Professional Documents

Culture Documents

Template Hazid Report

Uploaded by

Jagan BoseCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Template Hazid Report

Uploaded by

Jagan BoseCopyright:

Available Formats

Client:

Project: Fine Print

Educational/ Training Material

Issued as a service to the

industry

for Free Distribution

HAZID STUDY REPORT

EPC Contractor:

Engg Consultant:

Rev Date Issued For By Chk’d App’d

Engg Consultant Contractor Client

Job No Sec No Contract No Document No

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

ABBREVIATIONS & DEFINTIONS

ABBREVIATIONS

• AIV Acoustic Induced Vibration

• ALARP As Low As Reasonably Practicable

• CO2 Carbon di Oxide

• CPP Central Process Platform

• EIA Environmental Impact Assessment

• FEED Front End Engineering Design

• FIV Flow Induced Vibration

• FP Flare Platform

• FPSO Floating Production Storage and Offtake

• FSO Floating Storage and Offtake

• GRE Glass Reinforced Epoxy

• H2S Hydrogen Sulphide

• HAZID Hazard Identification Study

• HP High Pressure

• LNG Liquefied Natural Gas

• LP Low Pressure

• LQ Living Quarters

• MOC Material of Construction

• NOx Nitrogen Oxides

• P&ID Process and Instrumentation Diagram

• PFD Process Flow Diagram

• QRA Quantitative Risk Analysis

• SCUBA Self-Contained Underwater Breathing Apparatus

• SIMOPS SIMultaneous OPerationS

• SOx Sulphur Oxides

• VOC Volatile Organic Chemicals (Benzene, toluene etc considered carcinogens)

• WHP Wellhead Platform

DEFINTIONS

• CLIENT

• CONSULTANT

• CONTRACTOR

Note: This report is based on the documents referred to in Appendix A. Modifications or revisions

to these documents may invalidate the observations and conclusions recorded in this report.

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 2 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

Table of Contents

1.0 INTRODUCTION ...........................................................................................................................4

1.1 PURPOSE..................................................................................................................................4

1.2 REFERENCES ..........................................................................................................................4

2.0 OBJECTIVES ................................................................................................................................5

3.0 SCOPE OF WORK........................................................................................................................6

3.1 Process Systems Studied..........................................................................................................6

3.2 Locations Studied ......................................................................................................................6

3.3 Schedule ....................................................................................................................................6

3.4 Deliverables ...............................................................................................................................6

3.5 HAZID Team Members..............................................................................................................7

3.6 HAZID Software .........................................................................................................................7

3.7 HAZID Session ..........................................................................................................................7

4.0 HAZID STUDY BASIS ...................................................................................................................8

4.1 Process Facilities .......................................................................................................................8

4.1.1 Flowlines, well fluid manifold system and receivers ...........................................................8

4.1.2 Oil systems:.........................................................................................................................8

4.1.3 Gas systems:.......................................................................................................................8

4.1.4 Utility and Auxiliary Systems...............................................................................................8

4.2 Facilities Layout .........................................................................................................................9

4.3 Facility Information...................................................................................................................10

4.4 Safety Studies ..........................................................................................................................12

5.0 HAZID STUDY.............................................................................................................................13

5.1 Methodology.............................................................................................................................13

5.2 Findings....................................................................................................................................13

5.3 Key Findings ............................................................................................................................13

APPENDIX A – HAZID Study Reference Documents ...............................................................14

APPENDIX B – HAZID Study Worksheets ................................................................................14

APPENDIX C – HAZID study Summary of Recommendations.................................................14

APPENDIX D – HAZID Explained..............................................................................................15

HOLD LIST– This identifies holds in following sections

Section Hold Description

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 3 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

1.0 INTRODUCTION

1.1 PURPOSE

This document presents the findings of a Hazards Identification (HAZID) Study conducted for

the ------- on ---------- at ------------.

One paragraph on the project -----------------------------

Hazard Identification (HAZID) is a systematic risk assessment study carried out by a team of

engineers from different disciplines. The team looks at each part of a plant or facility, considers

potential hazards, analyses their consequences against any existing safeguards. Criteria

include safety, asset, environment, reputation, society, etc.

HAZID study records the identified hazards without proposing any solution. The record serves

as a guide to determine the Health, Safety and Environment (HSE) issues to be resolved during

the project.

HAZID is a guideword driven brainstorming technique, which requires a properly constructed

team.

1.2 REFERENCES

The HAZID study was conducted in accordance with the following documents

• ISO-17776 : Petroleum and natural gas industries – Offshore production installations –

Guidelines on tools and techniques for hazard identification and risk assessment, 1st

Edition, 2000-10–15

Project documents referred to during the study is listed in Appendix A.

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 4 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

2.0 OBJECTIVES

The objectives of the HAZID study are:

• Identify potential hazards and risks associated with a project and process facilities of this

nature to identify early safety and operational issues

• Understand these hazards or risks and determine their potential consequences

• Determine (design and procedural) safeguards or risk reduction measures incorporated

and evaluate their adequacy and

• Recommend additional safeguards or operational procedures as necessary.

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 5 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

3.0 SCOPE OF WORK

The HAZID study covered the design, construction and operational phases of the facility,

identifying threats that are of global in nature, that is, applicable to all the process systems and

plant area; then it identified threats that are specific to a system or location

Drilling phase is not adequately addressed in this study as drilling operations subject matter

experts did not participate in the study.

3.1 Process Systems Studied

Following process systems were taken note of:

• Flowlines, well fluid manifold system and receivers

• Oil systems: Separation, Oil Metering and Export, Condensate Export

• Gas systems: LP Gas Compression, Glycol Dehydration & Regeneration, HP Gas

Compression, Gas Metering and Export

• Flare and Vent Systems

• Fuel Gas System

• Open and Closed Drain System

• Produced Water System

• Diesel Oil System

• Waste Heat Recovery and Hot Oil Systems

• Water Injection System

• Fire water system and

• Chemical Injection Package

3.2 Locations Studied

Equipment, as laid out on the following decks is indicated below:

• Lower Deck at _-- m:

• Main Deck at +-- m:

• Upper Deck at +-- m:

• Mezzanine Deck at +-- m:

3.3 Schedule

The HAZID study was conducted in ----- -------- office from --- to ----- --------------- ---. A

presentation of the recommendations was made on ---- ----- ---.

3.4 Deliverables

As agreed with the client, the main deliverables of this study are:

1. HAZID methodology and typical worksheet for review, prior to commencement of the

study, that is, draft form of this report. This has been done.

2. Interim report on the findings and recommendation of the study. This has been done.

3. Draft report. This report.

4. Final report will be delivered after getting comments on this report

This draft report is submitted for review, electronically within 2 weeks of completing the study.

The final report will be submitted in 3 hard copies along with electronic copy of native file

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 6 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

incorporating review comments from all relevant parties. If necessary a meeting will be arranged

between Company/ Contractor/ Consultant to resolve conflicting comments.

3.5 HAZID Team Members

HAZID study was held on -------------------. Following persons participated, on part or full time

basis as noted.

Dates

No Name Organization & Role 1 2 Remarks

1

2

3

4

5

6

7

8

3.6 HAZID Software

MS-Word based worksheets were used to capture HAZID team discussions and findings.

3.7 HAZID Session

The HAZID study was started with an overview of process facilities and platform deck layout.

This helped the team members to become familiar with the facility. Safety or incident alerts

related to similar facilities were shared. A brief introduction was given on systems with high

pressure, high temperature, low temperature and hazardous chemicals.

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 7 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

4.0 HAZID STUDY BASIS

4.1 Process Facilities

Process Flow Scheme

4.1.1 Flowlines, well fluid manifold system and receivers

4.1.2 Oil systems:

Separation

Oil Metering and Export

Condensate Export

4.1.3 Gas systems:

LP Gas Compression

Glycol Dehydration & Regeneration

HP Gas Compression

Gas Metering and Export

4.1.4 Utility and Auxiliary Systems

Flare and Vent Systems

Fuel Gas System

Open and Closed Drain System

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 8 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

Produced Water System

Diesel Oil System

Waste Heat Recovery and Hot Oil Systems

Water Injection System

Fire water system and

Chemical Injection Package

4.2 Facilities Layout

The Central Process Platform CPP is kept separate from Living Quarters and Flare platforms by

bridges. It is bridge linked to an adjacent wellhead platform. Fluids from other remote wellhead

platforms are brought in by subsea 3 phase pipelines. Platform boat approach is from West

while risers are grouped on the southern and northern side.

Layout Sketch

Inlet Slug Catchers are located on Lower Deck, while Dehydrator is on the Main Deck.

Compressors and Generators are on the Upper Deck. Relative location of major equipment are

shown below, in an exploded view

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 9 OF 17

HAZID

Deck Sketch Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

4.3 Facility Information

Following information on the facility was presented to the HAZID team members to familiarize

them with the facility and its system.

Type of Facility : Onshore Offshore

: LNG Oil & Gas Gas & Condensate

: Refinery Petrochemical Chemical/ Fertilizer

Type of Field : Marginal Normal

Feed : Oil, Gas and Water

Products : Gas compressed, dehydrated and exported via pipeline

: Oil stabilized and exported via pipeline

: Condensate injected into gas pipeline

: Water deoiled and locally disposed

Gas : Daily Contractual Quantity (DCQ) XXX MMscfd

: Max Daily Quantity (MDQ) YYY (DCQ + 10%)

: Design ZZZ 125% MDQ

Condensate : Normal / Maximum XX,000 / YY,000 BPD

Produced Water : Normal / Maximum/ Design XX,000 / YY,000 BPD

Platform : Wellhead Process Platform

: No of Decks XX No of Piles YY Weight ZZ,000 t

: Single lift Modular lift Float over

: Bridge linked Wellhead LQ Flare Tripod

: Helipad on LQ on another location

: Unmanned Manned

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 10 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

Flare : Vertical on platform Cantilevered from platform

: Separate bridge linked platform

Pressure : Highest 165 barg lift gas; 75 barg export gas

Temperature : Lowest (–) 40°C HP flare lateral; Highest - 550°C GT exhaust

Location : Shallow Water Deepwater

If Deep water, familiar with

: Hydrate/ Wax Issues MEG/Methanol Injection

: Line Flushing Wetwells Drywells

If FPSO/ Semi-sub, familiar with or knows about

: Impact of ship motion on topsides

Hazardous & Corrosive Materials

Lethal, Toxic Components : H2S 500 to 2,000 ppm Mercury Arsenic

If H2S : Operator familiar. A few units in operation

: Material Selection Personal H2S Monitor SCUBA

: Familiar or knows pyrophoric issues

If Hg or As : Removal Handling Aluminum as MOC

: Low accumulation points Operator familiar

: Discharge to sea with produced water

Corrosive : CO2 4 – 6% Acid cleaning - compressor piping

: Wellfluids High Temp CO2 - H2O from regenerator

: Hypochlorite solution

If CO2 : Operator familiar. A few units in operation

: Material Selection Knows about wet CO2 issues

: Familiar or knows asphyxiation issues

Potential incompatibilities : Solids Sand Drill mud

: Acid/alkali handling Wax

Catalysts : Mercury Removal Dehydrator Mol Sieves None

Dust Handling : None

Firewater system uses : GRE pipes PE/ Cement lined pipes Alloy steel

Owner-Operator : First Installation Operates similar units

: Sub-contract operation Operated by own crew

: Isolation standards, including Double Block & Bleed

: Sampling Draining Venting Philosophy

: PSVs are spared not spared

: Familiar with Rupture disks, if used

Key Issues

• High Levels of H2S

• First of a kind for client??

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 11 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

A brief presentation was made on HAZID and its methodology. Then the actual HAZID session

was started.

4.4 Safety Studies

It is noted that following Safety related studies are being or proposed to be conducted for this

facility. This will be taken note of while considering design safeguards.

Equipment and Building Location Study

Smoke & Gas Ingress/ Toxic Gas Risk Analysis

Fire & Explosion / Blast Analysis

Escape, Evacuation and Rescue Analysis (EERA)

Emergency Systems Survivability Analysis (ESSA)

Quantitative Risk Assessment (QRA)

Environmental Impact Assessment (EIA) Studies

Inherent Safety Analysis - Eliminate by process changes, minimize inventory

Hazard Prevention - Overpressure protection, Area Classification, SIL

Hazard Detection - Fire & Gas Detection, ESD stations

Hazard Control - Isolation & Depressurization

Hazard Mitigation - Active & Passive Fire Protection, Firewater/ Foam Systems

Collision Study

Dropped Object study

AIV/ FIV Studies

Vibration/ Noise Study

Pipe Stress Study

SIMOPS Study

Human Factors

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 12 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

5.0 HAZID STUDY

5.1 Methodology

The HAZIP study was conducted in an industry standard approach. It is briefly discussed in

Appendix D.

5.2 Findings

The HAZID team made a total of about --- recommendations. About 20 are key

recommendations. Some are highlighted below. The HAZID study worksheets are in Appendix

B while the Summary of Recommendations is in Appendix C.

5.3 Key Findings

Following summarizes key findings

• Alert the Operation and Maintenance team to potential pyrophoric fire on opening H2S

laden vessels and exposing them to air. Suitable caution boxes will be provided in key

P&IDs and on equipment to keep the surfaces wet and/or follow company procedures.

• It is proposed to conduct a transient analysis of seawater pumps and Firewater pumps to

avoid pressure surges and make SPR (Single Point Responsibility) mandatory on GRE

pipe manufacturer for material, design, and layout review to avoid sharp turns, surge

analysis, fabrication and installation for GRE pipes.

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 13 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

APPENDIX A – HAZID Study Reference Documents

1. XXXX-YYY-ZZZ Rev A - Simplified Block Flow Diagram

2. XXXX-YYY-ZZZ Rev A - PFD 300 MMscfd Gas + 10,000 BPD Condensate to FSO

3. XXXX-YYY-ZZZ Rev A - Equipment Layout - Upper Deck

4. XXXX-YYY-ZZZ Rev A - Equipment Layout - Main Deck

5. XXXX-YYY-ZZZ Rev A - Equipment Layout - Lower Deck

6. XXXX-YYY-ZZZ Rev A - Equipment Layout - Elevation Looking East

7. XXXX-YYY-ZZZ Rev A - Equipment Layout - Elevation Looking West

8. XXXX-YYY-ZZZ Rev A - Facilities Layout – CPP, WHP, LQ, FP

Feedback on FPSO issues http://olf.no/en/FPSO-Experience-Transfer/FPSO-Lessons-overview/

APPENDIX B – HAZID Study Worksheets

APPENDIX C – HAZID study Summary of Recommendations

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 14 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

APPENDIX D – HAZID Explained

What? Hazard Identification (HAZID) study identifies hazards or risks in onshore and offshore

installations.

When? Any time but done best as early as possible at FEED stage as soon as a preliminary

layout and block flow diagrams for process and utility systems are available. If required

a follow-on study may be conducted during Detailed Engg stage to follow-up

recommendations of previous studies. Early studies enable timely inputs to proposed

design. Delayed studies fail to influence or apply course-correction to design

decisions.

Who? By a team of engineers. Suggested team members are: Study chairman or facilitator,

Scribe, Process engineer, Safety engineer, Layout or Piping engineer and Client

representatives. They are supplemented on a call basis by Civil or Structural engineer,

and Mechanical engineer.

Areas? Team selects areas to study - either plot or deck wise or system wise. Too many

wastes time leading to repetition and waning focus. Too few may miss out a few

threats. Experienced judgment is the key.

How? Each system or area of an installation is reviewed against a pre-agreed checklist.

When a hazard or risk is identified,

(1) All potential causes or scenarios that could initiate or trigger the hazard

(2) Their potential consequences - direct as well as escalated

(3) Impact on personnel, assets and environment

(4) Effectiveness of safeguards/ risk reduction/ or operating procedures present

(5) Recommendation, if any, to add to existing mitigation measures

were evaluated.

This process was repeated for each hazard and each system until all have been

studied. HAZID team should not attempt to provide a solution unless one is obvious.

Its role is to identify hazards and provide a high level qualitative assessment. The

project and discipline engineers should find an acceptable solution as part of design

development.

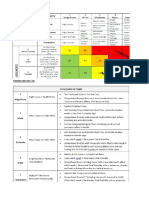

Some HAZID studies may assign Risk Ratings for the identified hazards, based on a

risk matrix by the client. These ratings help prioritize follow-on actions. Whether there

is a risk rating are not, all actions should be properly closed out.

During the study, the HAZID worksheet is projected overhead for members to see,

comment and concur. Hazards that are not present are not recorded.

Inputs? Field and facility layout drawings, Process and Utility flow diagrams.

Next? Actions or recommendations proposed are assigned to individuals by a project

engineer via a suitable tracking system. Actions closed out are recorded in the final

HAZID report issued as a project deliverable. A few projects may maintain a Hazard

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 15 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

Register wherein identified hazards are input by area and type. The HAZID report is

used to populate it.

Checklists Each organization has one of its choice or one can be developed as required.

Global Issues

Hydrocarbon, Chemicals & Utilities

1. Hydrocarbons release - with or without ignition

Dropped objects, Swing loads, Corrosion, Small bore pipes, Fitting leaks, Seal

failure, low temperature embrittlement, AIV/FIV, Gas blowby

2. Hydrocarbon ingress

Hydrocarbon ingress into gas turbine, diesel engine, fired heater air intakes

3. Moisture ingress

Water ingress into heated or hot oil storage

4. Draining / Sampling

Discharge of produced water (with mercury), mud, cuttings to sea or soil

5. Thermal radiation/ Flaring and Venting

Hazardous Chemicals & Health Hazards

6. Hazardous gas, liquids and solids release

Mercury, Arsenic, H2S, CO2, CH4, NOx, SOx, VOC

7. Non Process Fire/ Flammable chemicals

Fire in LER, GT Enclosure

8. Explosion

H2 in Hypochlorite Tank or Battery Room

9. Asphyxiation / Confined space

Inert gas release, Smoke, CO2, Vessel entry

10. Particulates (sand, dust, ash)

Sand, Catalysts, Desiccant,

11. Radioactive / Explosive material

Structural

12. Structural failure

Weather, Earthquake, Collision, Overload, Fire, Cyclic loads

Occupational Hazards

13. Electrical energy

Electrocution, Static electricity

14. Stored energy (Pneumatic / Thermal)

High pressure hoses, Hot surfaces

15. Vibration / Noise

High pressure drop valves, Machinery, slugging, Water hammer

16. Manual work

Rigging, Handling drums, Cutting & Welding, Hand tools, Fall overboard

17. Natural and Environmental Hazards

Wind, Cyclones/ hurricanes/ tornadoes, Waves, High tides, tsunami, Sea currents,

Floods, Ice, Blizzards, Earthquake, Volcano, Ground slide, Soil subsidence,

Summer, Winter, Saliferous or sand/ dust laden wind, Humidity, Heavy rains and

Lighting

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 16 OF 17

HAZID Worksheets ABC XYZ FIELD DEVELOPMENT PROJECT

Central Facilities

Marine

18. Marine operations

Personnel Transfer, Supply boat operations, Passing ships, Helicopter operations

19. SIMOP

Emergency, Escape and Rescue

20. Impeded Access / Approach / Escape/ Evacuation

Slippery steps, Blocked access, Laydown area, Maintenance activities

Man-made Hazards

21. Security issues

Unauthorized entry; Sabotage; Piracy, Terrorist activities

Construction and Start-up

22. Construction difficulties

Poor planning, Legislation, Compliance to local codes & standards

23. Start-up & Shutdown difficulties

Poor planning, Missing black start fuel, Low inventory, Untrained crew

System or location specific issues

Pigging Operation

Cellar or Lowest Deck

Upper Deck

FPSO

Poor planning - Hull delivery; Storage volume; hull to shipping standards (batch

mode) and topsides to process industry standards (continuous operation)

Effect of FPSO’s axial (Surge, Sway, Heave), rotational (Roll, Pitch, Yaw) and static

(List, Trim) motions on separation, distillation, liquid levels, internals support

Hogging/ sagging of decking plates on equipment support & structures, rotating

equipment support

Green water waves; Maintenance - storage tanks, sea chest, seawater pumps etc

Onshore Location

Proximity to population, Ground water contamination, Historical monuments

damaged by fumes, Public roads, Nearby land use (Farming/ Fishing)

Biological

Endemic diseases, Infection, Contaminated water / food, Biological agents (viruses,

pathogens, parasites, poisonous reptiles and plants)

Caution: What is normal practice in a company may be a hazardous practice in another company which may not have adequate

experience with a particular process or equipment. Example: regenerator insulation failure resulting in hot spots and vessel failure or H2S.

REPORT NUMBER: REV: A 26 MAY 2009 PAGE 17 OF 17

You might also like

- SPD0102ERN - 0 - HAZID, ENVID ProcedureDocument11 pagesSPD0102ERN - 0 - HAZID, ENVID ProcedureGabbar SinghNo ratings yet

- Review Formalities HAZID ReportDocument3 pagesReview Formalities HAZID ReportNaresh Nutakki50% (2)

- Container Securing HAZID Report Identifies HazardsDocument54 pagesContainer Securing HAZID Report Identifies Hazardsirfankaushar100% (2)

- HAZID Report Rev 0Document39 pagesHAZID Report Rev 0amalhaj20130% (1)

- HAZID WORKSHEET FOR ANOA PHASE 4 AGX PROJECTDocument15 pagesHAZID WORKSHEET FOR ANOA PHASE 4 AGX PROJECTMohdNajib Mahmud100% (4)

- HAZID Guideword ChecklistDocument2 pagesHAZID Guideword Checklistqhseconsult100% (2)

- I. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17Document15 pagesI. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17KehindeNo ratings yet

- HAZID Workshop PDFDocument45 pagesHAZID Workshop PDFNora Afzam Abd Wahab100% (1)

- Comparison of Pha Methods PDFDocument10 pagesComparison of Pha Methods PDFQayyum KhanNo ratings yet

- HAZID Report for North Bahariya DevelopmentDocument16 pagesHAZID Report for North Bahariya Developmentkokykarkar100% (2)

- 6.40 Offshore Platform Hazid Envid ReportDocument26 pages6.40 Offshore Platform Hazid Envid ReportGaluh Pramudipto100% (1)

- HAZOP Study Methodology - 2 IEDOSH JB - StudentDocument116 pagesHAZOP Study Methodology - 2 IEDOSH JB - StudentAhmad Fauzie Ibrahim IsmailNo ratings yet

- HAZID GuidewordsDocument8 pagesHAZID Guidewordsalex_E_bond100% (2)

- Attachment B - HAZID WorksheetDocument9 pagesAttachment B - HAZID Worksheetwibowo wibowo100% (1)

- 6.63 Pipeline Hazid Envid ReportDocument17 pages6.63 Pipeline Hazid Envid ReportGaluh Pramudipto100% (7)

- HAZOP ProcedureDocument10 pagesHAZOP Proceduresharjeel39100% (3)

- Hazid Vs HazopDocument5 pagesHazid Vs HazopElavarasan RamalingamNo ratings yet

- Application HAZOP LOPA Figueroa 2015Document225 pagesApplication HAZOP LOPA Figueroa 2015ravisankar100% (1)

- 02 - HAZID Techniques - Applications and LimitationsDocument12 pages02 - HAZID Techniques - Applications and Limitationsarman_morala100% (1)

- HazopDocument8 pagesHazopferrari.indiaNo ratings yet

- Integrating Hazop and Sil/Lopa Analysis: Best Practice RecommendationsDocument10 pagesIntegrating Hazop and Sil/Lopa Analysis: Best Practice Recommendationsavinash_mokashi7073100% (1)

- Hazop RequirementDocument43 pagesHazop RequirementTheVirus Papa100% (2)

- Fertil Hazop StudyDocument9 pagesFertil Hazop Studypkannan0% (1)

- PSM Course 2014 Day 3Document102 pagesPSM Course 2014 Day 3dcd1980No ratings yet

- Chastainw Advancesinlayerofprotectionanalysis PDFDocument37 pagesChastainw Advancesinlayerofprotectionanalysis PDFanon_770350620100% (1)

- HSE Parts Count Guide PDFDocument19 pagesHSE Parts Count Guide PDFBanjoNo ratings yet

- 1 PDFDocument8 pages1 PDFDrina20040% (1)

- Process Hazard Analysis MethodsDocument61 pagesProcess Hazard Analysis Methodsjcv235100% (1)

- Day 5 - Hazop Procedure For CompanyDocument57 pagesDay 5 - Hazop Procedure For CompanyPablo CastroNo ratings yet

- Hazop ProcedureDocument15 pagesHazop Procedureartlet100% (1)

- Chapter 5 - Hazard IdentificationDocument53 pagesChapter 5 - Hazard IdentificationChieng Tiew Hing100% (1)

- HAZID Worksheet FORM Rev 25 May 2012 Timas Premier Oil IndonesiaDocument15 pagesHAZID Worksheet FORM Rev 25 May 2012 Timas Premier Oil IndonesiaMatthew BennettNo ratings yet

- Operational Risk Management - (Chapter 3 Tools and Techniques) PDFDocument38 pagesOperational Risk Management - (Chapter 3 Tools and Techniques) PDFMaria MirandaNo ratings yet

- PhastDocument36 pagesPhastNilambar Bariha100% (1)

- HazidDocument91 pagesHazidrusticrage2883100% (4)

- HAZID TemplateDocument38 pagesHAZID TemplateMd AfzanNo ratings yet

- Probability of Ignition Probability of Personnel in Affected Area Probability of Fatal Injury OthersDocument1 pageProbability of Ignition Probability of Personnel in Affected Area Probability of Fatal Injury OthersTFattahNo ratings yet

- A Lopa Implementation Method: Breydon G Morton Dupont October 3, 2007Document19 pagesA Lopa Implementation Method: Breydon G Morton Dupont October 3, 2007asimozma100% (4)

- Template Hazid WorksheetDocument43 pagesTemplate Hazid WorksheetJagan Bose100% (3)

- Hazard Operability StudiesDocument8 pagesHazard Operability StudiesPendi Adi MertaNo ratings yet

- Risk Based Process Safety DesignDocument13 pagesRisk Based Process Safety DesignVan SotNo ratings yet

- Correct Hazid ChecklisterDocument16 pagesCorrect Hazid ChecklisterAkintoye AsaoluNo ratings yet

- 1.4 Reactive HazardsDocument16 pages1.4 Reactive HazardsFranklin RevillNo ratings yet

- Gas Release Tripod Beta Analysis Final-2Document28 pagesGas Release Tripod Beta Analysis Final-2Mostafa KhalifaNo ratings yet

- Methods of Determining Safety Integrity Level (SIL) Requirements - Pros and ConsDocument16 pagesMethods of Determining Safety Integrity Level (SIL) Requirements - Pros and Consibaig80100% (1)

- Center For Chemical Process Safety: An Introduction To Inherently Safer DesignDocument15 pagesCenter For Chemical Process Safety: An Introduction To Inherently Safer DesignJoe Rivers100% (1)

- Hazop-Hazid, Sil StudyDocument15 pagesHazop-Hazid, Sil Studydesign electricalNo ratings yet

- Hazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDocument110 pagesHazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDenstar Ricardo Silalahi94% (16)

- Safety Integrity Level (SIL) Classification, Verification and ValidationDocument2 pagesSafety Integrity Level (SIL) Classification, Verification and Validationjjmd181245880% (1)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Quantitative Risk Assessment A Complete Guide - 2020 EditionFrom EverandQuantitative Risk Assessment A Complete Guide - 2020 EditionNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Certified Functional Safety Expert A Complete Guide - 2020 EditionFrom EverandCertified Functional Safety Expert A Complete Guide - 2020 EditionNo ratings yet

- Health, Safety, and Environmental Management in Offshore and Petroleum EngineeringFrom EverandHealth, Safety, and Environmental Management in Offshore and Petroleum EngineeringRating: 5 out of 5 stars5/5 (1)

- 1007 DISQ 0 F MA 10030 Design Integrity ReportDocument15 pages1007 DISQ 0 F MA 10030 Design Integrity ReportAnonymous XbmoAFtINo ratings yet

- Ielts Writing Task 2 Useful PhrasesDocument7 pagesIelts Writing Task 2 Useful PhrasesJagan BoseNo ratings yet

- Listening Sample Task 9 PDFDocument3 pagesListening Sample Task 9 PDFJagan BoseNo ratings yet

- IELTS Listening Answer SheetDocument1 pageIELTS Listening Answer SheetFazle RabbyNo ratings yet

- Get Chartered - Applying knowledge and finding solutionsDocument2 pagesGet Chartered - Applying knowledge and finding solutionsJagan BoseNo ratings yet

- Salary Structure 2018Document1 pageSalary Structure 2018Jagan BoseNo ratings yet

- IELTS Writing Task 1 VocabularyDocument3 pagesIELTS Writing Task 1 VocabularyPaula GonzalezNo ratings yet

- Revised Fee Structure: Fellow (FIE)Document1 pageRevised Fee Structure: Fellow (FIE)Jagan BoseNo ratings yet

- CCReport Examples Aii PDFDocument2 pagesCCReport Examples Aii PDFJagan BoseNo ratings yet

- What Is Commissioning and Related Terms Rev 01Document1 pageWhat Is Commissioning and Related Terms Rev 01sunil601No ratings yet

- Helpful InterviewTipsDocument7 pagesHelpful InterviewTipsGp MishraNo ratings yet

- PWC LNG Progression CanadaDocument10 pagesPWC LNG Progression CanadaAF Dowell MirinNo ratings yet

- Hydrocarbon Conversion Table GuideDocument1 pageHydrocarbon Conversion Table GuidehypermekoolNo ratings yet

- Illustration For Your HDFC Life Click 2 Protect PlusDocument2 pagesIllustration For Your HDFC Life Click 2 Protect PlusJagan BoseNo ratings yet

- Energy Specialists / Senior Energy Specialists: This Job Is No Longer Accepting ApplicationsDocument3 pagesEnergy Specialists / Senior Energy Specialists: This Job Is No Longer Accepting ApplicationsJagan BoseNo ratings yet

- ERP Practice Questions Summary: Determinants of Offshore Drilling CostsDocument37 pagesERP Practice Questions Summary: Determinants of Offshore Drilling Costsjohn smithNo ratings yet

- Recording Lectures Links - Feb 19 To June-19Document1 pageRecording Lectures Links - Feb 19 To June-19Jagan BoseNo ratings yet

- What Are Adb Core and Managerial Competencies?Document3 pagesWhat Are Adb Core and Managerial Competencies?Jagan BoseNo ratings yet

- Why You Want To Join ADBDocument3 pagesWhy You Want To Join ADBJagan BoseNo ratings yet

- CHAPTERSDocument1 pageCHAPTERSJagan BoseNo ratings yet

- Value Investment Plan: SIP, One-Time or VIP, The Best Investment StrategyDocument3 pagesValue Investment Plan: SIP, One-Time or VIP, The Best Investment StrategyJagan BoseNo ratings yet

- Chemical/Process Engineer: Position DescriptionDocument2 pagesChemical/Process Engineer: Position DescriptionJagan BoseNo ratings yet

- Senior Process Engineer - Utilities - (1900064) : Job OverviewDocument2 pagesSenior Process Engineer - Utilities - (1900064) : Job OverviewJagan BoseNo ratings yet

- Answers SheetDocument23 pagesAnswers SheetJagan BoseNo ratings yet

- Online Class ModeDocument9 pagesOnline Class ModeJagan BoseNo ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word DocumentJagan BoseNo ratings yet

- PGDM (EXECUTIVE) Empowers Executives with Analytical Skills to Drive PerformanceDocument8 pagesPGDM (EXECUTIVE) Empowers Executives with Analytical Skills to Drive PerformanceEmba MadrasNo ratings yet

- The Conceptual Framework: Learning ObjectivesDocument15 pagesThe Conceptual Framework: Learning ObjectivesJagan BoseNo ratings yet

- Personalized Study Plan to Boost 5 Subject ScoresDocument1 pagePersonalized Study Plan to Boost 5 Subject ScoresJagan BoseNo ratings yet

- Class Schedule Sem 1Document7 pagesClass Schedule Sem 1Jagan BoseNo ratings yet

- CO2 SnuffingDocument2 pagesCO2 SnuffingJagan BoseNo ratings yet

- Untitled Document About BlastingDocument39 pagesUntitled Document About BlastingRichardNo ratings yet

- MsdsDocument6 pagesMsdsrashidalghifaryNo ratings yet

- BTLGT Day1Document104 pagesBTLGT Day1John Walter EstradaNo ratings yet

- Prepare Emergency Destruction Plan For An ASA 55B40A07 1.0. GeneralDocument32 pagesPrepare Emergency Destruction Plan For An ASA 55B40A07 1.0. GeneralMalikHodzicNo ratings yet

- Fire Gas Ignition Terminology & DevelopmentsDocument5 pagesFire Gas Ignition Terminology & DevelopmentsByamba BimbaNo ratings yet

- A Partial History of Hydrofluoric Acid IncidentsDocument17 pagesA Partial History of Hydrofluoric Acid IncidentsJorge Alberto Uribe RojasNo ratings yet

- Kohler tp-5982Document64 pagesKohler tp-5982Jokr Bob Snow100% (1)

- CGE653 Chapter2 Part2Document61 pagesCGE653 Chapter2 Part2Muhammad NursalamNo ratings yet

- Hitra Procedure Kz01 CG Pro 53 0113 A02Document41 pagesHitra Procedure Kz01 CG Pro 53 0113 A02odeinat100% (1)

- List of dangerous goods in numerical orderDocument90 pagesList of dangerous goods in numerical orderIan RidzuanNo ratings yet

- Suitability of Conventional Data For Blast DesignDocument18 pagesSuitability of Conventional Data For Blast DesignOkta ChristalNo ratings yet

- Magnetic Stirrer MR Hei-Standard, MR Hei-Tec: Safe Heating and MixingDocument39 pagesMagnetic Stirrer MR Hei-Standard, MR Hei-Tec: Safe Heating and MixingZákány ZoltánNo ratings yet

- Cased ChargesDocument10 pagesCased ChargeshezigrisaroNo ratings yet

- Appendix I JD Service Manual PDFDocument661 pagesAppendix I JD Service Manual PDFJoao Silva0% (1)

- Confined Spaces Code of Practice (February 2016 Edition)Document40 pagesConfined Spaces Code of Practice (February 2016 Edition)Charalampos ChatzivasileiouNo ratings yet

- A Text Book of Ordnance and Gunnery BruffDocument714 pagesA Text Book of Ordnance and Gunnery BruffRyan Rubinstein100% (1)

- FEE FinalDocument98 pagesFEE FinalAmos ParappalilNo ratings yet

- Peter Graneau's Paper On Over-Unity Power From Arcs in FogDocument3 pagesPeter Graneau's Paper On Over-Unity Power From Arcs in Fogjrod100% (1)

- Consequence Assessment of Separator Explosion For An Oil Production Platform in South of Iran With PHAST SoftwareDocument12 pagesConsequence Assessment of Separator Explosion For An Oil Production Platform in South of Iran With PHAST SoftwareEmad AkhavanNo ratings yet

- Oxygen Plant LocationDocument8 pagesOxygen Plant LocationSumit SharmaNo ratings yet

- Diesel EnginesDocument219 pagesDiesel EnginesSoeAye100% (2)

- Understanding The Machinery Breakdown Policy & MLOP PolicyDocument20 pagesUnderstanding The Machinery Breakdown Policy & MLOP Policylamdientran0% (1)

- Ex ProtectionDocument44 pagesEx ProtectionAnil MarkaleNo ratings yet

- 25 Major Engineering Failures (1977-2007Document10 pages25 Major Engineering Failures (1977-2007Mohd Faizal MfNo ratings yet

- Level Safety InstrumentationDocument118 pagesLevel Safety InstrumentationMariel Mendoza100% (1)

- 1968 US Army Vietnam War Field Fortifications 132pDocument131 pages1968 US Army Vietnam War Field Fortifications 132pwwwsurvivalebookscom50% (4)

- Unit-V (Advanced Forming Processes)Document30 pagesUnit-V (Advanced Forming Processes)Er Vishal Divya Jagadale100% (1)

- AirBlast Analysis With LS-DYNADocument65 pagesAirBlast Analysis With LS-DYNAAmir Iskandar100% (2)

- Platinum Wire MSDSDocument5 pagesPlatinum Wire MSDSAlbert PinedaNo ratings yet

- Guidelines Shatter Resistant FilmDocument8 pagesGuidelines Shatter Resistant FilmEdwinNo ratings yet