings yet

- Inside Clamping Beveling Machine Type US30: 01.04.2009 Revision A ISO 9001 April 2009 1/1Document1 pageInside Clamping Beveling Machine Type US30: 01.04.2009 Revision A ISO 9001 April 2009 1/1JorgeNo ratings yet

- 13 EZ Purge1Document1 page13 EZ Purge1JorgeNo ratings yet

- Plastic Piping Handbook PDFDocument359 pagesPlastic Piping Handbook PDFJorgeNo ratings yet

- Plastic Piping HandbookDocument359 pagesPlastic Piping Handbookludwing_ulloa100% (13)

- System Specification Flyer - PROGEF PlusDocument2 pagesSystem Specification Flyer - PROGEF PlusJorgeNo ratings yet

- WachsDocument64 pagesWachsJorgeNo ratings yet

- Pipework SpecificationDocument111 pagesPipework Specificationwentroprem100% (2)

- Sistemas de Sujeción de Carga: Abierto / Plataforma .. Cerrado / Furgon - Ferroviario - AereoDocument8 pagesSistemas de Sujeción de Carga: Abierto / Plataforma .. Cerrado / Furgon - Ferroviario - AereoJorgeNo ratings yet

- ASME B16.47 Series B FlangeDocument4 pagesASME B16.47 Series B Flange41h189No ratings yet

- Small Diameter Clamps EZ-Fit: Pipe Cutting and Aligning Systems For The Welder and Pipe FitterDocument1 pageSmall Diameter Clamps EZ-Fit: Pipe Cutting and Aligning Systems For The Welder and Pipe FitterDavid HerreraNo ratings yet

- Cap 6 - Coke Oven PlantsDocument94 pagesCap 6 - Coke Oven PlantsJorgeNo ratings yet

- PRCMC 0033 UsDocument8 pagesPRCMC 0033 UsJorgeNo ratings yet

- Estimation Man HourDocument241 pagesEstimation Man HourAnonymous ynJByUs52% (42)

- Parker - FluidConnectorsDocument192 pagesParker - FluidConnectorsJorgeNo ratings yet

- Method JanssenDocument308 pagesMethod JanssenJorgeNo ratings yet