Professional Documents

Culture Documents

Probe Ta

Uploaded by

jose manuel paz fernandezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Probe Ta

Uploaded by

jose manuel paz fernandezCopyright:

Available Formats

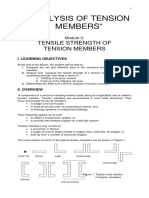

Dimensions

Standard Specimens Subsize Specimen

Plate-Type, 1½-in. Wide Sheet-Type, ½-in. Wide ¼-in. Wide

in. in. in.

G--Gage length (Note 1 and Note 2) 8.00:+: 0.01 2.000:+: 0.005 1.000 :+: 0.003

W-Width (Note 3 and Note 4) 1½+¼, -¼ 0.500:+: 0.010 0.250 :+: 0.005

T-Thickness (Note 5) thickness of material

R-Radius of fillet, min (Note 6) 1 ½ ¼

L-Over-all length, min (Note 2 and Note 7) 18 8 4

A-Length of reduced section, min 9 2¼ 1¼

8--Length of grip section, min (Note 8) 3 2 1¼

C-Width of grip section, approximate (Note 4 and Note 9) 2 ¾ ¾

Norn 1-For the 1 ½-in. wide specimen, punch marks for measuring elongation after fracture shall be made on the flat or on the edge ofthe specimen

and within the reduced section. Either a set of nine or more punch marks I in. apart, or one or more pairs of punch marks 8 in. apart may be used.

Norn 2-When elongation measurements of1 ½-in. wide specimens are not required, a mínimum length ofreduced section (A) of2¼ in. may be used

with all other dimensions similar to those of the plate-type specimen.

NoTE 3-For the three sizes ofspecimens, the ends ofthe reduced section shall not differ in width by more than 0.004, 0.002 or 0.001 in., respectively.

Also, there may be a gradual decrease in width from the ends to the center, but the width at each end shall not be more than 0.015, 0.005, or 0.003 in.,

respectively, larger than the width at the center.

NoTE 4-For each ofthe three sizes of specimens, narrower widths ( W and C) may be used when necessaty. In such cases the width ofthe reduced

section should be as large as the width ofthe material being tested permits; however, unless stated specifically, the requirements for elongation in a product

specification shall not apply when these narrower specimens are used.

Norn 5 The - dimension T is the thickness ofthe test specimen as provided for in the applicable material specifications. Minimum thickness of1 ½-in.

wide specimens shall be 3/16 in. Maximum thickness of ½-in. and ¼-in. wide specimens shall be ¾ in. and 1/4 in., respectively.

Norn 6-For the 1 1/2-in. wide specimen, a ½-in. mínimum radius at the ends of the reduced section is permitted for steel specimens under 100 000

psi in !ensile strength when a profile cutter is used to machine the reduced section.

Norn 7 To - aid in obtaining axial force application during testing of ¼-in. wide specimens, the over-all length should be as large as the material will

permit, up to 8.00 in.

Norn 8-It is desirable, ifpossible, to make the length ofthe grip section large enough to allow the specimen to extend into the grips a distance equal

to two thirds or more of the length of the grips. If the thickness of 1/2-in. wide specimens is over 3/s in., longer grips and correspondingly longer grip

sections of the specimen may be necessary to preven! failure in the grip section.

Norn 9 - For the three sizes ofspecimens, the ends of the specimen shall be symmetrical in width with the center line of the reduced section within

0.10, 0.05 and 0.005 in., respectively. However, for referee testing and when required by product specifications, the ends ofthe 1/2-in. wide specimen shall

be symmetrical within O.O! in.

NoTE 10-For each specimen type, the radii ofall fillets shall be equal to each other within a tolerance of0.05 in., and the centers ofcurvature ofthe

two fillets at a particular end shall be located across from each other (on a line perpendicular to the centerline) within a tolerance of 0.1O in.

Norn 11-Specimens with sides parallel throughout their length are permitted, except for referee testing, provided: (a) the above tolerances are used;

(b) an adequate number ofmarks are provided for determination ofelongation; and (e) when yield strength is determined, a suitable extensometer is used.

Ifthe fracture occurs at a distance ofless than 2 W from the edge ofthe gripping device, the !ensile properties determined may not be representative of

the material. In acceptance testing, ifthe properties meet the mínimum requirements specified, no further testing is required, but ifthey are less than the

mínimum requirements, discard the test and retes!.

FIG. 1 Rectangular Tension Test Specimens

Wedge Grips significan! cold work or shear burrs, or both, along the edges which should

Upper Heod of

,,0, be removed by machining.

e,--.,-��=a.=1·

Tesling Moch,ne

·<' , "'"' ·,

,7¡777.?::11

:·,/'.tri11"�"��. "","

""· '"''

6.1.3.2 Within the reduced section of rectangular speci

mens, edges or corners should not be ground or abraded in a

manner which could cause the actual cross-sectional area ofthe

Li�ers-Thickness Voried

According to Specimen Thick

specimen to be significantly different from the calculated area.

ness lo Keep Wedge Grips 6.1.3.3 For brittle materials, large radius fillets at the ends of

Flat Spec1men from Prorruding Above or

Below Heod of Tesling the gage length should be used.

Machi ne 6.1.3 .4 The cross-sectional area of the specimen should be

FIG. 2 Wedge Grips with Liners for Flat Specimens smallest at the center of the reduced section to ensure fracture

within the gage length. For this reason, a small taper is

permitted in the reduced section of each of the specimens

You might also like

- Methods of Test For Cables: Indian Standard "QQQM - RDocument3 pagesMethods of Test For Cables: Indian Standard "QQQM - RVatsalNo ratings yet

- Fig. 1: Lab Vane Shear ApparatusDocument2 pagesFig. 1: Lab Vane Shear ApparatusKishanNo ratings yet

- Tuft Height of Pile Floor Coverings: Standard Test Method ForDocument5 pagesTuft Height of Pile Floor Coverings: Standard Test Method ForJuanNo ratings yet

- 2D Boltsgask 9-01Document9 pages2D Boltsgask 9-01Javier GarcíaNo ratings yet

- FIG. 1 Rectangular Tension Test SpecimensDocument1 pageFIG. 1 Rectangular Tension Test SpecimensAlvaro Alexis Mendoza PradaNo ratings yet

- Calculation and Reporting: N 3-Rough Surfaces Make Wear Scar Measurement DifficultDocument1 pageCalculation and Reporting: N 3-Rough Surfaces Make Wear Scar Measurement DifficultBayu AmartaNo ratings yet

- Round Specimens: FIG. 5 Suggested Types of Ends For Standard Round Tension Test SpecimensDocument1 pageRound Specimens: FIG. 5 Suggested Types of Ends For Standard Round Tension Test Specimenskaveh-bahiraeeNo ratings yet

- Correct Sampling Methods and Regular SamplingDocument18 pagesCorrect Sampling Methods and Regular Samplingfanelenzima03No ratings yet

- Unprotected A3702003a 5Document1 pageUnprotected A3702003a 5kaveh-bahiraeeNo ratings yet

- D 2209 - 95 - RdiymdktukveDocument4 pagesD 2209 - 95 - RdiymdktukvePabasara HerathNo ratings yet

- Astm A370Document1 pageAstm A370Gerangaya Ray AngeloNo ratings yet

- Page 33 From API-1104-2016Document1 pagePage 33 From API-1104-2016Riaz AhmadNo ratings yet

- Screw Gauge Apparatus: To Be Written in The Right Page of The RecordDocument4 pagesScrew Gauge Apparatus: To Be Written in The Right Page of The RecordHemanth KNo ratings yet

- Effective Throat Welds: Table J2.2 Flare GrooveDocument4 pagesEffective Throat Welds: Table J2.2 Flare GrooveBuilders EngineeringNo ratings yet

- Steel Structures-Tension Members-1Document14 pagesSteel Structures-Tension Members-1Ceren ŞirinNo ratings yet

- Astm A370Document3 pagesAstm A370Kenny Wong50% (2)

- BS 5131 5.13 1980Document3 pagesBS 5131 5.13 1980Abraham ToxtleNo ratings yet

- Tensile Calculation PDFDocument2 pagesTensile Calculation PDFWendimagen Meshesha FantaNo ratings yet

- Rosca Acme 3-2 MasmecánicaDocument6 pagesRosca Acme 3-2 MasmecánicaBachoNo ratings yet

- 5.tension Test FinalDocument7 pages5.tension Test FinalFausto Da GamaNo ratings yet

- Experiment #4 Title: Testing of Reinforcing Steel BarsDocument9 pagesExperiment #4 Title: Testing of Reinforcing Steel BarsAnne Kristel Dela RosaNo ratings yet

- Shear Cutting of PET Film PDFDocument10 pagesShear Cutting of PET Film PDFAnonymous Tg2CozwSNo ratings yet

- Lect 4-Tension Members AISC (Compatibility Mode)Document15 pagesLect 4-Tension Members AISC (Compatibility Mode)Amr M. AbdallahNo ratings yet

- Design Guide - Sheet Metal Fabrication PDFDocument12 pagesDesign Guide - Sheet Metal Fabrication PDFŽeljko StefanovićNo ratings yet

- One Way SlabDocument12 pagesOne Way SlabChristine CernaNo ratings yet

- Flip Shopstop ManualDocument2 pagesFlip Shopstop Manual123anthonyNo ratings yet

- Indian Standard: Methods of Test For CablesDocument3 pagesIndian Standard: Methods of Test For CablesVatsalNo ratings yet

- Student Manual of Torsional Damped & Un Damped ApparatusDocument3 pagesStudent Manual of Torsional Damped & Un Damped ApparatusaqibNo ratings yet

- Radiata: JAS Log Volume Estimates of New Zealand Pine and Douglas-Fir LogsDocument5 pagesRadiata: JAS Log Volume Estimates of New Zealand Pine and Douglas-Fir LogsASEPNo ratings yet

- Design of Machine Elements Sample QuestionsDocument9 pagesDesign of Machine Elements Sample Questionsblogger100% (1)

- Bending StiffnessDocument6 pagesBending StiffnessMark Samsel RohanNo ratings yet

- Design Guide: Sheet Metal FabricationDocument12 pagesDesign Guide: Sheet Metal FabricationSubodh KumarNo ratings yet

- Design of DieDocument41 pagesDesign of DieKarthik ACNo ratings yet

- 1 Annaling TestDocument2 pages1 Annaling TestProduction TortekNo ratings yet

- Acme ThreadsDocument3 pagesAcme ThreadsUNIISCRIBDNo ratings yet

- CNC Calibration Test Pattern - MWP V1-1 121415 PDFDocument6 pagesCNC Calibration Test Pattern - MWP V1-1 121415 PDFCarlos TerrazaNo ratings yet

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionalbertoxinaNo ratings yet

- Rolling Threads DetailsDocument0 pagesRolling Threads DetailsfastenersworldNo ratings yet

- Specifying Bolt Length of High Strength BoltsDocument12 pagesSpecifying Bolt Length of High Strength BoltsUpadrasta HarishNo ratings yet

- Module 3 - Tensile MemberDocument9 pagesModule 3 - Tensile MemberJuan Paulo DiazNo ratings yet

- KES T-L461A 1995 Test Method of Lnteram Mat For AutomobileDocument8 pagesKES T-L461A 1995 Test Method of Lnteram Mat For Automobiles_omeone4usNo ratings yet

- Standard HFRW PDFDocument3 pagesStandard HFRW PDFGuidoColomboNo ratings yet

- Lab Vane Shear TestDocument4 pagesLab Vane Shear TestCharlyn Flores0% (1)

- Chapter 3 - Design of Tension and Compression Members PDFDocument84 pagesChapter 3 - Design of Tension and Compression Members PDFNiyibizi PromesseNo ratings yet

- Fasteners (Threaded and Non-Threaded) PDFDocument41 pagesFasteners (Threaded and Non-Threaded) PDFGcwalisile DlaminiNo ratings yet

- Welded Connections (Balanace Weld Group)Document13 pagesWelded Connections (Balanace Weld Group)angelica abanesNo ratings yet

- Fasteners Part-3 Is.1369.1.1993Document9 pagesFasteners Part-3 Is.1369.1.1993Manish ThakurNo ratings yet

- Topic 2 Tension MembersDocument15 pagesTopic 2 Tension MembersLyka TaborlupaNo ratings yet

- Chemistry - Unit 1 Activity: Thickness of A Thin LayerDocument1 pageChemistry - Unit 1 Activity: Thickness of A Thin LayerpcchemistryNo ratings yet

- Is 12779 1989 PDFDocument9 pagesIs 12779 1989 PDFravi kiranNo ratings yet

- IS 12779.1989 Steel - Tollerences Hot Rolled Parallel Flange Sections PDFDocument9 pagesIS 12779.1989 Steel - Tollerences Hot Rolled Parallel Flange Sections PDFJostin P JoseNo ratings yet

- Connections 1 - Ch.3 Welds Notes (94-153)Document15 pagesConnections 1 - Ch.3 Welds Notes (94-153)travis8zimmermannNo ratings yet

- Forging - Mechanical Test SA 105 SA 266 SA 350 SA 765Document3 pagesForging - Mechanical Test SA 105 SA 266 SA 350 SA 765manisami7036No ratings yet

- Design Guide: Sheet Metal FabricationDocument12 pagesDesign Guide: Sheet Metal FabricationSanatan ChoudhuryNo ratings yet

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Armox Machining Bending PDFDocument2 pagesArmox Machining Bending PDFCecilia YeniNo ratings yet

- Rebar CalculationDocument8 pagesRebar CalculationEr Pranabesh SenNo ratings yet

- Physics 111 Homework SOLUTION, Week 4, Chapter 5, Sec 1-7Document15 pagesPhysics 111 Homework SOLUTION, Week 4, Chapter 5, Sec 1-7Abdullah Ahsan AhmedNo ratings yet

- Manual Compresor Water FurnaceDocument50 pagesManual Compresor Water FurnaceFred GarciaNo ratings yet

- 2022-2 Spindle MultiphyicsDocument81 pages2022-2 Spindle Multiphyics潘季宏No ratings yet

- New Double Coin TBR CatelogueDocument55 pagesNew Double Coin TBR CatelogueJose Andres Jimenez CasallasNo ratings yet

- BOQ Hotel CiputraDocument2 pagesBOQ Hotel CiputraHendra AdriansyahNo ratings yet

- BPW 3Document58 pagesBPW 3ВЛАДИМИРNo ratings yet

- Rule Bki V Rules For Materials 2009Document249 pagesRule Bki V Rules For Materials 2009Saadi AlimNo ratings yet

- Air Starting System Slide Set 1Document10 pagesAir Starting System Slide Set 1Jigar PatelNo ratings yet

- Js205 Tracked Excavator I Specification: EngineDocument4 pagesJs205 Tracked Excavator I Specification: EngineKasidin100% (1)

- 5200 Series Crane: Volume 2 - Parts and SpecificationsDocument132 pages5200 Series Crane: Volume 2 - Parts and SpecificationsKiryl PyschnyNo ratings yet

- 4.1 Hyster H3.0FT LPG Spec Sheet PDFDocument6 pages4.1 Hyster H3.0FT LPG Spec Sheet PDFSamil Mammedov100% (1)

- A Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowDocument19 pagesA Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowPeerasak ArunNo ratings yet

- Unit-3 PsocDocument23 pagesUnit-3 PsocDESI BRAHMNNo ratings yet

- Engine Cooling - ID4 2.2L Diesel - : Item SpecificationDocument30 pagesEngine Cooling - ID4 2.2L Diesel - : Item SpecificationRichard Andrianjaka LuckyNo ratings yet

- Math EE IBDocument13 pagesMath EE IBCalc girl ReddingtonNo ratings yet

- Thermodynamics 2 & Fluid MechanicsDocument18 pagesThermodynamics 2 & Fluid MechanicsNicole Mae AllosadaNo ratings yet

- Hydroflo SelectionDocument1 pageHydroflo SelectionJosh SorensenNo ratings yet

- SST-140 Corporate BrochureDocument8 pagesSST-140 Corporate Brochureandri.plneNo ratings yet

- Uniform Rotary MotionDocument26 pagesUniform Rotary MotionMark RamosNo ratings yet

- P3E Choke: Valve SpecificationsDocument4 pagesP3E Choke: Valve SpecificationsJairo andres Guarnizo SuarezNo ratings yet

- Katalog 920 PDFDocument707 pagesKatalog 920 PDFbubulelaman100% (4)

- 5 Tool CatalogueDocument46 pages5 Tool Cataloguetruong100% (3)

- Plano 236D PDFDocument27 pagesPlano 236D PDFArle SalasNo ratings yet

- Flecha CardanDocument6 pagesFlecha CardanCarlos roberto Aguiirre rosalesNo ratings yet

- FEM9.756 Engl PDFDocument57 pagesFEM9.756 Engl PDFserkanNo ratings yet

- Banda Lido Datasheet - uni-OWLDocument2 pagesBanda Lido Datasheet - uni-OWLVilma sagresaNo ratings yet

- T Mech Clamp CatalogueDocument29 pagesT Mech Clamp CatalogueKABIR CHOPRANo ratings yet

- Yonas Thesis Final .Docx2Document87 pagesYonas Thesis Final .Docx2Noil Son100% (1)